Any idea if the adapter plate will let you use a Ford T56 Bellhousing to run the CD009 on a ModMotoer?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread : Project Crowdmower : Ford Chassis, Nissan Trans, And Chevy motor

- Joined

- Dec 21, 2016

- Messages

- 57

So, not really sure where the last two months went. Lots of things going on and little time to work on the toys.

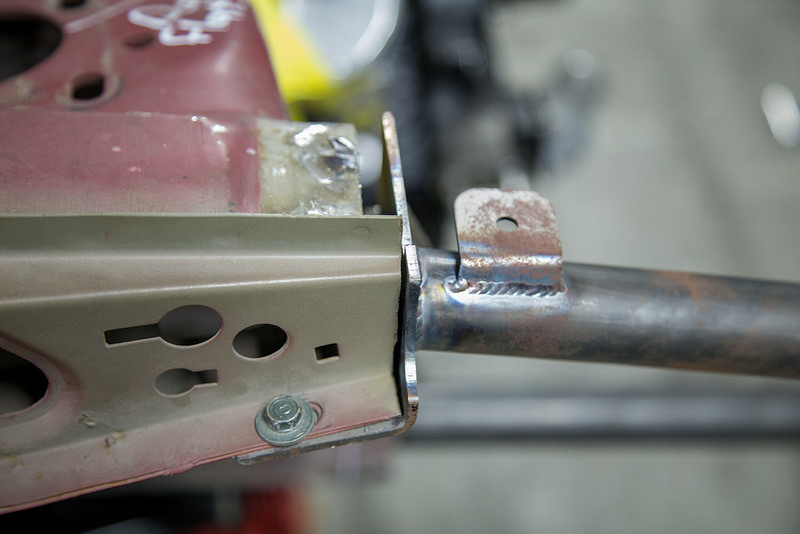

I pulled put the hardware so as I could mock up the front end, which would allow me to square up the tube front and get it ready to be welded on.

IMG_8727 by lawrx, on Flickr

IMG_8727 by lawrx, on Flickr

IMG_8728 by lawrx, on Flickr

IMG_8728 by lawrx, on Flickr

IMG_8729 by lawrx, on Flickr

IMG_8729 by lawrx, on Flickr

IMG_8731 by lawrx, on Flickr

IMG_8731 by lawrx, on Flickr

Pulled out our newly acquired Echo and got to work. It took a few minutes to get the tube front end square but I've got it pretty close. Slight a slight issue with the center fender mount holes, but not too big a deal. After squaring it up I made some marks so I could get it back to that position again in the future.

IMG_8732 by lawrx, on Flickr

IMG_8732 by lawrx, on Flickr

IMG_8733 by lawrx, on Flickr

IMG_8733 by lawrx, on Flickr

IMG_8734 by lawrx, on Flickr

IMG_8734 by lawrx, on Flickr

IMG_8735 by lawrx, on Flickr

IMG_8735 by lawrx, on Flickr

IMG_8737 by lawrx, on Flickr

IMG_8737 by lawrx, on Flickr

IMG_8738 by lawrx, on Flickr

IMG_8738 by lawrx, on Flickr

IMG_8739 by lawrx, on Flickr

IMG_8739 by lawrx, on Flickr

IMG_8775 by lawrx, on Flickr

IMG_8775 by lawrx, on Flickr

IMG_8778 by lawrx, on Flickr

IMG_8778 by lawrx, on Flickr

I pulled put the hardware so as I could mock up the front end, which would allow me to square up the tube front and get it ready to be welded on.

Pulled out our newly acquired Echo and got to work. It took a few minutes to get the tube front end square but I've got it pretty close. Slight a slight issue with the center fender mount holes, but not too big a deal. After squaring it up I made some marks so I could get it back to that position again in the future.

- Joined

- Dec 21, 2016

- Messages

- 57

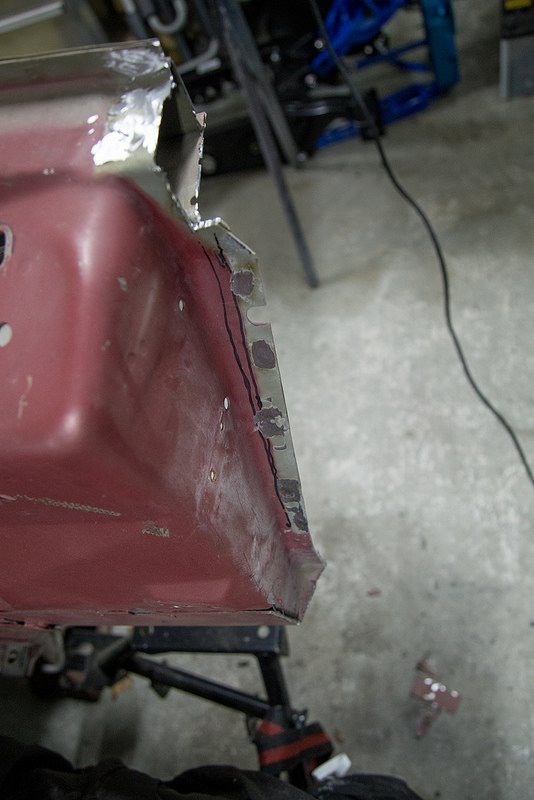

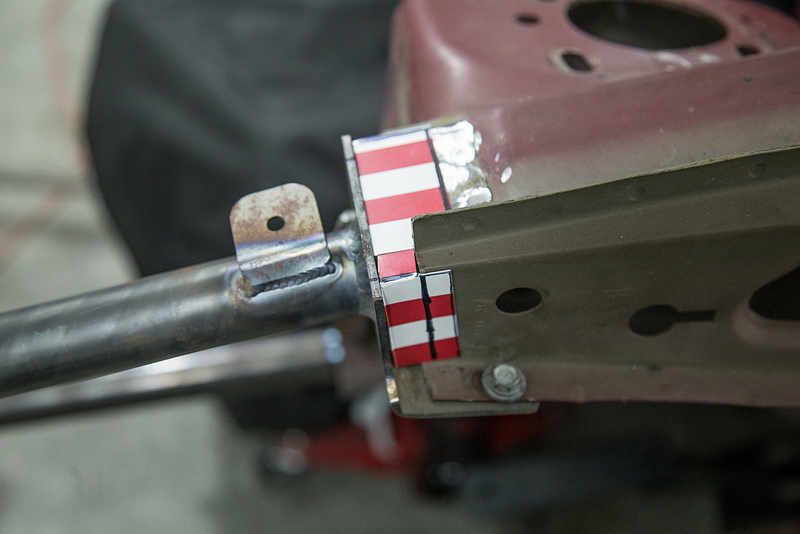

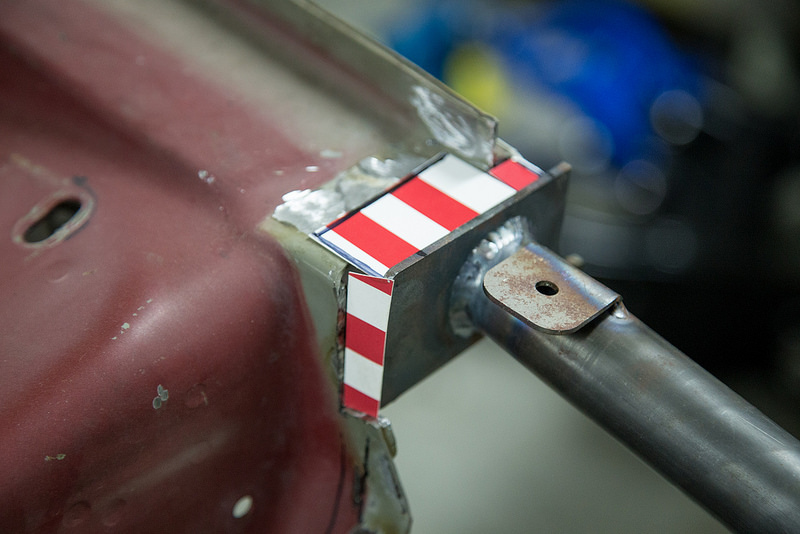

With its final location marked I pulled it back off to cut off some excess metal and grind down some welds left from cutting off the stock front end. Once the necessary trimming was done I fit the tubing back up to start making some templates for my mistakes when cutting off the front end. On the driver side I got my measurement incorrect and theres a decent gap that needs to be filled with plate and reinforced.

IMG_8779 by lawrx, on Flickr

IMG_8779 by lawrx, on Flickr

IMG_8780 by lawrx, on Flickr

IMG_8780 by lawrx, on Flickr

IMG_8782 by lawrx, on Flickr

IMG_8782 by lawrx, on Flickr

IMG_8784 by lawrx, on Flickr

IMG_8784 by lawrx, on Flickr

IMG_8785 by lawrx, on Flickr

IMG_8785 by lawrx, on Flickr

IMG_8786 by lawrx, on Flickr

IMG_8786 by lawrx, on Flickr

IMG_8789 by lawrx, on Flickr

IMG_8789 by lawrx, on Flickr

IMG_8790 by lawrx, on Flickr

IMG_8790 by lawrx, on Flickr

IMG_8791 by lawrx, on Flickr

IMG_8791 by lawrx, on Flickr

IMG_8792 by lawrx, on Flickr

IMG_8792 by lawrx, on Flickr

IMG_8793 by lawrx, on Flickr

IMG_8793 by lawrx, on Flickr

Is this thing done yet or what

- Joined

- Dec 21, 2016

- Messages

- 57

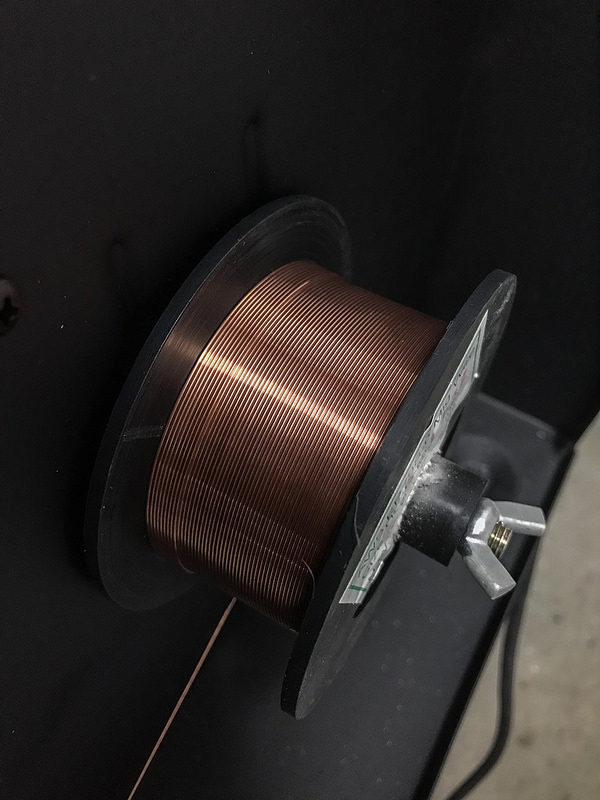

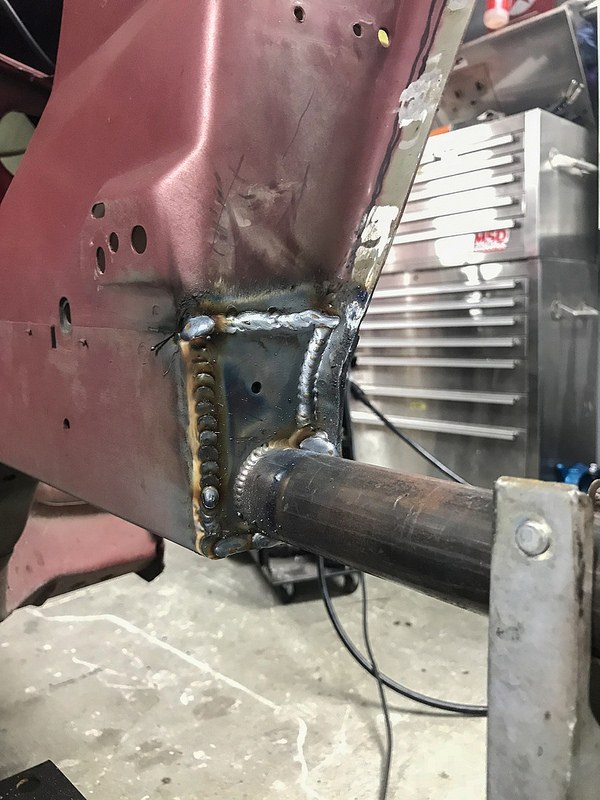

This past weekend and Tuesday we had Mardi Gras. Being so I had Tuesday off (still had to work Monday :/) and I was able to get a good bit work done. I had set out to get the front tube setup final welded to the car to where I could now start collecting parts to finalize motor placement with the motor plates. Its been a while since I've used my welder so took a little time fo rme to get back in the swing of it. I am by no means a highly skilled welder, but im capable enough to make decent welds, even tho I tend to rush it every now and then. Really need to work on my patience with that aspect lol. They aren't the prettiest welds and I will have to do some clean up and such before we spray the engine bay in the future but they will do their job.

IMG_2926 by lawrx, on Flickr

IMG_2926 by lawrx, on Flickr

IMG_9014 by lawrx, on Flickr

IMG_9014 by lawrx, on Flickr

IMG_9008 by lawrx, on Flickr

IMG_9008 by lawrx, on Flickr

IMG_9010 by lawrx, on Flickr

IMG_9010 by lawrx, on Flickr

IMG_9012 by lawrx, on Flickr

IMG_9012 by lawrx, on Flickr

IMG_9016 by lawrx, on Flickr

IMG_9016 by lawrx, on Flickr

IMG_9017 by lawrx, on Flickr

IMG_9017 by lawrx, on Flickr

IMG_2932 by lawrx, on Flickr

IMG_2932 by lawrx, on Flickr

IMG_9027 by lawrx, on Flickr

IMG_9027 by lawrx, on Flickr

IMG_9028 by lawrx, on Flickr

IMG_9028 by lawrx, on Flickr

- Joined

- Dec 21, 2016

- Messages

- 57

With the tube front end welded on I turned my attention to starting to shave the firewall. As im sure someone will point out yes I have welded up the master cylinder hole. I will be running manual brakes with my Tilton pedal setup. Its left over from my previous build.

Attachments

-

38480918460_582b9f1b18_c.jpg161.3 KB · Views: 123

38480918460_582b9f1b18_c.jpg161.3 KB · Views: 123 -

38480902670_6760a9f37a_c.jpg154.4 KB · Views: 99

38480902670_6760a9f37a_c.jpg154.4 KB · Views: 99 -

39579435764_292ed52a01_c.jpg232.6 KB · Views: 108

39579435764_292ed52a01_c.jpg232.6 KB · Views: 108 -

39579434584_99536308e3_c.jpg161.5 KB · Views: 110

39579434584_99536308e3_c.jpg161.5 KB · Views: 110 -

38480905330_005b2b334d_c.jpg73.4 KB · Views: 97

38480905330_005b2b334d_c.jpg73.4 KB · Views: 97 -

38480899660_db37624eca_c.jpg103.8 KB · Views: 97

38480899660_db37624eca_c.jpg103.8 KB · Views: 97 -

26418280318_a647b06454_c.jpg102.8 KB · Views: 104

26418280318_a647b06454_c.jpg102.8 KB · Views: 104 -

38480916780_a202e368ee_c.jpg174.8 KB · Views: 90

38480916780_a202e368ee_c.jpg174.8 KB · Views: 90 -

25419574927_a8a549b09d_c.jpg89.5 KB · Views: 108

25419574927_a8a549b09d_c.jpg89.5 KB · Views: 108 -

39579420774_abd1623c45_c.jpg91.2 KB · Views: 94

39579420774_abd1623c45_c.jpg91.2 KB · Views: 94

- Joined

- Dec 21, 2016

- Messages

- 57

The other day someone posted the same intake and intercooler setup im going to run showing its total height. Its F#$%ING huge. 17'' tall. With tube front end welded on I was able to roughly mock up motor height with the motor plates. Yeahhh these aren't going to work. Motor sits too low and there will be too much flex mounting the lower off the frame rail that low. Luckily I've found a different set that will work better. However im hoping I won't have to space the k member down for clearance. New hood I wil be getting should provide enough room.

- Joined

- Dec 21, 2016

- Messages

- 57

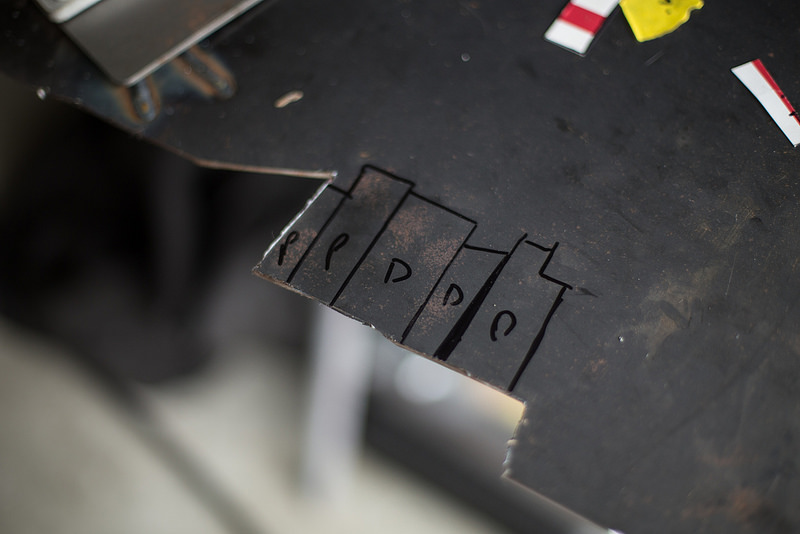

Doing a bit more thinking/measuring/eyeballing.

Its looking like how I want to route thinks just wasn't going to work with a big single. I couldn't find headers to sit where I wanted with the motor sitting as low as needed to fit the intercooler/intake setup I wanted.

Drew out an idea on the fender for a twin turbo setup. Id originally wanted to run a low pro hood, exhaust out the back etc to give it a more "sleeper" low profile attitude. going twin turbo vs big single with shorter intake would allow that. I still want proper ducting for front airflow and I feel this would work well.

Also did some mock up with some 3.5'' tubing and theres ample room to run a downpipe down each side with the block with the manifolds I want to run. Also issue I have is steering shaft. It will be right in the way, however I can shorten the output from the steering rack and use some custom joints to move it over slightly for exhaust routing.

After taking al this into account I was able to put the motor where I wanted in reference to the chassis while sitting on my trans jack. Soon I wil be ordering the front suspension to set the chassis level and motor will be ready to be placed accordingly and bolted up via motor plates in its permanent position.

IMG_9184 by lawrx, on Flickr

IMG_9184 by lawrx, on Flickr

IMG_9185 by lawrx, on Flickr

IMG_9185 by lawrx, on Flickr

IMG_9187 by lawrx, on Flickr

IMG_9187 by lawrx, on Flickr

IMG_9189 by lawrx, on Flickr

IMG_9189 by lawrx, on Flickr

IMG_9190 by lawrx, on Flickr

IMG_9190 by lawrx, on Flickr

IMG_9191 by lawrx, on Flickr

IMG_9191 by lawrx, on Flickr

Its looking like how I want to route thinks just wasn't going to work with a big single. I couldn't find headers to sit where I wanted with the motor sitting as low as needed to fit the intercooler/intake setup I wanted.

Drew out an idea on the fender for a twin turbo setup. Id originally wanted to run a low pro hood, exhaust out the back etc to give it a more "sleeper" low profile attitude. going twin turbo vs big single with shorter intake would allow that. I still want proper ducting for front airflow and I feel this would work well.

Also did some mock up with some 3.5'' tubing and theres ample room to run a downpipe down each side with the block with the manifolds I want to run. Also issue I have is steering shaft. It will be right in the way, however I can shorten the output from the steering rack and use some custom joints to move it over slightly for exhaust routing.

After taking al this into account I was able to put the motor where I wanted in reference to the chassis while sitting on my trans jack. Soon I wil be ordering the front suspension to set the chassis level and motor will be ready to be placed accordingly and bolted up via motor plates in its permanent position.

Users who are viewing this thread

Total: 4 (members: 0, guests: 4)