No, I didn't drop it nor do I intend to!

I have noticed the different weave patterns. Ron, do you know who did the lay up of the CF tube for PST?

BTW, I did speak with 'Joel' from the Tremec. We talked for a bit regarding the relationship between Ford and Tremec as well as some of the technical aspects of the 6060 as used in the GT500. He did acknowledge that some CJ owners were removing the damper on the fixed flange to reduce weight. Beyond that, I have yet to get any specific answers from them.

I highly suspect that in either Tremec's Queretaro, Mexico facility or at the Plymouth, Michigan facility, are a few '13 GT500 cup style flanges with early count splines. That piece alone could have made the installation a simple bolt in. Best I can tell from media provided by Tremec, is that the flanges are made in Queretaro and are supplied already installed on 6060's earmarked for Ford GT500's.

I initially wondered if Ford was producing and installing them stateside. Direct from the Ford plant where our S197's are pieced together, lies an engine/transmission assembly...

The above didn't confirm it though. I had previously seen boxed Ford 6060's (marked Hecho en Mexico) with the flange already on them though...

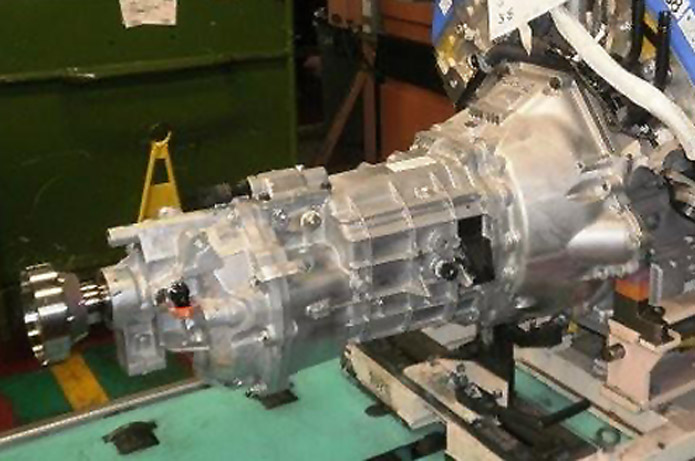

In addition, Tremec shows footage of various 6060 assemblies being manufactured/assembled at the Mexico plant with them installed (the following is a non-Ford 6060)...

Damn it! Why won't this go into gear!?!

Anyway, my understand is that Ford specifies much of what they want in the transmission from Tremec, and that includes the flange. I see engineers staffing both the Plymouth and Queretaro facilities, but what looks to be laser welding of the splined stub to the machined cup if you will, is done in Queretaro. Which leads to the following question. Why couldn't FRPP have a hybrid flange made (early spline stub mated to the '13 cup) by Tremec?

My assessment - they could. Corporate politics aside, a few phone calls to Mexico and a box of prototype flanges could be in the hands of FRPP engineers within a couple of weeks. Why won't they do it? Therein lies the rub (and a bit convoluted at that). Hopefully Mr Kershaw can be specific about this one.

I have noticed the different weave patterns. Ron, do you know who did the lay up of the CF tube for PST?

BTW, I did speak with 'Joel' from the Tremec. We talked for a bit regarding the relationship between Ford and Tremec as well as some of the technical aspects of the 6060 as used in the GT500. He did acknowledge that some CJ owners were removing the damper on the fixed flange to reduce weight. Beyond that, I have yet to get any specific answers from them.

I highly suspect that in either Tremec's Queretaro, Mexico facility or at the Plymouth, Michigan facility, are a few '13 GT500 cup style flanges with early count splines. That piece alone could have made the installation a simple bolt in. Best I can tell from media provided by Tremec, is that the flanges are made in Queretaro and are supplied already installed on 6060's earmarked for Ford GT500's.

I initially wondered if Ford was producing and installing them stateside. Direct from the Ford plant where our S197's are pieced together, lies an engine/transmission assembly...

The above didn't confirm it though. I had previously seen boxed Ford 6060's (marked Hecho en Mexico) with the flange already on them though...

In addition, Tremec shows footage of various 6060 assemblies being manufactured/assembled at the Mexico plant with them installed (the following is a non-Ford 6060)...

Damn it! Why won't this go into gear!?!

Anyway, my understand is that Ford specifies much of what they want in the transmission from Tremec, and that includes the flange. I see engineers staffing both the Plymouth and Queretaro facilities, but what looks to be laser welding of the splined stub to the machined cup if you will, is done in Queretaro. Which leads to the following question. Why couldn't FRPP have a hybrid flange made (early spline stub mated to the '13 cup) by Tremec?

My assessment - they could. Corporate politics aside, a few phone calls to Mexico and a box of prototype flanges could be in the hands of FRPP engineers within a couple of weeks. Why won't they do it? Therein lies the rub (and a bit convoluted at that). Hopefully Mr Kershaw can be specific about this one.