Decided to move my thread over to this forum. Might take a few days to get it all moved over and up to date. But, I like this forum better so...here I am!

Here is a link for the Tork Tech Terminator kit.

Terminator GT Kits for the '99-04 GT - Tork Tech

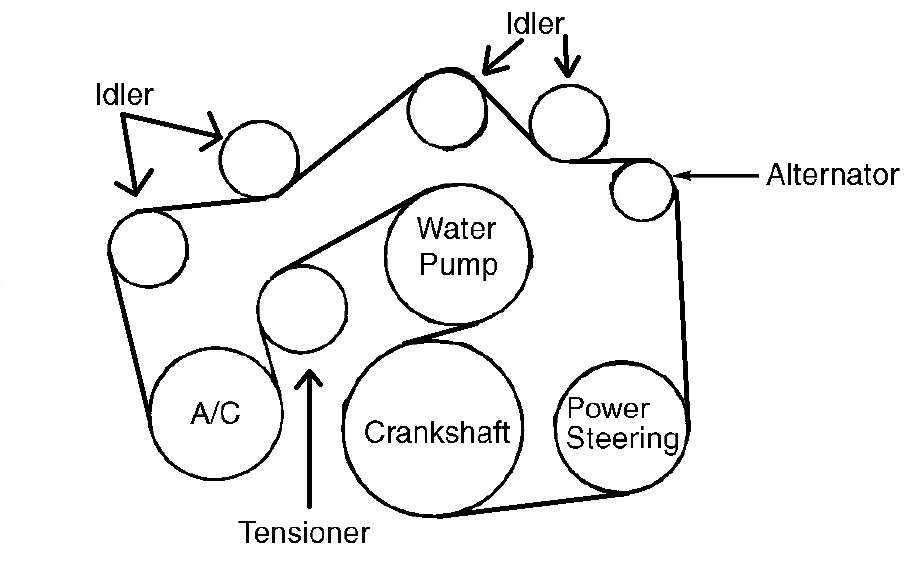

This kit, as outlined on the website. Only consist of the necessary components to get the Factory 2003-2004 Terminator Cobra Eaton M112 to bolt up to our PI 4.6 two valve Engines and drive it with a pulley system. The company does offer up other items to help complete the conversion but those components are not included in the kit.

Typical cost at this time will run you in the $1,850-$2,100 depending on which kit you get. The non-intercooled kit cost less and the intercooled kit cost more. My kit cost was a little over $2,100 and that included the shipping charge.

The website has a "parts list" and an estimated cost of said "needed" parts. Below is my parts list and what it cost me. My cost is substantially more but I also opted to purchase new parts and not used. I also opted the get a few things that would be considered an "up-grade" from the bare minimum of what is really needed. So, at this point my cost has become substantially more then what someone would be able to perform a budget build for.

Only the Tork Tech kit price includes shipping. None of the other prices include what I may have paid for shipping. I have also not included the fuel pumps, fuel tank, programmer in the "Kit List" or the Total Investment listed.

For those who are interested, Here is what I did not include in the "Tork Tech Parts List". This is what I have had for some time now already installed on the car. All parts are New except for the Dual pump assembly and the Eaton M112 as I have noted below.

Part Number--------------Manufacture ---------------------------Price Paid

M-9407-C46 -------------Cobra Dual Fuel Pumps (USED)------------$250.00

M-9002-C46A-------------Ford Racing Cobra Tank:-----------------$299.99

9600 --------------------SCT Livewire:----------------------------$509.00

4332 --------------------SCT Pro Racer:---------------------------$299.00

Parts with Part Numbers and price paid so fair. This is about a 14 month collection of parts so far.

Part Number------------Manufacture-------------------------------Price Paid

178-630----------------Saleen Intercoolor Expansion Tank------------$99.99

2R3Z-6F066-AA---------Stock Eaton M112 (USED)-------------------$550.00

Terminator Kit-----------Tork Tech Tork---------------------------$2,165.00

9C1Z-12A697-B---------Lightning threaded IAT sensor-----------------$18.99

2R3Z-9A758-AA---------Ford 03-04 cobra throttle cable---------------$48.99

2R3Z-9A825-AA---------Ford 03-04 cobra cruisecontrol cable----------$30.99

2R3Z-9728-BA-----------Ford 03-04 cable bracket---------------------$30.99

M-12579-L54------------Ford Racing 90mm Mass air meter-------------$79.99

280150558--------------Bosch 42 lbs flow matched injectors----------$299.00

JLTCAI-FMC-0304-------JLT true cold air CAI-------------------------$197.95

80275NDP--------------AFCO Dual Pass Heat Exchanger---------------$309.95

MEZ-WP136S----------Meziere Intercooler pump----------------------$195.95

MEZ-WP12034B--------Meziere Intercooler Pump Fittings---------------$39.90

M-9926-SC46----------Ford Throttlebody and elbow-------------------$150.00

F4SF-9B989-AA--------Throttle Position Sensor-------------------------$0.00 *Included New with TB

2R3V-9F715-AA--------Idle Air Control Valve----------------------------$0.00 *Included New with TB

BD-5009-4.6-----------Billet Depot EGR DELETE PLATE------------------$7.99

Total: $4,025.68

Including the the parts I already had (fuel pumps, fuel tank, programmer stuff) My total investment so far to get blown is $5,383.57

__________________

Here is a link for the Tork Tech Terminator kit.

Terminator GT Kits for the '99-04 GT - Tork Tech

This kit, as outlined on the website. Only consist of the necessary components to get the Factory 2003-2004 Terminator Cobra Eaton M112 to bolt up to our PI 4.6 two valve Engines and drive it with a pulley system. The company does offer up other items to help complete the conversion but those components are not included in the kit.

Typical cost at this time will run you in the $1,850-$2,100 depending on which kit you get. The non-intercooled kit cost less and the intercooled kit cost more. My kit cost was a little over $2,100 and that included the shipping charge.

The website has a "parts list" and an estimated cost of said "needed" parts. Below is my parts list and what it cost me. My cost is substantially more but I also opted to purchase new parts and not used. I also opted the get a few things that would be considered an "up-grade" from the bare minimum of what is really needed. So, at this point my cost has become substantially more then what someone would be able to perform a budget build for.

Only the Tork Tech kit price includes shipping. None of the other prices include what I may have paid for shipping. I have also not included the fuel pumps, fuel tank, programmer in the "Kit List" or the Total Investment listed.

For those who are interested, Here is what I did not include in the "Tork Tech Parts List". This is what I have had for some time now already installed on the car. All parts are New except for the Dual pump assembly and the Eaton M112 as I have noted below.

Part Number--------------Manufacture ---------------------------Price Paid

M-9407-C46 -------------Cobra Dual Fuel Pumps (USED)------------$250.00

M-9002-C46A-------------Ford Racing Cobra Tank:-----------------$299.99

9600 --------------------SCT Livewire:----------------------------$509.00

4332 --------------------SCT Pro Racer:---------------------------$299.00

Parts with Part Numbers and price paid so fair. This is about a 14 month collection of parts so far.

Part Number------------Manufacture-------------------------------Price Paid

178-630----------------Saleen Intercoolor Expansion Tank------------$99.99

2R3Z-6F066-AA---------Stock Eaton M112 (USED)-------------------$550.00

Terminator Kit-----------Tork Tech Tork---------------------------$2,165.00

9C1Z-12A697-B---------Lightning threaded IAT sensor-----------------$18.99

2R3Z-9A758-AA---------Ford 03-04 cobra throttle cable---------------$48.99

2R3Z-9A825-AA---------Ford 03-04 cobra cruisecontrol cable----------$30.99

2R3Z-9728-BA-----------Ford 03-04 cable bracket---------------------$30.99

M-12579-L54------------Ford Racing 90mm Mass air meter-------------$79.99

280150558--------------Bosch 42 lbs flow matched injectors----------$299.00

JLTCAI-FMC-0304-------JLT true cold air CAI-------------------------$197.95

80275NDP--------------AFCO Dual Pass Heat Exchanger---------------$309.95

MEZ-WP136S----------Meziere Intercooler pump----------------------$195.95

MEZ-WP12034B--------Meziere Intercooler Pump Fittings---------------$39.90

M-9926-SC46----------Ford Throttlebody and elbow-------------------$150.00

F4SF-9B989-AA--------Throttle Position Sensor-------------------------$0.00 *Included New with TB

2R3V-9F715-AA--------Idle Air Control Valve----------------------------$0.00 *Included New with TB

BD-5009-4.6-----------Billet Depot EGR DELETE PLATE------------------$7.99

Total: $4,025.68

Including the the parts I already had (fuel pumps, fuel tank, programmer stuff) My total investment so far to get blown is $5,383.57

__________________

Last edited: