Who wouldn't want the latest and greatest shaft on their earlier car? Why won't it work, as is? Who makes a kit for it? How much better is CF than steel or aluminum?

Gentlemen, I've yet to find a resource that addresses all these questions together, and in the context of our Ford GT500's. I'll do my best to change that.

What '07-'12 GT500 Vehicles Come With

To start, we all share a vehicle specific, Tremec supplied, TR6060. Not perfect, but designed to handle the abundance of torque that our beloved supercharged 5.4 liter engines produce. Throughout the above time period, Ford has instituted some small changes to the driveline, all aimed at improving durability.

That said, there have been issues. Owners have often complained that the transmission sometimes makes gear changing 'difficult.' Another issue worthy of discussion, but out of the context of the aim here. So aside from clutch, gear and shifter differences, I'd like to concentrate at the rear of the transmission. Why? Because that is the critical interface where transmission meets driveshaft.

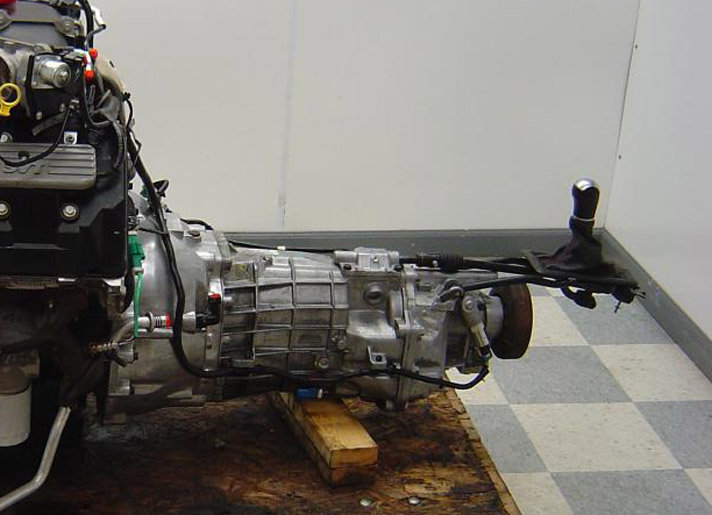

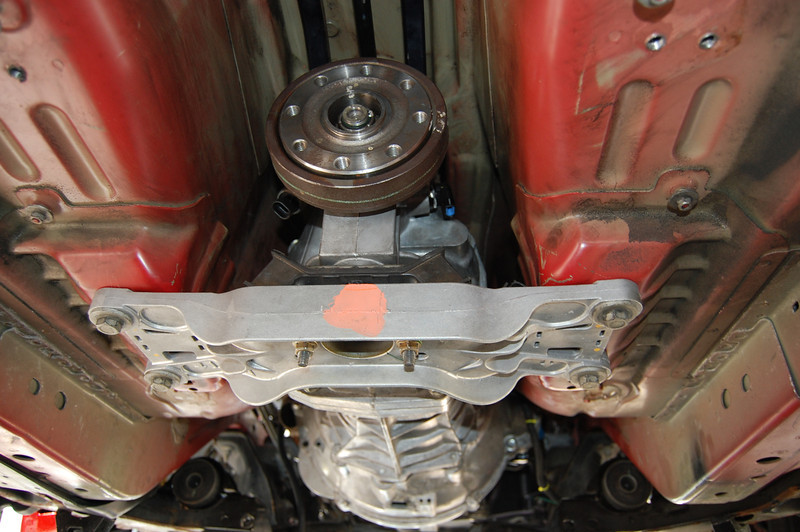

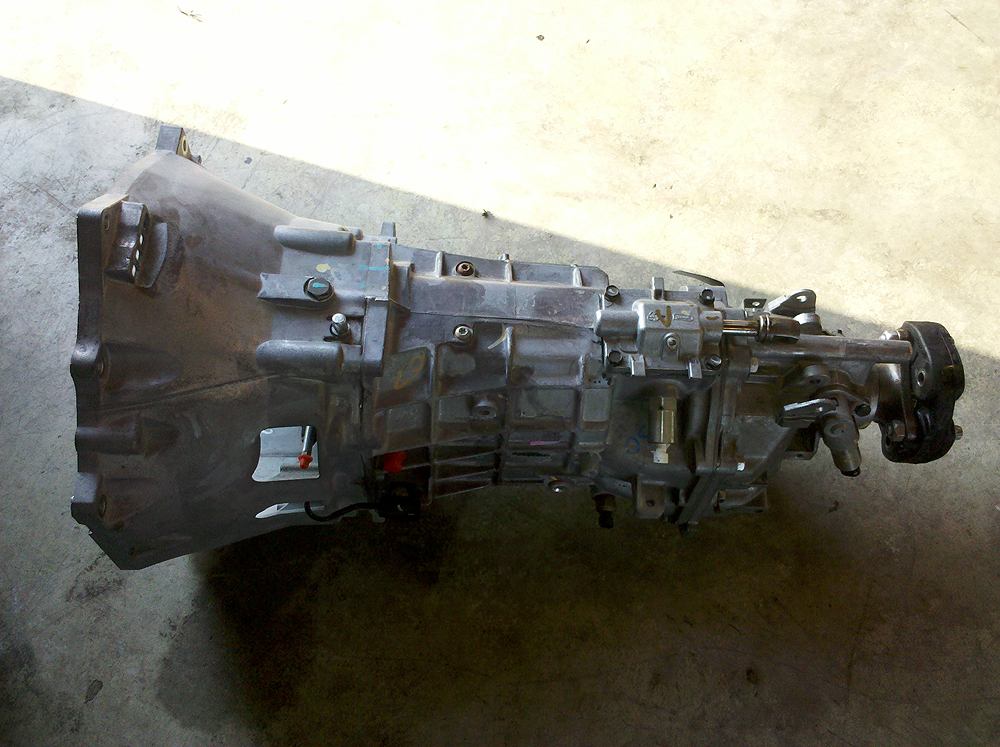

To wit, the typical '07-'09 GT500 TR6060. Note the flange (fixed flange to be more precise) at the rear...

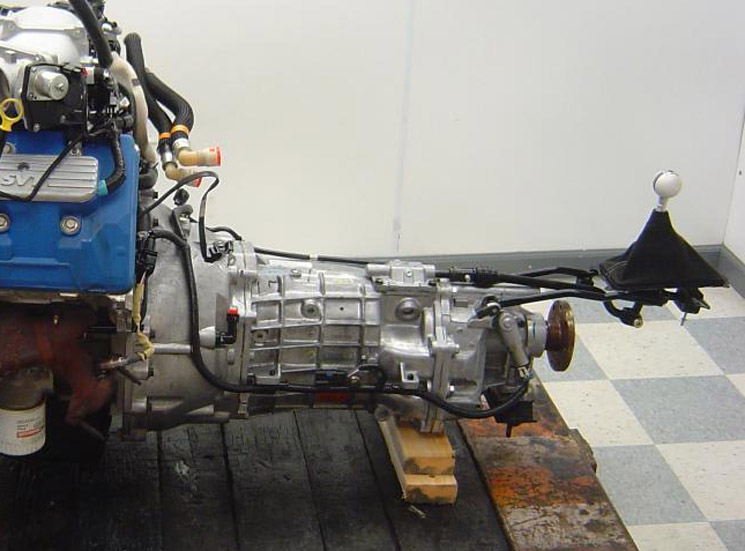

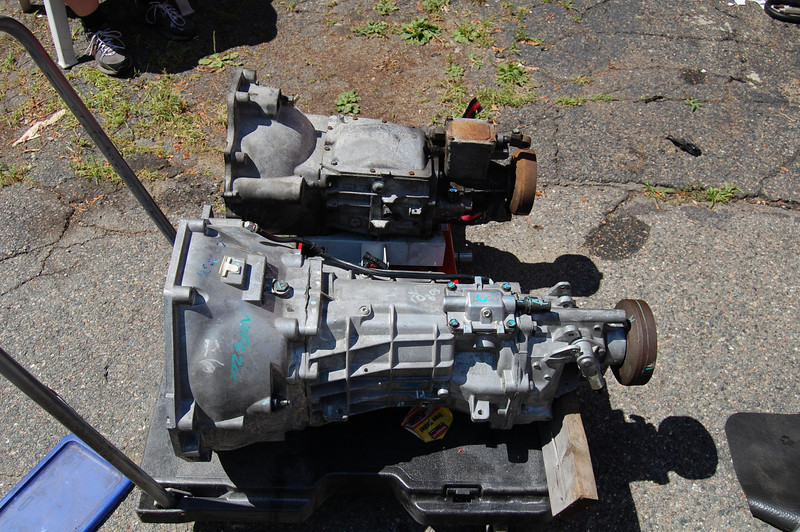

And a typical '10-'12 TR6060...

Note the change in flanges? The question is, why? There have been clutch changes at the engine interface but the two piece driveshaft has remained. I'll postulate that the ring that encircles the flange was originally put there for NVH. Witness the following:

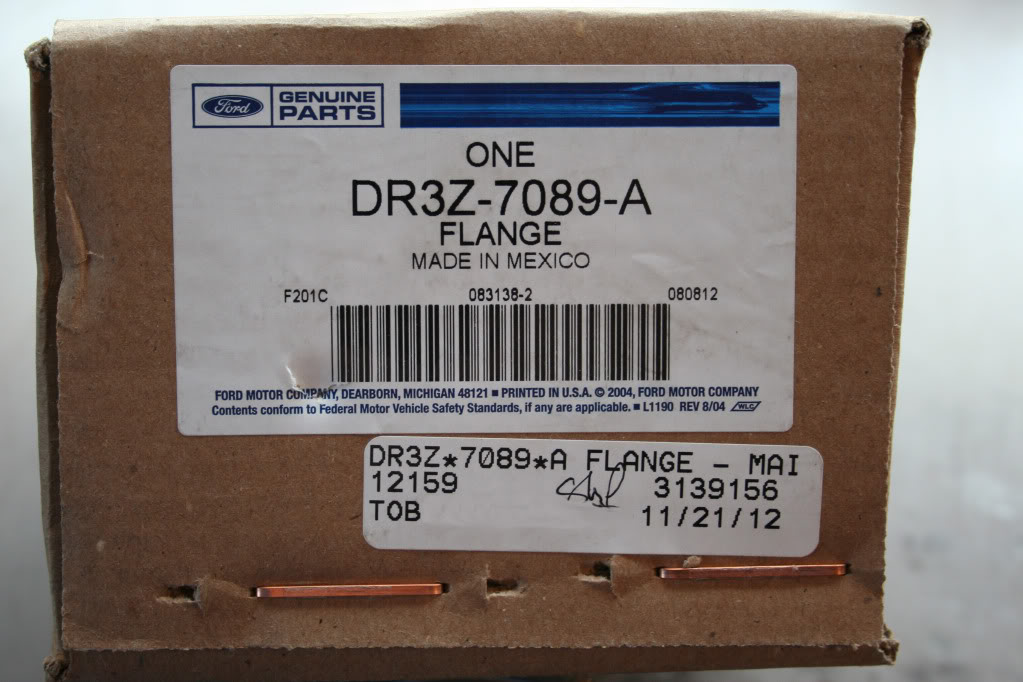

The '07-'09 6060 flange assembly from Ford...

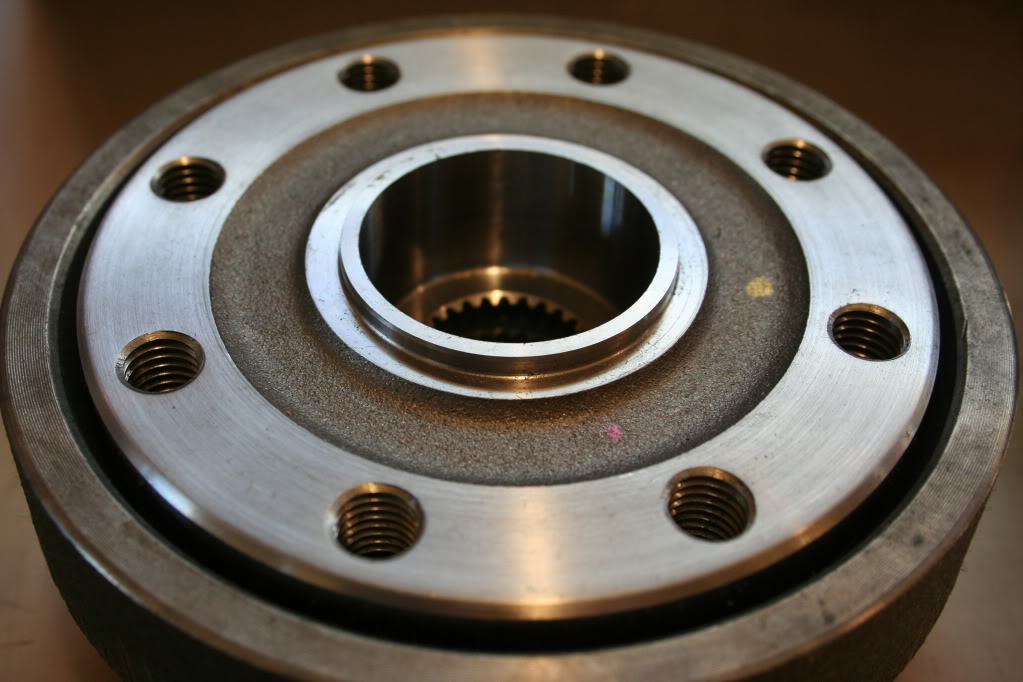

It interfaces onto the 6060 output shaft via splines and is then retained by a nut that is threaded onto the end of the output shaft...

The later flanges all work the same way. My interest at this point lies in why the ring was deleted. Here's an S197 Tremec 3650 and T5. Note the ring on their flanges...

Is it a two piece driveshaft issue (vibration attenuation)? Confusing, as I see other S197 transmissions, GT or otherwise, without the ring...

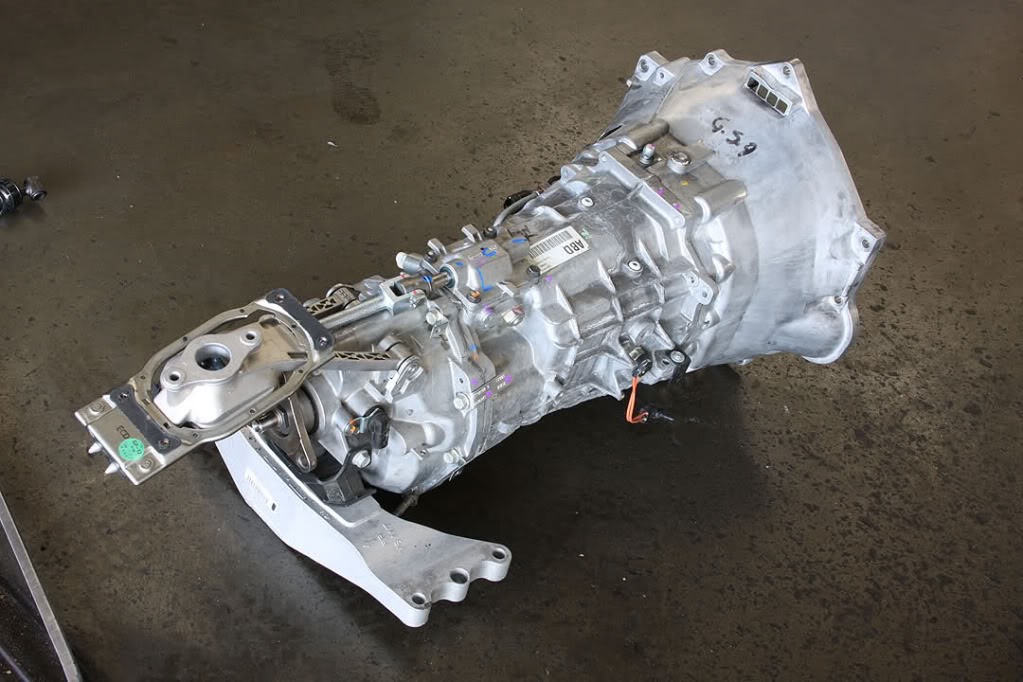

As well as some GM versions of the 6060 with a flange only...

Chrysler...

So it is a little difficult to get away with simple reasoning or process of elimination to determine why the ring was on there, respective of the two piece driveshaft or not. But the fact remains, Ford eliminated it in later years. Witness the Boss 302S 6060, which utilizes an aluminum one piece shaft...

But forget about guibo joint that GM used...

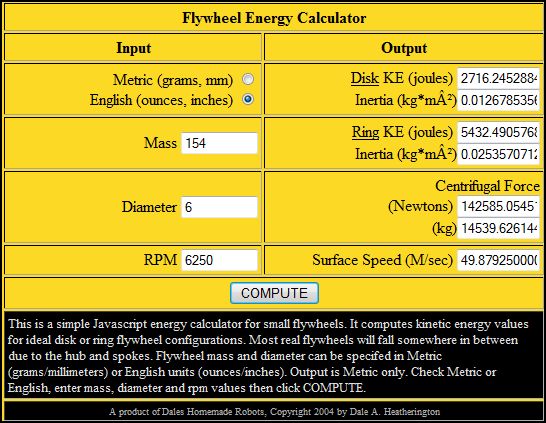

You may be asking, why the concern about the ring? Weight? In a word, yes. The '07-'09 flange assembly is more than double the weight of the later flanges. Using a handy calculator I found on the web, I inputted some general information regarding the '07-'09 flange assembly. It weighs 9 lbs 10 ounces and is almost 6 inches in diameter. Plugging in an arbitrary 6,250 rpm number in, note the forces in the right hand column...

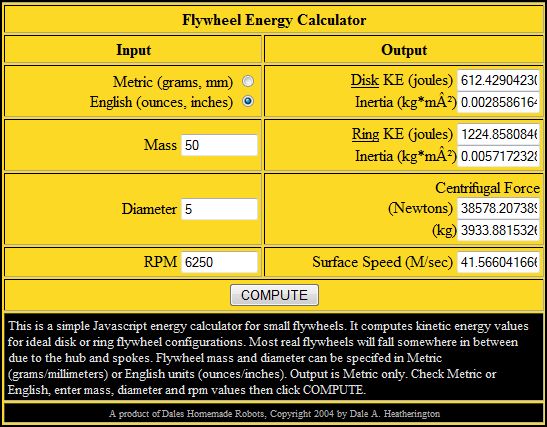

Then I changed the inputs to more closely match that of the '11/'12 flange (about 5 inches in diameter, and 3 lbs 2 ounces)...

The drop in centrifugal force is more than two thirds less between the early and later flanges (surface speed dropped slightly as well). Important, because the weight that the early flange carries is at the outer diameter along with the fact that the diameter itself is larger. Thanks to islander033. He pointed out my failure to convert pounds to ounces in the appropriate input fields. Thanks brother! I 're-upped' the above converting 9 lbs 10 ounces to 154 ounces and 3 lbs 2 ounces to 50 ounces.

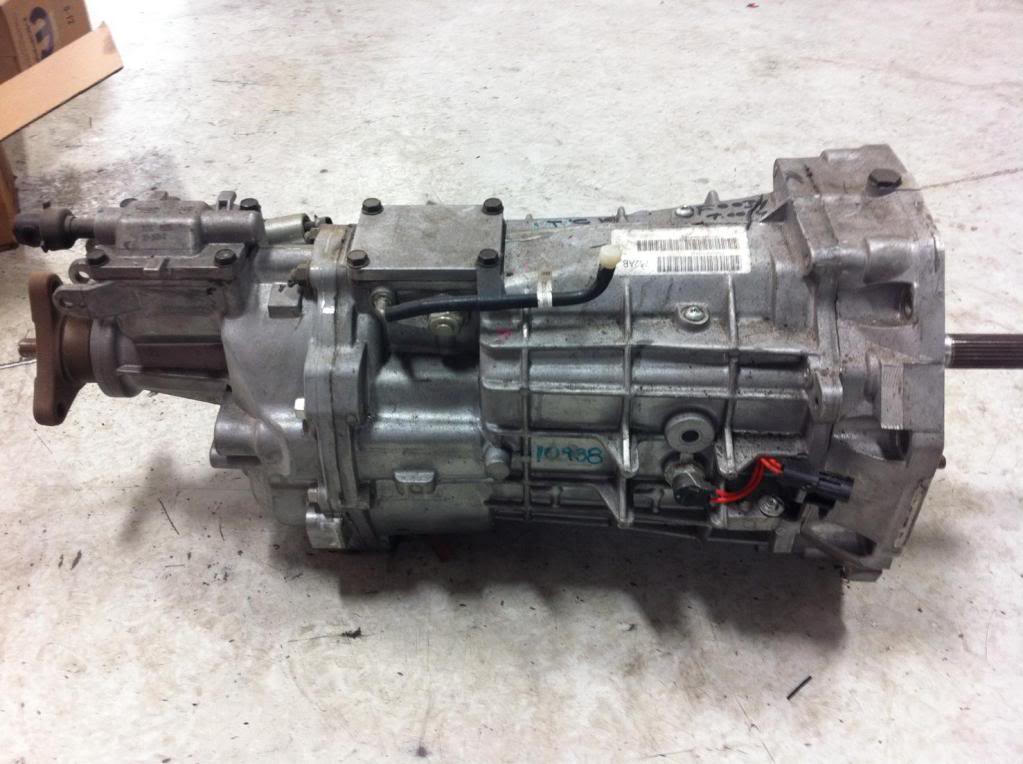

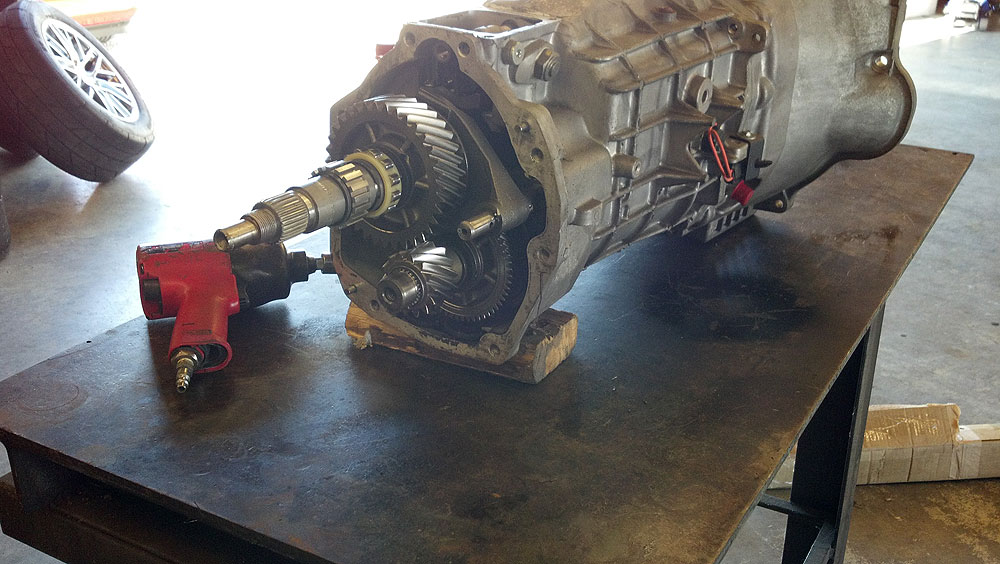

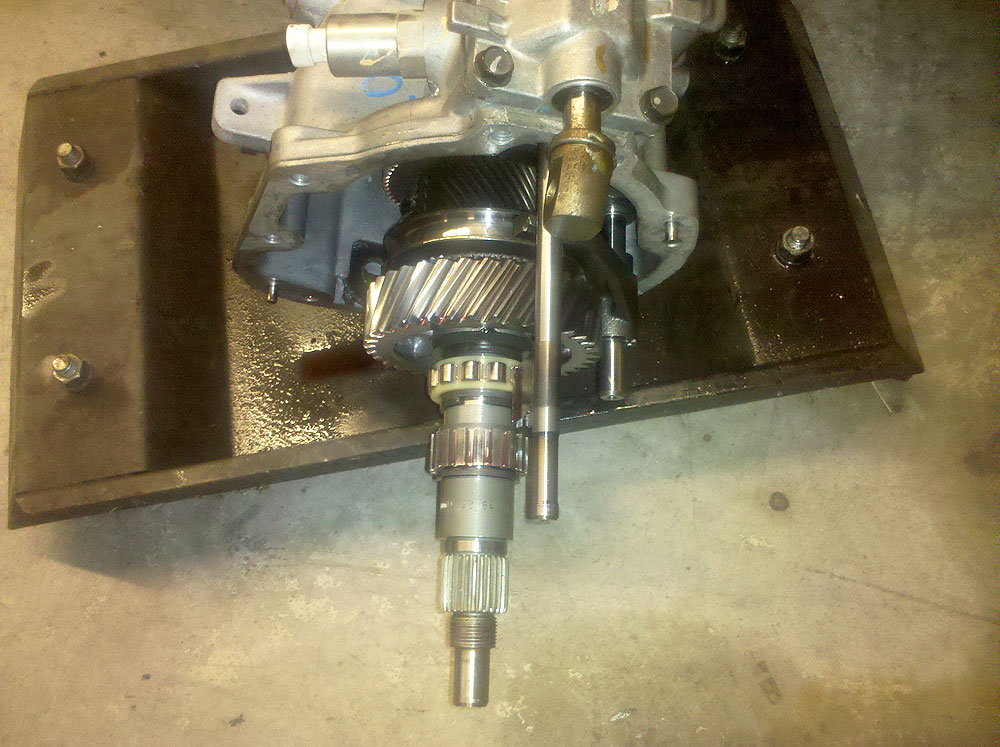

Note, there were issues of output shaft breakage on the early 6060's. They were snapping right where the splines ended for the flange interface. Here are some shots of the shaft on a typical, early 6060...

Gentlemen, I've yet to find a resource that addresses all these questions together, and in the context of our Ford GT500's. I'll do my best to change that.

What '07-'12 GT500 Vehicles Come With

To start, we all share a vehicle specific, Tremec supplied, TR6060. Not perfect, but designed to handle the abundance of torque that our beloved supercharged 5.4 liter engines produce. Throughout the above time period, Ford has instituted some small changes to the driveline, all aimed at improving durability.

That said, there have been issues. Owners have often complained that the transmission sometimes makes gear changing 'difficult.' Another issue worthy of discussion, but out of the context of the aim here. So aside from clutch, gear and shifter differences, I'd like to concentrate at the rear of the transmission. Why? Because that is the critical interface where transmission meets driveshaft.

To wit, the typical '07-'09 GT500 TR6060. Note the flange (fixed flange to be more precise) at the rear...

And a typical '10-'12 TR6060...

Note the change in flanges? The question is, why? There have been clutch changes at the engine interface but the two piece driveshaft has remained. I'll postulate that the ring that encircles the flange was originally put there for NVH. Witness the following:

The '07-'09 6060 flange assembly from Ford...

It interfaces onto the 6060 output shaft via splines and is then retained by a nut that is threaded onto the end of the output shaft...

The later flanges all work the same way. My interest at this point lies in why the ring was deleted. Here's an S197 Tremec 3650 and T5. Note the ring on their flanges...

Is it a two piece driveshaft issue (vibration attenuation)? Confusing, as I see other S197 transmissions, GT or otherwise, without the ring...

As well as some GM versions of the 6060 with a flange only...

Chrysler...

So it is a little difficult to get away with simple reasoning or process of elimination to determine why the ring was on there, respective of the two piece driveshaft or not. But the fact remains, Ford eliminated it in later years. Witness the Boss 302S 6060, which utilizes an aluminum one piece shaft...

But forget about guibo joint that GM used...

You may be asking, why the concern about the ring? Weight? In a word, yes. The '07-'09 flange assembly is more than double the weight of the later flanges. Using a handy calculator I found on the web, I inputted some general information regarding the '07-'09 flange assembly. It weighs 9 lbs 10 ounces and is almost 6 inches in diameter. Plugging in an arbitrary 6,250 rpm number in, note the forces in the right hand column...

Then I changed the inputs to more closely match that of the '11/'12 flange (about 5 inches in diameter, and 3 lbs 2 ounces)...

The drop in centrifugal force is more than two thirds less between the early and later flanges (surface speed dropped slightly as well). Important, because the weight that the early flange carries is at the outer diameter along with the fact that the diameter itself is larger. Thanks to islander033. He pointed out my failure to convert pounds to ounces in the appropriate input fields. Thanks brother! I 're-upped' the above converting 9 lbs 10 ounces to 154 ounces and 3 lbs 2 ounces to 50 ounces.

Note, there were issues of output shaft breakage on the early 6060's. They were snapping right where the splines ended for the flange interface. Here are some shots of the shaft on a typical, early 6060...