EDIT - update 2021: Although there are updates in the comments I still get questions on this all the time all these years later. So here's an updated summary right up top:

Deadhead works great at keeping the fuel cool but when the car sits for a few minutes warmed up it does heat soak the rails causing hard starts.

A more traditional flow through design with a fuel cooler after the rails before the fuel returns to the tank is the best solution I've found and what I've ran for a number of years now. It has no side affects of hard starts or heat soak and it keeps the fuel cool. Original post and content below.....

I thought I'd share my recent fuel temp issues and how I solved it. I know a few other guys I've chatted to on here have run into similar and done their own fixes but thought I'd share mine.

So first what's the problem? I noticed after driving around 45 min ~ an hour (granted driving the car hard) my fuel filter was so scolding hot I couldn't even touch it. My fuel in the tank was quite literally over 220F.

So why do I care? Well how long are my fuel pumps going to survive those kind of temps? probably not long at all.

In the process of researching the problem I spoke to Fore and they indicated it's a somewhat common issue they see and have had customers driving for extended periods (like 2 to 3 hours) and burning up their fuel pumps and getting stranded. They suggest staging the pumps by putting them on a HOBs switch so only a single pump is running at a time and the second one comes on only when in boost. They said a pair of 455 pumps, which is what I'm running, puts out 450 watts of heat. In their own tests in a 5 gallon bucket they heated fuel to 170F in two hours running two pumps.

I really wasn't buying that all the heat is coming from the pumps. I can see some but not enough for what I was experiencing. Yes the pair of pumps may draw 450 watts of power but a lot of that energy is going to pumping the fuel, it's not like a 450 watt heater in the tank.

So I did my own fuel heating test. I backed the car out of the garage in the morning with everything cold and hooked up my truck and left it idling with jumper cables. It was powering the pumps on the Cobra. I let this setup run for 70 minutes before stopping the test.

About 40 minutes into the test I noticed the battery on the Cobra was down to 12.5 volts and declining. Those pumps draw so much current the jumper cables where really hot and struggling to keep up. So I added a 6 amp battery charger in addition and that was just enough to hold the 12.5 for the remainder of the test.

So what did I learn? My pumps ran non stop for 70 minutes and heated the fuel a whole 7F. I had right around 10 gallons in there. So the pumps where really not my main source of heat by any means. I did however realize what a massive drain they put on the electrical system and also made sense why recently lots of short drives back and forth to the bank, grocery store etc. and the battery would struggle to stay fully charged. I'd see as low as 12.3 at times on it before firing up in the morning for a drive.

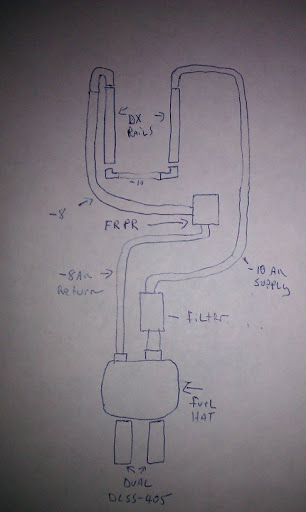

So back to my heat issue. I was convinced it's from the heat of the engine. When designing my return fuel system I looked at so many aspects of it performance wise I became tunnel visioned and never even considered the heat issue. My routing was from the fuel hat up to the passenger's side rail, daisy changed to the driver's rail, then to the FPR and back to the tank. Here's a really old drawing from the design days that's my basic layout.

See the huge problem here? It's basically like a hot water heat. Pump fuel around scolding hot motor and back to tank and repeat. You're effectively heating the crap out of your fuel.

So my though was change it so the fuel comes up and goes straight to the FPR and back to the tank. Run the rails in a dead head configuration so the fuel that runs up to the rails and gets heated gets burnt and never returns back to the tank. Initially I placed the FPR right here like this

Initial results where good. Fuel temps where way down but still getting hot. Turns out that regulator while tiny and not having all the surface area of the fuel rails along the motor was still heating the fuel a fair amount. I thought about building a heat shield but questioned how well it would work.

So next I moved the regulator completely inside the passenger's fender well in front of the tire inside the black plastic liner. Bingo. That did it. Our 1 hour "race track" of back highway testing yielded only about 21F increase in fuel temps. Amazing. After an hour of hammering on the car I can grab the fuel filter and it's only luke warm. We had a really hot day a few weeks ago and I had made some other changes to the car so my son and I were out for several hours data logging and tuning the car. Making countless pulls on the highways, stopping at various places and tweaking the tune, analyzing data logs etc. We played with the car for over 6 hours straight in 90+ heat and the fuel did get quite warm in those conditions but still not even close to the way it was when we started. I could still grab the fuel filter in my hand although it was hot not scolding like before.

A few other interesting things I learned along the way. Not all fuel pressure regulators behave the same at all. So bare this in mind when replacing one. If you switch brands you need to re-tune. For example an Aeromotive unit set at a base of 39 PSI swapped out for a Fore set at base of 39 PSI will not adjust pressure as you go into boost/vacuum by the same ratio and throws your tune off. Each time we swapped regulators we had to re-tune.

I also discovered switching up the way you plumb your rails requires re-tuning as well. So if your fuel supply to the rails then to the pressure regulator which goes to the tank and then change it to fuel to regulator which connects to rails in dead end config you have to re tune again because the pressures don't hold exactly the same. It throws the AF off as you get into higher boost levels.

In my testing I found the dead head configuration had the most consistent fuel pressure through out the RPM and boost ranges.

Performance wise and drivability wise I see no difference in the various ways of plumbing up the rails and FPR. They all seemed to perform equally as well once tuned. The only big difference was the heat.

Another thing I looked at in my quest to drop heat and also reduce that massive burden on my electrical system was to stage my pumps. Initially I hooked up a HOBs switch I got from Fore. It kicks on at 2 PSI and is not adjustable. It kicks on the second pump. The one thing I really hated about it was our cars come into boost all the time. Any gear and any tip in on the throttle and you're seeing boost even on very low load and partial throttle driving. So the second pump was constantly snapping in and it was making tuning the car hell. Granted I'm picky on my tunes but did not like the constant fluctuations. This is what initially lead me to swapping out fuel pressure regulators as they don't all behave the same between one and two pumps running.

The short version is the Fore regulator is the way to go for this issue. With a single 455 pump running and a second 455 I was only seeing 1 PSI difference in fuel pressure. On a few others I tried I had in the garage I was seeing 3 ~ 5 PSI difference.

I still wasn't overly happy with the setup so I designed and built a little fuel pump module. Basically it monitors the MAF curve and only when you get up to a pre-set point in the curve it knows your first pump is about to run out and it turns on the second pump. This was the perfect cure to my tuning issues as now I only have one spot in the entire MAF curve where the second pump comes on and it's always at the same spot.

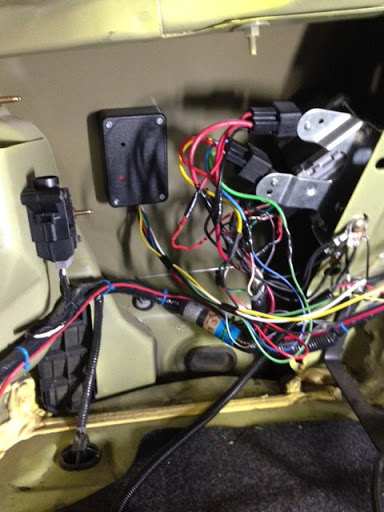

You can see the module mounted on the inner fender well of the trunk behind the FPDM. Don't mind the wiring mess at the time. I was constantly changing things up and trying new things.

This allows me to WOT in 1st, 2nd, lower part of 3rd, some heavy throttle (not WOT) in 4th, 5th and 6th for passing, partially heavy throttle in boost up hills in back roads etc. all without ever triggering the 2nd pump as it's simply not needed.

So hope that helps others realize the fuel heating issue you can experience depending on how you plumb a return system and hopefully your pumps don't over heat and strand you.

EDIT: had a few requests for pics of regulator inside passenger's wheel well area. Here's a copy of the post from page 4.

Finally snapped a few pics earlier this evening when I had the wheel and wheel well out.

As you can see in this pic I labeled the supply fuel line and the return line going back to the tank. The other two lines run to each of the rails.

Here's a close up of the regulator. You can see the sort of Z shaped bracket I made to bolt it up where the bumper bolts to the inner fender.

Closer up of bracket. Really hard to get good pics in tight space lol.

Another shot

Here's a shot from lower down looking up. Notice the regulator is upside down. I did that so if I ever wanted to adjust or tweak the base pressure I wouldn't have to pull the wheel and liner. I can simply jack that corner up or drive up a ramp and reach up and change it.

Overall shot.

Deadhead works great at keeping the fuel cool but when the car sits for a few minutes warmed up it does heat soak the rails causing hard starts.

A more traditional flow through design with a fuel cooler after the rails before the fuel returns to the tank is the best solution I've found and what I've ran for a number of years now. It has no side affects of hard starts or heat soak and it keeps the fuel cool. Original post and content below.....

I thought I'd share my recent fuel temp issues and how I solved it. I know a few other guys I've chatted to on here have run into similar and done their own fixes but thought I'd share mine.

So first what's the problem? I noticed after driving around 45 min ~ an hour (granted driving the car hard) my fuel filter was so scolding hot I couldn't even touch it. My fuel in the tank was quite literally over 220F.

So why do I care? Well how long are my fuel pumps going to survive those kind of temps? probably not long at all.

In the process of researching the problem I spoke to Fore and they indicated it's a somewhat common issue they see and have had customers driving for extended periods (like 2 to 3 hours) and burning up their fuel pumps and getting stranded. They suggest staging the pumps by putting them on a HOBs switch so only a single pump is running at a time and the second one comes on only when in boost. They said a pair of 455 pumps, which is what I'm running, puts out 450 watts of heat. In their own tests in a 5 gallon bucket they heated fuel to 170F in two hours running two pumps.

I really wasn't buying that all the heat is coming from the pumps. I can see some but not enough for what I was experiencing. Yes the pair of pumps may draw 450 watts of power but a lot of that energy is going to pumping the fuel, it's not like a 450 watt heater in the tank.

So I did my own fuel heating test. I backed the car out of the garage in the morning with everything cold and hooked up my truck and left it idling with jumper cables. It was powering the pumps on the Cobra. I let this setup run for 70 minutes before stopping the test.

About 40 minutes into the test I noticed the battery on the Cobra was down to 12.5 volts and declining. Those pumps draw so much current the jumper cables where really hot and struggling to keep up. So I added a 6 amp battery charger in addition and that was just enough to hold the 12.5 for the remainder of the test.

So what did I learn? My pumps ran non stop for 70 minutes and heated the fuel a whole 7F. I had right around 10 gallons in there. So the pumps where really not my main source of heat by any means. I did however realize what a massive drain they put on the electrical system and also made sense why recently lots of short drives back and forth to the bank, grocery store etc. and the battery would struggle to stay fully charged. I'd see as low as 12.3 at times on it before firing up in the morning for a drive.

So back to my heat issue. I was convinced it's from the heat of the engine. When designing my return fuel system I looked at so many aspects of it performance wise I became tunnel visioned and never even considered the heat issue. My routing was from the fuel hat up to the passenger's side rail, daisy changed to the driver's rail, then to the FPR and back to the tank. Here's a really old drawing from the design days that's my basic layout.

See the huge problem here? It's basically like a hot water heat. Pump fuel around scolding hot motor and back to tank and repeat. You're effectively heating the crap out of your fuel.

So my though was change it so the fuel comes up and goes straight to the FPR and back to the tank. Run the rails in a dead head configuration so the fuel that runs up to the rails and gets heated gets burnt and never returns back to the tank. Initially I placed the FPR right here like this

Initial results where good. Fuel temps where way down but still getting hot. Turns out that regulator while tiny and not having all the surface area of the fuel rails along the motor was still heating the fuel a fair amount. I thought about building a heat shield but questioned how well it would work.

So next I moved the regulator completely inside the passenger's fender well in front of the tire inside the black plastic liner. Bingo. That did it. Our 1 hour "race track" of back highway testing yielded only about 21F increase in fuel temps. Amazing. After an hour of hammering on the car I can grab the fuel filter and it's only luke warm. We had a really hot day a few weeks ago and I had made some other changes to the car so my son and I were out for several hours data logging and tuning the car. Making countless pulls on the highways, stopping at various places and tweaking the tune, analyzing data logs etc. We played with the car for over 6 hours straight in 90+ heat and the fuel did get quite warm in those conditions but still not even close to the way it was when we started. I could still grab the fuel filter in my hand although it was hot not scolding like before.

A few other interesting things I learned along the way. Not all fuel pressure regulators behave the same at all. So bare this in mind when replacing one. If you switch brands you need to re-tune. For example an Aeromotive unit set at a base of 39 PSI swapped out for a Fore set at base of 39 PSI will not adjust pressure as you go into boost/vacuum by the same ratio and throws your tune off. Each time we swapped regulators we had to re-tune.

I also discovered switching up the way you plumb your rails requires re-tuning as well. So if your fuel supply to the rails then to the pressure regulator which goes to the tank and then change it to fuel to regulator which connects to rails in dead end config you have to re tune again because the pressures don't hold exactly the same. It throws the AF off as you get into higher boost levels.

In my testing I found the dead head configuration had the most consistent fuel pressure through out the RPM and boost ranges.

Performance wise and drivability wise I see no difference in the various ways of plumbing up the rails and FPR. They all seemed to perform equally as well once tuned. The only big difference was the heat.

Another thing I looked at in my quest to drop heat and also reduce that massive burden on my electrical system was to stage my pumps. Initially I hooked up a HOBs switch I got from Fore. It kicks on at 2 PSI and is not adjustable. It kicks on the second pump. The one thing I really hated about it was our cars come into boost all the time. Any gear and any tip in on the throttle and you're seeing boost even on very low load and partial throttle driving. So the second pump was constantly snapping in and it was making tuning the car hell. Granted I'm picky on my tunes but did not like the constant fluctuations. This is what initially lead me to swapping out fuel pressure regulators as they don't all behave the same between one and two pumps running.

The short version is the Fore regulator is the way to go for this issue. With a single 455 pump running and a second 455 I was only seeing 1 PSI difference in fuel pressure. On a few others I tried I had in the garage I was seeing 3 ~ 5 PSI difference.

I still wasn't overly happy with the setup so I designed and built a little fuel pump module. Basically it monitors the MAF curve and only when you get up to a pre-set point in the curve it knows your first pump is about to run out and it turns on the second pump. This was the perfect cure to my tuning issues as now I only have one spot in the entire MAF curve where the second pump comes on and it's always at the same spot.

You can see the module mounted on the inner fender well of the trunk behind the FPDM. Don't mind the wiring mess at the time. I was constantly changing things up and trying new things.

This allows me to WOT in 1st, 2nd, lower part of 3rd, some heavy throttle (not WOT) in 4th, 5th and 6th for passing, partially heavy throttle in boost up hills in back roads etc. all without ever triggering the 2nd pump as it's simply not needed.

So hope that helps others realize the fuel heating issue you can experience depending on how you plumb a return system and hopefully your pumps don't over heat and strand you.

EDIT: had a few requests for pics of regulator inside passenger's wheel well area. Here's a copy of the post from page 4.

Finally snapped a few pics earlier this evening when I had the wheel and wheel well out.

As you can see in this pic I labeled the supply fuel line and the return line going back to the tank. The other two lines run to each of the rails.

Here's a close up of the regulator. You can see the sort of Z shaped bracket I made to bolt it up where the bumper bolts to the inner fender.

Closer up of bracket. Really hard to get good pics in tight space lol.

Another shot

Here's a shot from lower down looking up. Notice the regulator is upside down. I did that so if I ever wanted to adjust or tweak the base pressure I wouldn't have to pull the wheel and liner. I can simply jack that corner up or drive up a ramp and reach up and change it.

Overall shot.

Last edited: