I received another tune revision from Jon Lund and captured some more data. He leaned the air/fuel ratio 20% across the board to get a cleaner reading. The tune is still in open loop mode with the o2 sensors disabled. Although Jon expected the engine to idle this time around, it didn't. So my dad had to manually work the throttle again to keep the engine alive during the data logging session. I was hoping for a successful idle because I'm anxious to get the car on the ground and put load on the engine. I'm starting to wonder if our idle issue isn't tune-related.

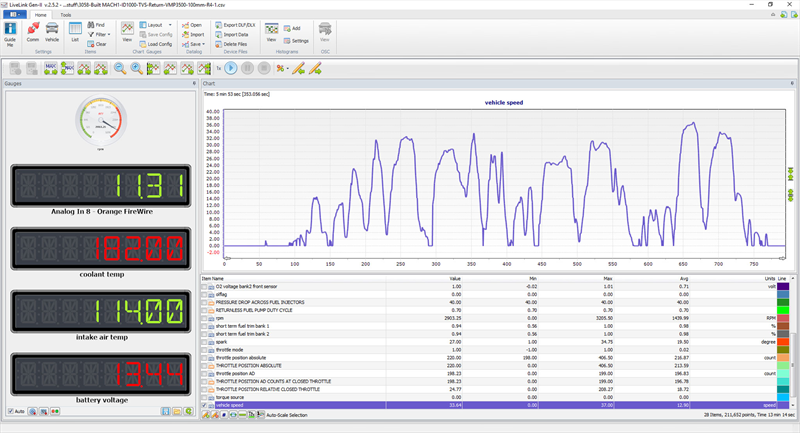

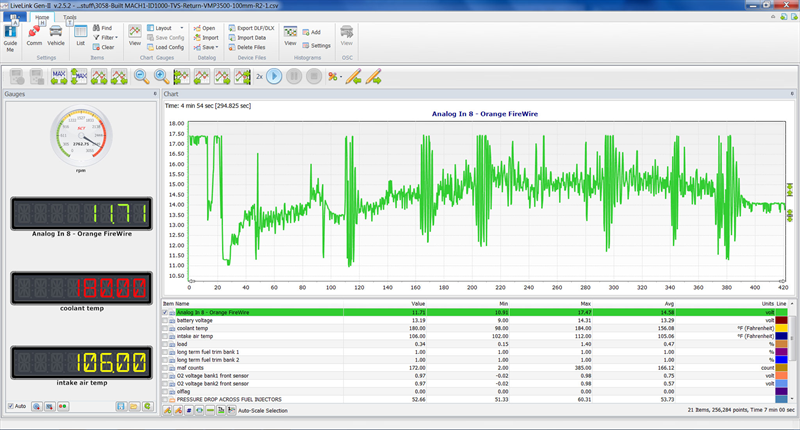

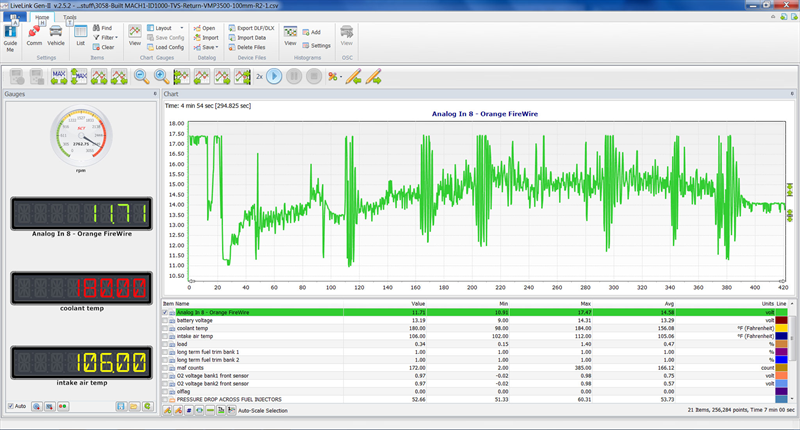

During this latest data logging session, the temperature in our shop was 116°F. I ran my intercooler bilge pump, but left the heat exchanger fans off. With the engine at operating temperature, my IAT2 reading was 106°F. In our first data logging session, I didn't have the intercooler pump or fans running. It was probably 95°F in our shop, and the IAT2 readings reached 140°F. I'm thinking the TigVision kit is pulling its own weight.

Here's a screenshot of my latest data, at a moment of interest. Our RPM here is roughly 2800, although the gauge shows red:

The SCT LiveLink Gen-II software is pretty cool.

I have another leak story, and this time there's actually a leak:

After we completed the 2nd data logging session, we sat down for a beer break. I glanced at the ground under the engine and, sure enough, I saw a small puddle of engine oil amounting to no more than half a shot. When I got under the car to investigate, I found that the bottom-most bolt for the MMR oil adapter plate on the side of the block was mostly covered with oil. Once again, I was disturbed and concerned. I checked the bolt and found it to be fully tightened. I figured if it was a gasket leak behind the plate, there would be oil all over the place. Then I considered that maybe the bolt hole isn't a blind hole in the side of the block, and is allowing oil to work itself down the threads.

I slept on the issue and didn't get much sleep. That night I decided that the leak likely wasn't coming from the oil adapter's bottom-most bolt, as it appeared to be.

The next morning, I was relieved to find that no oil was coming from the driver side valve cover, or the timing cover. Eventually, I found the source of the leak. There's a very small hex plug along an edge of MMR's oil adapter plate, which wasn't fully tightened down and had no thread sealant. After the engine was warm, oil worked its way out of the plug threads and trickled downward towards the bottom-most plate bolt and soaked it. Thankfully it's possible to get to this small plug without removing any of the adapter lines, which is a pain.

I haven't fixed the plug issue yet, but I'm super stoked the oil leak isn't serious.

For the exhaust, I went to two muffler shops and asked about having single slip joints welded into place on our tailpipes, so that we can put the pipes up as separate pieces and work around the welded panhard chassis mount. One guy was polite in turning the job down, and made a few recommendations. The other guy was a dick about it, and was more concerned with offering criticism than listening to my problem.

So we're back to the drawing board on the exhaust, but we'll come up with something.

Let's hope the third tune is a charm with respect to a successful idle!

During this latest data logging session, the temperature in our shop was 116°F. I ran my intercooler bilge pump, but left the heat exchanger fans off. With the engine at operating temperature, my IAT2 reading was 106°F. In our first data logging session, I didn't have the intercooler pump or fans running. It was probably 95°F in our shop, and the IAT2 readings reached 140°F. I'm thinking the TigVision kit is pulling its own weight.

Here's a screenshot of my latest data, at a moment of interest. Our RPM here is roughly 2800, although the gauge shows red:

The SCT LiveLink Gen-II software is pretty cool.

I have another leak story, and this time there's actually a leak:

After we completed the 2nd data logging session, we sat down for a beer break. I glanced at the ground under the engine and, sure enough, I saw a small puddle of engine oil amounting to no more than half a shot. When I got under the car to investigate, I found that the bottom-most bolt for the MMR oil adapter plate on the side of the block was mostly covered with oil. Once again, I was disturbed and concerned. I checked the bolt and found it to be fully tightened. I figured if it was a gasket leak behind the plate, there would be oil all over the place. Then I considered that maybe the bolt hole isn't a blind hole in the side of the block, and is allowing oil to work itself down the threads.

I slept on the issue and didn't get much sleep. That night I decided that the leak likely wasn't coming from the oil adapter's bottom-most bolt, as it appeared to be.

The next morning, I was relieved to find that no oil was coming from the driver side valve cover, or the timing cover. Eventually, I found the source of the leak. There's a very small hex plug along an edge of MMR's oil adapter plate, which wasn't fully tightened down and had no thread sealant. After the engine was warm, oil worked its way out of the plug threads and trickled downward towards the bottom-most plate bolt and soaked it. Thankfully it's possible to get to this small plug without removing any of the adapter lines, which is a pain.

I haven't fixed the plug issue yet, but I'm super stoked the oil leak isn't serious.

For the exhaust, I went to two muffler shops and asked about having single slip joints welded into place on our tailpipes, so that we can put the pipes up as separate pieces and work around the welded panhard chassis mount. One guy was polite in turning the job down, and made a few recommendations. The other guy was a dick about it, and was more concerned with offering criticism than listening to my problem.

So we're back to the drawing board on the exhaust, but we'll come up with something.

Let's hope the third tune is a charm with respect to a successful idle!

Last edited: