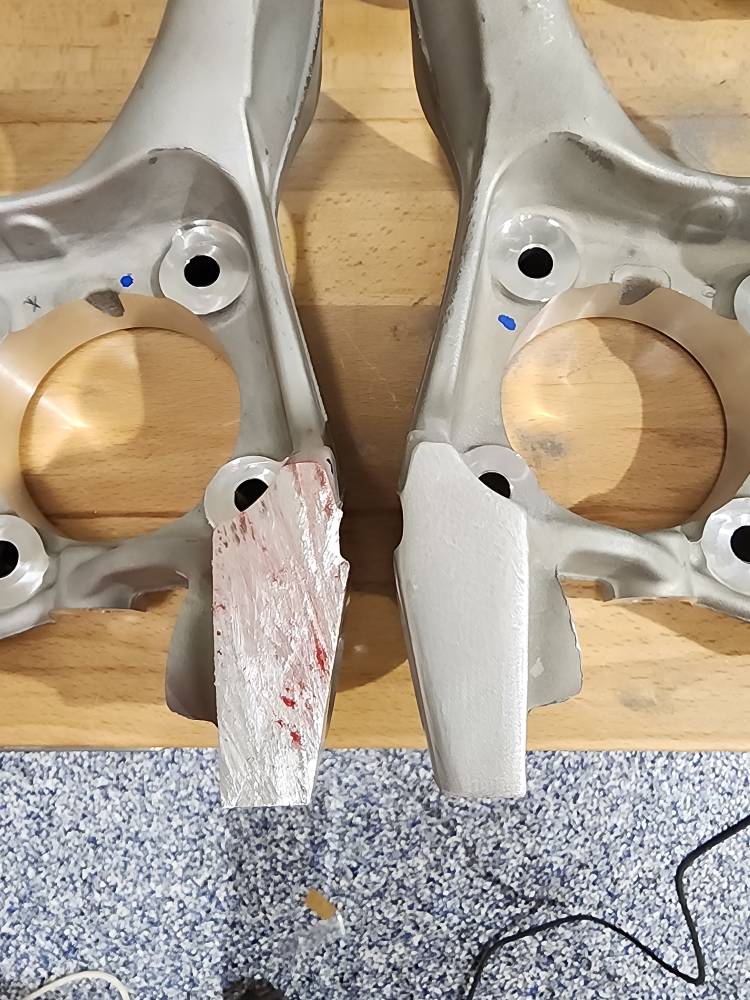

The manual instructs you to cut off the ear of the spindle bracket. This was a bit nerve racking, cutting a brand new part, but I just dove right in. It needs to be cut off to clear the upper control arm adjustment. Knowing the why made this easier to cut.

Once I cut it off, I sanded it down to make it look more presentable. These are before and after sanding.

Your government is lying to you

Once I cut it off, I sanded it down to make it look more presentable. These are before and after sanding.

Your government is lying to you