- Joined

- Dec 21, 2016

- Messages

- 57

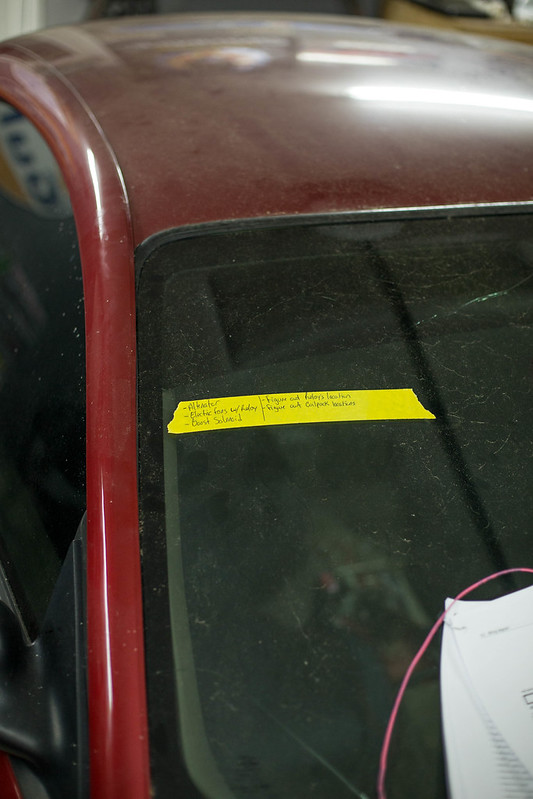

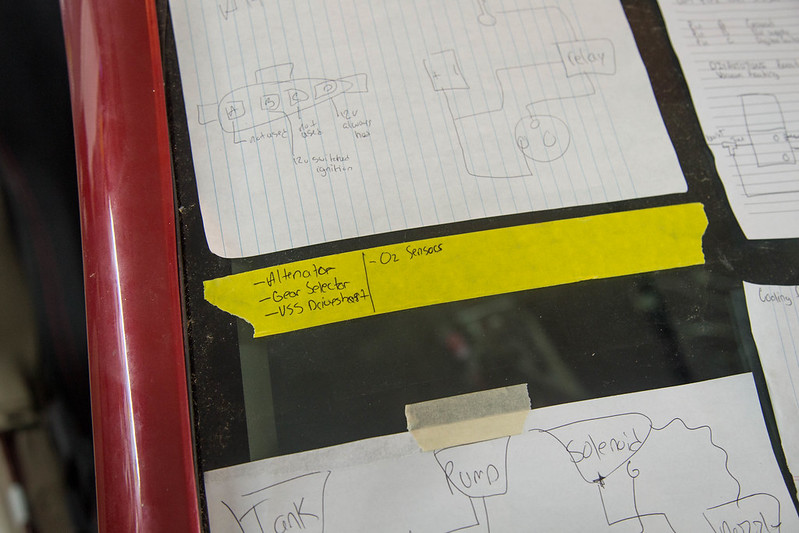

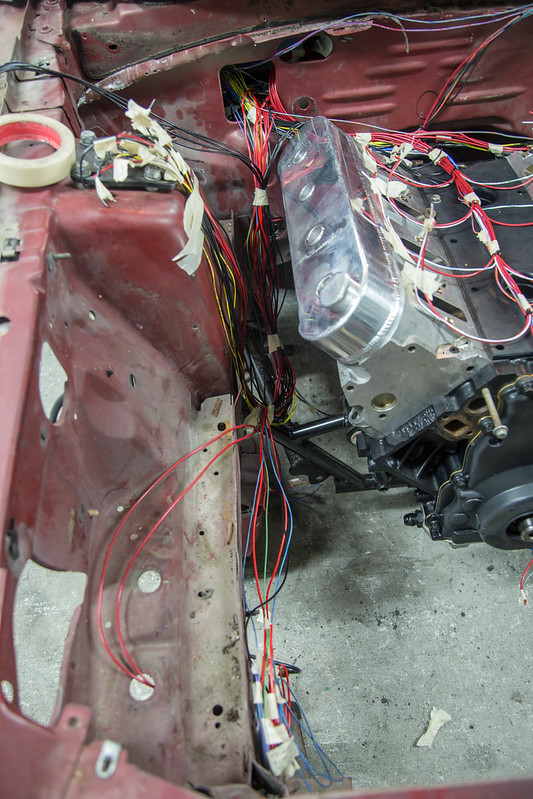

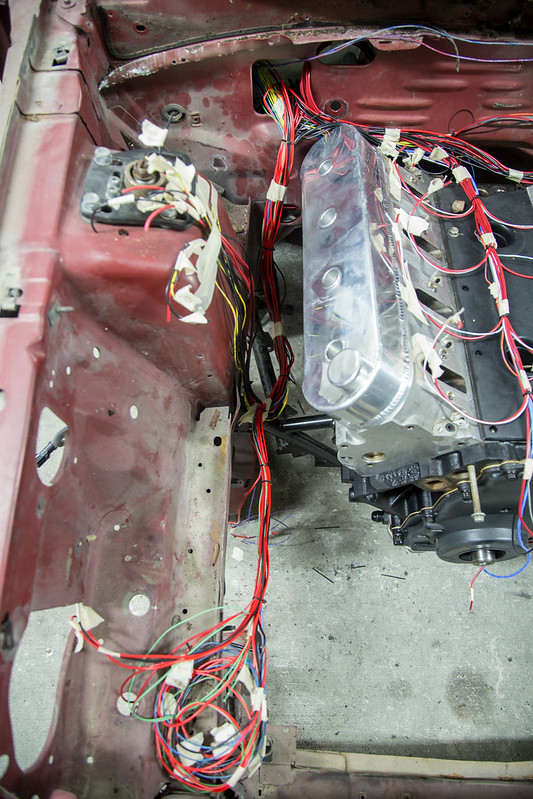

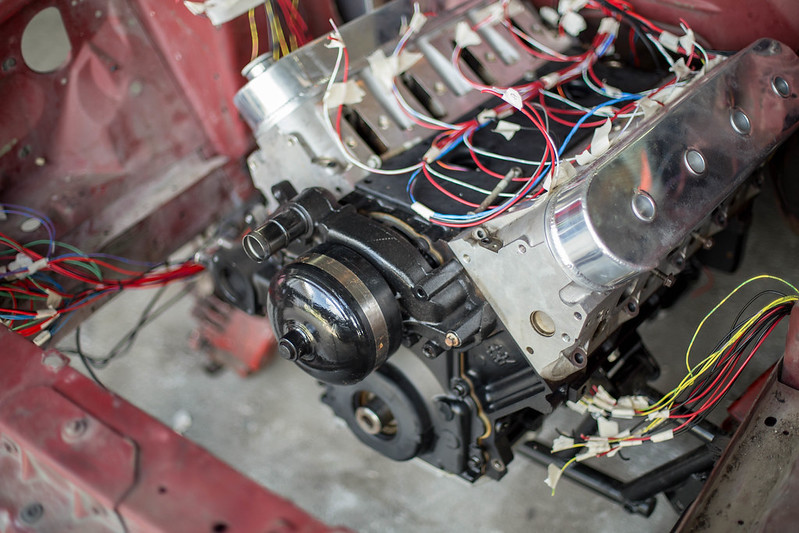

SHE IS HOME

That is all.

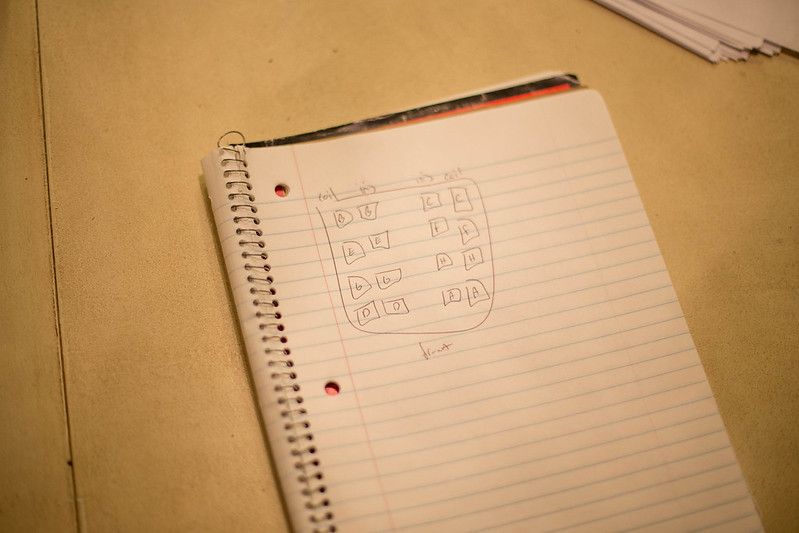

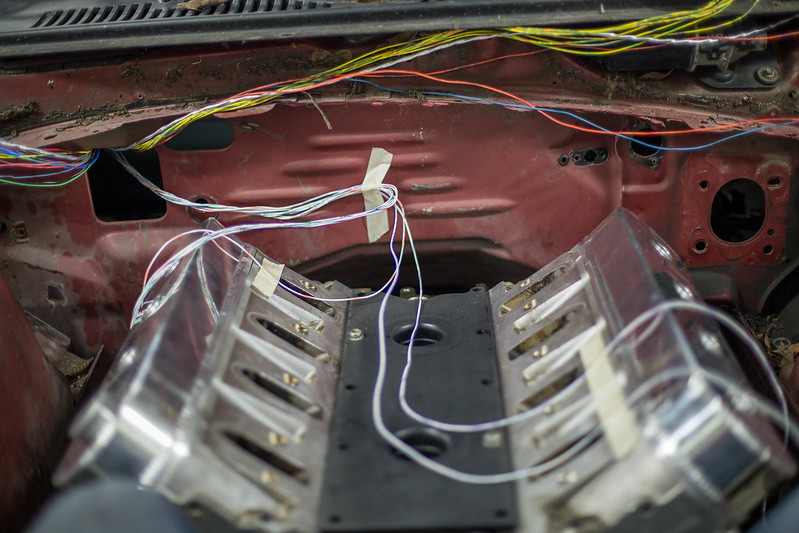

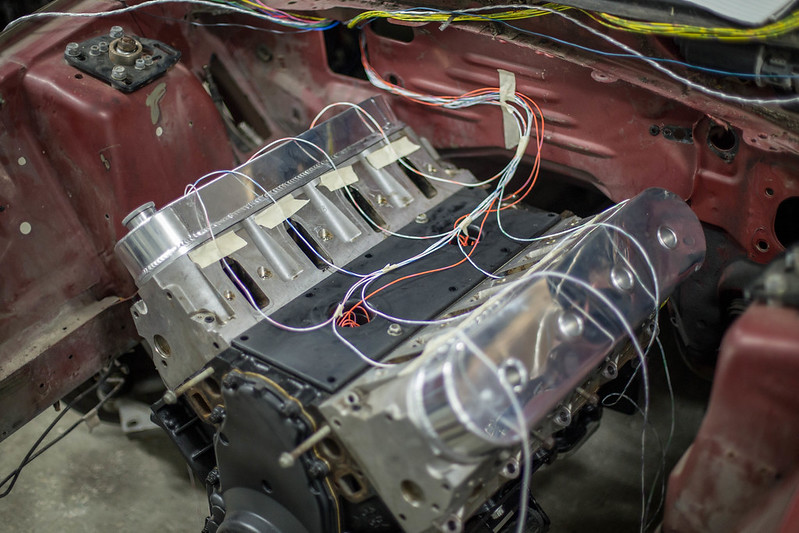

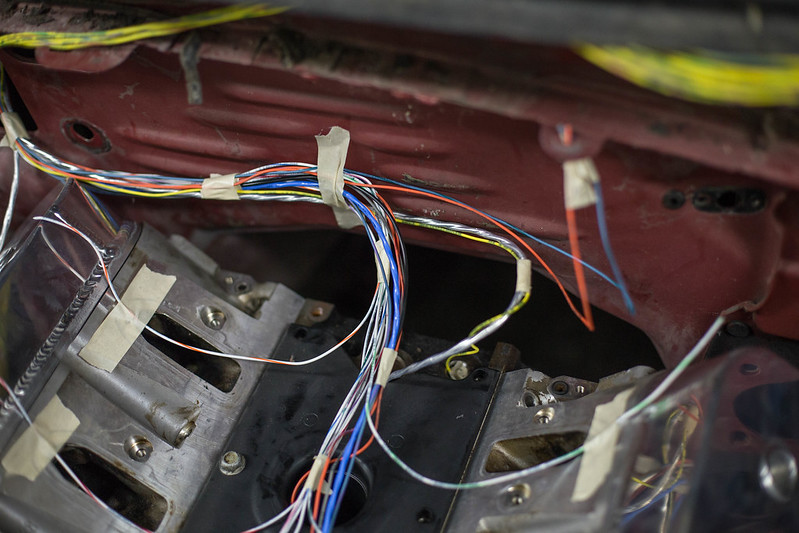

new computer (1 of 2) by lawrx, on Flickr

new computer (1 of 2) by lawrx, on Flickr

new computer (2 of 2) by lawrx, on Flickr

new computer (2 of 2) by lawrx, on Flickr

That is all.

new computer (1 of 2) by lawrx, on Flickr

new computer (1 of 2) by lawrx, on Flickr new computer (2 of 2) by lawrx, on Flickr

new computer (2 of 2) by lawrx, on Flickr

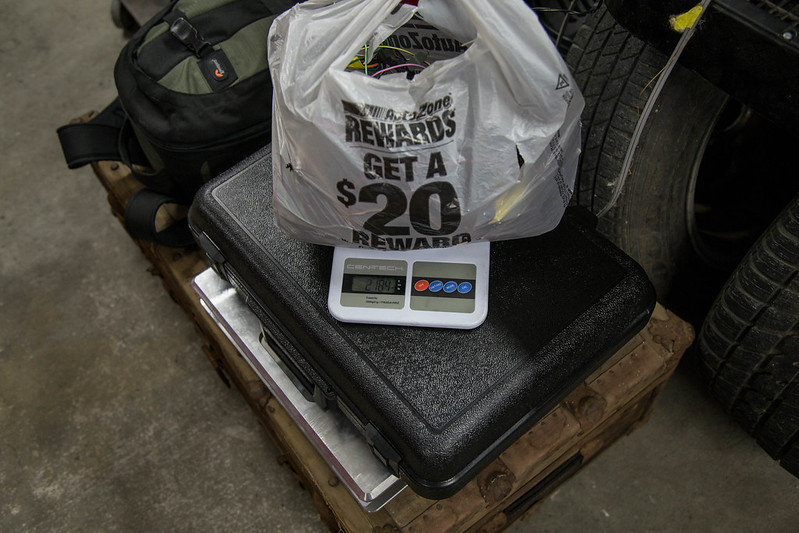

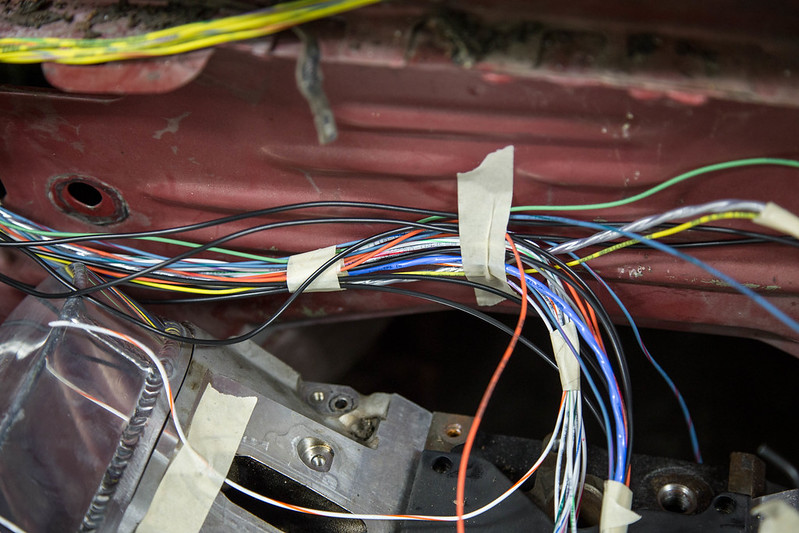

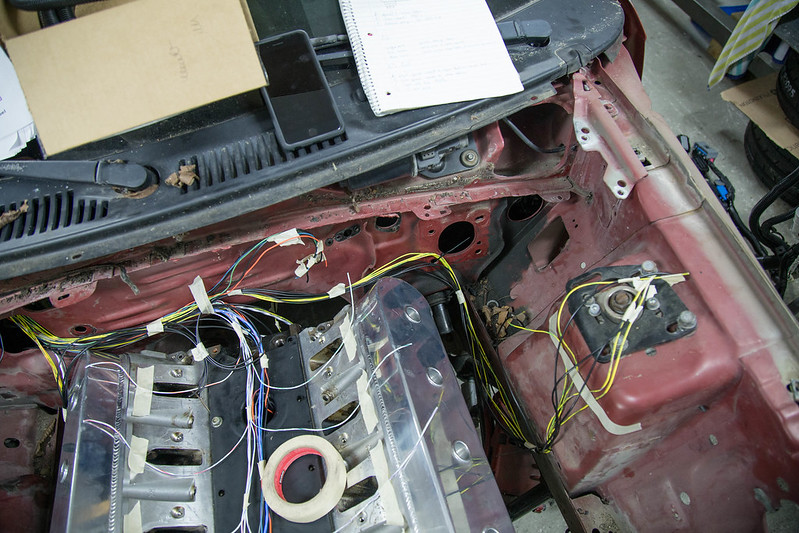

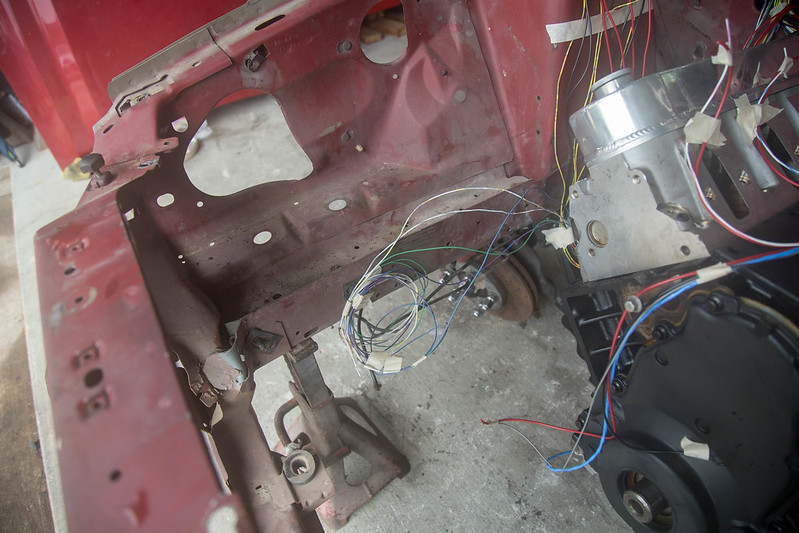

new computer (2 of 24)

new computer (2 of 24) new computer (3 of 24)

new computer (3 of 24) new computer (4 of 24)

new computer (4 of 24) new computer (5 of 24)

new computer (5 of 24) new computer (6 of 24)

new computer (6 of 24) new computer (7 of 24)

new computer (7 of 24) new computer (8 of 24)

new computer (8 of 24) new computer (9 of 24)

new computer (9 of 24) new computer (10 of 24)

new computer (10 of 24) new computer (11 of 24)

new computer (11 of 24) new computer (12 of 24)

new computer (12 of 24) new computer (13 of 24)

new computer (13 of 24) new computer (14 of 24)

new computer (14 of 24) new computer (15 of 24)

new computer (15 of 24) new computer (17 of 24)

new computer (17 of 24) new computer (18 of 24)

new computer (18 of 24) new computer (20 of 24)

new computer (20 of 24) new computer (21 of 24)

new computer (21 of 24) new computer (22 of 24)

new computer (22 of 24) new computer (1 of 18)

new computer (1 of 18) new computer (2 of 18)

new computer (2 of 18) new computer (23 of 24)

new computer (23 of 24) new computer (24 of 24)

new computer (24 of 24) new computer (4 of 18)

new computer (4 of 18) new computer (5 of 18)

new computer (5 of 18) new computer (6 of 18)

new computer (6 of 18) new computer (7 of 18)

new computer (7 of 18) new computer (8 of 18)

new computer (8 of 18) new computer (9 of 18)

new computer (9 of 18) new computer (10 of 18)

new computer (10 of 18) new computer (11 of 18)

new computer (11 of 18) new computer (12 of 18)

new computer (12 of 18) new computer (15 of 18)

new computer (15 of 18) new computer (16 of 18)

new computer (16 of 18) new computer (17 of 18)

new computer (17 of 18) new computer (18 of 18)

new computer (18 of 18) new computer (1 of 18)-2

new computer (1 of 18)-2 new computer (2 of 18)-2

new computer (2 of 18)-2 new computer (3 of 18)-2

new computer (3 of 18)-2 new computer (4 of 18)-2

new computer (4 of 18)-2 new computer (5 of 18)-2

new computer (5 of 18)-2 new computer (6 of 18)-2

new computer (6 of 18)-2 new computer (7 of 18)-2

new computer (7 of 18)-2 new computer (8 of 18)-2

new computer (8 of 18)-2 new computer (9 of 18)-2

new computer (9 of 18)-2 new computer (10 of 18)-2

new computer (10 of 18)-2 new computer (11 of 18)-2

new computer (11 of 18)-2 new computer (12 of 18)-2

new computer (12 of 18)-2 new computer (15 of 18)-2

new computer (15 of 18)-2 new computer (13 of 18)-2

new computer (13 of 18)-2 new computer (14 of 18)-2

new computer (14 of 18)-2 new computer (16 of 18)-2

new computer (16 of 18)-2 new computer (17 of 18)-2

new computer (17 of 18)-2 new computer (18 of 18)-2

new computer (18 of 18)-2 new computer (24 of 36)

new computer (24 of 36) new computer (22 of 36)

new computer (22 of 36) new computer (25 of 36)

new computer (25 of 36) new computer (26 of 36)

new computer (26 of 36) new computer (12 of 36)

new computer (12 of 36) new computer (13 of 36)

new computer (13 of 36) new computer (14 of 36)

new computer (14 of 36) new computer (15 of 36)

new computer (15 of 36) new computer (16 of 36)

new computer (16 of 36) new computer (17 of 36)

new computer (17 of 36) new computer (18 of 36)

new computer (18 of 36) new computer (19 of 36)

new computer (19 of 36) new computer (27 of 36)

new computer (27 of 36) new computer (28 of 36)

new computer (28 of 36) new computer (29 of 36)

new computer (29 of 36) new computer (30 of 36)

new computer (30 of 36) new computer (31 of 36)

new computer (31 of 36) new computer (32 of 36)

new computer (32 of 36) new computer (33 of 36)

new computer (33 of 36) new computer (34 of 36)

new computer (34 of 36) new computer (35 of 36)

new computer (35 of 36) new computer (36 of 36)

new computer (36 of 36) new computer (1 of 36)

new computer (1 of 36) new computer (2 of 36)

new computer (2 of 36) new computer (3 of 36)

new computer (3 of 36) new computer (4 of 36)

new computer (4 of 36) new computer (5 of 36)

new computer (5 of 36) new computer (6 of 36)

new computer (6 of 36) new computer (7 of 36)

new computer (7 of 36) new computer (8 of 36)

new computer (8 of 36) new computer (9 of 36)

new computer (9 of 36) new computer (10 of 36)

new computer (10 of 36) new computer (11 of 36)

new computer (11 of 36) new computer (20 of 36)

new computer (20 of 36) new computer (21 of 36)

new computer (21 of 36) new computer (23 of 36)

new computer (23 of 36) new computer (1 of 25)

new computer (1 of 25) new computer (2 of 25)

new computer (2 of 25) new computer (3 of 25)

new computer (3 of 25) new computer (4 of 25)

new computer (4 of 25) new computer (5 of 25)

new computer (5 of 25) new computer (6 of 25)

new computer (6 of 25) new computer (7 of 25)

new computer (7 of 25) new computer (8 of 25)

new computer (8 of 25) new computer (9 of 25)

new computer (9 of 25) new computer (10 of 25)

new computer (10 of 25) new computer (11 of 25)

new computer (11 of 25) new computer (12 of 25)

new computer (12 of 25) new computer (13 of 25)

new computer (13 of 25) new computer (17 of 25)

new computer (17 of 25) new computer (16 of 25)

new computer (16 of 25) new computer (18 of 25)

new computer (18 of 25) new computer (14 of 25)

new computer (14 of 25) new computer (15 of 25)

new computer (15 of 25) new computer (19 of 25)

new computer (19 of 25) new computer (20 of 25)

new computer (20 of 25) new computer (21 of 25)

new computer (21 of 25) new computer (22 of 25)

new computer (22 of 25) new computer (23 of 25)

new computer (23 of 25) new computer (24 of 25)

new computer (24 of 25) new computer (25 of 25)

new computer (25 of 25) new computer (1 of 12)

new computer (1 of 12) new computer (2 of 12)

new computer (2 of 12) new computer (3 of 12)

new computer (3 of 12) new computer (4 of 12)

new computer (4 of 12) new computer (5 of 12)

new computer (5 of 12) new computer (7 of 12)

new computer (7 of 12) new computer (8 of 12)

new computer (8 of 12) new computer (9 of 12)

new computer (9 of 12) new computer (11 of 12)

new computer (11 of 12) new computer (12 of 12)

new computer (12 of 12) new computer (1 of 6)

new computer (1 of 6) new computer (5 of 6)

new computer (5 of 6) new computer (6 of 6)

new computer (6 of 6)