Whats up all.

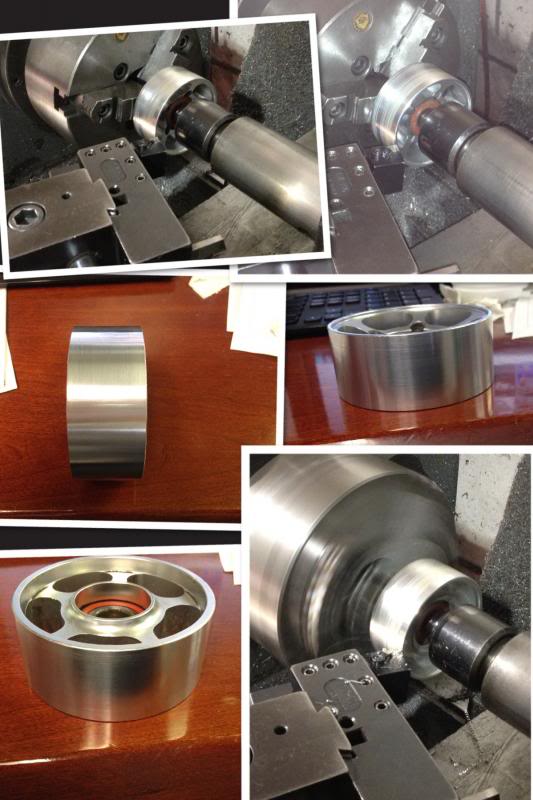

Well I got to work early today and slapped one of my old groove damaged idlers on the lathe.

I just wanted to see if I could safely resurface it.

Everything went better then expected.:rockon:

And it looks like Ill be bringing the rest of them to work with me in the next few days..

Sorry I didnt take any before pics of the idler. I wasnt expecting it to go so smoothly.

Well I got to work early today and slapped one of my old groove damaged idlers on the lathe.

I just wanted to see if I could safely resurface it.

Everything went better then expected.:rockon:

And it looks like Ill be bringing the rest of them to work with me in the next few days..

Sorry I didnt take any before pics of the idler. I wasnt expecting it to go so smoothly.