Then you can call this guy a liar.

LINK

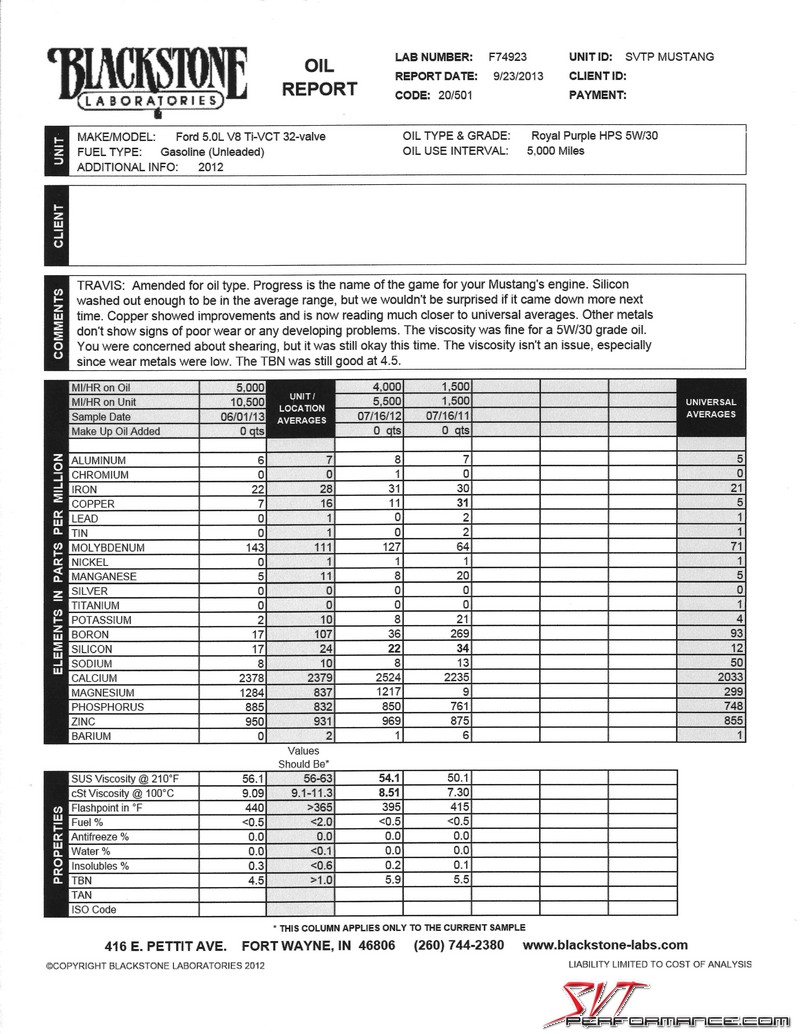

0% antifreeze was traced in that sample. Despite 8 ppm potassium, explain the 0%. Let's also not forget, this sample was taken after 8,000 miles.

LINK

0% antifreeze was traced in that sample. Despite 8 ppm potassium, explain the 0%. Let's also not forget, this sample was taken after 8,000 miles.

Last edited: