My car is currently down to swap in a Lentech 4R70W Strip Terminator trans, ans at the same time I'm also working on a custom inlet tube for my Kenne Bell supercharger.

I realized that I have a throttle body that can flow over 1600 CFM, but the stock Kenne Bell inlet elbow is only rated at 1000 CFM, so that's my choke point. I'm already planning on putting a 4 1/2 inch tube from a Kenne Bell Mammoth kit from the filter to the throttle body which will take care of everything up to the TB, the goal is to get the rest of the intake up to, or more than, the capacity of the TB.

Thanks to an idea from a friend, and some research online, I'm going to work on creating a sheet metal intake for the back of the Kenne Bell that will be more open and flowing than the KB inlet elbow. I will work on piecing everything together, and then I just have to find someone to weld it together for me. I will also be using the Accufab elbow from the throttle body to the back of the blower since it can already keep up with the CFM of the throttle body.

I'll try to keep everyone updated as I move along through this up until I get the car back to Adam for a new tune with the upgraded inlet and the automatic trans. I'm hoping the extra 600+ CFM will make a significant difference in power.

I've been spending today working on the blower removal and I'm going to prep the sheet metal to cut for the intake.

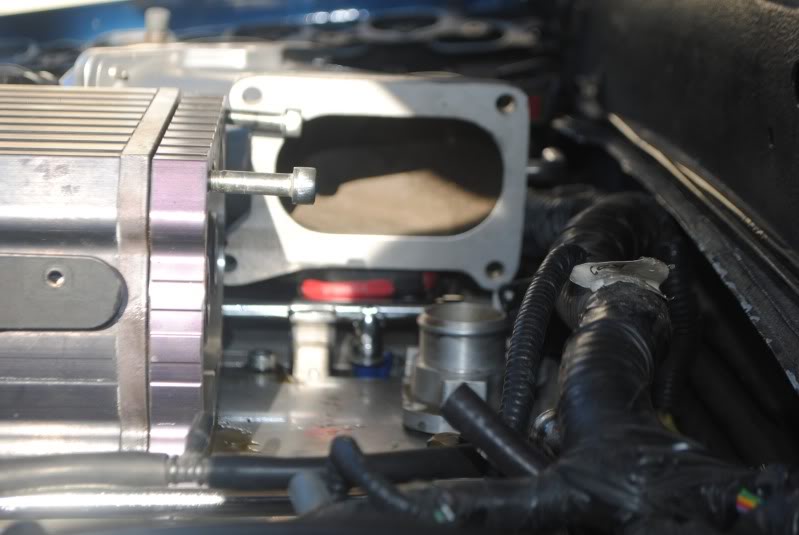

Here's some pics of the mock-up of the inlet elbow and throttle body. The open area behind the blower is what I need to fab up.

I realized that I have a throttle body that can flow over 1600 CFM, but the stock Kenne Bell inlet elbow is only rated at 1000 CFM, so that's my choke point. I'm already planning on putting a 4 1/2 inch tube from a Kenne Bell Mammoth kit from the filter to the throttle body which will take care of everything up to the TB, the goal is to get the rest of the intake up to, or more than, the capacity of the TB.

Thanks to an idea from a friend, and some research online, I'm going to work on creating a sheet metal intake for the back of the Kenne Bell that will be more open and flowing than the KB inlet elbow. I will work on piecing everything together, and then I just have to find someone to weld it together for me. I will also be using the Accufab elbow from the throttle body to the back of the blower since it can already keep up with the CFM of the throttle body.

I'll try to keep everyone updated as I move along through this up until I get the car back to Adam for a new tune with the upgraded inlet and the automatic trans. I'm hoping the extra 600+ CFM will make a significant difference in power.

I've been spending today working on the blower removal and I'm going to prep the sheet metal to cut for the intake.

Here's some pics of the mock-up of the inlet elbow and throttle body. The open area behind the blower is what I need to fab up.