Im going to be swapping to some custom grind bullet racing cams for my turbo setup in the near future( dont know what specs yet e-mailed them my build info yesterday ) and have been putting together a parts list of all the stuff i will need.

My PREVIOUS combo was with a Vortech T-trim with the cam specs below.. I was informed they had to much exh duration for my current turbo setup and would slow spool time and off boost power would suffer also, so its time for them to come out .

I thought about just leaving them in an go ahead and bring the car to get tuned and see what it made with them and then bringing it back after the cam swap to see what kind of gains i will pick up

but at this point i just want to change them out and be done with it while i have the time ..

Specs on the cams in the car right now that were for a Blower setup.

int. lift - 0.452

ext. lift- 0.452

int.-209

ext.-225

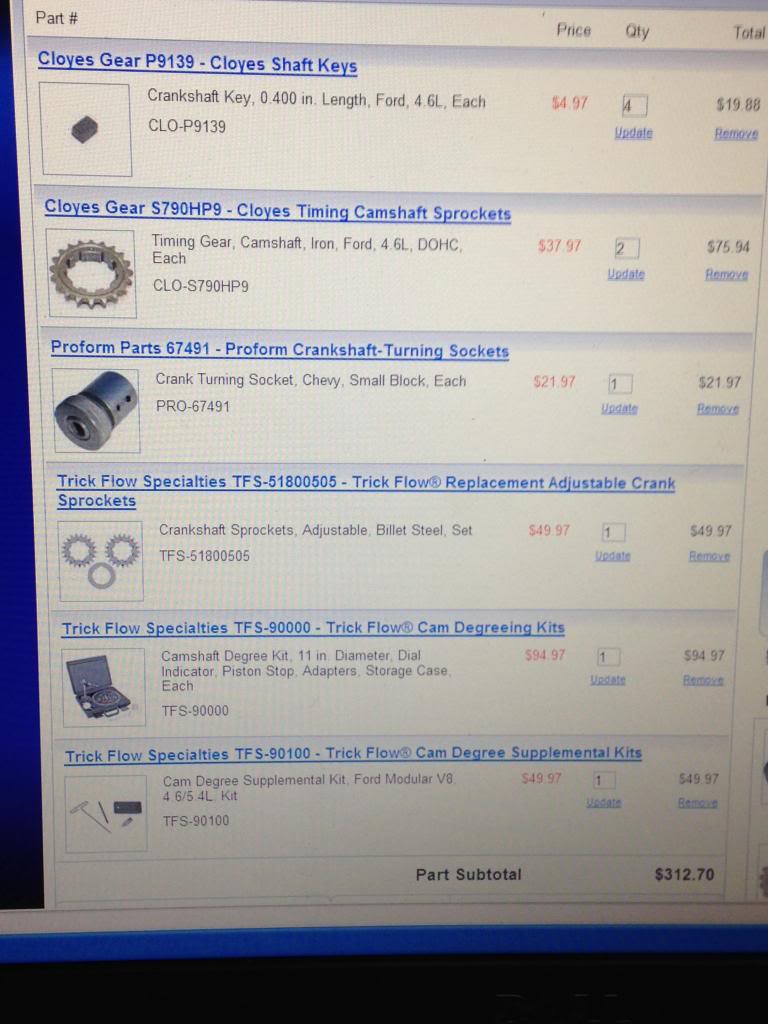

Am i forgetting anything ?? This what i have so far :

****Also wanted to mention i will be using the Intake Centerline Method when i degree the cams in . Which will actually be the exhaust centerline method in the 4v's case since the exhaust cams drive the intake cams . I think I said that right lol ..

I will also be buying a new 4v timing kit from ford that comes with new primary and secondary chains, sprockets , chain tensioners etc.

New ford lash adjusters : Let the lash adjusters and tensioners soak in oil for atleast 48 hours before installing them right.???

Im not sure on the cam follower arms if i should buy new ones or not ?? When i take everything apart i will check the condition of them ..

I will most likely be buying these Springs to go with the cams :.525" Lift Ford 4V Modular Springs - Brian Tooley Racing

On the Valve seals should i buy oem or will these FEL-PRO Viton # SS72888 ones be sufficient ?

This is the valve spring compressor that i will be using since im doing all this with the motor still in the car

Valve Spring Compressor 4 6 and 5 4 2 Valves Engine 1998

^ Says 2v but i saw a thread on the corral where a guy said it worked on his 4V and that he changed all 32 springs with the motor still in the car and didnt have any problems using it

Also some ARP cam bolts will be going on

And i was also told on the TFS adjustable crank gears to roll pin or have them welded after you get them setup where they need to be due to the stock keyway not being long enough if i recall and this is why ford went to a one piece design.

My PREVIOUS combo was with a Vortech T-trim with the cam specs below.. I was informed they had to much exh duration for my current turbo setup and would slow spool time and off boost power would suffer also, so its time for them to come out .

I thought about just leaving them in an go ahead and bring the car to get tuned and see what it made with them and then bringing it back after the cam swap to see what kind of gains i will pick up

but at this point i just want to change them out and be done with it while i have the time ..

Specs on the cams in the car right now that were for a Blower setup.

int. lift - 0.452

ext. lift- 0.452

int.-209

ext.-225

Am i forgetting anything ?? This what i have so far :

****Also wanted to mention i will be using the Intake Centerline Method when i degree the cams in . Which will actually be the exhaust centerline method in the 4v's case since the exhaust cams drive the intake cams . I think I said that right lol ..

I will also be buying a new 4v timing kit from ford that comes with new primary and secondary chains, sprockets , chain tensioners etc.

New ford lash adjusters : Let the lash adjusters and tensioners soak in oil for atleast 48 hours before installing them right.???

Im not sure on the cam follower arms if i should buy new ones or not ?? When i take everything apart i will check the condition of them ..

I will most likely be buying these Springs to go with the cams :.525" Lift Ford 4V Modular Springs - Brian Tooley Racing

On the Valve seals should i buy oem or will these FEL-PRO Viton # SS72888 ones be sufficient ?

This is the valve spring compressor that i will be using since im doing all this with the motor still in the car

Valve Spring Compressor 4 6 and 5 4 2 Valves Engine 1998

^ Says 2v but i saw a thread on the corral where a guy said it worked on his 4V and that he changed all 32 springs with the motor still in the car and didnt have any problems using it

Also some ARP cam bolts will be going on

And i was also told on the TFS adjustable crank gears to roll pin or have them welded after you get them setup where they need to be due to the stock keyway not being long enough if i recall and this is why ford went to a one piece design.

Last edited: