Then I decided to make one more patch panel before I called it a day.

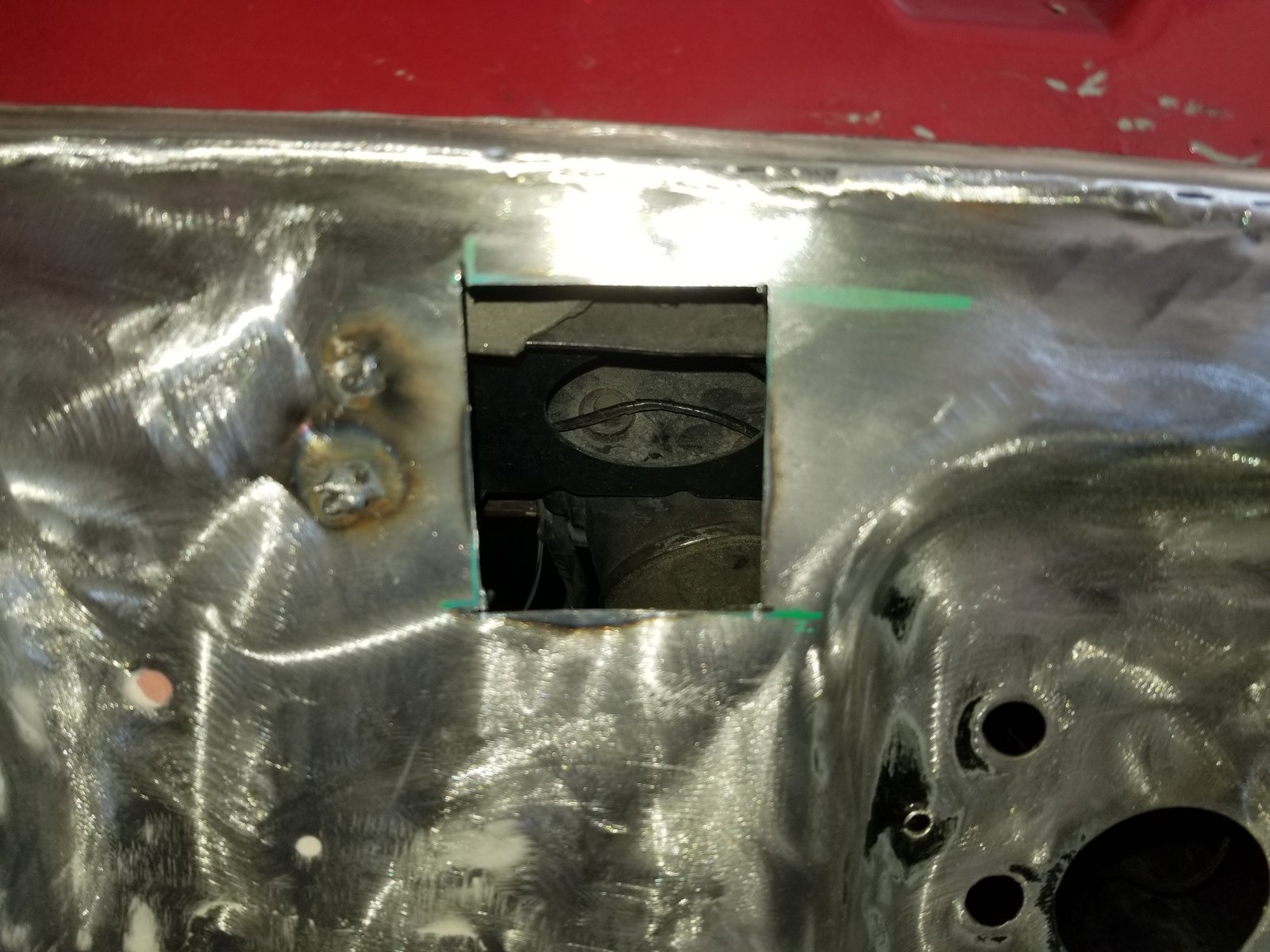

The two circles with the rectangle underneath are where my engine harness goes through the firewall. I'm going to reroute those wire in order to give my firewall a cleaner look. So, out with the cutting wheel...….

Patch panel made. I'm really happy with how my ability to make these patches to line up great is getting. Makes welding so much easier...….

And this is where I ended. Didn't get a chance to get all my welds grinded smooth. It was just too damn hot LOL. As you can see I didn't even get a chance to get those two patches for the lower part of the passenger side firewall completed either...……

The two circles with the rectangle underneath are where my engine harness goes through the firewall. I'm going to reroute those wire in order to give my firewall a cleaner look. So, out with the cutting wheel...….

Patch panel made. I'm really happy with how my ability to make these patches to line up great is getting. Makes welding so much easier...….

And this is where I ended. Didn't get a chance to get all my welds grinded smooth. It was just too damn hot LOL. As you can see I didn't even get a chance to get those two patches for the lower part of the passenger side firewall completed either...……

Last edited: