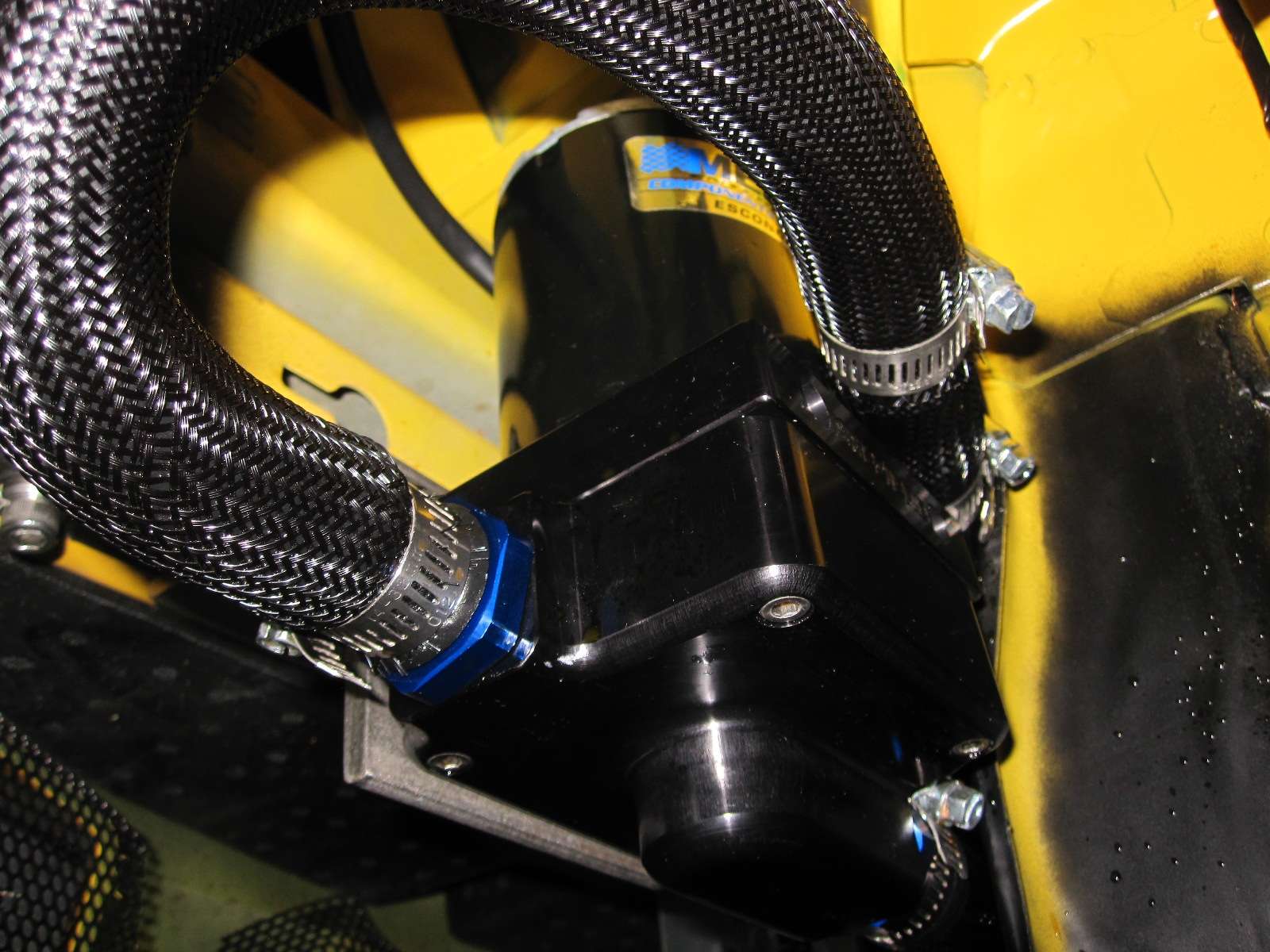

I did not use or make the rod to support this tank. I simply used an aluminum "L" bracket.

This one--> https://www.speedymetals.com-2203-8344-3-x-4-x-14-angle-6061-t6-aluminum-extruded.aspx

This one--> https://www.speedymetals.com-2203-8344-3-x-4-x-14-angle-6061-t6-aluminum-extruded.aspx