"Well, I stand up next to a mountain

I chop it down with the edge of my hand"

Jimi Hendrix

Much like Mr Hendrix, the group at Ford tasked with creating a modern day rendition of a decades-ago GT350, let nothing stand in their way. They took on an assignment to bring a Mustang to a level heretofore unparalleled. On June 2, 2015, SVTP was given access to some of the individuals that designed and tested the powertrain that will motivate one of the most track capable machines ever to be manufactured and assembled by the people of Ford Motor Company. I was lucky enough to be invited to witness the reveal and the following is my accounting of that day.

EARLY BIRDS

Travis Hill (the owner of SVTP), Steve Turner (Editor in Chief at SVTP), and myself discussed and organized a plan to collect data, images, and anything else relevant to the outing of the day in order to present it to the public as accurately and quickly as possible. Travis and Steve have been around the block a quite few times before but this had remained a road not taken for me. Gear in hand, Travis and I made our way to 777 Republic Drive in Allen Park, Michigan. We arrived a few minutes early and immediately got to work. Travis got his gear setup and I started snapping shots with my trusty Canon 6D. People started rolling in and were quickly greeted, given a name tag, and fed. I have to offer my sincerest gratitude to Monique Brentley, Tony McCloud, and Brian Cotter for their efforts in organizing this event. They did a wonderful job.

If I was Jamal I wouldn't have been able to contain the smile either.

TALK ABOUT A GRAND ENTRANCE...

Jamal Hameedi, Ford Performance Chief Engineer, kicked off the session by making his way through the nearby lot in slightly hurried fashion and pulling up in an absolutely gorgeous red GT350 R. I'll be honest. I've never owned a red car and had never planned on it. I don't think Jamal had even exited the vehicle yet and I knew my plans had just been blown out of the water.

I had the opportunity to talk to Jamal for quite a bit and found him to be nothing less than a true gentleman. My heart lay in the challenges that were faced and how they were overcome by the engineers responsible for this effort. There had been rumor from across the web that NVH was posing a formidable challenge, so I inquired. I'll bullet the highlights.

- Jamal laid down the goals that this group would work to achieve. He wanted no less than 500hp, naturally aspirated. Believe it or not, the decision to go with a flat plane crank (or FPC) was secondary, not primary.

- Why not an optimized Coyote instead of treading over untested waters? Because they wanted more than what the Coyote had to offer and the FPC was one of the many integrated components that helped them to achieve it. Jamal made it clear that this effort was the result of engineering each and every piece of hardware to work together without compromise. I asked if any Factors of Safety had to be lowered in order to hit their overall target and the answer was a resounding no.

- The group was able to achieve the power goals they sought as well as those of durability and emissions without affecting the range of power they were looking for. When I asked if the cats were more robust than those last used on the 662hp GT500 he stated that it was fair to say they were at least as robust but that they used different materials than those of the former forced induction engine and were not the same.

- I inquired as to why (cost aside) a carbon fiber shaft was not tapped for this application and Jamal repeated a comment he had previously made that a CF shaft simply isn't stiff enough for this application. When I mentioned the critical speed that the CF shafts offer (such that the '13-'14 GT500 could hit over 200mph) Jamal corrected me by stating that it was critical frequency that was the concern. This is where the engineers put the time in to ensure these frequencies were in the range where they needed to be. The two-piece shaft that the GT350 will utilize is not what will limit its top speed.

Jamal was great to talk to and very concise when responding to any number of questions. Our conversation had only been over for a brief time when he approached and asked if he could talk to me about something, behind the red R he had arrived in, and away from everyone else for a moment. I honestly thought I had done something wrong but had no idea what it could have been. Travis joined and the three of us stood at the back of the red R.

GT350 exhaust tips. The place where internet myths are born.

Jamal asked if we could debunk a myth that he continues to see on the web with respect to the tail end of the exhaust system. Any number of internet experts have commented negatively about the "tube within a tube" as if it was some sort of cosmetic afterthought, and it isn't. Jamal mentioned how its design allows cool air to pass through the outer tube and around the tailpipe. Both Travis and I commented that we understood it to be similar to that of the diesel trucks at that juncture and Jamal agreed. He then mentioned that those who remove the outer tube and track or run their GT350 hard may find a heat distorted rear fascia as a result.

THE SCIENTIST

On deck was the opportunity to talk to Adam Christian, ICE Technical Specialist. Adam was key behind the Coyote engine effort a few years ago. Not only a brilliant engineering mind, but skilled hands as well. For those that never read the superb article done by Steve Turner and Tom Wilson on Coyote development, Adam took matters into his own hands when nobody seemed to be able to produce a satisfactory short tube header and took his work home with him and fired up the welder. Knowing this, I knew I could delve deeper at this point as I can directly relate to fab work.

Adam gave me quite a bit of his time and I did my best not to waste so I got right to the point.

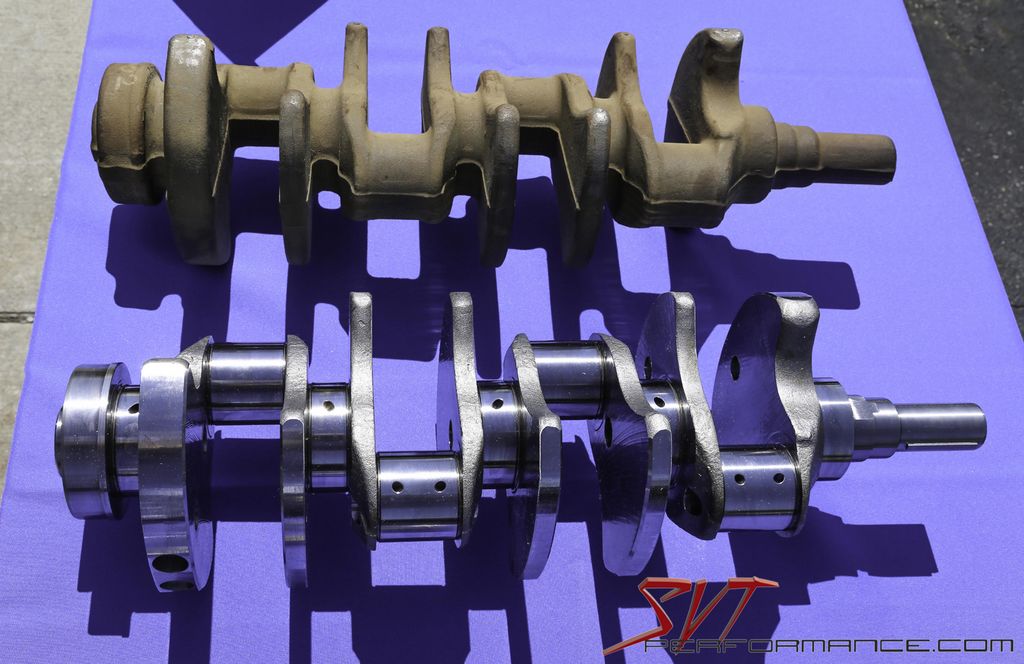

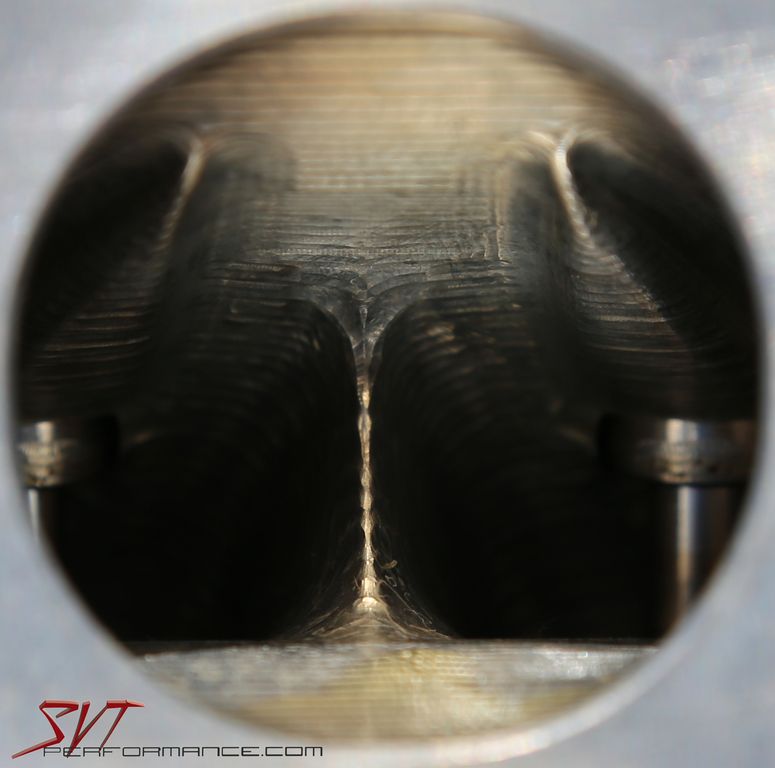

I brought up the undercut fillets I saw on the crank to Adam and mentioned that they have proved to be a weak point on the GT500 5.4/5.8 crankshafts. I told him that while it was nice to see a forged crank in FPC form, that I had really hoped for some crank exotica such as fully radiused journals. Adam was quick to point out that what I was witnessing was not an undercut per se but rather an intentional and engineered process. Huh? I was unaware but Adam explained how Ford forces a very small high strength ball around the circumference at those areas, increasing the strength. I second guessed him (a mistake) and at that point he had me get as close as I possibly could and take another look. Yup, something was clearly different. My bad Adam.:read:

Regarding the gun drilling, Adam stated that it happened a bit easier than he expected. He told me that he approached his "crank guy" about it and that it didn't take him long to say that he could make that happen. I inquired about any potential weakness being the result of removing material in that area and Adam made it clear that it was in an area that had zero effect on strength.

Adam pointed out how the counterweights take more than one pass to machine on their outside diameter due to their being more than one radius. Production wants to make one pass with a giant wheel but these guys weren't having that.

Note converging arcs on the outside of the counterweights.

Some at the event had used the term "forged" with respect to the connecting rods which can cause some confusion so I attempted to clarify. They are indeed fracture split but with so many referring to powder forged rods as forged, implying traditional drop forging, I tried to make the point of clarification worthy. The grain and parting line on the side of the beam sure had me thinking forged. I asked about the material properties of the rods and Adam pulled out his phone and said he'd get through to the individual that had all the data (he tried three times but couldn't reach him). I'm still hoping to learn more so as to be as specific as possible when referencing them.

I mentioned to Adam that when I heard rumors about the rpm range and the possibility of a FPC that I became hopeful that we may once again see a billet forged rod, ala the Manley last used in the '03-'04 Cobra engines. He made it clear that the rod they came up with does the job and that the Manley may not be everything I think it is. I brought up how a couple of years ago in Pirelli World Challenge when a few teams suffered engine failures that the governing body then allowed the Manley H beam as a legal substitute for stock. Adam then filled me in on a Manley rod failure that Ford engineers witnessed. Nuff said, I recalibrated once again.:read:

I hadn't seen it in print so I inquired as to the source of the block. Since this block was going to use PWTA I wondered if Honsel in Germany would be doing them such as the last GT500 blocks were done. I also wondered if as part of trying to keep costs down on this beast if Ford would use the Windsor plant now. Adam said they would be cast at the Essex engine plant, or as we refer to them, Windsor. Win.

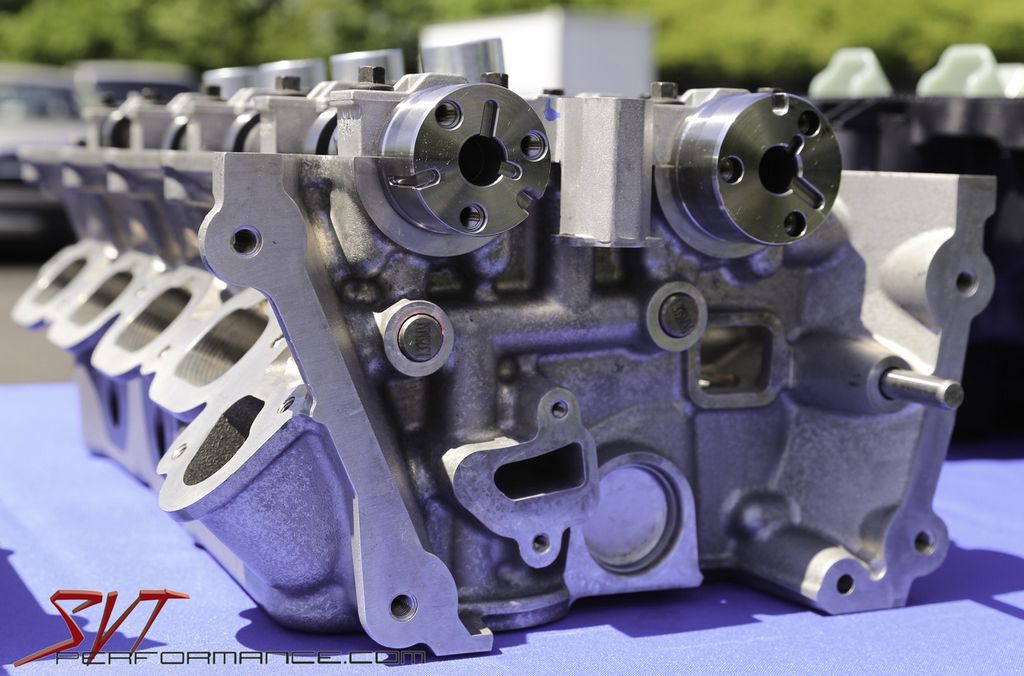

Adam had to take a call with the promise to return asap but left me with a challenge. He flipped a cylinder head on its side, pointed to some blind holes and asked me if I could figure out what they were for. There were four holes on one of the cylinder head faces, about 5/8" in diameter, that ran in about an inch or two. Weight reduction. Wherever possible, even in aluminum, heft was sliced.

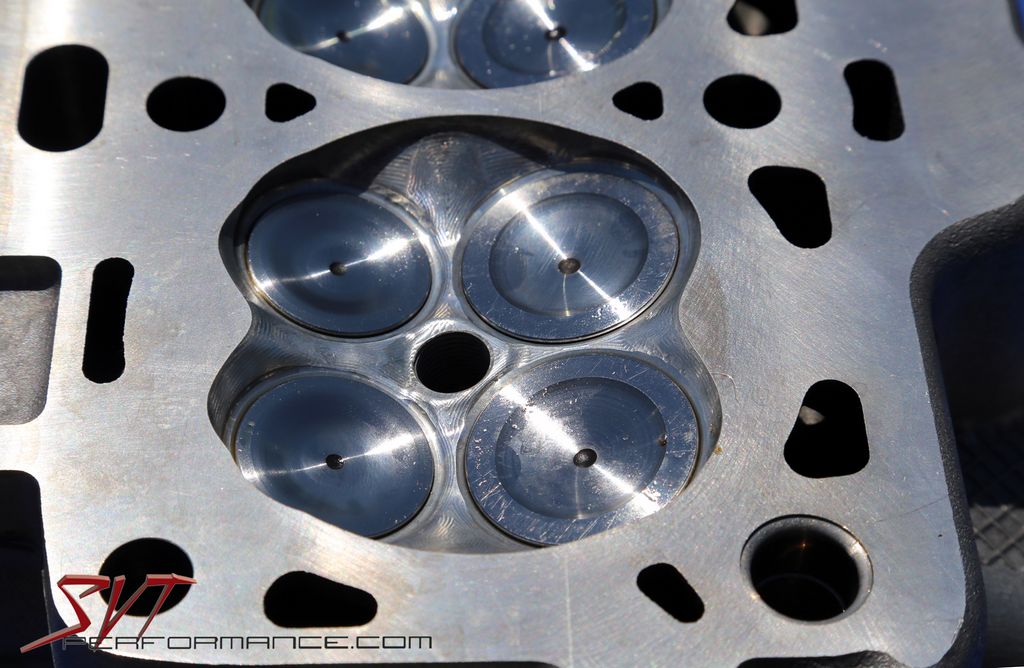

The CNC chambers are absolutely works of art. No "bump" for direct injection as it isn't needed.

Speaking of CNC work on the cylinder ports, here's a shot you won't see anywhere else...

Regarding direct inject injection, we talked about this for a while. Short version, in a normally aspirated application, Ford engineers achieved better atomization with a port fuel injection setup. DI shows weakness when fuel hits "metal" (slang for aluminum, etc, in this case) and doesn't perform as well. Supercharged/turbocharged applications are another ball of wax. In the end, Adam suggested that it is going to take some pretty drastic conditions (ie, legislative) to necessitate its use. Apparently EPA particulate mandates for gasoline engines are right around the corner.

The 5.2 tubular exhaust manifolds are gorgeous. There will be those that will yank them and slip in a set of long tubes, tune the car, and post up their supporting dyno graph for all to see. Even if they lost power it'd still be done. But in the scope of this reveal, the stock hardware, I must admit that these are extremely well done.

Construction consists of CNC mandrel bent stainless tubing (Looked like 409 to me and Adam was checking to see if final production was going to be 300 series instead), a CNC cut flange, and a cast stainless steel collector. There's a mix of tig and mig welding at various points of fusion.

Inside the flanges, there's a fairly "tall" wire fed machine bead that sometimes gets dressed or hit quickly with a carbide cutter. Given the level of detail at every square inch of this engine I have no doubt that they either have no impact or somehow serve a favorable function, beyond just fusing the tubes to the flange.

Tig, done by hand where the tubes converge upon the cast collector.

The scallops inside the collector are cast for optimal flow characteristics and not machined.

I gave these pieces extra attention not only because they deserve it but because of Adam's previous efforts with them on the Coyote. I mentioned that I knew how hard he had pushed for them on the 5.0 and how close they were to getting the axe in favor of a cast iron manifold. I asked if that effort had any influence on their being accepted on this engine as well. Adam stated that was how corporate structure works in that you have to push as hard as you can if you want to do something different. He laughed when he said that now the tubular headers were expected. I asked if the tig welds were just for the pre-production units and would go away for production. Adam stated that this was one of those rare situations where such low volume actually proved to be less expensive when done by hand as opposed to setting up and using robots for all of the welds.

All in all, great discussion with Adam. His rapid fire response to any tech question thrown his way was truly impressive. When he slipped out "negative radius of curvature" (see Steve's writeup on this for more) he smiled when I gave him the look.:??: Then he broke it down in a way that anyone could understand. Great guy.

THE DOCTOR

Eric Ladner, Engine Systems Supervisor, has as much patience as one could imagine. He stuck it out and answered questions on most every item on the table and was one of the last engineers to leave.

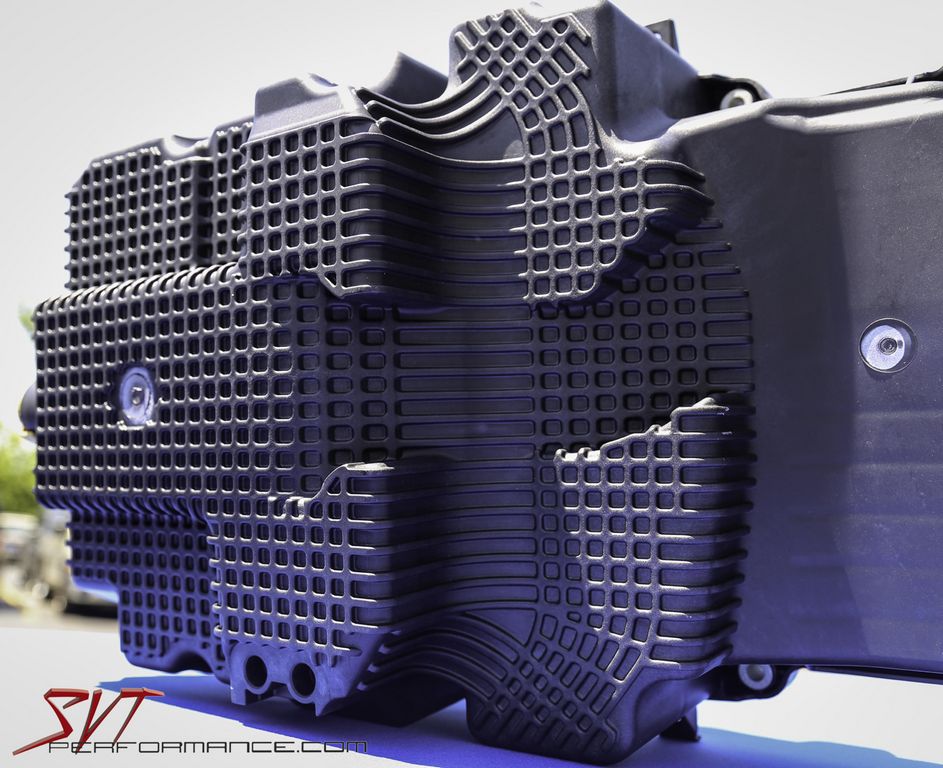

We moved into a great discussion regarding the composite oil pan. I mentioned a concern for a pan over impact resistance for a car sitting this low that gets driven hard on tracks with curbing, debris, agricultural excursions, etc. I also brought to light a vision of the typical backyard mechanic, looking to raise the motor up an inch or so to slip in some headers, may typically put a block of wood under the pan and support it there with a jack. The composite pan is very light. Eric quickly pointed out that the composite piece met the relevant criterion and allowed for some interesting sculpting which in turn allowed for an additional two quarts of oil capacity.

The ribs provide a considerable strength benefit. Additional cooling, not so much.

Adam also brought up the fact that the GT350 oil pan has additional protection in the form of a belly pan that resides between it and the road.

The integrated pickup and windage tray make for for a very well integrated and engineered piece. Eric converted me into a believer.

Eric and I also discussed the composite intake manifold, its "scroll" design, and glass filled nylon construction (similar to that of the oil pan but with different material percentages). The question I didn't ask but should have was whether or not it would bolt onto a Coyote engine. If I get the opportunity to ask Eric I will. Another great guy.

Having some insight into the individual components, I think the no frills, minimalist, topside deserves reconsideration. It is all that it needs to be with zero fluff for cosmetic appearance.

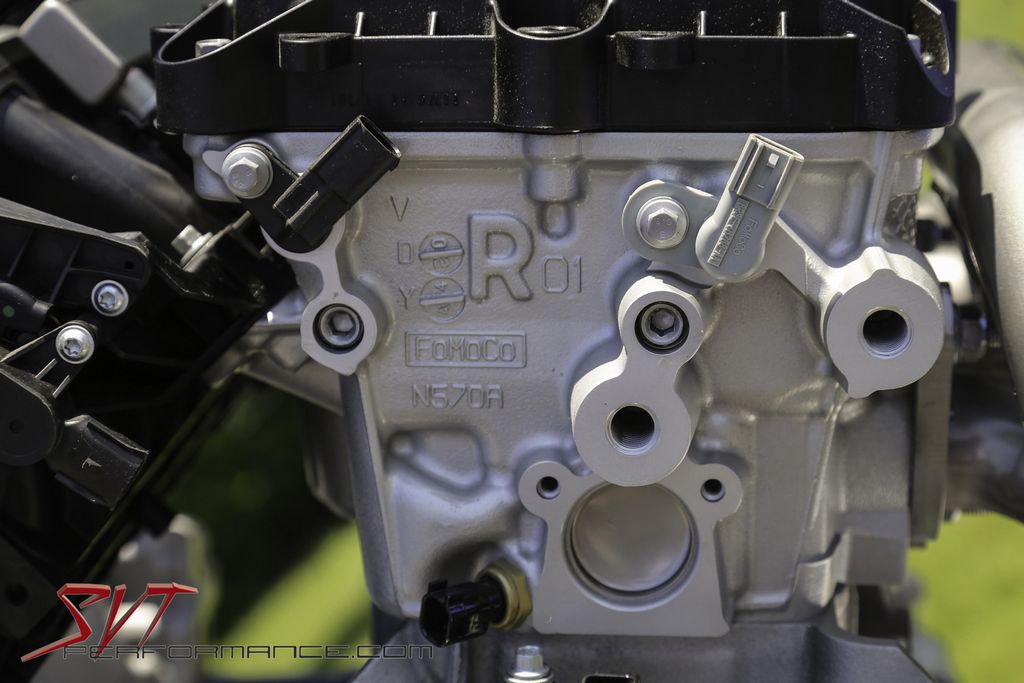

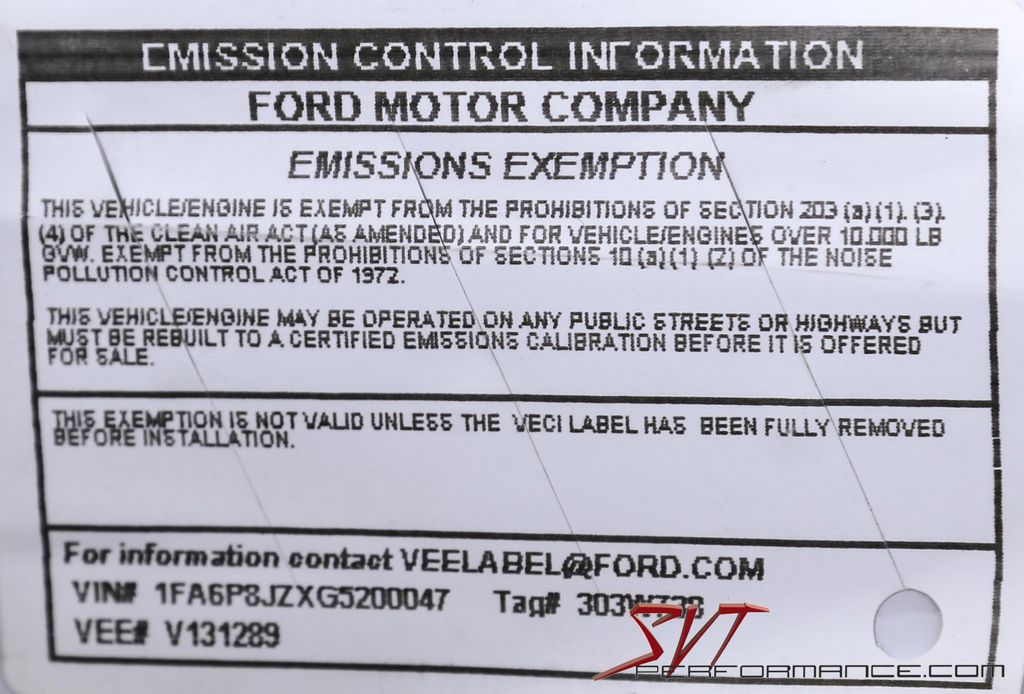

Something I never see detailed and has always driven me nuts to not be able to read whenever pre-production engine bay photos are taken. How I wish I could just pay a fee at DMV, install something similar, and have at it (I'm in NY and we've adopted much of California's stringent emission law).

WHAT OF THE TRANSMISSION?

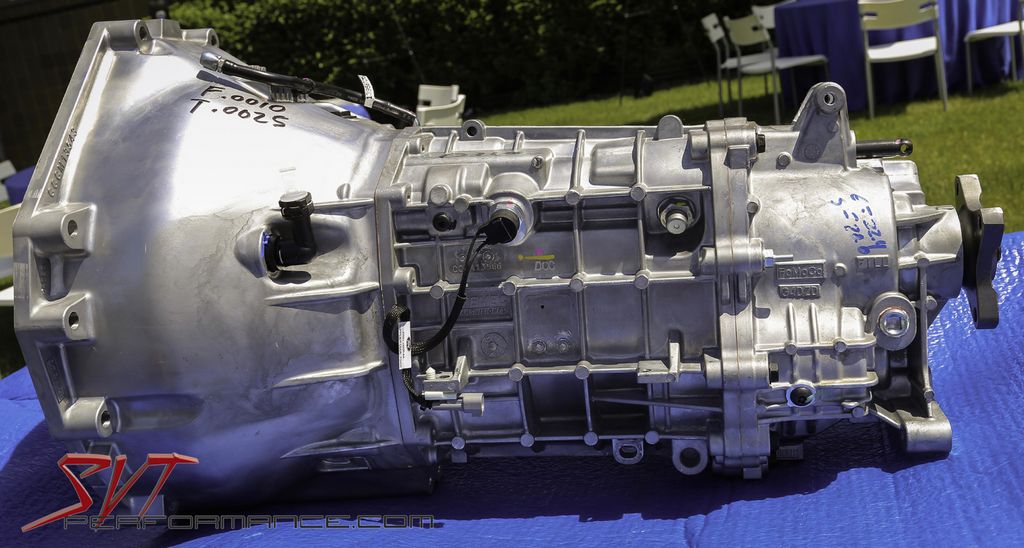

Most already know that the Tremec TR6060 reign is past us and that the GT350 will use a new for the Mustang TR3160. A lower torque capacity than what backed the Trinity behemoth but a design geared towards towards finesse. Hollow shafts, latest bearing and synchro design, lighter weight, all in a unit designed to match the rpm characteristics of the 5.2L engine.

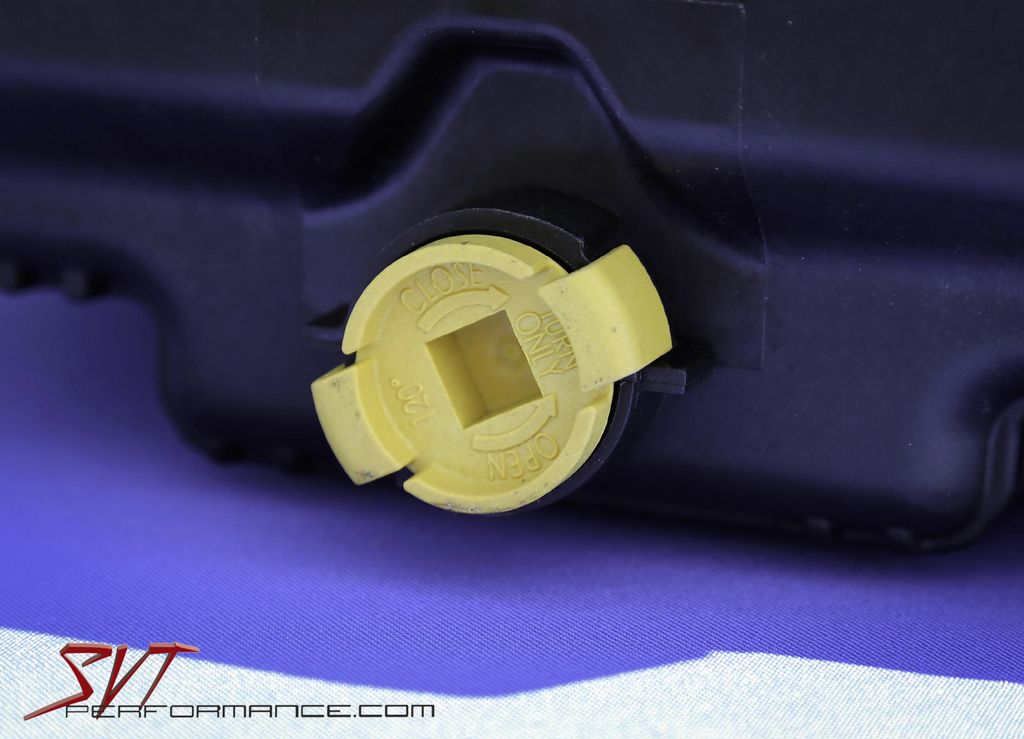

Note how the vent is at a higher elevation and brought forward of the last TR6060 vent location.

Heavily ribbed inside the bellhousing you can also see the casting boss for the internal pump.

No shifter in sight to inspect but from the single pair of ears it is clear that this is a one arm design as opposed to that of the TR6060 GT500 twin arm shifter. Thankfully, this is not an MT82. Many are hoping that the shifter has nothing in common either. Seeing how this group has hit every other mark I don't see why this important piece of the puzzle wouldn't be given the same consideration.

BEYOND THE SCOPE?

Let's face it. This was a powertrain forum but it was hard to limit curiosity when so much high tech hardware sat right in front of everyone. This includes the brake, wheel, and tire on the R...

The Man, doing his thing.

Of note, I had the opportunity to deviate a little and talk vehicle dynamics with Kerry Baldori, Chief Functional Engineer, as well as with Eric Zinkosky, Vehicle Dynamics Supervisor/Suspension Technical Specialist. Finding them off to the side and eager to talk was like finding a box of diamonds after finding a box of gold. I dove right into 'Ring times and smiled as I know how Ford handles all that silliness. The smile was returned. They did admit to being extremely happy with how this S550 iteration performed relative to those that like to advertise their "times."

I posed the same question I had asked Jamal about CF shaft stiffness and Kerry repeated Jamal's response with precision. The three of us discussed the benefits of the new magnetic dampers and how happy the engineers were to be able to add them to this vehicle's repertoire. I did ask Eric if the R model's dampers had a (in general) "stiffer" calibration and he made it clear that stiffer was not the best way to describe them but rather they are a better match for the hardware and conditions that the R is intended for. Before leaving them I mentioned two things - a hearty thanks to the team for not utilizing a '15 Coyote driver side mani-cat as well as for being an integral part of this great effort. I can't wait to hear more from each of these two when we finally see these track monsters unleashed on a road course.

In summation, if you've waited a lifetime for a Mustang that pushes you beyond the edge, this may indeed be the one.