Looks good, hopefully my Cobra alternator will fit up. Sounds like I need to buy a tap & die set

Posted via Topify on Android

Posted via Topify on Android

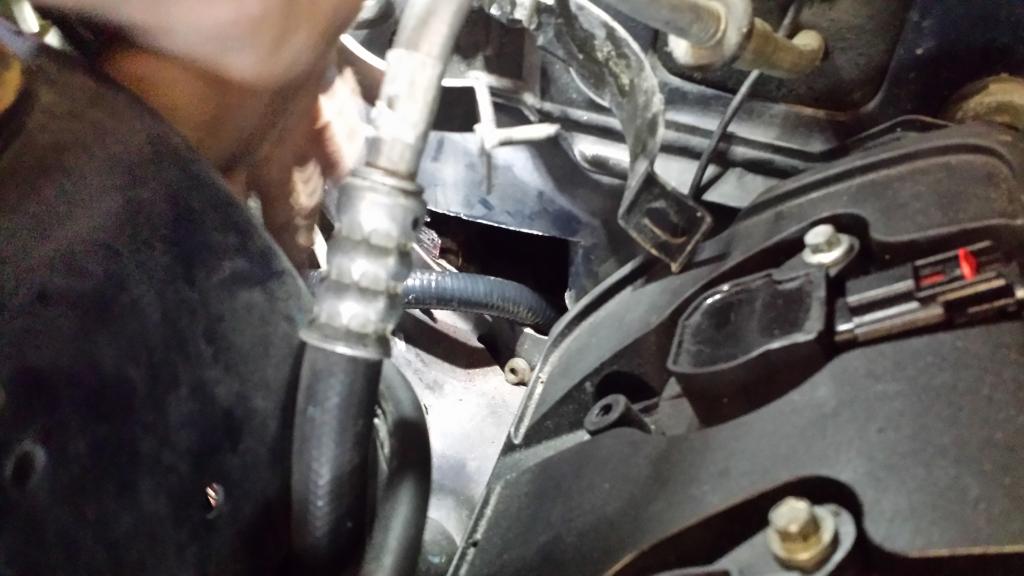

Instructions address both, however does not matter, some serious(well more than I thought) grinding and shaving needs to occur to get that alternator on there to have the pulley miss the PBH bracket as well as leave enough room for the belt to wrap around it as well. Tight squeeze for sure, alternator being used does not matter, just a L bracket for added support. I sort of forgot to take a picture, but be sure to grind down the old peg on the cover, grind down a little on the edge before the valve cover and I had to grind down a little just below the PBH alternator bracket (well my friend did which I appreciated lol)

Also, the headers were a complete pain in the ace to bolt on, I used mostly factory studs to avoid possible exhaust leaks but used the BbK bolts where I had to. Man Oh man was that rediculous doing it at basically a quarter of a turn for what felt like 3 hours. YOU have to mount the MOTOR MOUNTS and STARTER first, then bolt the headers on, you will NOt have an easy time getting those in after, trust me. Pic time.

Engine on the hoist and basically bolted up to the k.

Driver side tight squeeze but NO modification

Passenger side tight squeeze too but no modification or further hammering necessary. Washers can be used here to space the motor mounts out if you have a tight fit.

Pass side near the bottom of K

And walaaaa!

Another thing of advice, bolt engine to K first, then lower car into the K if possible, then before the car is fully nestled in and you are still shy of bolting the K to the car, hook the engine back up to the engine hoist with a chain so you can wiggle the engine around, it is a very tight squeeze where the dipstick tube is, and where the ac lines run on the passenger side of the engine compartment. We had to jack the trans up a little and support with a stand and do some wiggling to clear the VCT sensors and not break the dipstick tube off. Aside from that it goes in like a 5.4 would in this car. No big thang. Hope this helps.

Looks great!!!! Thanks for the advise of the started and motor mounts with the headers.

I'm gonna have a HELL of a time with this on jackstands in my garage

nicely done!!!! great info and man that looks like some tight fits. I would imagine there is going to be a little noise at times with the headers hitting.

If you are using a stock K-member (I'm not) you should be able to grind off material there to avoid contact with the headers. This is obviously why they recommend the tubular K-member like MM.

I have always pulled my 4.6L - 4v from the top and plan to do so again. I do it with the headers, starter, and engine mounts attached. I would like to try that first and see if it works before pulling the K-member. I don't have a lift so I have the car on jack stands and an engine hoist.

I've never pulled a motor but I plan to pull from the top and replacing the stock K-member with MM or something similar

Posted via Topify on Android

throttle body spacer and throttle body bolted on, no issues there.

Cut hole in the firewall and ran the wires inside, mounted the Ford box thingy to the passenger side kick panel.

ONLY ISSUE AS OF THIS MOMENT, i can not figure out how to get this older alternator to hold a charge...the new one/new harness one is computer controlled on a 2011+. This one needs a power wire, the connector on the FRPP harness is different than my 97 alternator and they do not sell a 2011 voltage regulator for me to swap to and use the frpp plug. So what do i do?

Thanks again, I'd rather not either, but I wasn't sure what was & was not needed/required for the 5.0. Seems all I may need is AN fittings & hose, regulator and hose. Maybe new fuel rails.If your car is a 1996-1997 you will not, I just did a walbro 255lph fuel pump, a aeromotive fuel pressure regulator, and all an/compression fittings and hose. You do not need to drop that kind of coin but that's up to you.