You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil pan removal

- Thread starter Tx5.0

- Start date

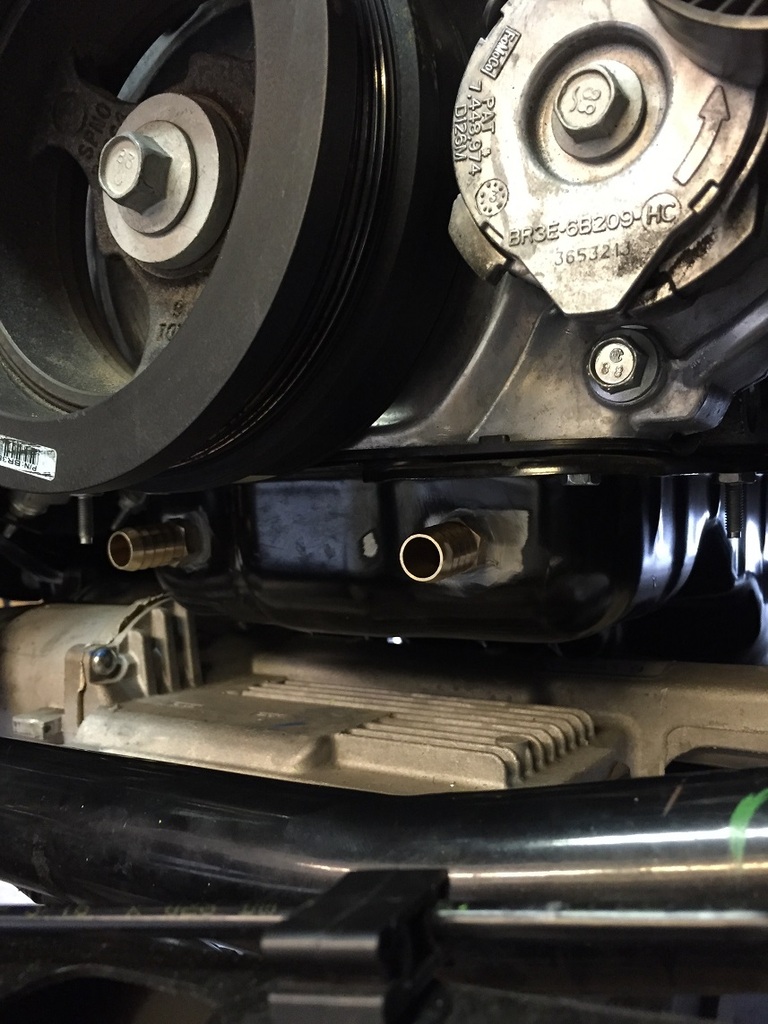

I dropped my k-member and removed my pan to have bungs welded in.

Had a friend tell me he used diesel fuel and a hose hooked to the oil return to wash any debris out of the pan.

I pulled mine, welded, cleaned and put back on.

I pulled mine, welded, cleaned and put back on.

You can leave the pan on. Don't drill it. You need to punch it. Punching it also pushes the metal inward allowing lots of material to be present when you tap.

When you tap, pack the tap with grease real well and it will capture all of the shavings.

I followed this procedure twice on mine (on3 twins) and no leaks whatsoever and motor is fine as in.. no shavings.

I did drain the oil and run a small magnet in the pan and around the new holes to grab any shavings that were left over.

All is well.

I have lots of pics of this... PM me and i'll text them to you if need be.

I guess the bigger question is......... WHY ARE YOU RUNNING A RETURN? ;-):thumbsup:

When you tap, pack the tap with grease real well and it will capture all of the shavings.

I followed this procedure twice on mine (on3 twins) and no leaks whatsoever and motor is fine as in.. no shavings.

I did drain the oil and run a small magnet in the pan and around the new holes to grab any shavings that were left over.

All is well.

I have lots of pics of this... PM me and i'll text them to you if need be.

I guess the bigger question is......... WHY ARE YOU RUNNING A RETURN? ;-):thumbsup:

Last edited:

Did the whole punch tap method when I had the timing cover off for opg's.

Ended up dropping the k member and welding a bung in. 1/2"NPT.

Harbor freight has a cradle to support the motor when the k member is dropped for about 60$.

Pulled manifold and used 2 points at the front (center) of block.

Ended up dropping the k member and welding a bung in. 1/2"NPT.

Harbor freight has a cradle to support the motor when the k member is dropped for about 60$.

Pulled manifold and used 2 points at the front (center) of block.

Oilless turbos FTW lol

You can leave the pan on. Don't drill it. You need to punch it. Punching it also pushes the metal inward allowing lots of material to be present when you tap.

When you tap, pack the tap with grease real well and it will capture all of the shavings.

I followed this procedure twice on mine (on3 twins) and no leaks whatsoever and motor is fine as in.. no shavings.

I did drain the oil and run a small magnet in the pan and around the new holes to grab any shavings that were left over.

All is well.

I have lots of pics of this... PM me and i'll text them to you if need be.

I guess the bigger question is......... WHY ARE YOU RUNNING A RETURN? ;-):thumbsup:

Good advice. But wouldn't dropping the K-member (in order to remove the oil pan) make removing the headers much easier anyway? Just wondering, for people who are installing turbo kits.

Oilless turbos FTW lol

If I haven't seen so many Comp turbo's not performing, I would be all over that. But every time I see a thread about a comp oil-les turbo, I hear about how laggy and little power they make compared to other equally sized turbos.

if you need to drop the kmember... dont bother buying any cradles.

Just put a block of wood between the ribs of the transmission and the jack and just up on the transmission as close to the motor as you can.

I had the engine suspended like that for 2 days while doing my long tubes (ran into a few snags) and it worked like a charm.

Just put a block of wood between the ribs of the transmission and the jack and just up on the transmission as close to the motor as you can.

I had the engine suspended like that for 2 days while doing my long tubes (ran into a few snags) and it worked like a charm.

You can leave the pan on. Don't drill it. You need to punch it. Punching it also pushes the metal inward allowing lots of material to be present when you tap.

When you tap, pack the tap with grease real well and it will capture all of the shavings.

I followed this procedure twice on mine (on3 twins) and no leaks whatsoever and motor is fine as in.. no shavings.

I did drain the oil and run a small magnet in the pan and around the new holes to grab any shavings that were left over.

All is well.

I have lots of pics of this... PM me and i'll text them to you if need be.

I guess the bigger question is......... WHY ARE YOU RUNNING A RETURN? ;-):thumbsup:

Yup, that's the method I used as well for my JT

Kits like the JPC turbo kit recomend having the fitting welded in to ensure leak free operation.

The pan has a "baffle/sump" in the bottom. Debris can sit on the top of this sump. Fill and drain will not get all the crud out. Not to mention the front lip of the pan can catch all kinds of crap when the timing cover is off.

The pan is really thin and in my case a -10 ton3/8" NPT adapter didn't have a large enough ID. I had to go -10 to 1/2".

Driving a punch in the pan large enough to tap 1/2" NPT deforms it pretty bad.

If you used a punch/tap and are happy with it then it's all good. I wasn't happy with it and had leaks.

I use my cradle on other vehicles also. I used a motor cycle jack to lower the k. A jack with a block of wood under the trans would have been in my way big time.

The pan has a "baffle/sump" in the bottom. Debris can sit on the top of this sump. Fill and drain will not get all the crud out. Not to mention the front lip of the pan can catch all kinds of crap when the timing cover is off.

The pan is really thin and in my case a -10 ton3/8" NPT adapter didn't have a large enough ID. I had to go -10 to 1/2".

Driving a punch in the pan large enough to tap 1/2" NPT deforms it pretty bad.

If you used a punch/tap and are happy with it then it's all good. I wasn't happy with it and had leaks.

I use my cradle on other vehicles also. I used a motor cycle jack to lower the k. A jack with a block of wood under the trans would have been in my way big time.

if you need to drop the kmember... dont bother buying any cradles.

Just put a block of wood between the ribs of the transmission and the jack and just up on the transmission as close to the motor as you can.

I had the engine suspended like that for 2 days while doing my long tubes (ran into a few snags) and it worked like a charm.

Never use a jack to suspend any part of the car while working under it, always use a jack stand.

If I haven't seen so many Comp turbo's not performing, I would be all over that. But every time I see a thread about a comp oil-les turbo, I hear about how laggy and little power they make compared to other equally sized turbos.

:shrug: I'm making power just fine on them lol

Good advice. But wouldn't dropping the K-member (in order to remove the oil pan) make removing the headers much easier anyway? Just wondering, for people who are installing turbo kits.

Once the motor mounts are pulled (easy) they headers come right out. Pretty easy stuff. I did it laying on my back lol.

Kits like the JPC turbo kit recomend having the fitting welded in to ensure leak free operation.

The pan has a "baffle/sump" in the bottom. Debris can sit on the top of this sump. Fill and drain will not get all the crud out. Not to mention the front lip of the pan can catch all kinds of crap when the timing cover is off.

The pan is really thin and in my case a -10 ton3/8" NPT adapter didn't have a large enough ID. I had to go -10 to 1/2".

Driving a punch in the pan large enough to tap 1/2" NPT deforms it pretty bad.

If you used a punch/tap and are happy with it then it's all good. I wasn't happy with it and had leaks.

I use my cradle on other vehicles also. I used a motor cycle jack to lower the k. A jack with a block of wood under the trans would have been in my way big time.

Pullling the pan and welding in a bung is without a doubt the "right" way to do it.

However, its certianly not necessary. The punch i ended with was 9/16 (maybe 5/8? dont remember) and what you say was not true in my case. The pan "deformed" just enough to create lots of meat for the tap to bite into.

Worked perfect 2x and both are leak free.

EDIT: Word of caution. For someone doing twins and using the same locations as i did below, the pass side return is VERY close to the oil pick up tube. Take extra care to not bash it in while punching/tapping.

Last edited:

:shrug: I'm making power just fine on them lol

Glad there working out for you, maybe they're hit and miss. I just know a couple of Supra's that had horrible power bands with the Comp oiless turbos-they switched to an equal sized precision and made lots more power every where under the curve.

Once the motor mounts are pulled (easy) they headers come right out. Pretty easy stuff. I did it laying on my back lol.

Pullling the pan and welding in a bung is without a doubt the "right" way to do it.

However, its certianly not necessary. The punch i ended with was 9/16 (maybe 5/8? dont remember) and what you say was not true in my case. The pan "deformed" just enough to create lots of meat for the tap to bite into.

Worked perfect 2x and both are leak free.

EDIT: Word of caution. For someone doing twins and using the same locations as i did below, the pass side return is VERY close to the oil pick up tube. Take extra care to not bash it in while punching/tapping.

Good info. I'm sure i'll be PMing you since I just ordered the "China twin turbo" too.

Once the motor mounts are pulled (easy) they headers come right out. Pretty easy stuff. I did it laying on my back lol.

Pullling the pan and welding in a bung is without a doubt the "right" way to do it.

However, its certianly not necessary. The punch i ended with was 9/16 (maybe 5/8? dont remember) and what you say was not true in my case. The pan "deformed" just enough to create lots of meat for the tap to bite into.

Worked perfect 2x and both are leak free.

EDIT: Word of caution. For someone doing twins and using the same locations as i did below, the pass side return is VERY close to the oil pick up tube. Take extra care to not bash it in while punching/tapping.

Just saved me a lot of time thinking about where I am gonna put mine next summer lol. Thanks for the pics.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)