I'm remote tuning to get my new 2.3 Whipple dialed in. I ordered a 9-pin mini din cable for my XCal2 and it came in today. Cut the cable in two, broke out the multimeter and Analog 1 was blue and Ground was red. Hooked up Analog 1 to the gray wire from my AEM UEGO sensor and ran the ground to a ground. I used the equation (v*2)+9.75 and started logging. During my pulls the A/F gauge read consistent, as in around 11 and dipped into upper 10's near redline. But when I look at the logs, Analog 1 was all over the place. Bouncing back and forth between 9.xx and 19.xx. At no time did it jump around like that on the gauge. I even checked on the excel version of the logs and it was the same way. All over the place. But when I look at the average it sat at around 11.3. It seems I'm doing something wrong. I would expect the Datalog to more consistently match the gauge reading.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SCT XCal2 A/F Datalog Confusion

- Thread starter mrose75

- Start date

OK, I've tried with out the ground. Same results. I've tried with ground and 9-pin shield wire grounded. Same results. I've tried both analog 1 and 2 with the same results. I did notice that when I turned the engine off, the reading stabilized while I was still logging. It seems when the engine is running that it's jumping all over the place. Any ideas, anyone? Thanks.

I thought someone said you shouldn't splice the analog to the gauge and the xcal. You should run a separate analog for each one. For my LC1 I have analog 1 go to my Aeroforce gauge setup for AFR. My Analog 2 is setup to read Lambda and goes to my Xcal3.

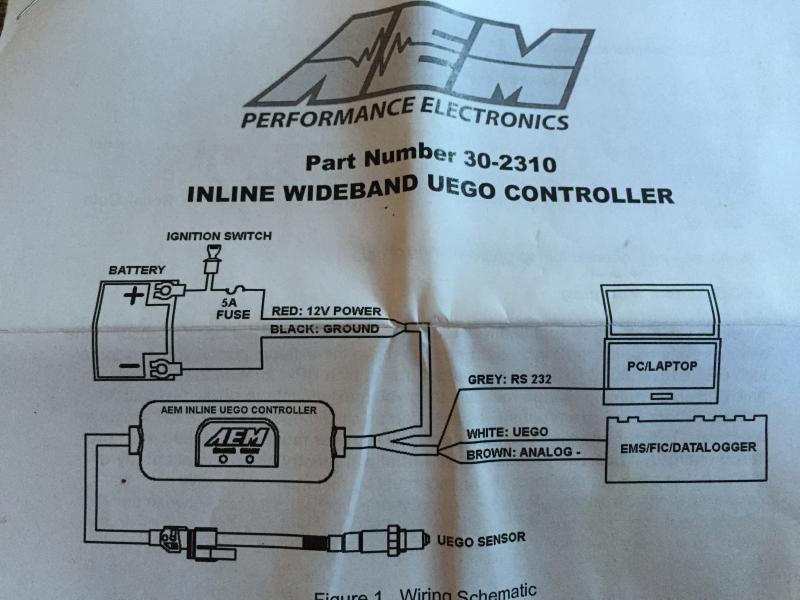

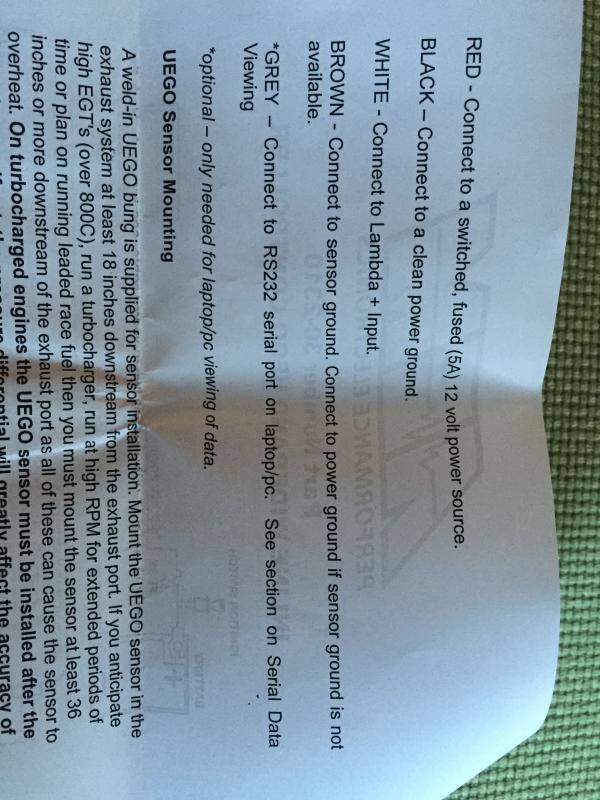

Ok, I'm confused CJ. Both analog 1 and 2 read similar. They are connected from the 9-pin mini din to the gray wire in the pic below. The white wire is running to my SpeedHut A/F gauge. Th brown wire is running to ground as directed in 2nd pic.

Last edited by a moderator:

Ok, I think I understand how you have it wired now. Do you have to configure both the outputs on your Wideband? On the Innovate LC1 there are 2 outputs on it called Analog 1 and Analog 2. You can configure each one to output in totally different ways. For example you can set one up to read in lambda, the other in AFR or set them up both identically. Its how ever you want to set them up. Could the AEM be that way?

Well, what you posted got me wondering and I went out and looked. The brown wire reads analog, but also power ground. So, I disconnected it and the gauge stopped working. So that's wired correct, it is not an analog wire. AEM does not have two outputs that I can tell. I truly only need one analog, I've just read that some have used Analog 2. Some have wired them both together. I was just trying all possible combinations to get a clean A/F reading. I'm getting is a reading that is all over the place. Don can't tune off of that. Funny thing is, when I killed the engine while still logging, the reading cleared up and read constant like you would expect it to while running, with the exception that it's reading low because the engine is off.

I have an Auto Meter Cobalt gauge and I'll have to get the instructions out but it seems there were three wires one for a wide open throttle switch, one for data logging and the last was a ground seemed pretty strait forward.

Are you sure your using the right wires in the 9 pin for Analog 1 and 2, also it looks like the ground is super important. What I just read they were going to the engine block. If I'm reading this right you have to ground the wire coming from the gauge and the wire coming off the 9 pin also.

This might help

http://www.innovatemotorsports.com/resources/Xcal2_tutorial.php

Are you sure your using the right wires in the 9 pin for Analog 1 and 2, also it looks like the ground is super important. What I just read they were going to the engine block. If I'm reading this right you have to ground the wire coming from the gauge and the wire coming off the 9 pin also.

This might help

http://www.innovatemotorsports.com/resources/Xcal2_tutorial.php

Last edited:

Check your manual and see if there's an option to change the sampling rate...if so, see what speeds it gives you and where it's set now. Maybe it needs to be slowed down

Also, check your analog equation. Here's what the manual says

Here's what you said

UEGO Analog Output

The analog output from the UEGO controller is a linear dc voltage signal that varies from 0.5 Vdc at 8.5:1 AFR Gasoline (0.58 Lambda) to 4.5Vdc at 18.0:1 AFR Gasoline (1.22 Lambda) over the operating range of the X-WIFI. The signal is used for sending information to a data logger or an engine management system like the AEM EMS or F/IC. The transfer function for the output is listed below.

AFR = 2.375(V) + 7.3125

For example, if the output is 2.0 Vdc, the AFR is 12.06:1 2.375 * 2.0 + 7.3125 = 12.06

Here's what you said

I used the equation (v*2)+9.75 and started logging.

I have an Auto Meter Cobalt gauge and I'll have to get the instructions out but it seems there were three wires one for a wide open throttle switch, one for data logging and the last was a ground seemed pretty strait forward.

Are you sure your using the right wires in the 9 pin for Analog 1 and 2, also it looks like the ground is super important. What I just read they were going to the engine block. If I'm reading this right you have to ground the wire coming from the gauge and the wire coming off the 9 pin also.

This might help

http://www.innovatemotorsports.com/resources/Xcal2_tutorial.php

That is the link I used to make my 9-pin cable. The wire schematics for my WB are in the pic above. Only wire not in use is the gray one label RS-232.

Check your manual and see if there's an option to change the sampling rate...if so, see what speeds it gives you and where it's set now. Maybe it needs to be slowed down

I see nothing about a sampling rate in the manual. Could it perhaps be the SCT LiveLink that needs sampling adjusted? Like it read sensibly once the engine was turned off, but I need the A/F while its running obviously.

Last edited by a moderator:

Also, check your analog equation. Here's what the manual says

Here's what you said

I'll give that a try, gimme 5 minutes to get an answer. I'm doubtful though, because even when it's just reading voltage it's all over the place. But I'll give it a try.

That is the link I used to make my 9-pin cable. The wire schematics for my WB are in the pic above. Only wire not in use is the gray one label RS-232.

I see nothing about a sampling rate in the manual. Could it perhaps be the SCT LiveLink that needs sampling adjusted? Like it read sensibly once the engine was turned off, but I need the A/F while its running obviously.

I just skimmed the manual online and didn't see anything, either.

However, you definitely want to check that analog equation.

Ok, so when I went with the AFR = 2.375(V) + 7.3125 I got an error message that popped up stating "Invalid" and it stopped logging. If I went with the (v*2) + 10 it would log again, but still be all over the place. So confused.

Ok, so when I went with the AFR = 2.375(V) + 7.3125 I got an error message that popped up stating "Invalid" and it stopped logging. If I went with the (v*2) + 10 it would log again, but still be all over the place. So confused.

Try it like this

(V*2.375) + 7.3125

Ok I'm on my lap top and I don't know how to do a screen shot, but the second half of this message looks like your problem. Go to advanced and slow down the speed of the sensor. C6zhombr has already suggested this

Once LM Programmer is launched click on ‘Analog Out 2’ tab. Next, select the ‘use-air-fuel-ratio’ button. There are four boxes you can modify. The two on the left are voltages and the two on the right are the air/fuel ratios that these voltages correlate to. If you have an LM-1 change your settings to 0V = 7.35 AFR and 5V = 22.39 and click ‘Program.’ If you have the LC-1 these should be your default settings.

If you click on the ADVANCED button, you can change the Response Speed of the sensor. Too fast of a response speed will cause your air/fuel data log to be sporadic. Too slow of a response speed will be less accurate. You want the fastest speed possible that creates a smooth enough data log to be readable. I would start with “1/12 sec“ and try it. If that‘s too sporadic, try “1/6 sec“. The “Instant” setting is too fast, and causes Live Link to show a jumpy Air/Fuel ratio.

Once LM Programmer is launched click on ‘Analog Out 2’ tab. Next, select the ‘use-air-fuel-ratio’ button. There are four boxes you can modify. The two on the left are voltages and the two on the right are the air/fuel ratios that these voltages correlate to. If you have an LM-1 change your settings to 0V = 7.35 AFR and 5V = 22.39 and click ‘Program.’ If you have the LC-1 these should be your default settings.

If you click on the ADVANCED button, you can change the Response Speed of the sensor. Too fast of a response speed will cause your air/fuel data log to be sporadic. Too slow of a response speed will be less accurate. You want the fastest speed possible that creates a smooth enough data log to be readable. I would start with “1/12 sec“ and try it. If that‘s too sporadic, try “1/6 sec“. The “Instant” setting is too fast, and causes Live Link to show a jumpy Air/Fuel ratio.

Ok I'm on my lap top and I don't know how to do a screen shot, but the second half of this message looks like your problem. Go to advanced and slow down the speed of the sensor. C6zhombr has already suggested this

Once LM Programmer is launched click on ‘Analog Out 2’ tab. Next, select the ‘use-air-fuel-ratio’ button. There are four boxes you can modify. The two on the left are voltages and the two on the right are the air/fuel ratios that these voltages correlate to. If you have an LM-1 change your settings to 0V = 7.35 AFR and 5V = 22.39 and click ‘Program.’ If you have the LC-1 these should be your default settings.

If you click on the ADVANCED button, you can change the Response Speed of the sensor. Too fast of a response speed will cause your air/fuel data log to be sporadic. Too slow of a response speed will be less accurate. You want the fastest speed possible that creates a smooth enough data log to be readable. I would start with “1/12 sec“ and try it. If that‘s too sporadic, try “1/6 sec“. The “Instant” setting is too fast, and causes Live Link to show a jumpy Air/Fuel ratio.

Yes, that's what I was referring to, as I have an lc1 controller as well.....but YGOSLO has an aem uego 30-2310 controller and apparently it doesn't have programmable analog outputs (or I didn't see it the manual I looked at online).

http://www.jegs.com/InstallationInstructions/0/017/017-30-2310.pdf

Try it like this

(V*2.375) + 7.3125

Duh!!! I don't know why I didn't think of that! Too much time inhaling exhaust fumes I guess. I'll have to try that and report back. I'm calling SCT tomorrow and probably AEM also.

I am using an AEM WB with SCT LiveLink, not LM Programmer. But I appreciate all the responses.

I thought there was a automatic drop down selection in Live Link depending on your wide band in analog 1.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)