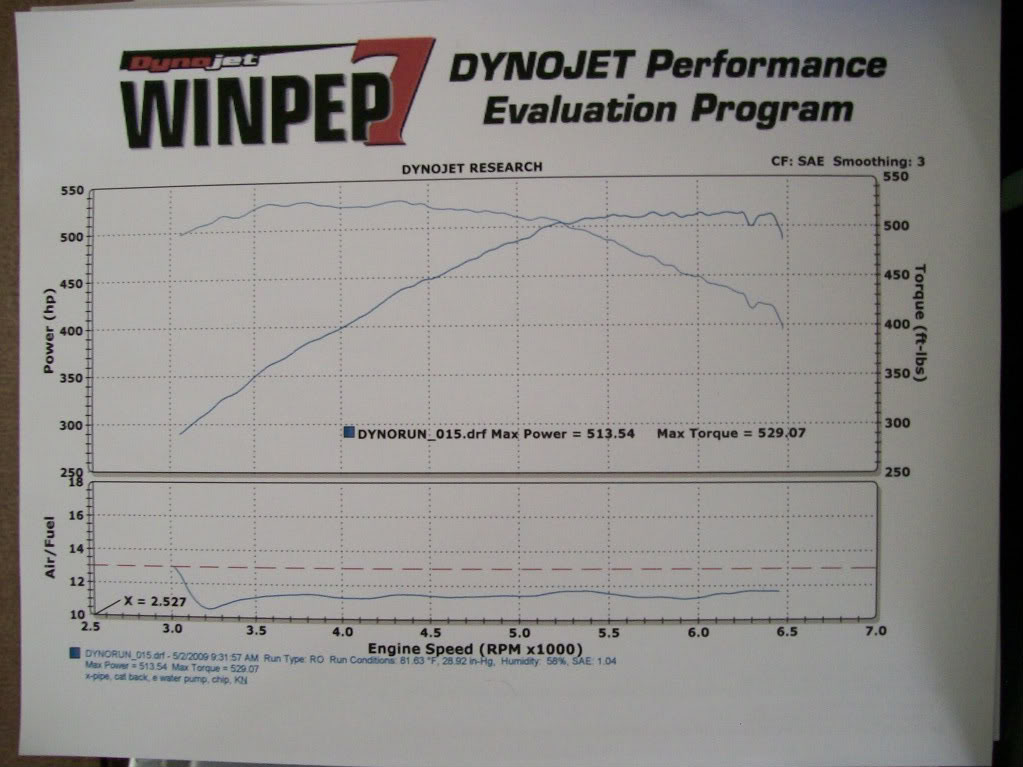

I was very impressed....guess I did something right on my portwork

This is @ 22*s timing

and then I globally added 1* timing with my handheld.(23*s timing) Red line is what the power went to and the Blue line was when I dynoed the car just after I got it....so I can see the difference

Red line mods= 3.1 upper/6# lower, 12" filter, JLT elbo, SCT BA-2600? MAF (aluminum one), Self ported blower, Accufab SBTB, self ported and port matched accufab plenum, bassani X pipe W/ pypes cats, Bassani catback.

Blue line mods= 6# lower, slightly ported stock plenum, Bassani O/R X pipe (no cats back then), bassani catback, 9" filter with stock elbo/inlet, and stock MAF.

Not too shabby. Car made 478/506 @ RWTD last year with the 3.1/6# combo and a crap port (didnt have time to finish before the dyno), with a crap ported plenum and stock slightly ported TB....and no cats. So the new port and SBTB made a good difference....car feels totally different now. My goal with this car was to hit 500RWHP....and now FINALLY I hit it....so im happy :rockon:

EDIT: Just for reference, #s are 527/543 STD. My above dyno sheets are SAE...which I prefer to use unless im comparing with steggy or anyone else who uses STD #s.

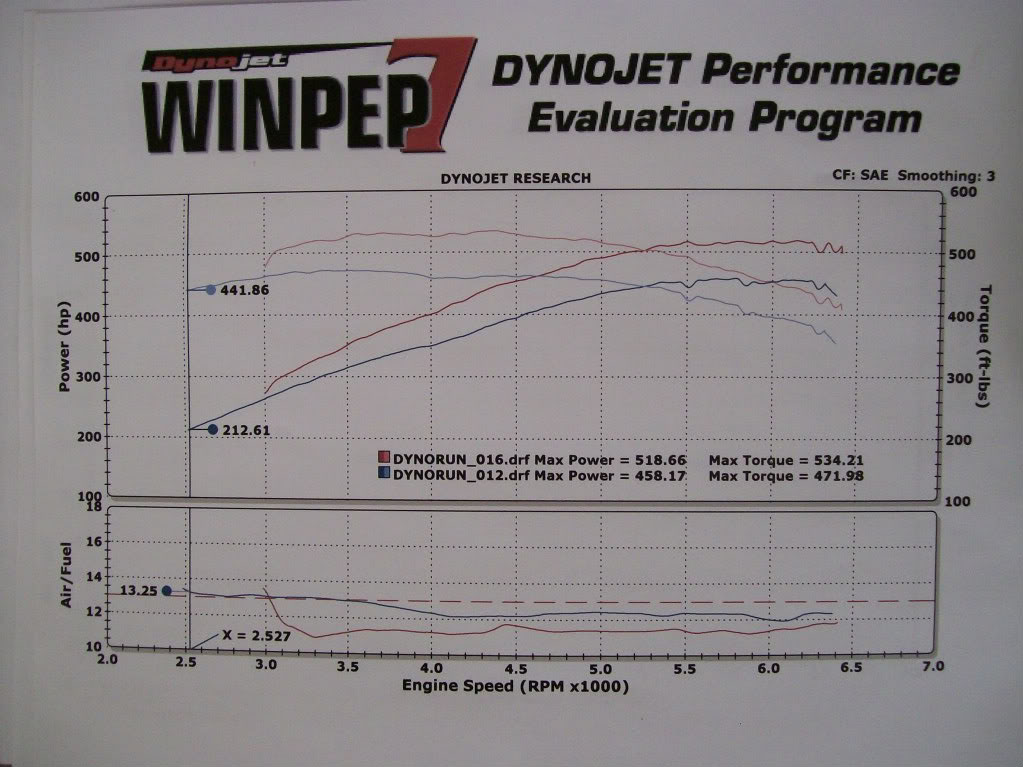

This is @ 22*s timing

and then I globally added 1* timing with my handheld.(23*s timing) Red line is what the power went to and the Blue line was when I dynoed the car just after I got it....so I can see the difference

Red line mods= 3.1 upper/6# lower, 12" filter, JLT elbo, SCT BA-2600? MAF (aluminum one), Self ported blower, Accufab SBTB, self ported and port matched accufab plenum, bassani X pipe W/ pypes cats, Bassani catback.

Blue line mods= 6# lower, slightly ported stock plenum, Bassani O/R X pipe (no cats back then), bassani catback, 9" filter with stock elbo/inlet, and stock MAF.

Not too shabby. Car made 478/506 @ RWTD last year with the 3.1/6# combo and a crap port (didnt have time to finish before the dyno), with a crap ported plenum and stock slightly ported TB....and no cats. So the new port and SBTB made a good difference....car feels totally different now. My goal with this car was to hit 500RWHP....and now FINALLY I hit it....so im happy :rockon:

EDIT: Just for reference, #s are 527/543 STD. My above dyno sheets are SAE...which I prefer to use unless im comparing with steggy or anyone else who uses STD #s.

Last edited: