I'm going to be installing a set of h&r race springs in a few days and taking out a set of cut springs the previous owner did (25.5in from fender to ground on stock size wheels/tires all the way around) needless to say its low. I'm going to go ahead and replace the balljoints while I have everything apart, should I use the steeda x2 joints or just get a replacement set from Moog?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

steeda balljoints

- Thread starter N20JUNKY

- Start date

Steeda 2x and while your at it the bump steer kit

here's why....

here's why....

Last edited:

+1should I use the steeda x2 joints

Let me know if I can help assist you with placing an order?

X2 balljoints are a must when lowering Mustang 2" or more. The X2 balljoints are extremely strong, assist in providing excellent steering and overall handling. A+++ Product.

We picked these up after lowering our 2001 Mustang by 1.75". Our geometry was so out of whack, plus having 90,xxx miles on the car had our balljoints destroyed. These went on in a snap, came with extremely detailed instructions, and installed in about 2 hours with simple hand tools and the use of a balljoint press (rented from parts store).

Would definitely recommend these to anyone lowering their car, especially if you are going greater than 1.5"

Best Regards,

TJ

Steeda's for sure. Great mod plus you dont need to use their spacer if you want it even lower. Doesnt sound like you do though. Need a grease gun...

Bump steer and maybe new isos if you dont have any. Might as well pick up some swap bar end links and energy suspension bushings

Bump steer and maybe new isos if you dont have any. Might as well pick up some swap bar end links and energy suspension bushings

Last edited:

I've been reading on the x2 balljoints and it seems that a lot of people have problems with them prematurely wearing out, I've read a lot of people are having to replace them within a year and some even quicker then that. Also some have to tack weld them in the control arm? I understand they help but also aren't needed 100%, my car right now is lowered probably close to 3in and doesn't have anything else besides camber bolts, it doesn't pull too bad and not a ton of bump steer. I think I'm just going to go with a replacement set of joints, thanks for the info guys!

Last edited:

If you do the x2 joints is a bumpsteer kit required? I'd imagine it is since now the relationship between the tie rod and control arm is now not in line

If you do the x2 joints is a bumpsteer kit required? I'd imagine it is since now the relationship between the tie rod and control arm is now not in line

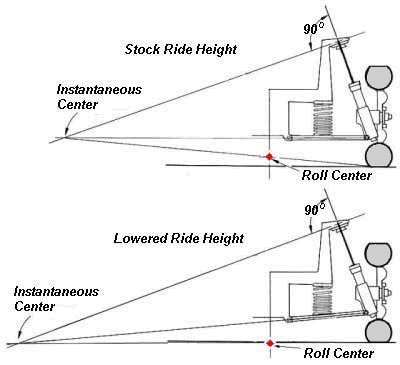

Yes, the 2x joints raise the lower ball joint where it connects to the spindle, so the tie rod will now head up hill from the steering rack to the spindle. So you have 2 choices, you can use offset rack bushings to get you part of the way there, but it's been my experience that you will still need the bump steer kit.

BTW a quick word about the rack bushings, many guys like the solid bushings, however, again, it's been my experience that sometimes the K member is not "flat" across the front, so when you use the solid bushings they try to conform to the k-member and place a stress on the rack. I've dresses some K members with a sander/ grinder to try and relieve this problem but it's hit and miss. IMO I'd use the urethane bushings simply because they have a little "give" in them in order to make up for any irregularities in the K member, hence, less stress on the rack, maybe save it from cracking...etc.

Just my opinion, not everyone is going to agree with it.

Alright I have on order a set of X2 joints, steeda bumpsteer kit, and the new style MM solid rack bushings. I have put these rack bushings in a few different cars and they seem to work very well. I have decided to go away with the H&R springs for now until I can afford a set of matched set of shocks/struts for the springs rate and just cut a coil off another set of factory springs.

I've been reading on the x2 balljoints and it seems that a lot of people have problems with them prematurely wearing out, I've read a lot of people are having to replace them within a year and some even quicker then that. Also some have to tack weld them in the control arm? I understand they help but also aren't needed 100%, my car right now is lowered probably close to 3in and doesn't have anything else besides camber bolts, it doesn't pull too bad and not a ton of bump steer. I think I'm just going to go with a replacement set of joints, thanks for the info guys!

That has not been my experience, I have a set in a car that are 8 years old, but I maintain them. As far as tack welding them in the control arm, it is because the hole in the control arm is worn out, they are a press fit, just like the stockers. I have, on occasion tack welded them in place to avoid buying a new control arm, just be careful because you don't want to damage the urethane bushing material in the new joint.

That has not been my experience, I have a set in a car that are 8 years old, but I maintain them. As far as tack welding them in the control arm, it is because the hole in the control arm is worn out, they are a press fit, just like the stockers. I have, on occasion tack welded them in place to avoid buying a new control arm, just be careful because you don't want to damage the urethane bushing material in the new joint.

I tack welded my balljoints in a few spots just because I've read on corner carvers that they have been known to pop out. A quick grinder can pops those tacks right off.

Sounds good thanks guys! Ill be sure to throw a tack or two on the joints when they go in.

This is the first I've heard of tacking them in. I've had them on my other car for 4years no problems and at least 5 years on this car with no issues. Just make sure to grease them or you will have a terrible noise when turning going slow, like into parking spaces.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)