I've used both of those fillers in the past with good results. They were recommended to me by people that actually know what they're doing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Black Gold 380R's 65 Mustang Build Thread

- Thread starter Black Gold 380R

- Start date

I've used both of those fillers in the past with good results. They were recommended to me by people that actually know what they're doing.

SWEET! Thanks Bob! Guess that means I did well in my research LOL.

Sanding is hard work, but those products do seem to work very well. I'm still learning how to balance the hardener to product ratio. It's hot here so it cooks off fast if I use too much hardener. And since I'm slow I need it to harden a little slower than normal.

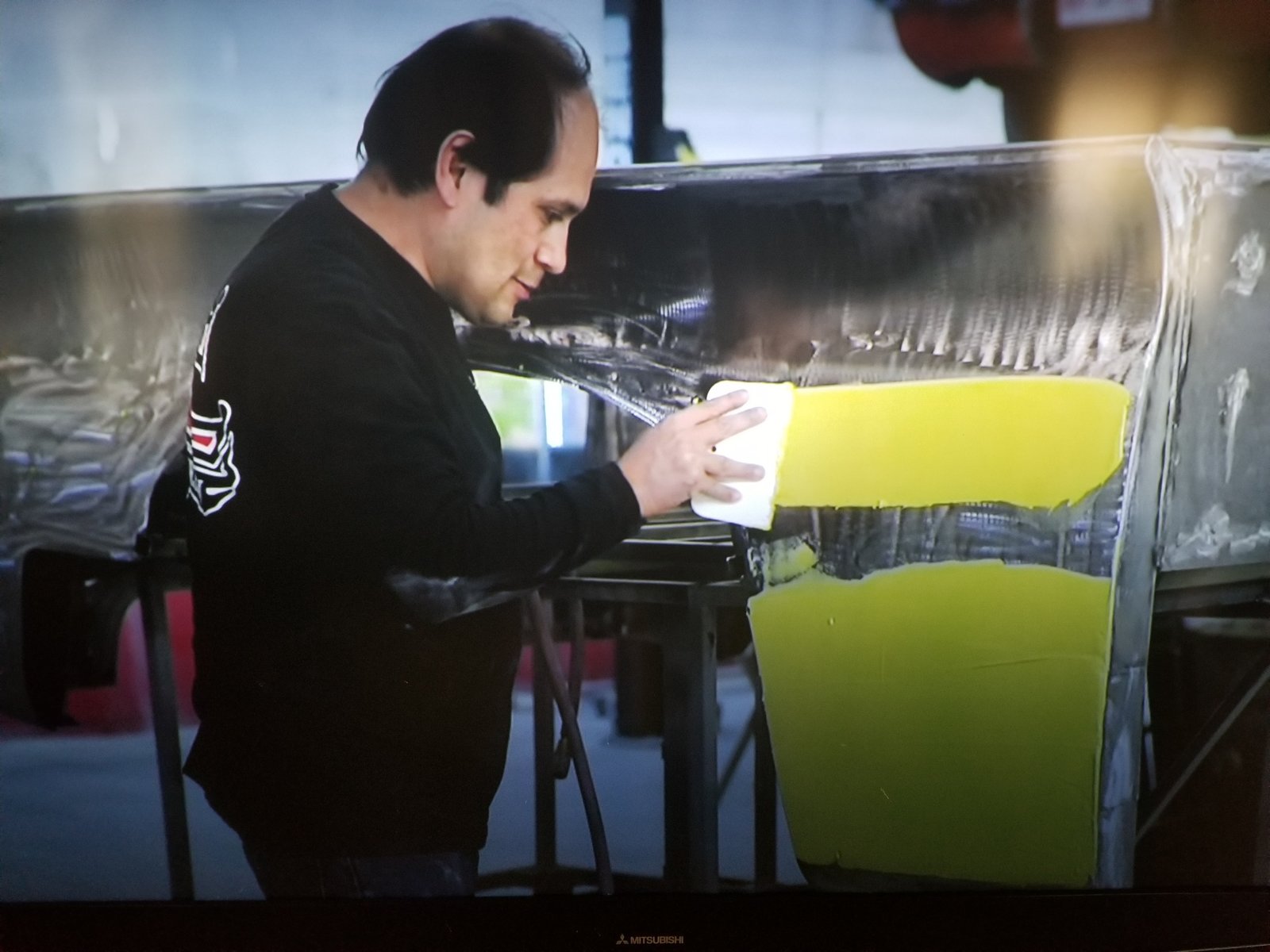

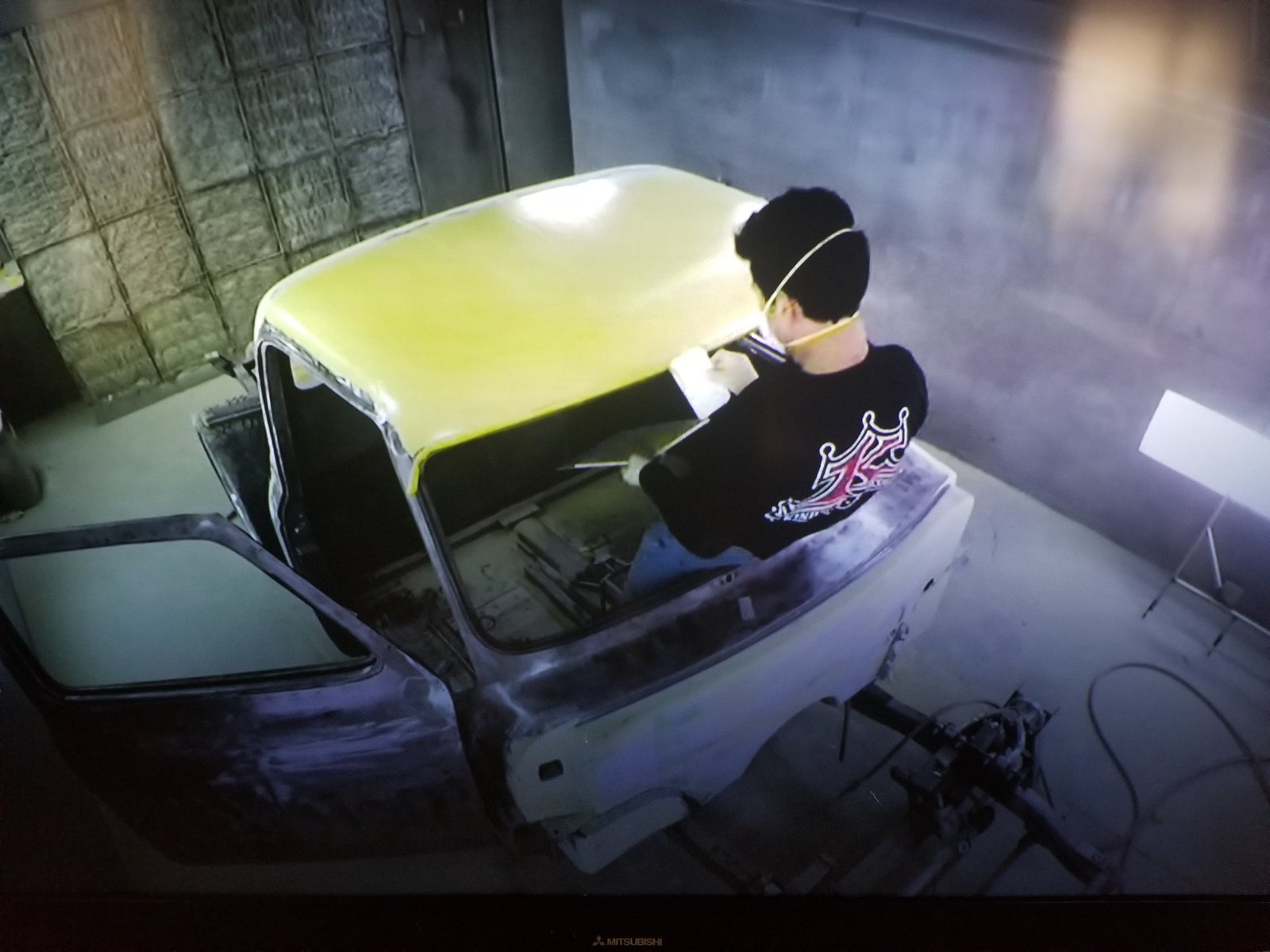

I was applying the body filler and trying to fill in low spots, but when I would sand it down I could still feel a transition from body filer to bare metal. So, I was watching Bitchin Rides and noticed that even though their metal work is pretty straight they skim "ALL" the metal and then shape the body filler.

Once I seen that I tried it myself. I'm not as good as they are, but noticed their technique worked better for me. So, I'm happy with how the body work is coming out.

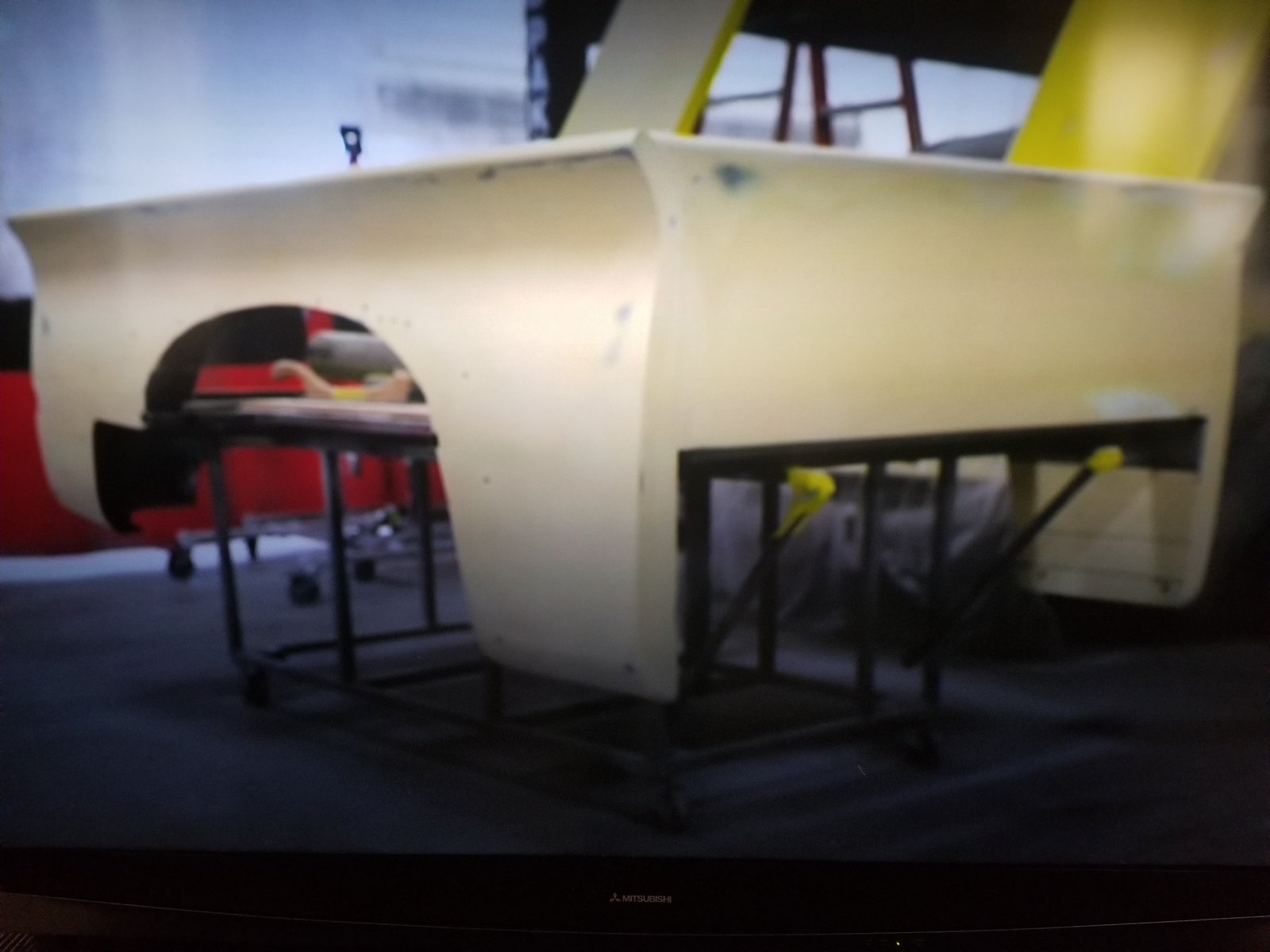

This is them working on an F-100. They even removed the front section to get better access the the firewall area. This is why I started on the body work before completing the engine bay. I didn't want to be climbing in and out to do body work. Seems to be working so far.

Once I seen that I tried it myself. I'm not as good as they are, but noticed their technique worked better for me. So, I'm happy with how the body work is coming out.

This is them working on an F-100. They even removed the front section to get better access the the firewall area. This is why I started on the body work before completing the engine bay. I didn't want to be climbing in and out to do body work. Seems to be working so far.

Well, just like metal work (which is obviously not finished LOL), body work is the same process. Apply body filler, sand, shape and smooth and sand some more LOL.

This weekend I got the top portion of the firewall completed. Started working on the bottom part of the firewall (transmission tunnel) and the frame rails.

Still got a long way to go, but I am making progress every weekend.

This is where I started back on the project.

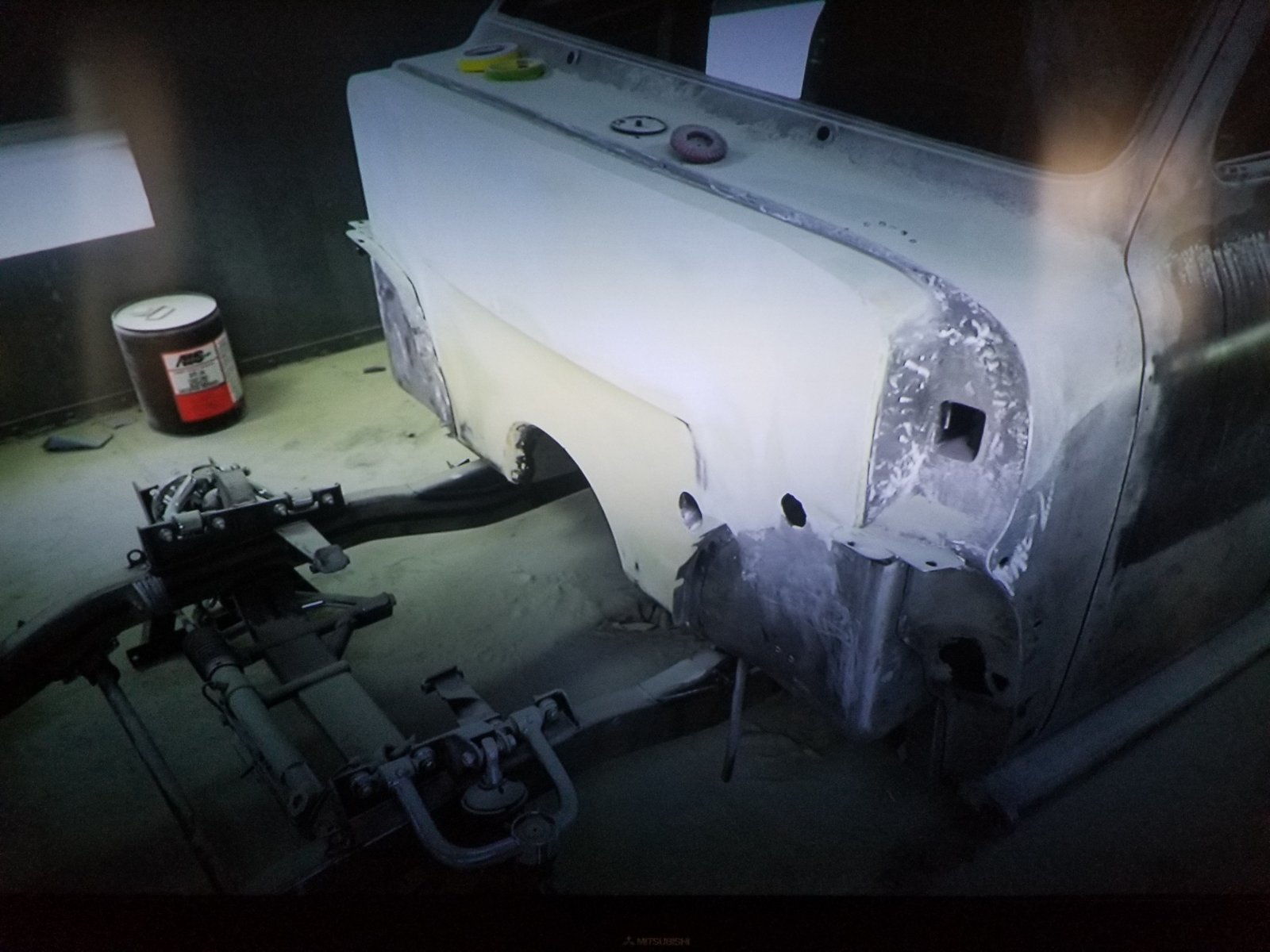

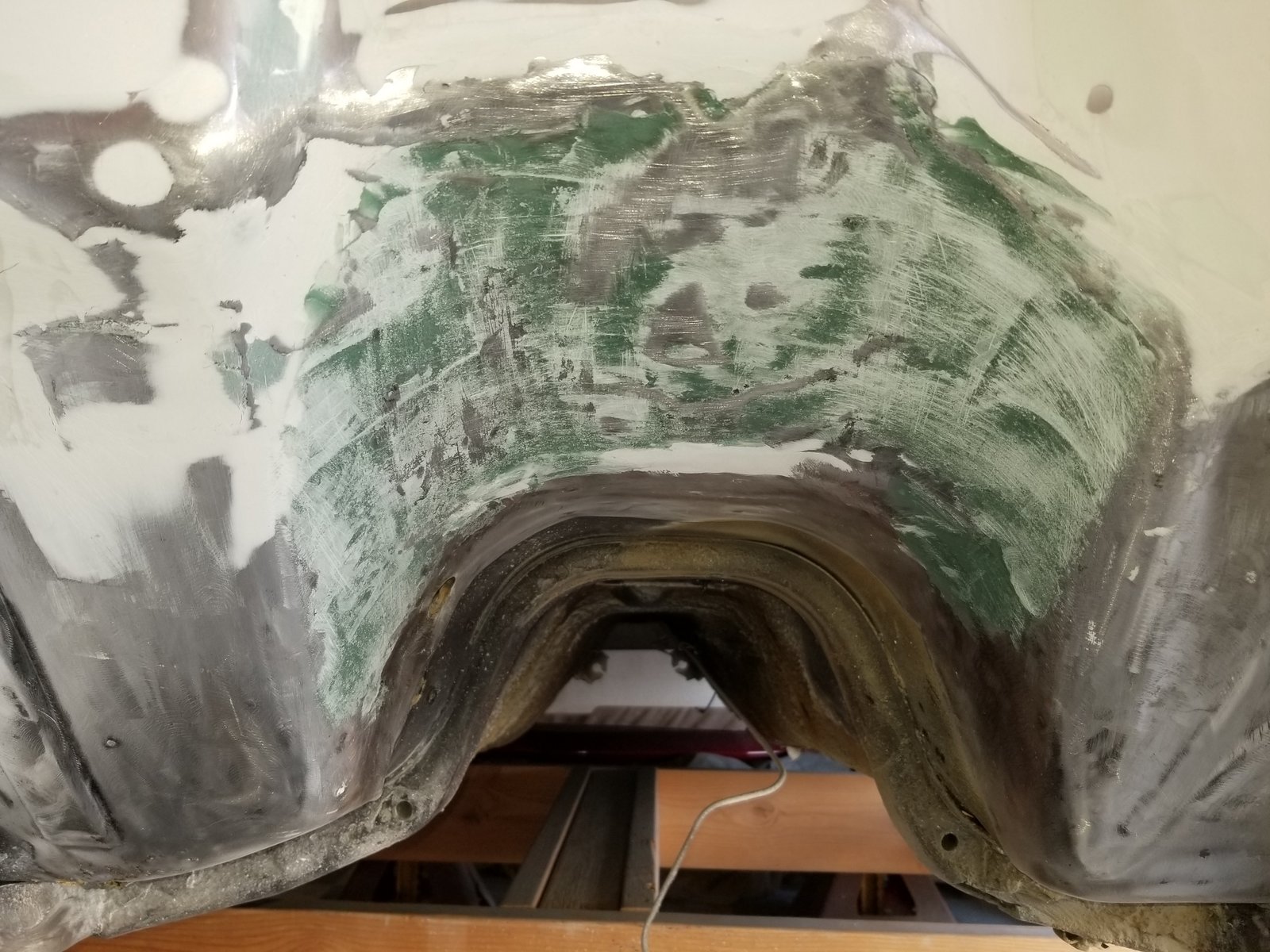

Doing work on the rear drivers side apron.

Had some low spots and needed a little more filler.

Driver's side rear apron finished up.

This is actually the second coat of filler in the transmission tunnel.

This is the finished tunnel. I know it is not perfect, but this is not a show car and you really won't see this once the car is back together. So, I'm good with this. Trying to focus more and areas that will be seen.

Got started on the driver's side frame rail.

Rear portion of driver's side frame rail about 90%.

Got started on the passenger side frame rail. Initial skim and knock down with 40 grit.

And this is where I ended this weekend. Man, now I know why it is so expensive to have a car built. This is a "TON" of work. However, it will be well worth it when it's all said and done......

This weekend I got the top portion of the firewall completed. Started working on the bottom part of the firewall (transmission tunnel) and the frame rails.

Still got a long way to go, but I am making progress every weekend.

This is where I started back on the project.

Doing work on the rear drivers side apron.

Had some low spots and needed a little more filler.

Driver's side rear apron finished up.

This is actually the second coat of filler in the transmission tunnel.

This is the finished tunnel. I know it is not perfect, but this is not a show car and you really won't see this once the car is back together. So, I'm good with this. Trying to focus more and areas that will be seen.

Got started on the driver's side frame rail.

Rear portion of driver's side frame rail about 90%.

Got started on the passenger side frame rail. Initial skim and knock down with 40 grit.

And this is where I ended this weekend. Man, now I know why it is so expensive to have a car built. This is a "TON" of work. However, it will be well worth it when it's all said and done......

Last edited:

I see this as very painful tedious work with a huge satisfaction level when completed. Have you ever looked into Nelson Racing? They built that charger in 100% metal finish. I can’t imagine the level of OCD needed to complete that. That Charger was widened 3”per side.

You will have a bitchin car when you have it back on the road plus it will have all been done by you. Brings the built not bought phrase home

Sent from my iPhone using svtperformance.com

You will have a bitchin car when you have it back on the road plus it will have all been done by you. Brings the built not bought phrase home

Sent from my iPhone using svtperformance.com

You need to put together a photo album for the shows and make sure people know you did the work yourself.

I see this as very painful tedious work with a huge satisfaction level when completed. Have you ever looked into Nelson Racing? They built that charger in 100% metal finish. I can’t imagine the level of OCD needed to complete that. That Charger was widened 3”per side.

You will have a bitchin car when you have it back on the road plus it will have all been done by you. Brings the built not bought phrase home.

Thank you geoffmt! Man, you hit the nail on the head with "very painful tedious work with a huge satisfaction level when completed" statement. Sometimes I find myself sitting in the garage and just staring at the car and seeing how far I have to go. Then I push myself to get some welding done or body work done. Then at the end of the day I grab a shower and cool off. Then I go back in the garage and look at what I accomplished and man it is VERY satisfying to know I got it to where it currently is.

I'm not familiar with Nelson racing, but have seen that car. It is amazing and WAY beyond anything I could even think about attempting LOL.

I'm hoping it will be bitchin when it is done (and thank you for saying that). I have a very big vision for this car (at least when it comes to my abilities and available tools) and I hope people can appreciate that vision once it's done.

Thanks again for your comments and for posting in my thread. I always appreciate the feedback!

You need to put together a photo album for the shows and make sure people know you did the work yourself.

That's a good idea Bob. If I'm asked "who built this?" you know I'm going to have a huge smile on my face and proudly point to myself LOL.

I wouldn't mind making a book, but man that's going to be a lot of printer ink LOL.

I actually thought about having business cards made with the link to this thread for those who may be that interested in the build process of my car. Not sure how feasible that would be or if it would be cost effective though.

Maybe just hit the highlights. Plus places like CVS and Walgreens will still print photos. You can take them in on a thumb drive.That's a good idea Bob. If I'm asked "who built this?" you know I'm going to have a huge smile on my face and proudly point to myself LOL.

I wouldn't mind making a book, but man that's going to be a lot of printer ink LOL.

I actually thought about having business cards made with the link to this thread for those who may be that interested in the build process of my car. Not sure how feasible that would be or if it would be cost effective though.

Hello everyone,

Well this weekend I had a minor set back. When I went outside to work I had noticed that every where I did work last weekend had cracks in the body filler. I'm not sure if it was hardener to product ratio, if I put too much, but I was well within the recommended thickness or if it was the heat. With it being up to 104 outside my garage gets pretty hot during the week. The funny thing is my firewall does not have any cracks in it and I'm pretty sure I did everything the same. So, I'm baffled.

Anyway, I fixed everything and the got some other stuff done as well.

(Disclaimer: I'm trying to show everything as they happened so those who may be trying this can avoid my mistakes. Not trying to only take pictures of the good stuff. I want to show the good, the bad and the ugly ).

).

Here you can see the driver's side and passenger side frame rails had to be sanded back down to bare metal in spots. Also, had to take the transmission tunnels back down.

Okay time to start the process all over again. Some of you may notice the notch in this frame rail from the picture above. I did fill that with fiberglass filler prior to this layer of body filler.

The frame rails are pretty straight, but the transmission tunnel has some pretty serious wrinkles from the factory stamping process. So, this time I decided to fill the wrinkles with the fiberglass filler since it is stronger. Then I'll lay body filler over it to smooth it out a bit.

Okay got everything smoothed back out. I still need to go over some areas with the glazing putty to fill pin holes or minor low spots (That's what those black circles are. Areas I marked with a sharpie that need some attention). It's a lot of work, but as long as I make progress I won't complain too much LOL.

Okay, got up to this point on Saturday. The final sanding of the fiberglass filler. I left it rough to give the body filler something to "bite" on to.

Well this weekend I had a minor set back. When I went outside to work I had noticed that every where I did work last weekend had cracks in the body filler. I'm not sure if it was hardener to product ratio, if I put too much, but I was well within the recommended thickness or if it was the heat. With it being up to 104 outside my garage gets pretty hot during the week. The funny thing is my firewall does not have any cracks in it and I'm pretty sure I did everything the same. So, I'm baffled.

Anyway, I fixed everything and the got some other stuff done as well.

(Disclaimer: I'm trying to show everything as they happened so those who may be trying this can avoid my mistakes. Not trying to only take pictures of the good stuff. I want to show the good, the bad and the ugly

Here you can see the driver's side and passenger side frame rails had to be sanded back down to bare metal in spots. Also, had to take the transmission tunnels back down.

Okay time to start the process all over again. Some of you may notice the notch in this frame rail from the picture above. I did fill that with fiberglass filler prior to this layer of body filler.

The frame rails are pretty straight, but the transmission tunnel has some pretty serious wrinkles from the factory stamping process. So, this time I decided to fill the wrinkles with the fiberglass filler since it is stronger. Then I'll lay body filler over it to smooth it out a bit.

Okay got everything smoothed back out. I still need to go over some areas with the glazing putty to fill pin holes or minor low spots (That's what those black circles are. Areas I marked with a sharpie that need some attention). It's a lot of work, but as long as I make progress I won't complain too much LOL.

Okay, got up to this point on Saturday. The final sanding of the fiberglass filler. I left it rough to give the body filler something to "bite" on to.

Okay, on Sunday I got the transmission tunnel and the lower side of the passenger side firewall done. Then I did the top part of the passenger side frame rail and got started on the motor mount portion of the frame rails and then finally I did the inside front portion of the driver's side frame rail.

Transmission tunnel redone.

Got the lower passenger side of the firewall about 95%. Still need to add some glazing putty to finish it off.

Top portion of the passenger side frame rail. Again need to finish it off with glazing putty.

Got started on the motor mount areas on both sides.

Here is the inside of the front driver's side frame rail. It needs one more skim coat of body filler to level it out. I'm only doing the inside because I still need to weld in the engine panels and I don't want welding slag to fall on top of my body work.

And this is where I ended on Sunday. Hopefully no cracks show up this week. I want to complete this portion of the body work (firewall and frame rails) next weekend so I can get back on the metal work. I need to mount the Mustangs to Fear frame rail supports, radiator support and engine panels. Then I'll complete the body work and finally lay down some primer. That's the plan anyway. We will see how it gets executed lol.

Transmission tunnel redone.

Got the lower passenger side of the firewall about 95%. Still need to add some glazing putty to finish it off.

Top portion of the passenger side frame rail. Again need to finish it off with glazing putty.

Got started on the motor mount areas on both sides.

Here is the inside of the front driver's side frame rail. It needs one more skim coat of body filler to level it out. I'm only doing the inside because I still need to weld in the engine panels and I don't want welding slag to fall on top of my body work.

And this is where I ended on Sunday. Hopefully no cracks show up this week. I want to complete this portion of the body work (firewall and frame rails) next weekend so I can get back on the metal work. I need to mount the Mustangs to Fear frame rail supports, radiator support and engine panels. Then I'll complete the body work and finally lay down some primer. That's the plan anyway. We will see how it gets executed lol.

Last edited:

BTW, Thanks to all who convinced me to keep this thread active here. This thread has over 3700 views right now. My thread on the vintage Mustang site has just over 1000 views.

Thanks everyone!

Thanks everyone!

I like seeing the regular updates on this thread, bummer you had to redo a bunch of stuff though.

Sent from my iPhone using svtperformance.com

Sent from my iPhone using svtperformance.com

Keep it going. Looks good. I always look forward to updates.

Thank you Todd! Appreciate the support and you keeping up with this thread.

I like seeing the regular updates on this thread, bummer you had to redo a bunch of stuff though.

Thank you geoffmt! Yeah, saying I was disappointed is putting it lightly. The good thing is it only put me one day behind. Also, the passenger side frame rail and transmission tunnel were not 100%. Only the driver's side frame rail was done. The good news is at least it cracked while still bare. If it were to crack after priming or paint then that would really be a bad situation LOL.

Hello everyone,

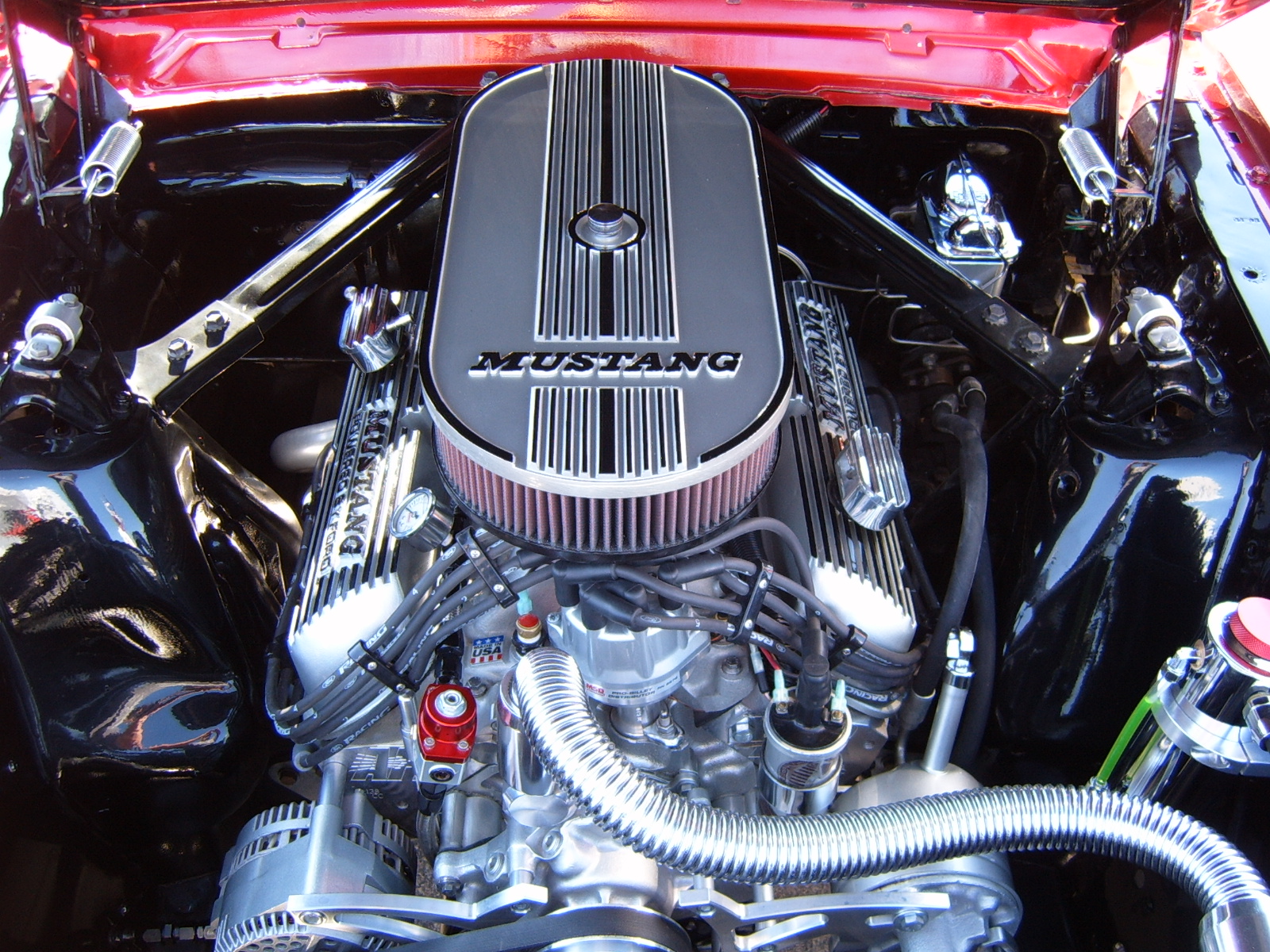

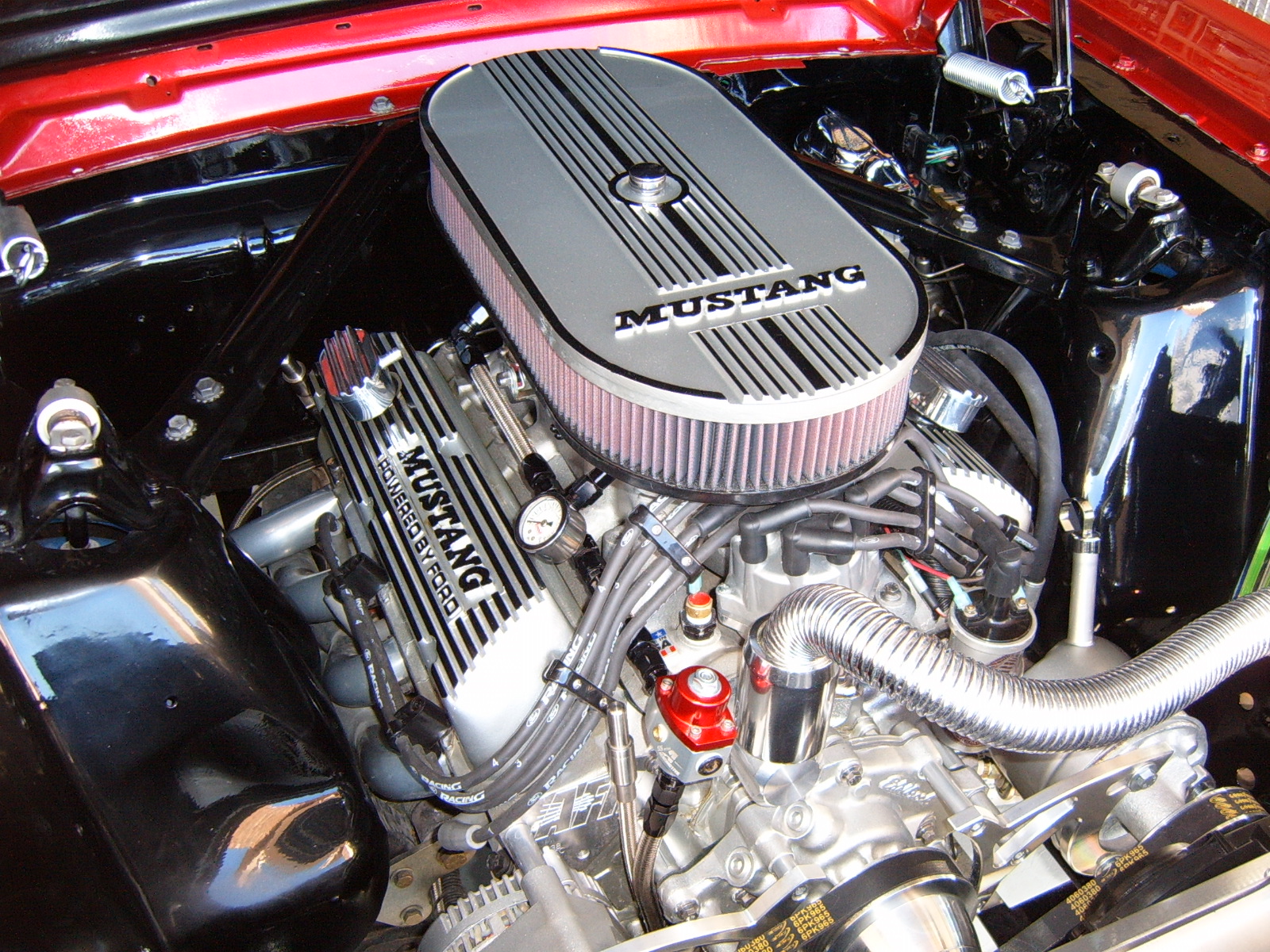

I was looking through my archives last night and found a folder with some old pictures of my car (Back when she was pretty LOL).

When I complete the car it should look very similar to this, minus the engine bay and the wheels (I want to go with a polished Halibrand style wheel). I have not decided if I want to change the hood or not. My brother says keep the cowl, but I like the stock hood with Shelby hood scoop. I'm also not sure if I want the hood to stay black or go back to body color.

I was at an MSD car show and the pictures labeled with the MSD logos were taken by MSD staff and placed on their website, which is why they are different from the others.

Anyway, just wanted to share.

I was looking through my archives last night and found a folder with some old pictures of my car (Back when she was pretty LOL).

When I complete the car it should look very similar to this, minus the engine bay and the wheels (I want to go with a polished Halibrand style wheel). I have not decided if I want to change the hood or not. My brother says keep the cowl, but I like the stock hood with Shelby hood scoop. I'm also not sure if I want the hood to stay black or go back to body color.

I was at an MSD car show and the pictures labeled with the MSD logos were taken by MSD staff and placed on their website, which is why they are different from the others.

Anyway, just wanted to share.

Okay Everyone,

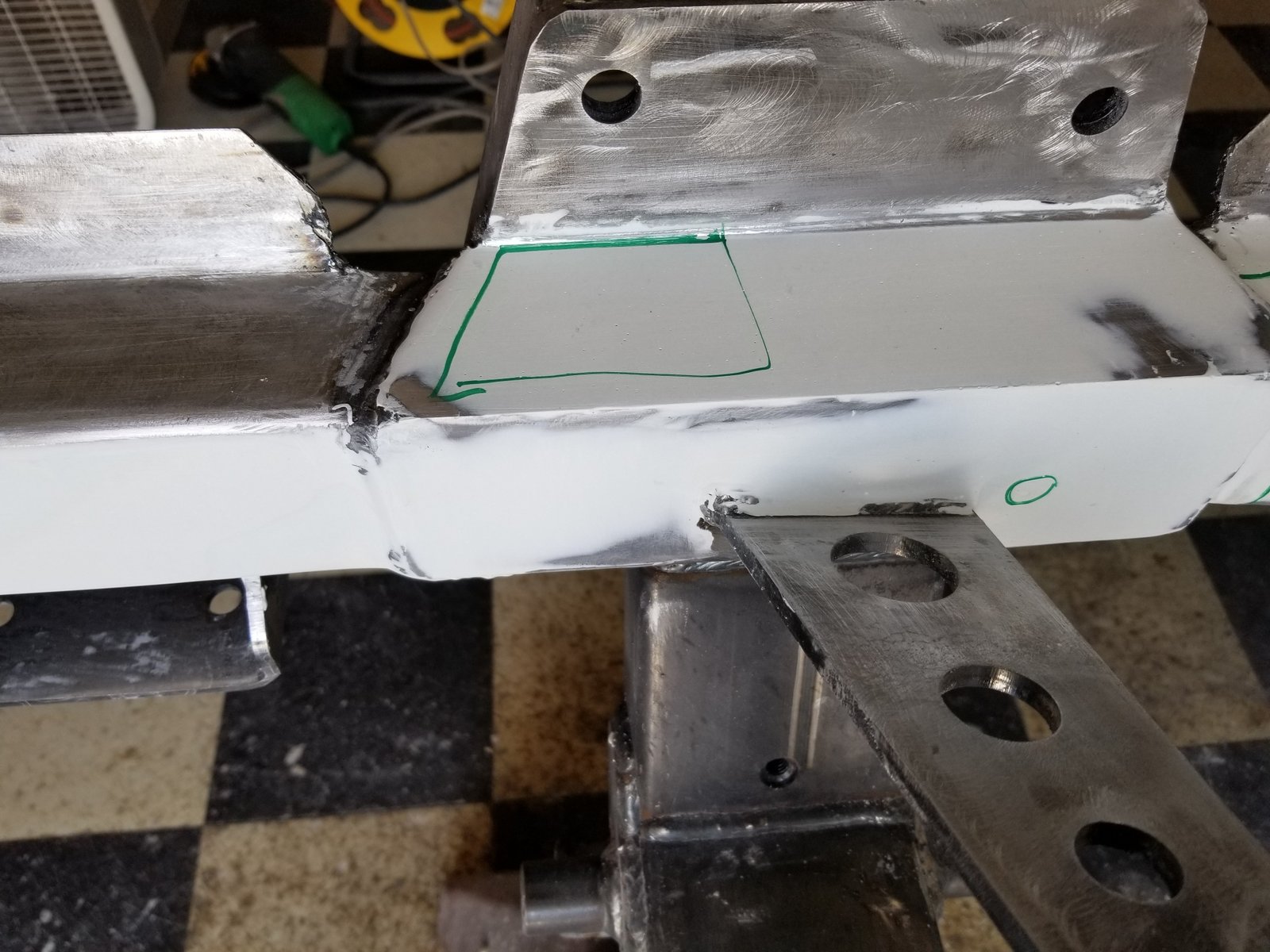

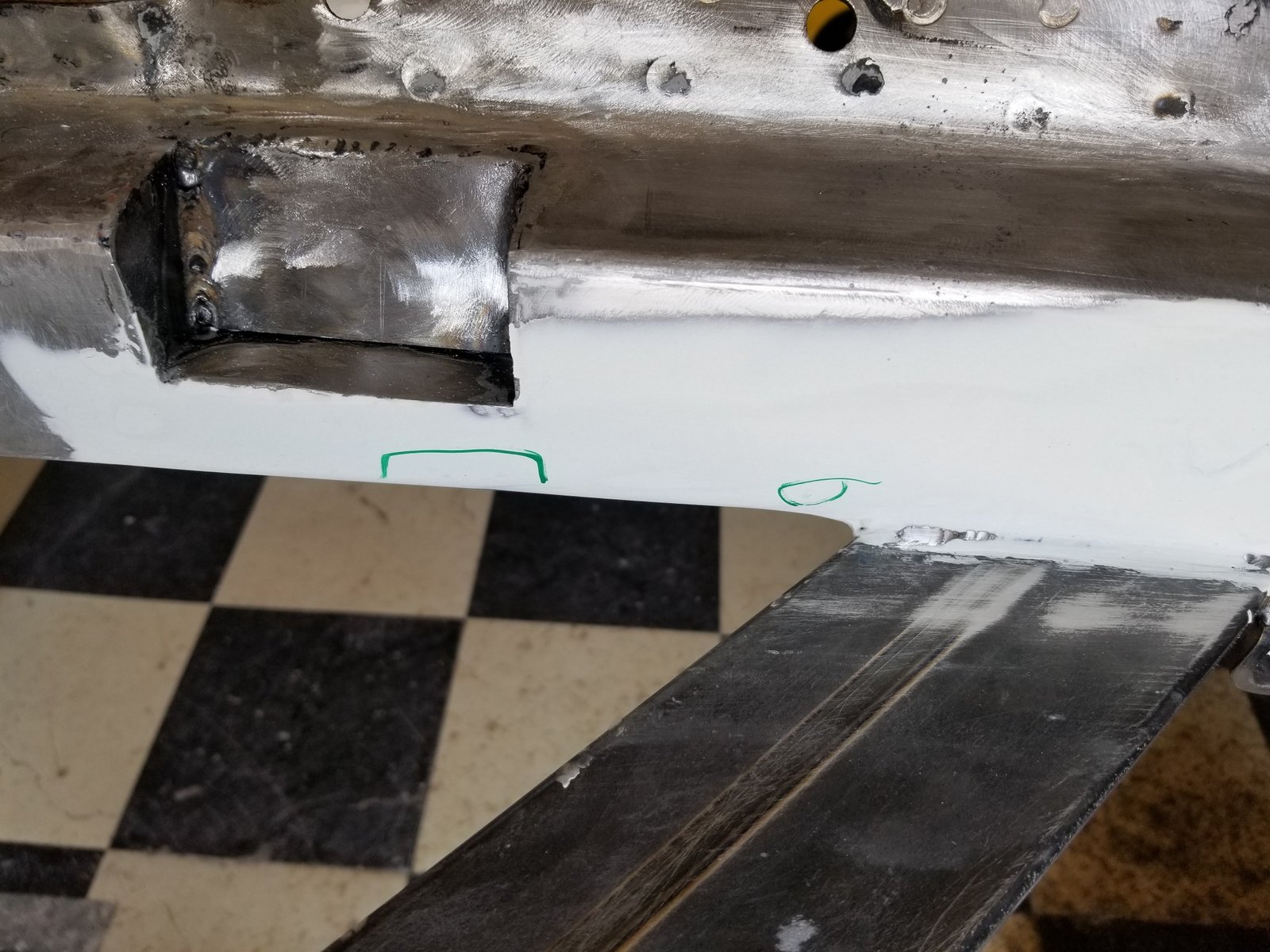

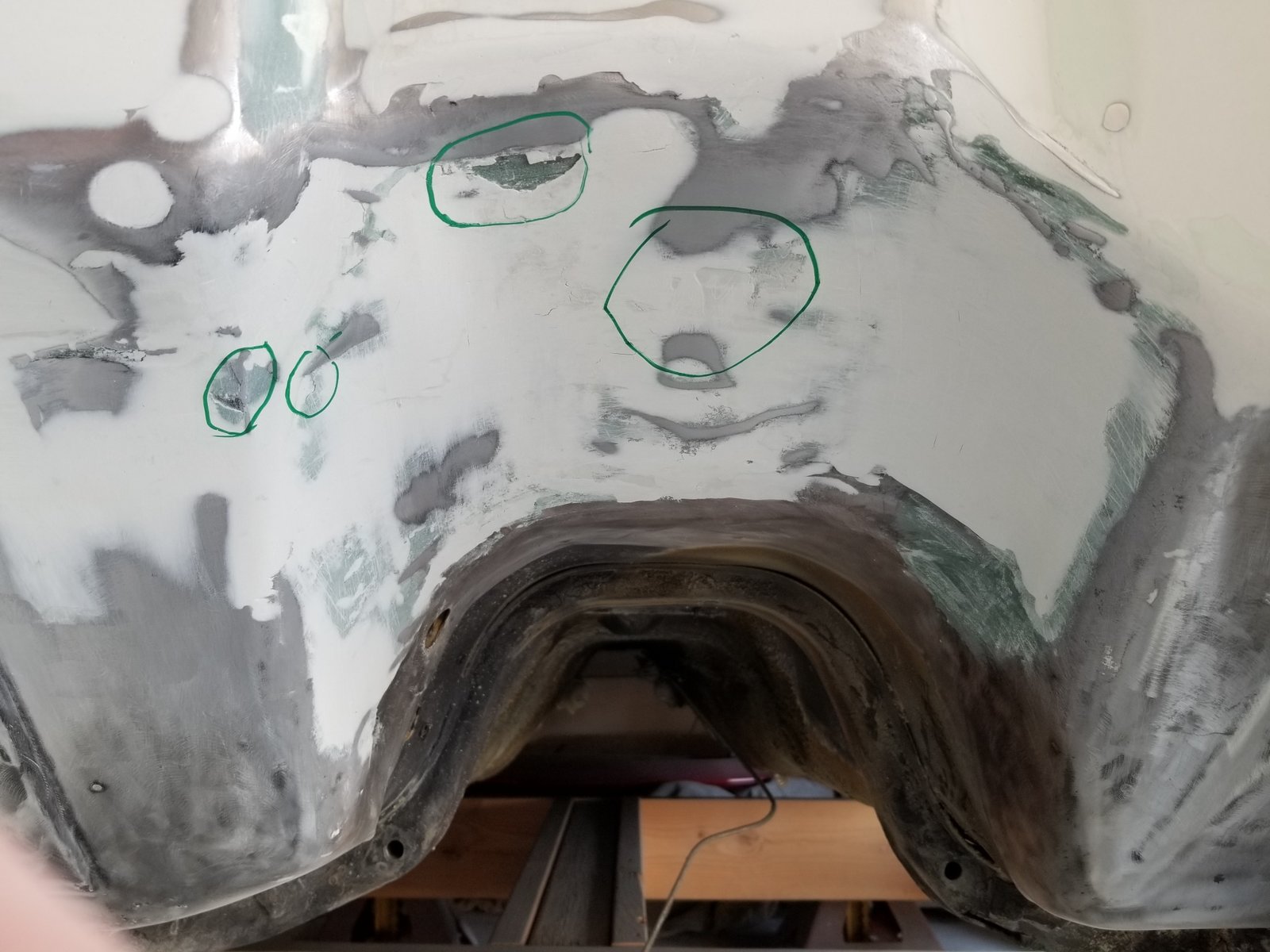

On Saturday I finished up the body work on the firewall, transmission tunnel and about 90% of the frame rails (left some bare metal near areas I still need to weld). I know in the pictures it's hard to tell, but there were a lot of little imperfections that I needed to go over with glazing putty. This is the final step in body work to fill pin holes, minor low spots and blemishes.

To show just how much there is I used my green paint pen to circle all the areas (a sharpie didn't work well for me) I needed to address.

On Saturday I finished up the body work on the firewall, transmission tunnel and about 90% of the frame rails (left some bare metal near areas I still need to weld). I know in the pictures it's hard to tell, but there were a lot of little imperfections that I needed to go over with glazing putty. This is the final step in body work to fill pin holes, minor low spots and blemishes.

To show just how much there is I used my green paint pen to circle all the areas (a sharpie didn't work well for me) I needed to address.

On Sunday I got back on the metal work. It's starting to come together now. I can tell you after starting with metal work and then doing body work and going back to metal work, I like metal work much better. Body work is just too labor intensive LOL. Problem is body work is the basis of the final product. So, it has to be right.

Anyway, needless to say I'm very happy with how it is progressing.

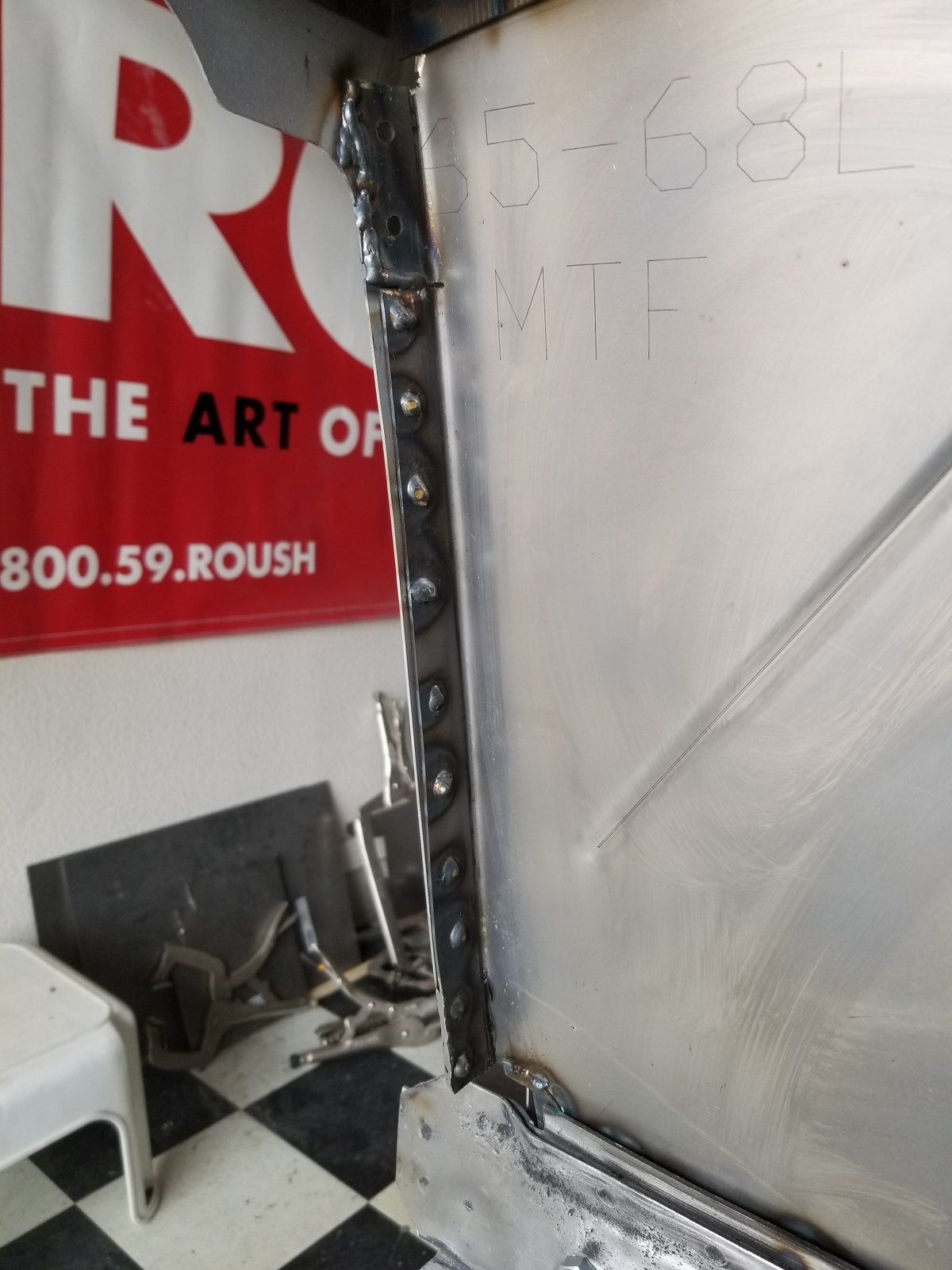

I got the radiator support welded in place, the upper fender mounts in place and the driver's side engine panel tacked in place.

Got the front area ready with weld through primer.

Got the radiator support mocked up.

Here I got the driver's side engine panel prepped.

Here is the engine panel with the rear flange installed per the instructions.

The engine panel mocked up.

And here is where I ended on Sunday. Got the panel tacked into place. Mustangs to Fear indicate this panel is very easy to warp if I get to excited with my welding. So, I'm taking it slow.

Anyway, needless to say I'm very happy with how it is progressing.

I got the radiator support welded in place, the upper fender mounts in place and the driver's side engine panel tacked in place.

Got the front area ready with weld through primer.

Got the radiator support mocked up.

Here I got the driver's side engine panel prepped.

Here is the engine panel with the rear flange installed per the instructions.

The engine panel mocked up.

And here is where I ended on Sunday. Got the panel tacked into place. Mustangs to Fear indicate this panel is very easy to warp if I get to excited with my welding. So, I'm taking it slow.

Looking good, it's moving along nicely.

Okay everyone,

Made some progress on the car this weekend. A neighbor of mine came over. He rebuilds cars and was giving me some very good constructive criticism and provided good information on some products he uses. He also provided me with a flap disk that he said would smooth out the metal more after an initial grinding. That flap disk worked great. I'm definitely going to the store to get a few more.

I was able to get the engine panels in. Next weekend I will mount the MTF frame rail supports and then I'll get back on the body work to smooth out the areas I welded the engine bay panels. Then the next thing I will do is smooth out the radiator support and then it should be time for some epoxy primer...…...

Slow and steady seems to be my pace LOL.

Passenger side mocked up. You can see the rear of the panel significantly overlaps the rear apron. Have to mark it on the rear, cut it, notch it to give it a lip and then weld it in.

Here I got it all tack welded into place. Damn, tack welding takes forever on a piece this size...….

Here the driver's side is all tack welded into place.

Got the passenger side all grinded down. This "IS" after using that flap disk my neighbor gave me. (Notice the top rear corner of where I welded the panel to the fender rail? My neighbor said it look low and I should pound it out. So, I did. I'll show the result in the next post).

Driver's side grinded down.

Here is the backside of the engine panel spot welded to the radiator support.

Passenger side. In the factory set up this area is normally kicked out in order to accommodate the battery. That's why there is so much over hang here.

Here you can see the radiator support has a form to it at the bottom. So, I had to cut the engine panel and do some bending in order to get it to fit the contour.

Then I had to trim the engine panel to align with the radiator support.

Made some progress on the car this weekend. A neighbor of mine came over. He rebuilds cars and was giving me some very good constructive criticism and provided good information on some products he uses. He also provided me with a flap disk that he said would smooth out the metal more after an initial grinding. That flap disk worked great. I'm definitely going to the store to get a few more.

I was able to get the engine panels in. Next weekend I will mount the MTF frame rail supports and then I'll get back on the body work to smooth out the areas I welded the engine bay panels. Then the next thing I will do is smooth out the radiator support and then it should be time for some epoxy primer...…...

Slow and steady seems to be my pace LOL.

Passenger side mocked up. You can see the rear of the panel significantly overlaps the rear apron. Have to mark it on the rear, cut it, notch it to give it a lip and then weld it in.

Here I got it all tack welded into place. Damn, tack welding takes forever on a piece this size...….

Here the driver's side is all tack welded into place.

Got the passenger side all grinded down. This "IS" after using that flap disk my neighbor gave me. (Notice the top rear corner of where I welded the panel to the fender rail? My neighbor said it look low and I should pound it out. So, I did. I'll show the result in the next post).

Driver's side grinded down.

Here is the backside of the engine panel spot welded to the radiator support.

Passenger side. In the factory set up this area is normally kicked out in order to accommodate the battery. That's why there is so much over hang here.

Here you can see the radiator support has a form to it at the bottom. So, I had to cut the engine panel and do some bending in order to get it to fit the contour.

Then I had to trim the engine panel to align with the radiator support.

Users who are viewing this thread

Total: 34 (members: 0, guests: 34)