I've been in the market for a wideband gauge for years. But I always put it off. Now that I've been trying to determine if my car needs a new tune, I've been trying to learn as much as possible about the car's actual performance by reading live PID data from a code reader, and now, I am able to read the actual air fuel ratio, not to mention, boost and RPM.

My car has been throwing lean codes because it has high long term fuel trims for both banks. As a result, the computer is overcompensating and adding fuel. I'm not sure why it thinks it's running lean. It may have to do with the way the MAF signal is intercepted by the computer, and I think that might need to be tweaked with a new tune.

Anyway, I was able to gather some data last night with the new AEM wideband failsafe gauge.

Here is a quick video of my gauge setup at idle, including the new AEM gauge at the bottom.

[youtube_browser]y0_8UmLVHTs&hd=1[/youtube_browser]

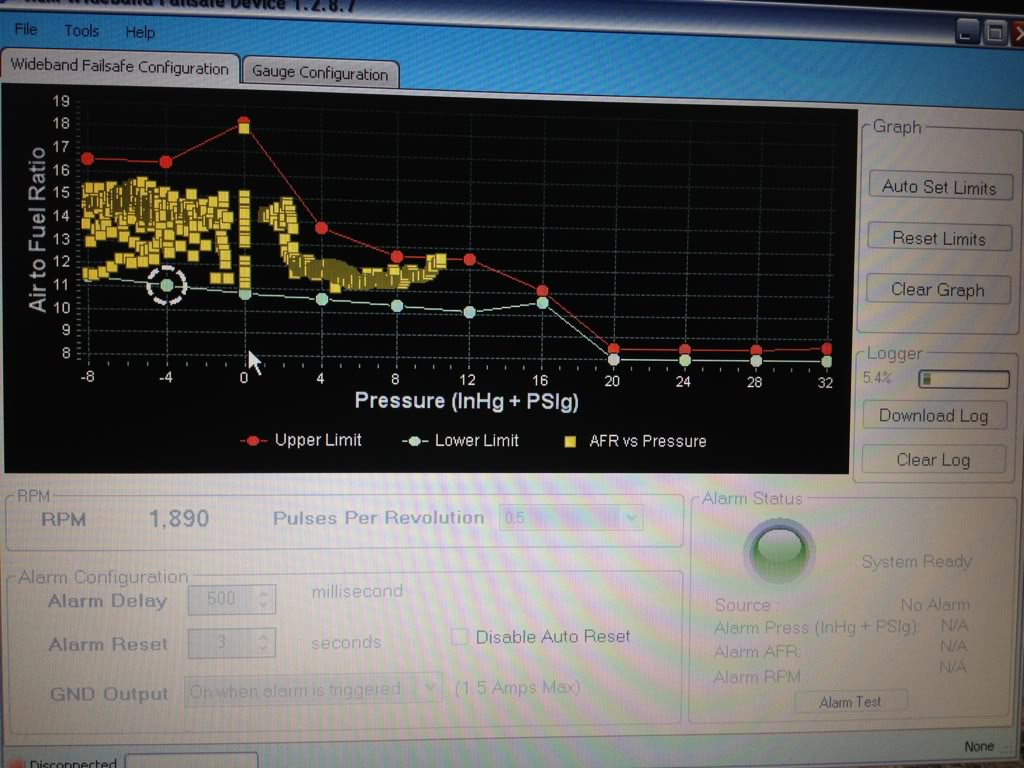

This first picture is a live readout from the AEM gauge software that plots all the AFR and Boost readings on an XY axis. It's important to note that this is not spread out over time, it's a cumulative set of readings for the entire time the car was running, which included a mix of start and stop driving (which is why there is a lot of yellow plots when the engine is under vacuum), plus a couple full throttle runs. You can see that both full throttle runs are pretty consistent when graphed together.

After exporting the datalogs from the gauge software, I opened up the log file in the AEMdata program that shows the data in greater detail over a specific timeline.

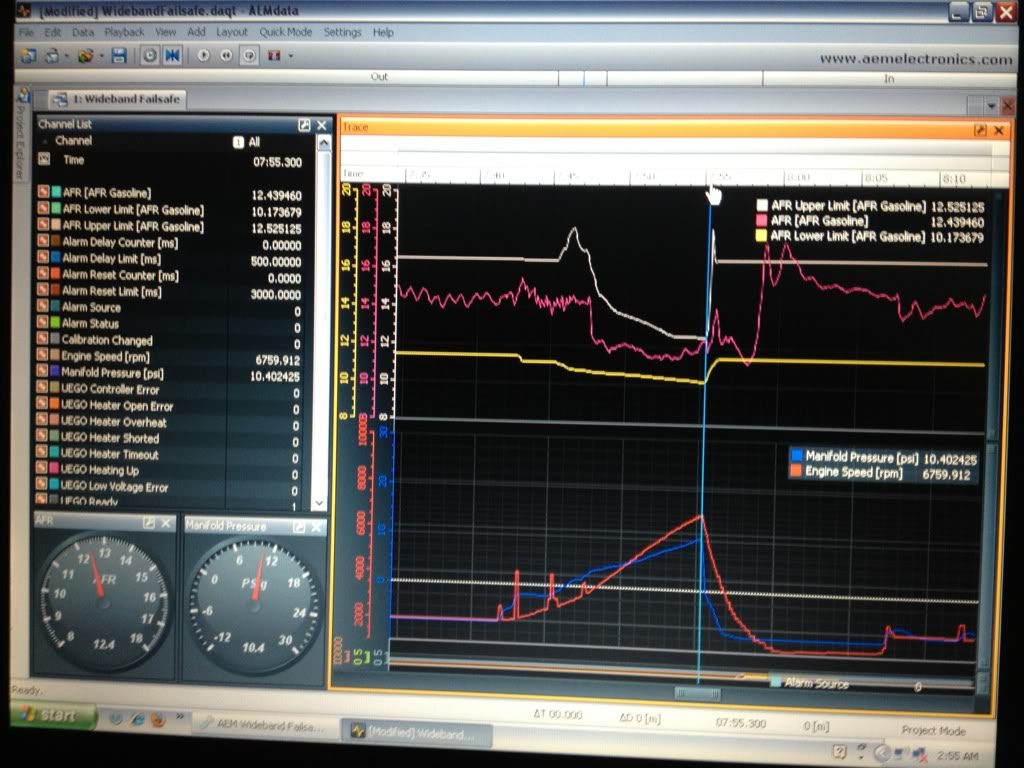

This graph shows a timeline of about 5 minutes and 35 seconds to show normal driving conditions before and after a full throttle run.

The top graph shows the widband air fuel ratio. The pink like is the actual AFR, while the white and yellow lines on top and bottom of the air fuel ratio are the failsafe limits I had previously programmed into the system. I'm still tweaking it, but for the most part, the air fuel ratio should stay within the white and yellow lines.

The bottom graph is the boost and RPM as an overlay. Those little RPM spikes before the full pull may be short partial runs before I went "all out" just to make sure I wasn't going to blow anything. Also, keep in mind that I tapped into an injector wire for the tach signal and programmed the gauge to read .5 pulses per revolution. So, it may also be an additional injector pulse for whatever reason.

The vertical line is to select at which point in the time line to show data in the chart legend and the gauges for boost and AFR in the corner.

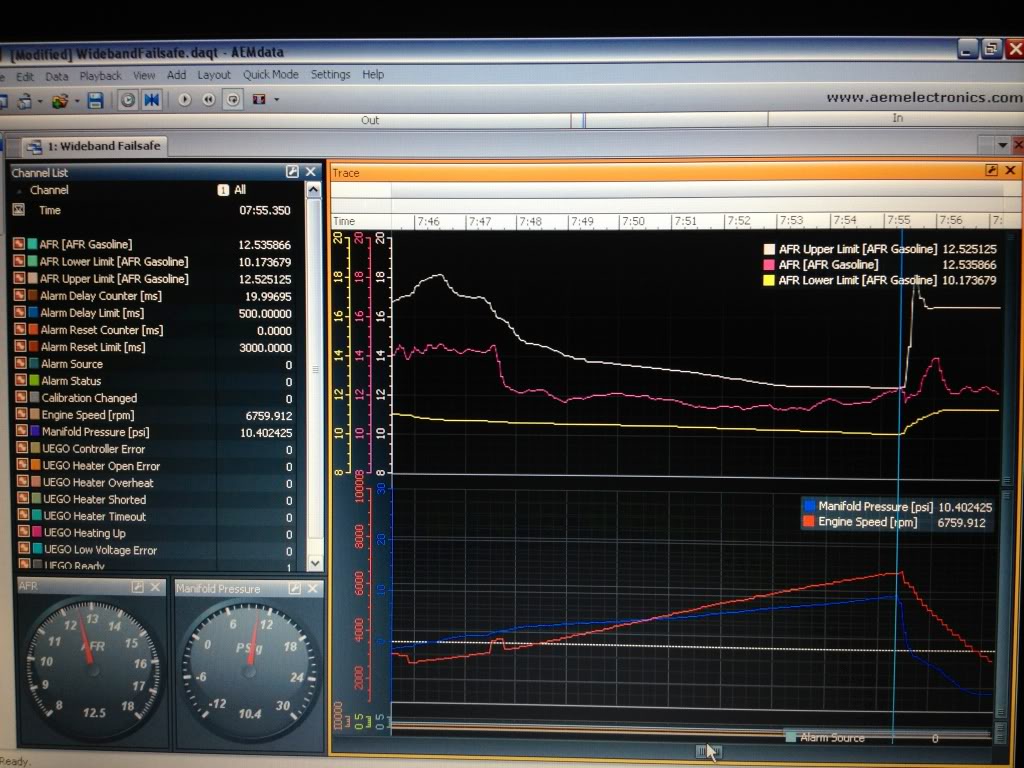

The third picture above shows the same exact data except it is spread out over about 11 seconds instead of 5 minutes to show the full pull in greater detail.

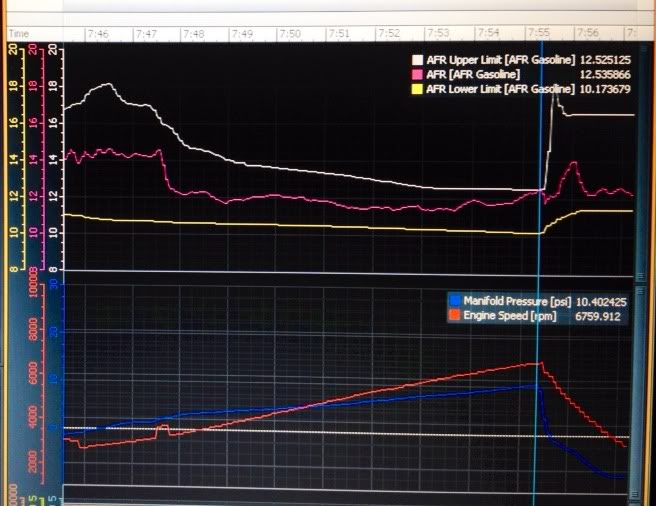

This picture shows the same exact data above, except it is zoomed in only on the graph instead of showing the whole window so you can see the numbers on the legend better.

Overall, the information I'm getting from this is that during cruising I have a nice healthy A/F ratio that hardly goes below 14.0.

But looking at the data from the full pull, you can see that the A/F drops almost immediately down to about 11.5 until 6,000 rpm and gradually rises to about 12.5 because the fuel system is reaching it's limits toward the higher RPM and boost range.

The boost rises steadily as the RPM increases up to a max of 6759 RPM and 10.40245 LBS of peak boost. Notice how the boost slope is almost perfectly linear throughout the entire pull, especially in the upper RPM range. That tells me belt slip is minimal. If it had flattened out towards the end, I would know the belt may be slipping.

I'm really happy with this gauge and the information I have learned. This gauge is such a great bang for the buck. No one else makes a gauge that displays both boost and AFR in the same unit, plus built in datalogging capabilities of boost, AFR, and RPM. And the killer feature is the failsafe function. If the AFR goes outside the paramers you set, it will not only flash the gauge, but it will trigger an output wire that can be used to control a timing retard box, wastegate (for turbo people), a warning light, siren, or anything else you can think of. Since I don't have a wastegate or an aftermarket ignition box, my options are pretty much limited. I saw a similar install in an 03 cobra where the failsafe wire was wired into relays that simply cut power to the ECU. I was also thinking of a way to use a solenoid to manipulate the boost signal going to the bypass valve so I can electronically force it to dump boost. Either that or a second bleeder valve. Who knows.

If anyone could provide me with some thoughts about this data...What might you change? Why are my fuel trims are high at idle (the car thinks it's running lean), but the actual AFR is pretty close to being spot on? Or how to best wire up the failsafe wire.

Any thoughts or opinions would be greatly appreciated

My car has been throwing lean codes because it has high long term fuel trims for both banks. As a result, the computer is overcompensating and adding fuel. I'm not sure why it thinks it's running lean. It may have to do with the way the MAF signal is intercepted by the computer, and I think that might need to be tweaked with a new tune.

Anyway, I was able to gather some data last night with the new AEM wideband failsafe gauge.

Here is a quick video of my gauge setup at idle, including the new AEM gauge at the bottom.

[youtube_browser]y0_8UmLVHTs&hd=1[/youtube_browser]

This first picture is a live readout from the AEM gauge software that plots all the AFR and Boost readings on an XY axis. It's important to note that this is not spread out over time, it's a cumulative set of readings for the entire time the car was running, which included a mix of start and stop driving (which is why there is a lot of yellow plots when the engine is under vacuum), plus a couple full throttle runs. You can see that both full throttle runs are pretty consistent when graphed together.

After exporting the datalogs from the gauge software, I opened up the log file in the AEMdata program that shows the data in greater detail over a specific timeline.

This graph shows a timeline of about 5 minutes and 35 seconds to show normal driving conditions before and after a full throttle run.

The top graph shows the widband air fuel ratio. The pink like is the actual AFR, while the white and yellow lines on top and bottom of the air fuel ratio are the failsafe limits I had previously programmed into the system. I'm still tweaking it, but for the most part, the air fuel ratio should stay within the white and yellow lines.

The bottom graph is the boost and RPM as an overlay. Those little RPM spikes before the full pull may be short partial runs before I went "all out" just to make sure I wasn't going to blow anything. Also, keep in mind that I tapped into an injector wire for the tach signal and programmed the gauge to read .5 pulses per revolution. So, it may also be an additional injector pulse for whatever reason.

The vertical line is to select at which point in the time line to show data in the chart legend and the gauges for boost and AFR in the corner.

The third picture above shows the same exact data except it is spread out over about 11 seconds instead of 5 minutes to show the full pull in greater detail.

This picture shows the same exact data above, except it is zoomed in only on the graph instead of showing the whole window so you can see the numbers on the legend better.

Overall, the information I'm getting from this is that during cruising I have a nice healthy A/F ratio that hardly goes below 14.0.

But looking at the data from the full pull, you can see that the A/F drops almost immediately down to about 11.5 until 6,000 rpm and gradually rises to about 12.5 because the fuel system is reaching it's limits toward the higher RPM and boost range.

The boost rises steadily as the RPM increases up to a max of 6759 RPM and 10.40245 LBS of peak boost. Notice how the boost slope is almost perfectly linear throughout the entire pull, especially in the upper RPM range. That tells me belt slip is minimal. If it had flattened out towards the end, I would know the belt may be slipping.

I'm really happy with this gauge and the information I have learned. This gauge is such a great bang for the buck. No one else makes a gauge that displays both boost and AFR in the same unit, plus built in datalogging capabilities of boost, AFR, and RPM. And the killer feature is the failsafe function. If the AFR goes outside the paramers you set, it will not only flash the gauge, but it will trigger an output wire that can be used to control a timing retard box, wastegate (for turbo people), a warning light, siren, or anything else you can think of. Since I don't have a wastegate or an aftermarket ignition box, my options are pretty much limited. I saw a similar install in an 03 cobra where the failsafe wire was wired into relays that simply cut power to the ECU. I was also thinking of a way to use a solenoid to manipulate the boost signal going to the bypass valve so I can electronically force it to dump boost. Either that or a second bleeder valve. Who knows.

If anyone could provide me with some thoughts about this data...What might you change? Why are my fuel trims are high at idle (the car thinks it's running lean), but the actual AFR is pretty close to being spot on? Or how to best wire up the failsafe wire.

Any thoughts or opinions would be greatly appreciated

Last edited: