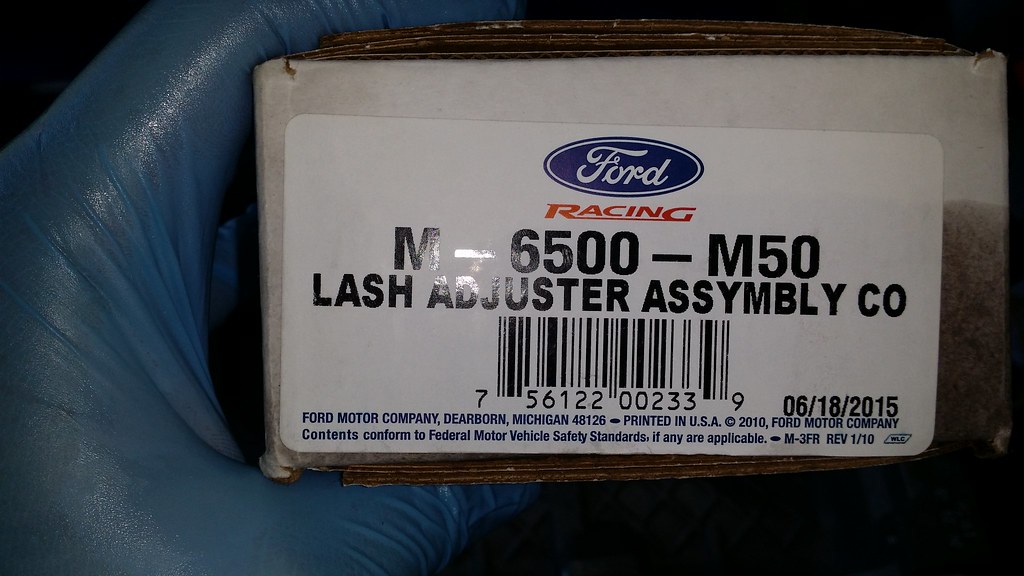

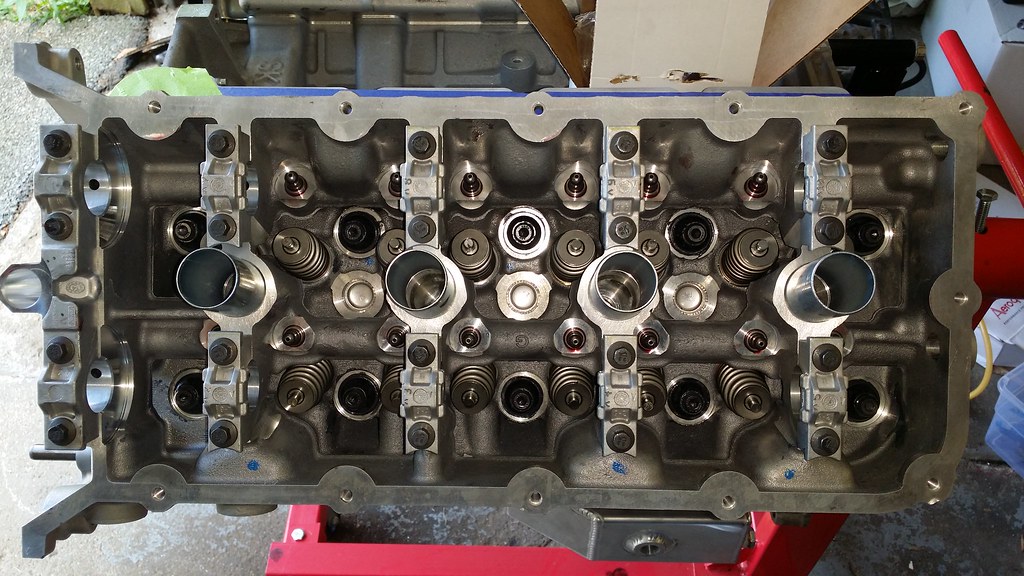

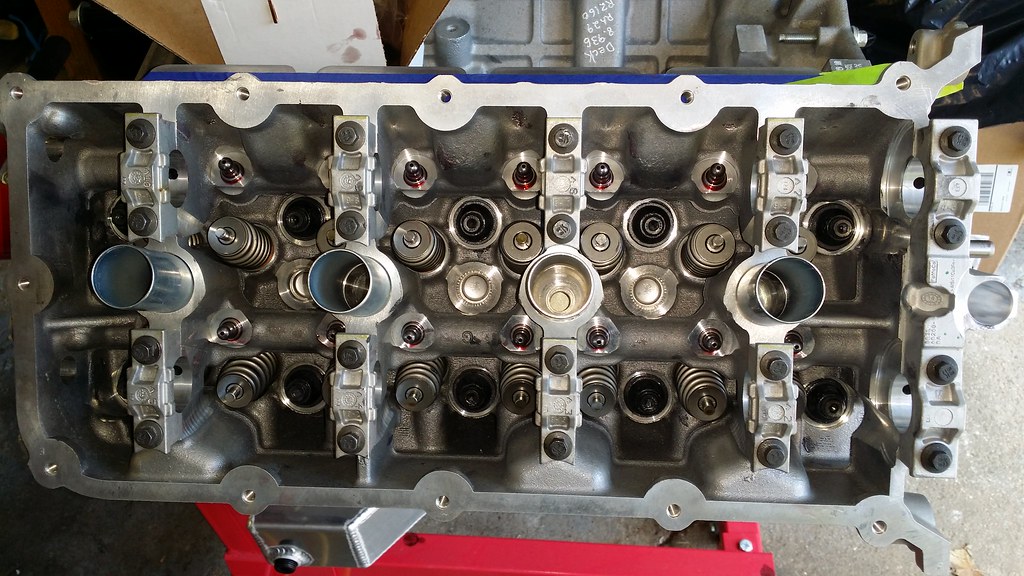

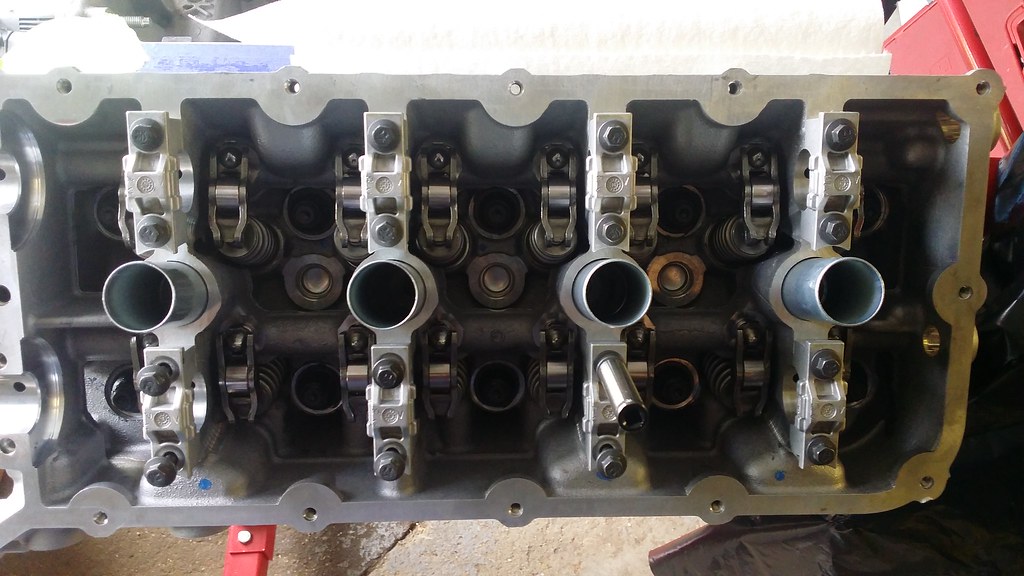

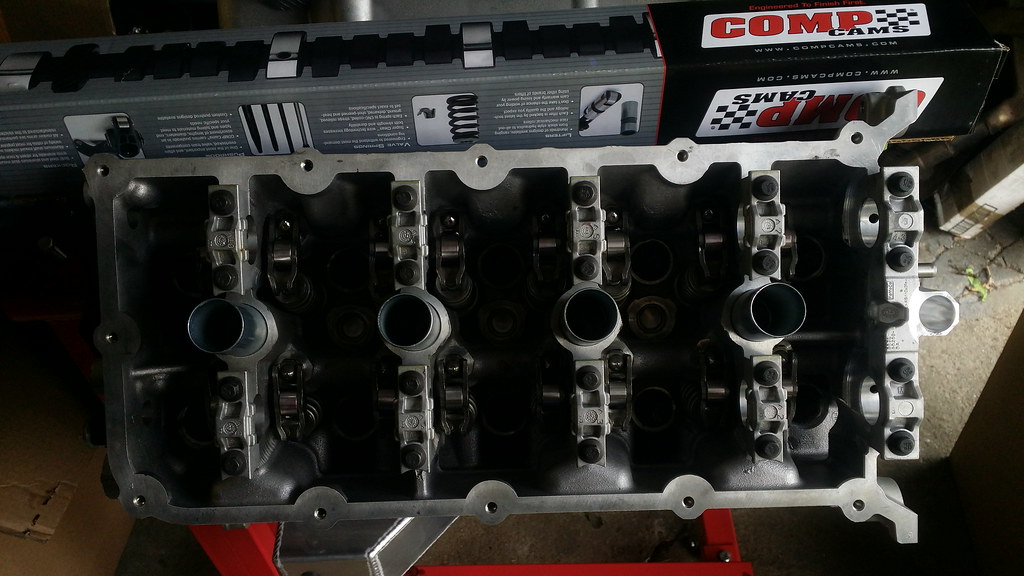

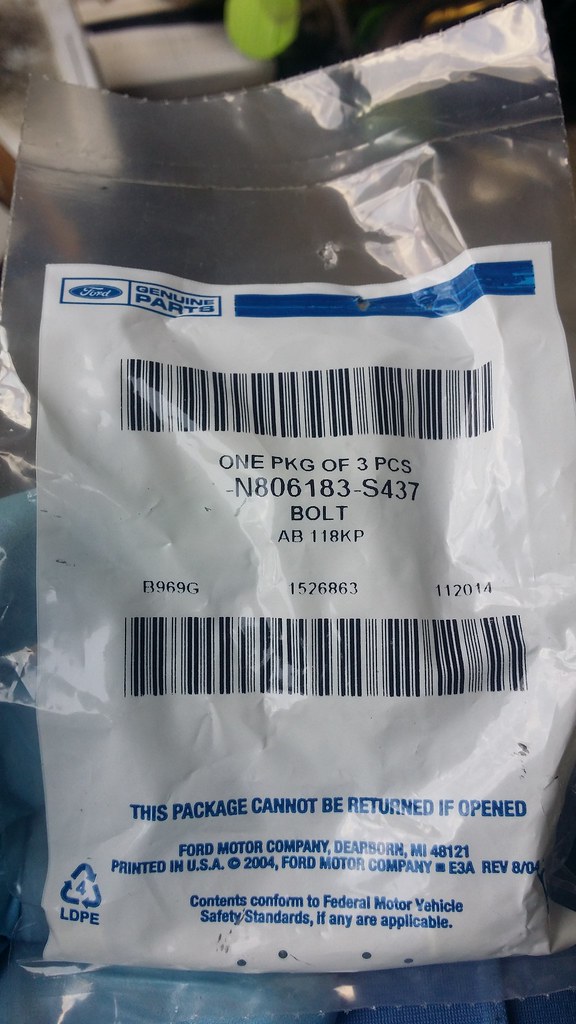

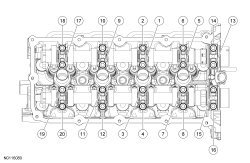

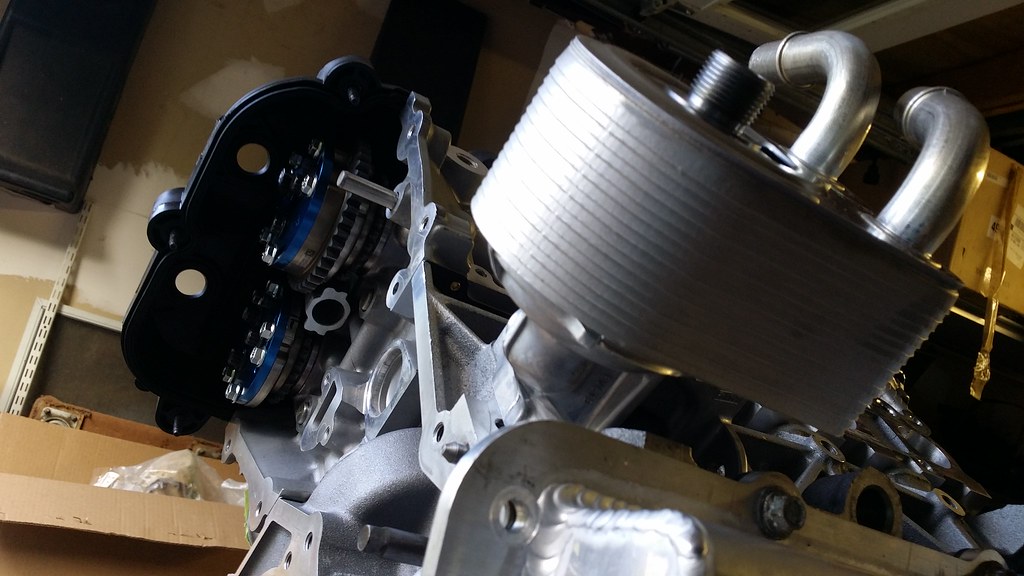

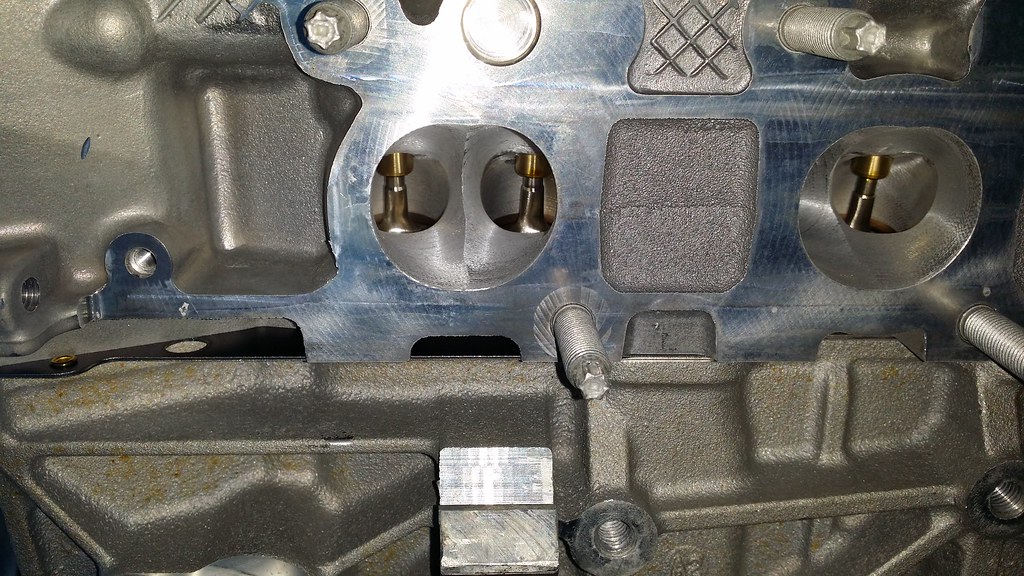

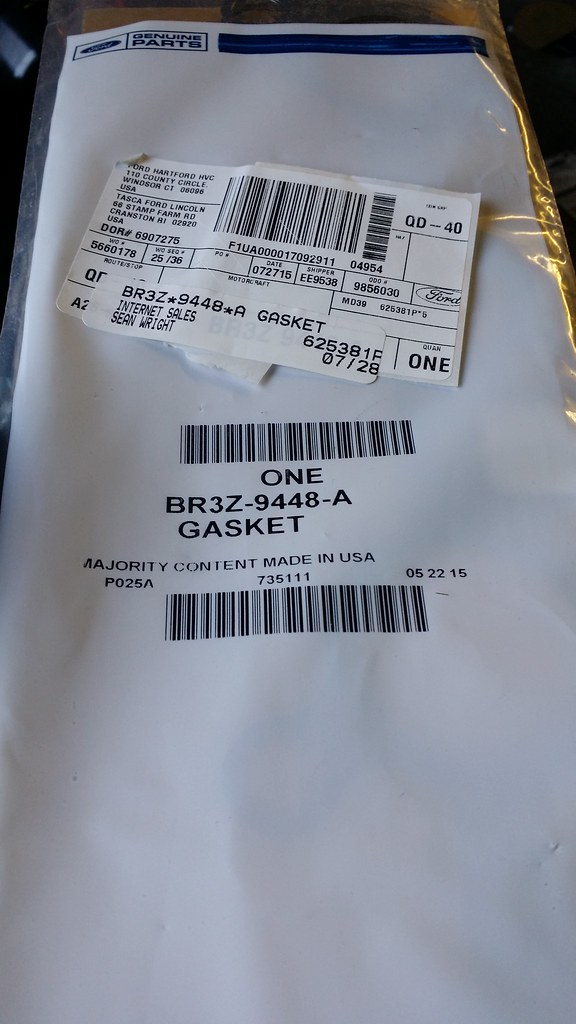

Sweet looking heads Sean. Once you get this beast up and running you should compile all your posts into a wiki for the good of mankind. You've really taken the time to share all the details of your build. Part numbers and all. My hats off to you! Bravo.:rockon:

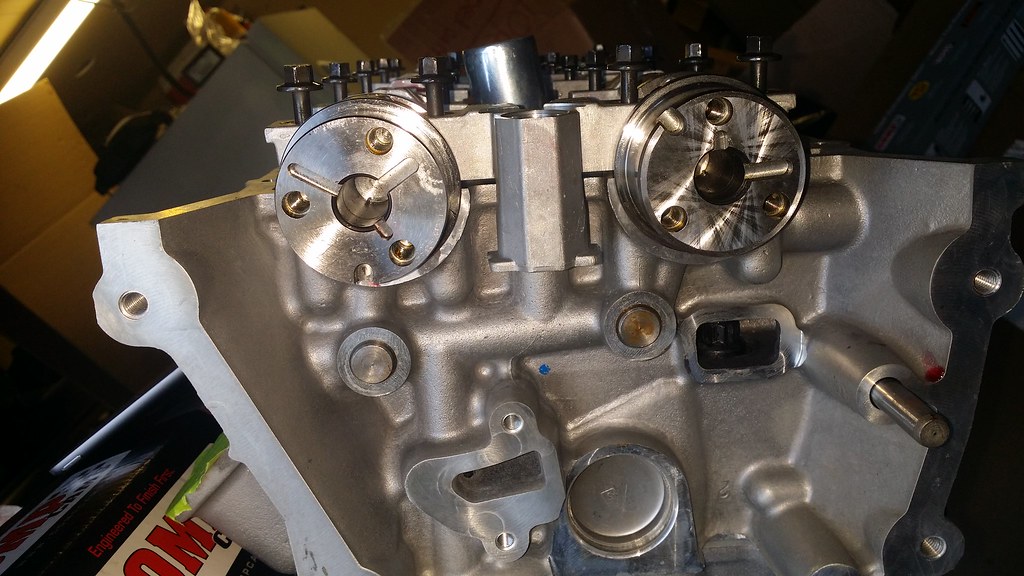

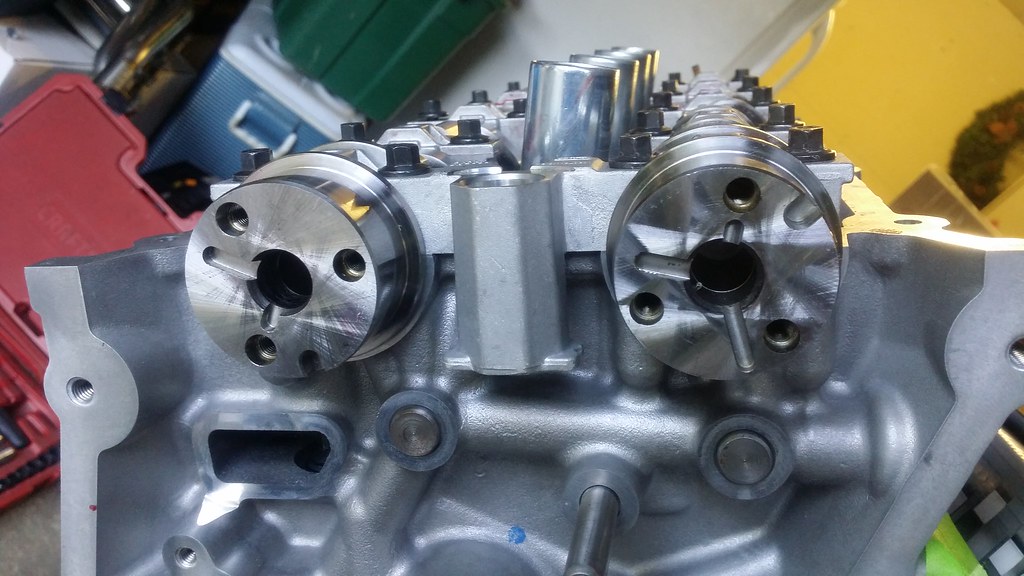

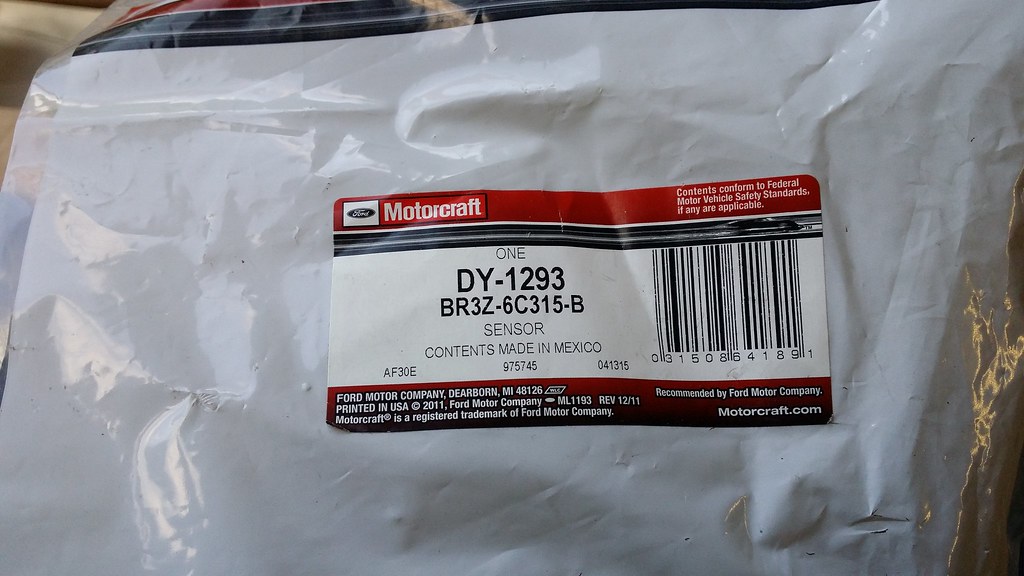

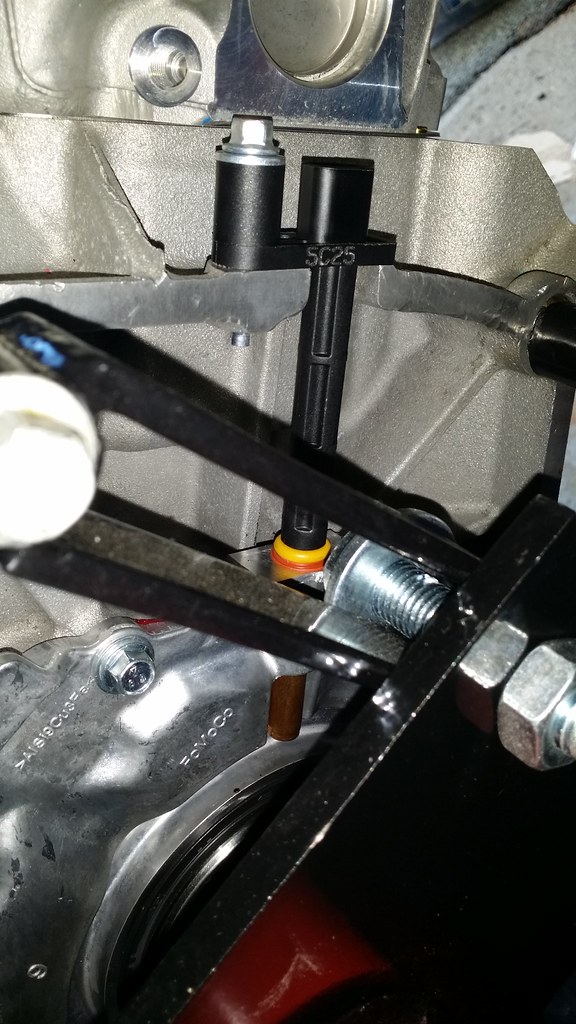

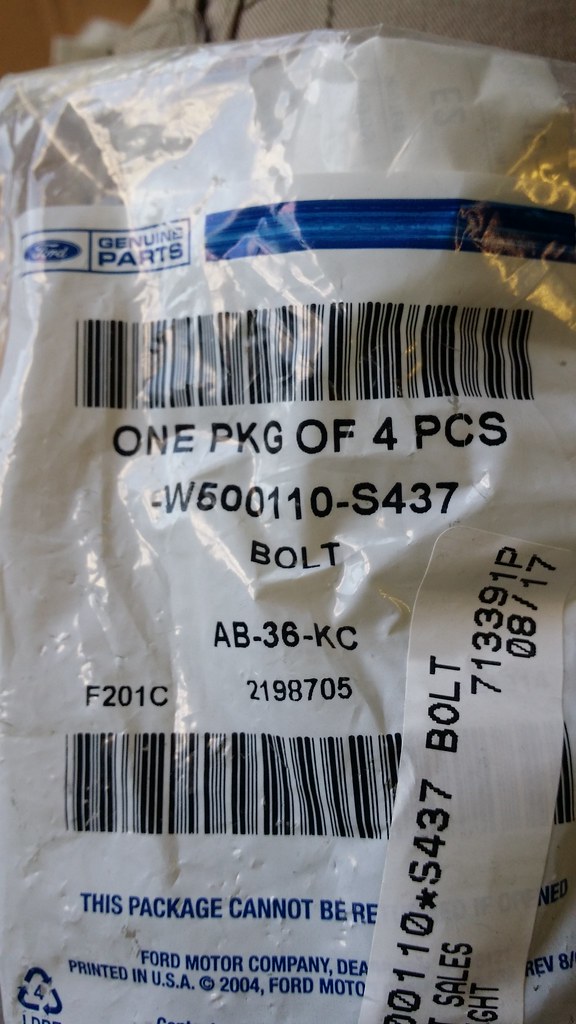

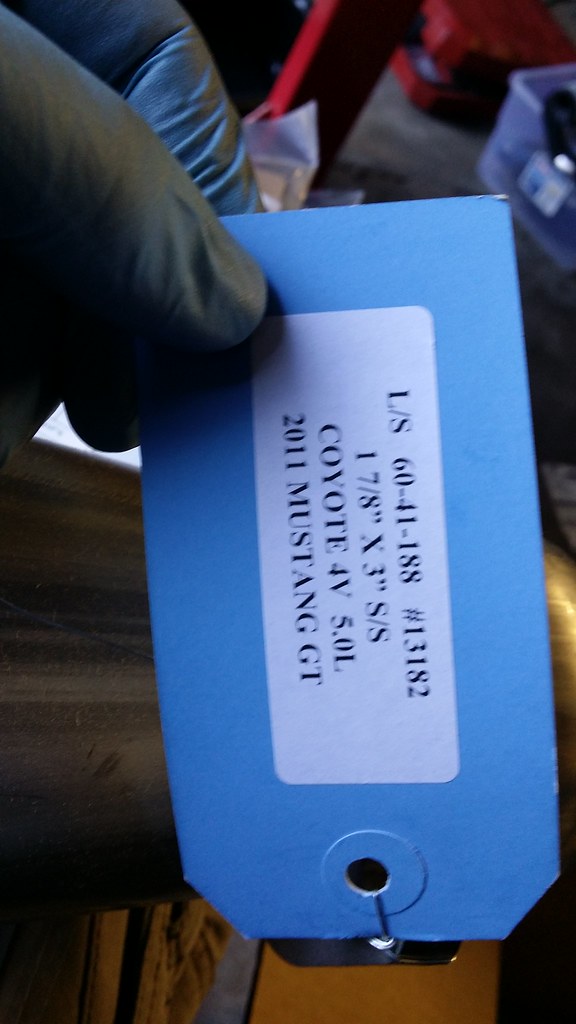

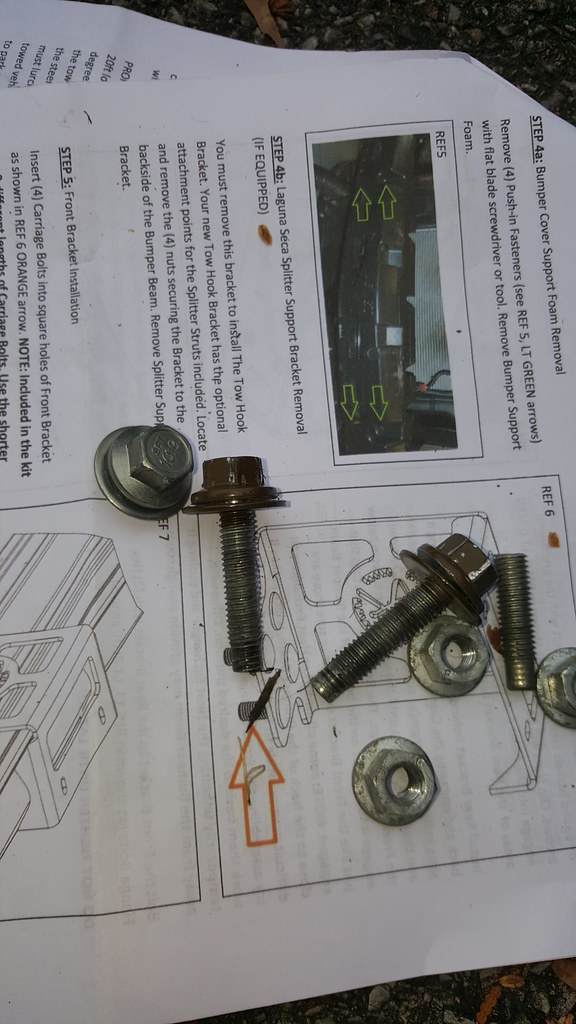

That is a Badass idea Darren! I will probably do that once I get the car up and running. Ran into a few snags this weekend degreeing the cams unfortunately:/. So I should be able to update this up until that point tomorrow.