Ok picked up a set of MMR's Hurricane Billet oil pump gears when they where having there special promo last month. Let me start this off by saying the only reason why I choose to do these gears now is because I am going FI in the next few weeks.

GENERAL LIST OF TOOLS NEEDED:

CLEAN DRAIN PAN (TO REUSE COOLANT)

DIRTY DRAIN PAN (IF CHANGING ENGINE OIL)

8MM SHALLOW AND DEEP SOCKETS

9MM SHALLOW SOCKET (FOR 1 STUD ON OIL PUMP ASSEMBLY)

10MM SHALLOW AND DEEP SOCKETS

13MM SHALLOW AND DEEP SOCKETS

15MM SHALLOW AND DEEP SOCKETS

18MM 1/2 SOCKET (FOR CRANK PULLEY BOLT)

19MM WRENCH OF SOCKET (FOR RADIATOR COOLANT DRAIN VALVE)

2 OR 3 JAW PULLER (TO REMOVE CRANK PULLEY)

10MM RATCHETING WRENCH

10MM COMBO WRENCH

SMALL-MEDIUM PRY BARS

PLIERS FOR RADIATOR HOSES

VARIOUS PICKS FOR CLIPS

BENDABLE MAGNET

RAZOR BLADE/SCRAPER (FOR SILICONE)

CAULKING GUN (FOR TA-30 SILICONE)

TRIM PANEL TOOL (FOR ALL THE WIRING PUSH PINS)

MMR HARMONIC BALANCER INSTALL BOLT ( FOR $13.99 YOU CANT GO WRONG)

PARTS/MATERIALS NEEDED:

LEFT SIDE FRONT COVER GASKET BR3Z-6020-B

RIGHT SIDE FRONT COVER GASKET BR3Z-6020-D

MIDDLE TOP FRONT COVER GASKET BR3Z-6020-C

RH VALVE COVER GASKET BR3Z-6584-D

LH VALVE COVER GASKET BR3Z-6584-A

FRONT CRANKSHAFT SEAL XW4Z-6700-B

CRANKSHAFT TTY BOLT BR3Z-6A340-A

THERMOSTAT HOUSING O-RING 7T4Z-8590-A

TA-30 SILICONE (THIS WILL BE IN A TUBE FOR A CAULKING GUN)

BRAKE CLEAN

SHOP RAGS

8-8.5 QTS OF OIL

OIL FILTER

PATIENCE

THE START:

20140208_083550 by spaded707, on Flickr

STEP 1:

DISCONNECT BATTERY AND REMOVE BATTERY AND TRAY.

3 8MM BOLTS UNDER BATTERY AND THEN IT COMES OUT.

20140208_084426 by spaded707, on Flickr

STEP 2:

REMOVE UNDERSHIELD AND DRAIN ENGINE COOLANT (19MM DRAIN VALVE)

20140208_084712 by spaded707, on Flickr

20140208_085208 by spaded707, on Flickr

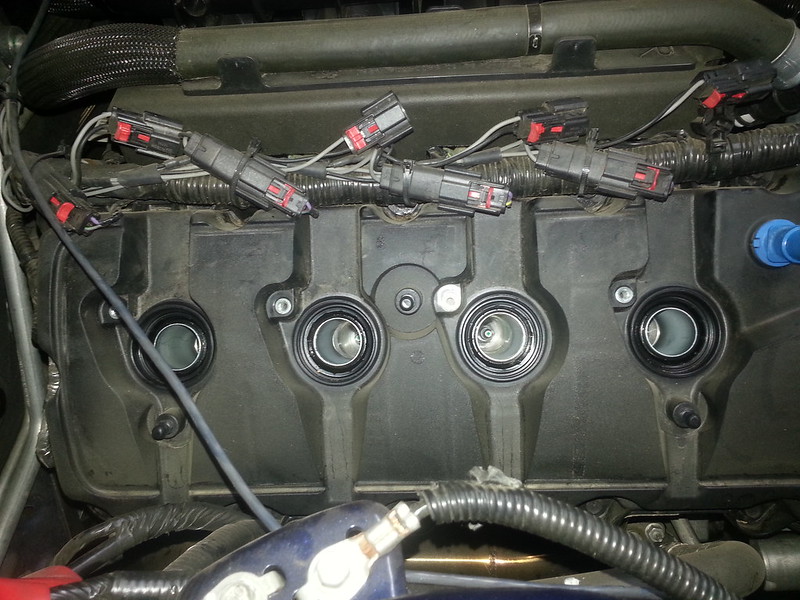

STEP 3:

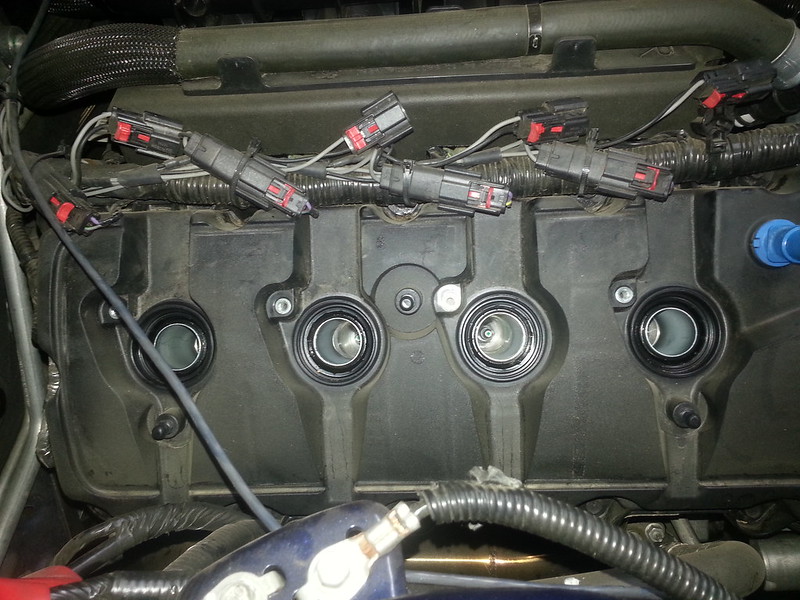

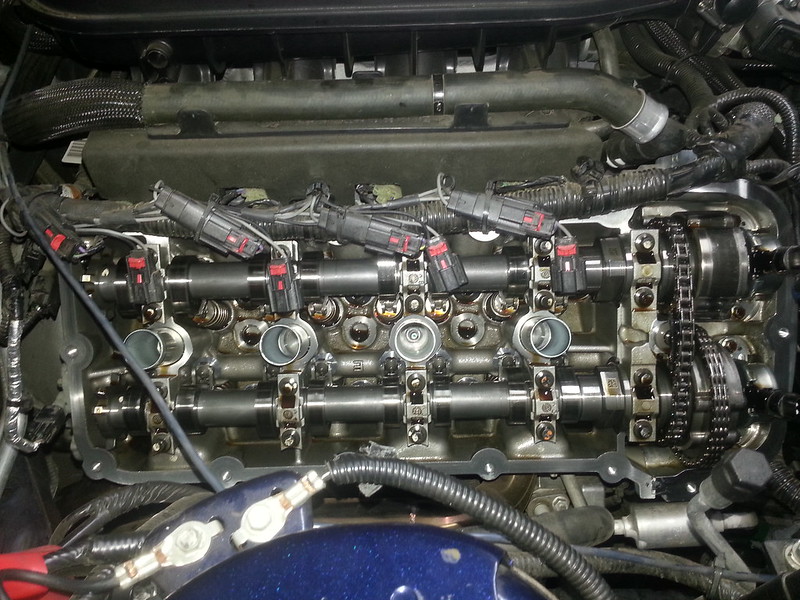

DISCONNECT PCV LINE TO RH VALVE COVER, REMOVE COIL COVER, DISCONNECT BOTH VCT SOLINOIDS ELECTRICAL CONNECTORS, DISCONNECT ALL 4 IGNITION COILS AND ALL 4 8MM BOLTS AND REMOVE ALL 4 IGNITION COILS. THEN REMOVE ALL 14 OF THE 10MM VALVE COVER BOLTS AND REMOVE RH VALVE COVER. (YOU WILL HAVE TO PULL SLIGHTLY HARDER THEN YOU THINK, THE VCT SOLINOID SEALS HOLD THE VALVE COVER ON TIGHT)

20140208_085523 by spaded707, on Flickr

20140208_085652 by spaded707, on Flickr

20140208_085934 by spaded707, on Flickr

20140208_090004 by spaded707, on Flickr

20140208_091157 by spaded707, on Flickr

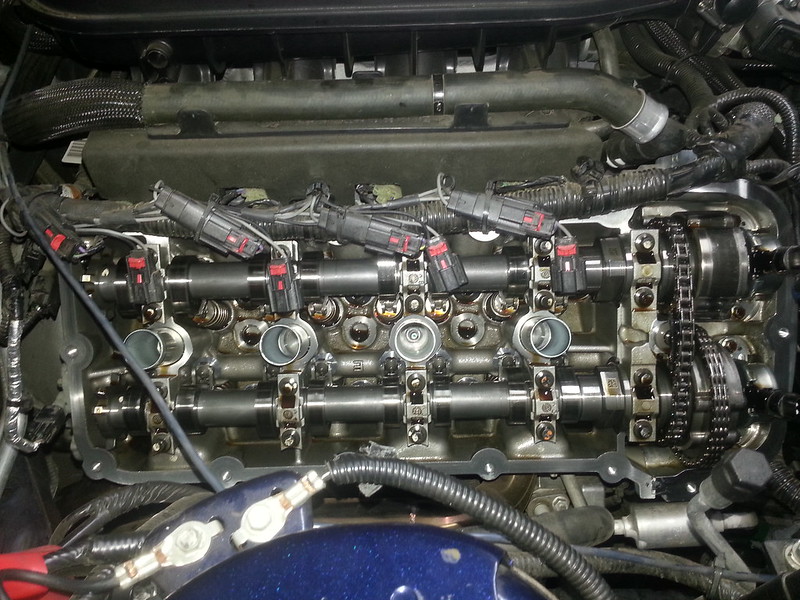

STEP 4:

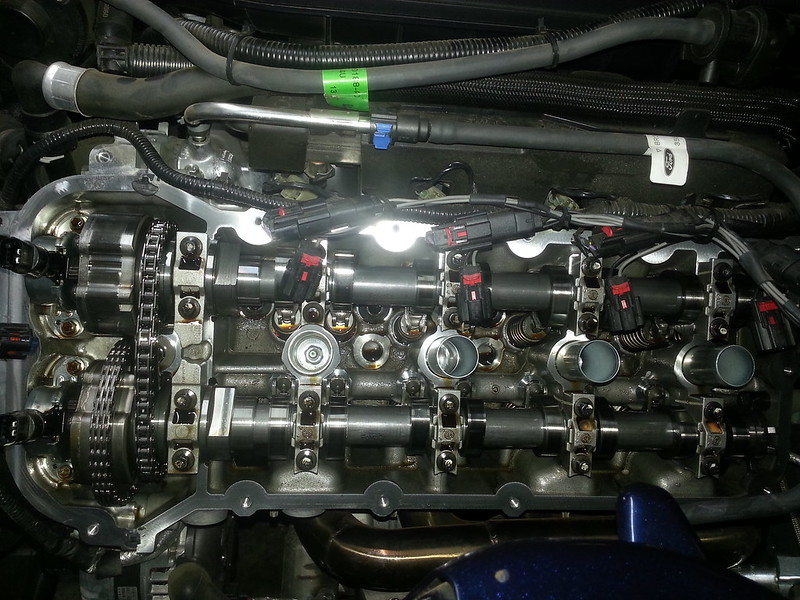

REMOVE AIR INTAKE ASSEMBLY, REMOVE CANISTER PURGE VALVE LINE, REMOVE OIL DIPSTICK, REMOVE BOTH VCT SOLINOIDS ELECTRICAL CONNECTORS, DISCONNECT ALL 4 IGNITION COILS AND ALL 4 8MM BOLTS AND REMOVE ALL 4 IGNITION COILS. THEN REMOVE ALL 14 10MM VALVE COVER BOLTS AND REMOVE LH VALVE COVER. (AGAIN YOU WILL HAVE TO PULL SLIGHTLY HARDER THEN YOU THINK, THE VCT SOLINOID SEALS HOLD THE VALVE COVER ON TIGHT)

20140208_091455 by spaded707, on Flickr

20140208_091505 by spaded707, on Flickr

**WARNING** BE CAREFULLY WHEN PULLING UP LH VALVE COVER THE OIL LEVEL DIPSTICK TUBE IS A BRITTLE PLASTIC AND CAN BREAK.

20140208_093838 by spaded707, on Flickr

STEP 5:

REMOVE OEM TOP RADIATOR SHROUD, REMOVE BOTH 10MM BOLTS FOR DEGAS BOTTLE, REMOVE BOTH SMALLER COOLANT LINES TO DEGAS BOTTLE, REMOVE BOTTOM COOLANT HOSE TO DEGAS BOTTLE. REMOVE DEGAS BOTTLE.

20140208_095252 by spaded707, on Flickr

20140208_095643 by spaded707, on Flickr

20140208_100148 by spaded707, on Flickr

20140208_101226 by spaded707, on Flickr

STEP 6:

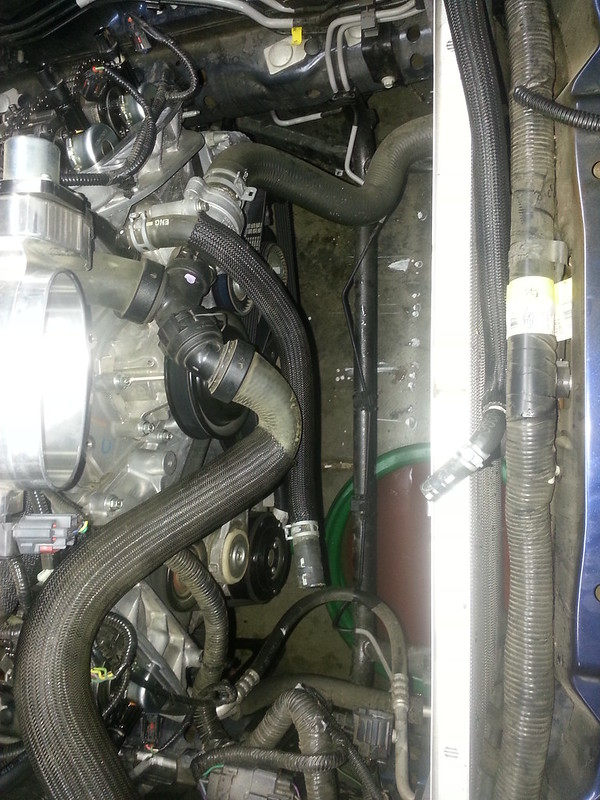

REMOVE THE LH SIDE FRESH AIR FEED 10MM NUT ON COOLING FAN SHROUD, REMOVE 10MM STUD ON LH SIDE AND REMOVE THE 10MM BOLT ON RH SIDE. DISCONNECT COOLING FAN ELECTRICAL CONNECTOR AND REMOVE COOLING FAN MOTOR/SHROUD ASSEMBLY.

STEP 7:

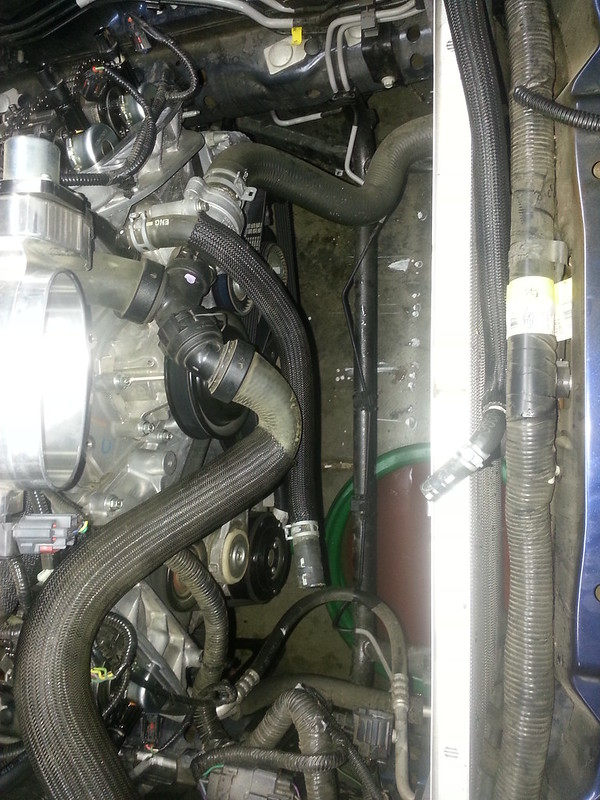

REMOVE WATER PUMP PULLEY 4 10MM'S (USE OF A 3/8 IMPACT GUN HELPS), REMOVE BOTH THE A/C BELT AND LH SIDE BELT, BOTH IDLER'S 13MM'S, REMOVE LH SIDE BELT TENSIONER 13MM. REMOVE 15MM NUT AND 15MM BOLT FOR ALTERNATOR AND PUSH ALTERNATOR TO THE SIDE, REMOVE UPPER RADIATOR HOSE AND DISCONNECT LOWER RADIATOR HOSE ASSEMBLY.

20140208_102525 by spaded707, on Flickr

20140208_102641 by spaded707, on Flickr

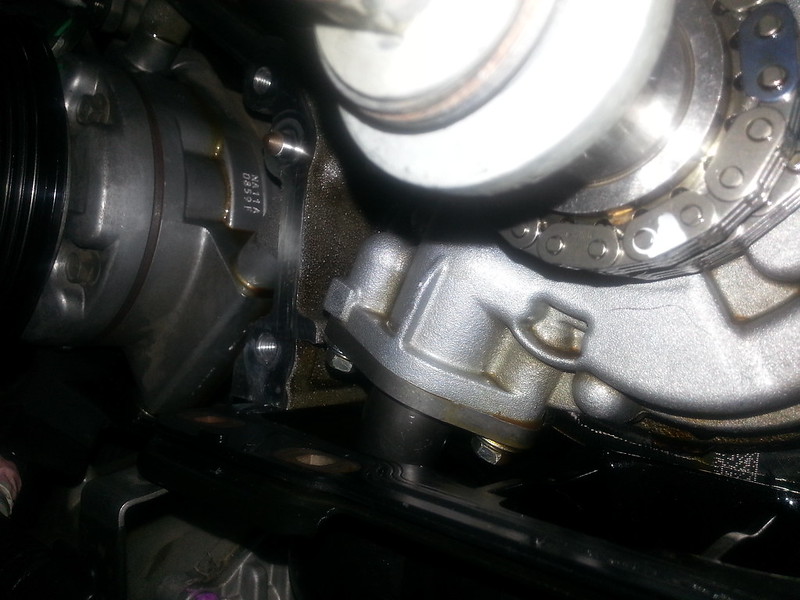

STEP 8:

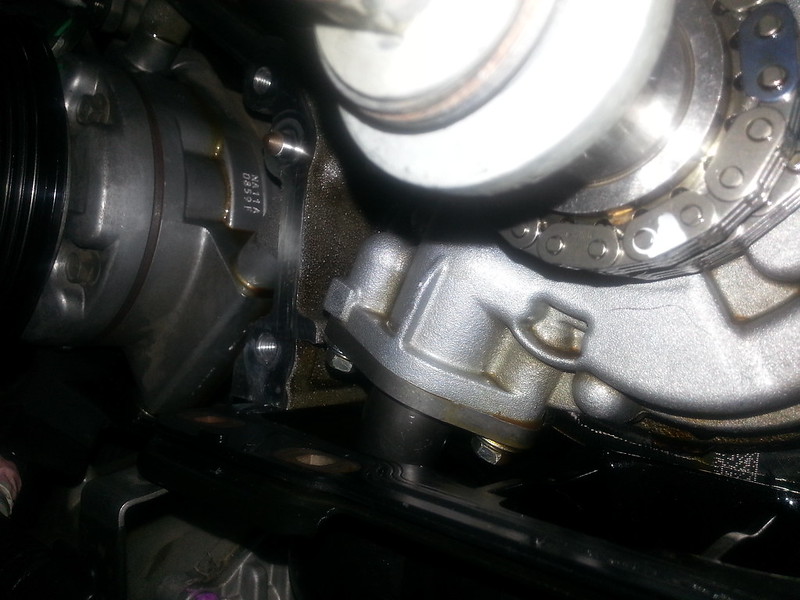

REMOVE 2 8MM BOLTS AND REMOVE THERMOSTAT HOUSEING ASSEMBLY AND REMOVE 4 10MM BOLTS AND REMOVE WATER PUMP ASSEMBLY. (MAKE SURE DRAIN PAN IS POSITIONED UNDER FRONT MIDDLE DUE TO COOLANT BEING BEHIND WATER PUMP).

20140208_102838 by spaded707, on Flickr

20140208_103131 by spaded707, on Flickr

20140208_103702 by spaded707, on Flickr

STEP 9:

REMOVE 18MM BOLT AND SPACER ON CRANKSHAFT PULLEY, USING EITHER A 2 JAW OR 3 JAW PULLER REMOVE CRANKSHAFT PULLEY.

20140208_110458 by spaded707, on Flickr

STEP 10:

FROM UNDER VEHICLE REMOVE THE 2 FRONT STUDS 13MM AND 2 FRONT BOLTS 10MM ON OIL PAN THAT GOES THROUGH TO FRONT ENGINE COVER. REMOVE THE 13 BOLTS AND 2 STUDDED BOLTS ON FRONT COVER MOST 10MM AND SOME 13MM. (UPPER RH SIDE HAS A 10MM NUT HOLDING A GROUND STRAP TO A 13MM STUD) REMOVE FRONT ENGINE COVER.

20140208_113047 by spaded707, on Flickr

20140208_113104 by spaded707, on Flickr

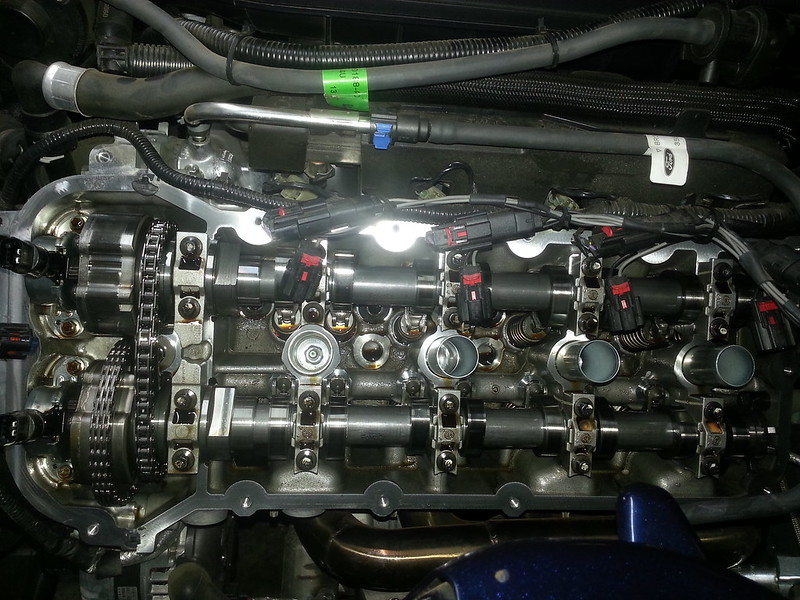

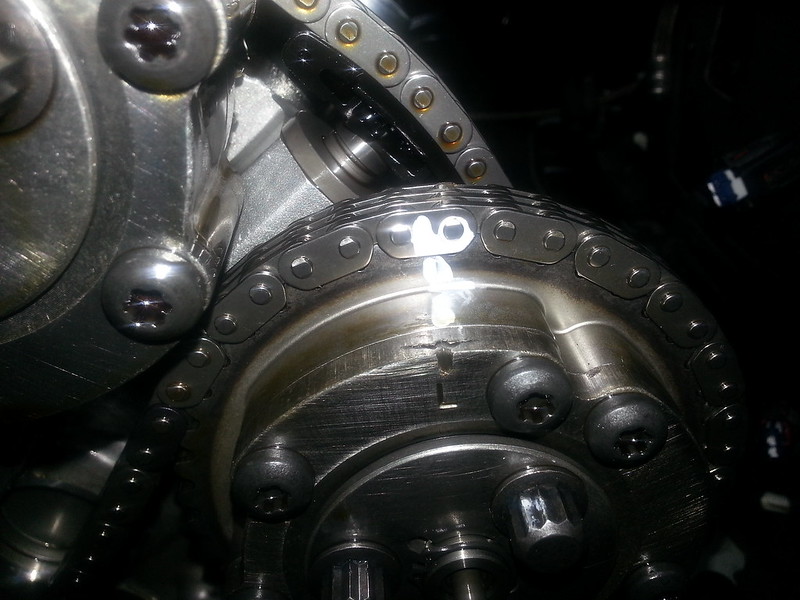

STEP 11: **SETTING UP TIMING TO REMOVE CHAINS**

20140208_114314 by spaded707, on Flickr

1: TURN OVER CRANKSHAFT UNTIL SLOTTED KEYWAY IS AT 12'O CLOCK POSITION.

20140208_121221 by spaded707, on Flickr

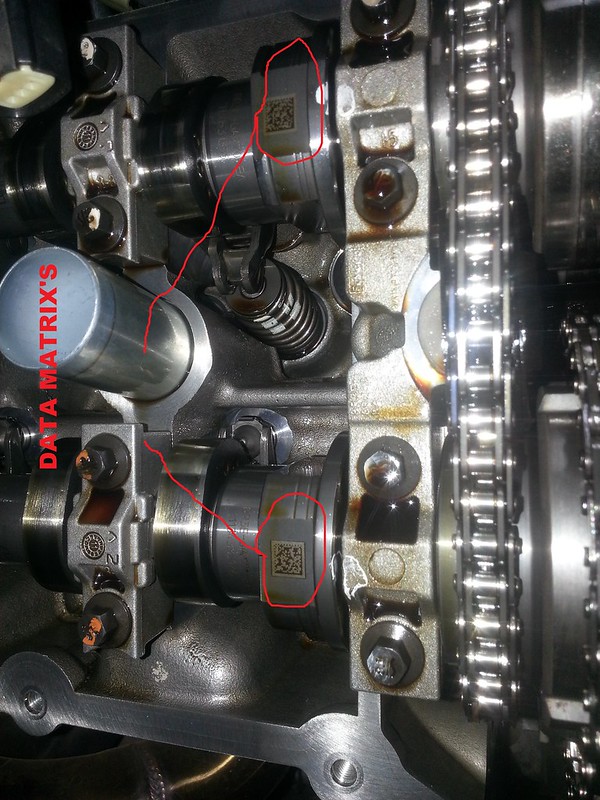

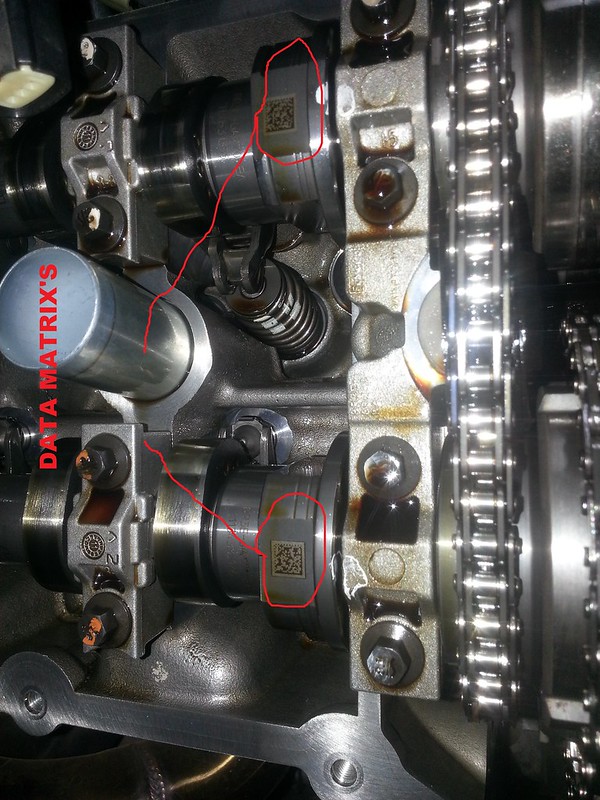

2:VERIFY THAT ON TOP OF ALL 4 CAM SHAFTS THE DATA MATRIX'S ARE FACING UP. (IF NOT THEN ROTATE CRANKSHAFT 1 FULL ROTATION MORE)

20140208_121252 by spaded707, on Flickr

20140208_121300 by spaded707, on Flickr

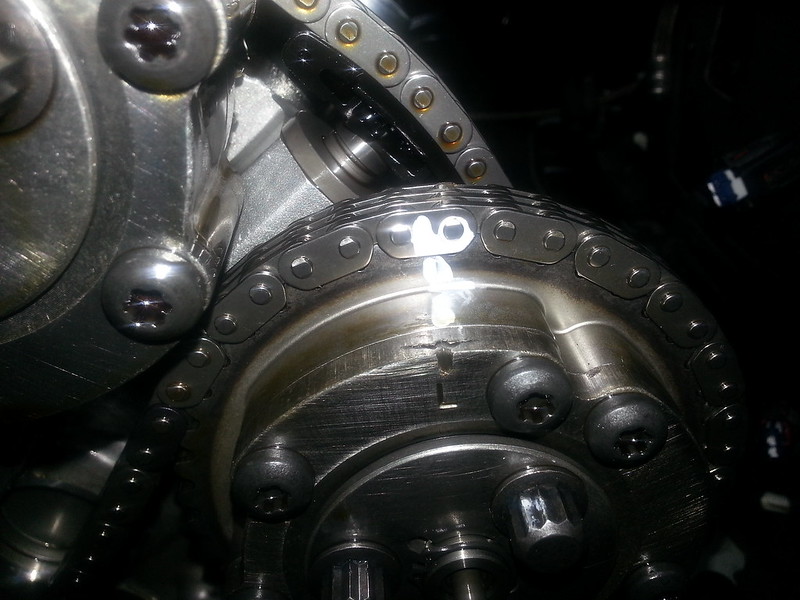

WHAT I DO IS MARK 1 LINK WITH WHITE OUT THAT IS RIGHT WHERE THE R IS ON THE RH SIDE CAM PHASER AND THEN MARK 1 LINK ON THE PART OF THE CHAIN THAT IS ON THE CRANKSHAFT SPROCKET.

20140208_121237 by spaded707, on Flickr

20140208_121244 by spaded707, on Flickr

20140208_122235 by spaded707, on Flickr

3: REMOVE THE 2 10MM BOLTS HOLDING THE RH SIDE CHAIN TENSIONER, REMOVE THE CHAIN TENSIONER AND CHAIN. REMOVE RH TIMING CHAIN TENSIONER ARM AND 1 10MM BOLT FOR TIMING CHAIN GUIDE ON RH SIDE.

20140208_122243 by spaded707, on Flickr

4: NOW ROTATE CRANKSHAFT OVER COUNTERCLOCKWISE SO KEYWAY IS AT 9'O CLOCK POSITION. MARK WITH WHITEOUT ON THE LINK ABOVE THE L ON THE LH CAM PHASER. THEN MARK A LINK ON THE CRANKSHAFT SPROCKET.

5: REMOVE THE 2 10MM BOLTS HOLDING THE LH SIDE CHAIN TENSIONER, REMOVE THE CHAIN TENSIONER AND CHAIN. REMOVE THE LH SIDE TIMING CHAIN TENSIONER ARM AND THE 1 10MM BOLT FOR THE TIMING CHAIN GUIDE ON THE LH SIDE. REMOVE THE CRANKSHAFT SPROCKET.

STEP 12:

NOW REMOVE THE 2 8MM, 1 9MM STUD AND 1 13MM STUD ON THE OIL PUMP ASSEMBLY. REMOVE 2 10MM BOLTS FOR THE OIL PICKUP TUBE ON THE BOTTOM (I USED A COMBO 10MM WRENCH AND A RATCHETING 10MM WRENCH) THE BOTTOM ONE IS THE HARDEST PART OF THIS JOB. I POSITIONED A MAGNET UNDER JUST INCASE THE BOLT DROPPED. NOW REMOVE OIL PUMP ASSEMBLY. (VERIFY THAT ORING FOR OIL PICKUP TUBE IS THERE AND ON THE OIL PICKUP TUBE)

20140208_123058 by spaded707, on Flickr

20140208_124043 by spaded707, on Flickr

20140208_132129 by spaded707, on Flickr

20140208_132135 by spaded707, on Flickr

STEP 13:

NOW REMOVE ALL THE T30 TORX BOLTS ON BACK OF PUMP AND REMOVE OLD OIL PUMP GEARS. COAT NEW GEARS IN OIL. INSTALL INTO HOUSEING WITH MMR LOGO FACING TOWARDS YOU THE INSTALLER. REINSTALL ALL T30 TORX BOLTS BACK ONTO PUMP HOUSEING WITH NEW GEARS INSIDE AND TURN PUMP INSIDE WITH FINGERS TO VERIFY NO BINDING INSIDE OF HOUSEING.

20140208_132146 by spaded707, on Flickr

20140208_132657 by spaded707, on Flickr

20140208_133032 by spaded707, on Flickr

20140208_140731 by spaded707, on Flickr

STEP 14: REINSTALL PUMP BACK ONTO CRANKSHAFT, INSTALL BOTH 10MM BOLTS ON OIL PICKUP, THEN INSTALL BOTH 8MM'S, 1 9MM AND 1 13MM STUD BACK ONTO PUMP. TORQUE SPEC FOR PUMP IS...

Stage 1: Hand tighten.

Stage 2: Tighten the bolt (1) to 10 Nm (89 lb-in), the stud bolt (2) to 25 Nm (18 lb-ft), the bolt (3) to 10 Nm (89 lb-in) and the stud bolt (4) to 20 Nm (177 lb-in).

Stage 3: Tighten the bolt (1) an additional 45 degrees, the stud bolt (2) an additional 75 degrees, the bolt (3) an additional 45 degrees and the stud bolt (4) an additional 60 degrees.

20140208_141952 by spaded707, on Flickr

20140208_142444 by spaded707, on Flickr

20140208_142449 by spaded707, on Flickr

20140208_142457 by spaded707, on Flickr

20140208_145241 by spaded707, on Flickr

20140208_145246 by spaded707, on Flickr

20140208_145257 by spaded707, on Flickr

STEP 15:

THEN REVERSE ORDER OF INSTALLING TIMING COMPONENTS BACK ON.

INSTALL LH SIDE CHAIN BACK ON WITH MATCHING BACK UP MARKED COMPONENTS ON TOP AND BOTTOM.

THEN ROTATE CRANKSHAFT BACK CLOCKWISE SO KEYWAY IS BACK AT 12'O CLOCK POSITION.

THEN REINSTALL RH SIDE TIMING CHAIN AND COMPONENTS, MATCH UP MARKED SPOTS.

**NOTE**

**Compress the primary timing chain tensioner plunger, using an edge of a vise. Using a small screwdriver or pick, push back and hold the ratchet mechanism, then push the ratchet arm back into the tensioner housing. Install a suitable pin into the hole of the tensioner housing to hold the ratchet assembly and plunger in place during installation. **

TORQUE BOTH RH AND LH TIMING CHAIN TENSIONER BOLTS TO 89 INCH POUNDS, TORQUE BOTH 10MM TIMING GUIDE BOLTS TO 89 INCH POUNDS.

STEP 16:

BEFORE INSTALLING FRONT ENGINE COVER MAKE SURE TO TURN ENGINE OVER BY HAND SO IT DOES AT LEAST 4 COMPLETE REVOLUTIONS TO VERIFY NOTHING IS HITTING AND ENGINE TURNS OVER FREELY. (WILL MAKE IT EASY IF SPARK PLUGS ARE ALL REMOVED).

20140208_151636 by spaded707, on Flickr

STEP 17:

INSTALL NEW GASKETS ON FRONT ENGINE COVER AND CLEAN OFF OLD SILICONE. PUT NEW SILICONE ON SPOTS MARKED IN PICTURE BELOW.

20140208_123051 by spaded707, on Flickr

STEP 18:

TORQUE FRONT COVER WITHIN 5 MINS OF APPLYING SILICONE, JUST USE A SORT OF STAR PATTERN ON TORQUING DOWN FRONT COVER.

ALL FRONT ENGINE COVER BOLTS GET TORQUED TO 18 FOOT POUNDS AND THEN AN ADDITIONAL 60DEGREES.

THEN TORQUE THE 2 STUDS AND 2 BOLTS ON THE FRONT OF THE OIL PAN TO 89 INCH POUNDS THEN AN ADDITIONAL 45 DEGREES.

20140208_153402 by spaded707, on Flickr

20140208_162845 by spaded707, on Flickr

STEP 19:

REINSTALL ALTERNATOR ASSEMBLY, CRANKSHAFT PULLEY, IDLER'S, BELT TENSIONER, WATER PUMP ASSEMBLY, THERMOSTAT ASSEMBLY, COOLING FAN ASSEMBLY, SERP BELTS, BOTH RH AND LH VALVE COVERS (DONT FORGET TO PUT SILICONE ON WHERE THE FRONT COVER AND CYLINDER HEAD MEETS BEFORE PUTTING ON THE VALVE COVERS), BATTERY TRAY AND BATTERY, AIR CLEANER ASSEMBLY AND DEGAS BOTTLE AND HOSES.

20140208_162913 by spaded707, on Flickr

20140208_163257 by spaded707, on Flickr

20140208_165508 by spaded707, on Flickr

20140208_170331 by spaded707, on Flickr

20140208_174327 by spaded707, on Flickr

20140208_181026 by spaded707, on Flickr

20140208_184029 by spaded707, on Flickr

OTHER TORQUE SPECS:

ALTERNATOR BOLTS- 35 FOOT POUNDS

IDLERS- 35 FOOT POUNDS

BELT TENSIONER- 35 FOOT POUNDS

WATER PUMP BOLTS- 177 INCH POUNDS THEN ADDITIONAL 60 DEGREES

THERMOSTAT HOUSING BOLTS- 89 INCH POUNDS

VALVE COVER BOLTS- 89 INCH POUNDS

WATER PUMP PULLEY BOLTS- 18 FOOT POUNDS

CRANKSHAFT PULLEY BOLT-

Stage 1: Tighten to 140 Nm (103 lb-ft).

Stage 2: Loosen 360 degrees.

Stage 3: Tighten to 100 Nm (74 lb-ft).

Stage 4: Tighten an additional 90 degrees.

STEP 20:

PERFORM ENGINE OIL AND FILTER CHANGE THEN REFILL AND BLEED COOLANT. I ALSO CRANKED ENGINE OVER A COUPLE TIMES BEFORE STARTING TO MAKE SURE OIL GOT EVERYWHERE FIRST.

20140208_184035 by spaded707, on Flickr

-Thomas

<TABLE id=Table4 cellSpacing=2 cellPadding=1 width=600 align=center> <TBODY> <TR> <TD class=cg_text></TD> <TD class=cg_text></TD></TR></TBODY></TABLE>

GENERAL LIST OF TOOLS NEEDED:

CLEAN DRAIN PAN (TO REUSE COOLANT)

DIRTY DRAIN PAN (IF CHANGING ENGINE OIL)

8MM SHALLOW AND DEEP SOCKETS

9MM SHALLOW SOCKET (FOR 1 STUD ON OIL PUMP ASSEMBLY)

10MM SHALLOW AND DEEP SOCKETS

13MM SHALLOW AND DEEP SOCKETS

15MM SHALLOW AND DEEP SOCKETS

18MM 1/2 SOCKET (FOR CRANK PULLEY BOLT)

19MM WRENCH OF SOCKET (FOR RADIATOR COOLANT DRAIN VALVE)

2 OR 3 JAW PULLER (TO REMOVE CRANK PULLEY)

10MM RATCHETING WRENCH

10MM COMBO WRENCH

SMALL-MEDIUM PRY BARS

PLIERS FOR RADIATOR HOSES

VARIOUS PICKS FOR CLIPS

BENDABLE MAGNET

RAZOR BLADE/SCRAPER (FOR SILICONE)

CAULKING GUN (FOR TA-30 SILICONE)

TRIM PANEL TOOL (FOR ALL THE WIRING PUSH PINS)

MMR HARMONIC BALANCER INSTALL BOLT ( FOR $13.99 YOU CANT GO WRONG)

PARTS/MATERIALS NEEDED:

LEFT SIDE FRONT COVER GASKET BR3Z-6020-B

RIGHT SIDE FRONT COVER GASKET BR3Z-6020-D

MIDDLE TOP FRONT COVER GASKET BR3Z-6020-C

RH VALVE COVER GASKET BR3Z-6584-D

LH VALVE COVER GASKET BR3Z-6584-A

FRONT CRANKSHAFT SEAL XW4Z-6700-B

CRANKSHAFT TTY BOLT BR3Z-6A340-A

THERMOSTAT HOUSING O-RING 7T4Z-8590-A

TA-30 SILICONE (THIS WILL BE IN A TUBE FOR A CAULKING GUN)

BRAKE CLEAN

SHOP RAGS

8-8.5 QTS OF OIL

OIL FILTER

PATIENCE

THE START:

20140208_083550 by spaded707, on Flickr

STEP 1:

DISCONNECT BATTERY AND REMOVE BATTERY AND TRAY.

3 8MM BOLTS UNDER BATTERY AND THEN IT COMES OUT.

20140208_084426 by spaded707, on Flickr

STEP 2:

REMOVE UNDERSHIELD AND DRAIN ENGINE COOLANT (19MM DRAIN VALVE)

20140208_084712 by spaded707, on Flickr

20140208_085208 by spaded707, on Flickr

STEP 3:

DISCONNECT PCV LINE TO RH VALVE COVER, REMOVE COIL COVER, DISCONNECT BOTH VCT SOLINOIDS ELECTRICAL CONNECTORS, DISCONNECT ALL 4 IGNITION COILS AND ALL 4 8MM BOLTS AND REMOVE ALL 4 IGNITION COILS. THEN REMOVE ALL 14 OF THE 10MM VALVE COVER BOLTS AND REMOVE RH VALVE COVER. (YOU WILL HAVE TO PULL SLIGHTLY HARDER THEN YOU THINK, THE VCT SOLINOID SEALS HOLD THE VALVE COVER ON TIGHT)

20140208_085523 by spaded707, on Flickr

20140208_085652 by spaded707, on Flickr

20140208_085934 by spaded707, on Flickr

20140208_090004 by spaded707, on Flickr

20140208_091157 by spaded707, on Flickr

STEP 4:

REMOVE AIR INTAKE ASSEMBLY, REMOVE CANISTER PURGE VALVE LINE, REMOVE OIL DIPSTICK, REMOVE BOTH VCT SOLINOIDS ELECTRICAL CONNECTORS, DISCONNECT ALL 4 IGNITION COILS AND ALL 4 8MM BOLTS AND REMOVE ALL 4 IGNITION COILS. THEN REMOVE ALL 14 10MM VALVE COVER BOLTS AND REMOVE LH VALVE COVER. (AGAIN YOU WILL HAVE TO PULL SLIGHTLY HARDER THEN YOU THINK, THE VCT SOLINOID SEALS HOLD THE VALVE COVER ON TIGHT)

20140208_091455 by spaded707, on Flickr

20140208_091505 by spaded707, on Flickr

**WARNING** BE CAREFULLY WHEN PULLING UP LH VALVE COVER THE OIL LEVEL DIPSTICK TUBE IS A BRITTLE PLASTIC AND CAN BREAK.

20140208_093838 by spaded707, on Flickr

STEP 5:

REMOVE OEM TOP RADIATOR SHROUD, REMOVE BOTH 10MM BOLTS FOR DEGAS BOTTLE, REMOVE BOTH SMALLER COOLANT LINES TO DEGAS BOTTLE, REMOVE BOTTOM COOLANT HOSE TO DEGAS BOTTLE. REMOVE DEGAS BOTTLE.

20140208_095252 by spaded707, on Flickr

20140208_095643 by spaded707, on Flickr

20140208_100148 by spaded707, on Flickr

20140208_101226 by spaded707, on Flickr

STEP 6:

REMOVE THE LH SIDE FRESH AIR FEED 10MM NUT ON COOLING FAN SHROUD, REMOVE 10MM STUD ON LH SIDE AND REMOVE THE 10MM BOLT ON RH SIDE. DISCONNECT COOLING FAN ELECTRICAL CONNECTOR AND REMOVE COOLING FAN MOTOR/SHROUD ASSEMBLY.

STEP 7:

REMOVE WATER PUMP PULLEY 4 10MM'S (USE OF A 3/8 IMPACT GUN HELPS), REMOVE BOTH THE A/C BELT AND LH SIDE BELT, BOTH IDLER'S 13MM'S, REMOVE LH SIDE BELT TENSIONER 13MM. REMOVE 15MM NUT AND 15MM BOLT FOR ALTERNATOR AND PUSH ALTERNATOR TO THE SIDE, REMOVE UPPER RADIATOR HOSE AND DISCONNECT LOWER RADIATOR HOSE ASSEMBLY.

20140208_102525 by spaded707, on Flickr

20140208_102641 by spaded707, on Flickr

STEP 8:

REMOVE 2 8MM BOLTS AND REMOVE THERMOSTAT HOUSEING ASSEMBLY AND REMOVE 4 10MM BOLTS AND REMOVE WATER PUMP ASSEMBLY. (MAKE SURE DRAIN PAN IS POSITIONED UNDER FRONT MIDDLE DUE TO COOLANT BEING BEHIND WATER PUMP).

20140208_102838 by spaded707, on Flickr

20140208_103131 by spaded707, on Flickr

20140208_103702 by spaded707, on Flickr

STEP 9:

REMOVE 18MM BOLT AND SPACER ON CRANKSHAFT PULLEY, USING EITHER A 2 JAW OR 3 JAW PULLER REMOVE CRANKSHAFT PULLEY.

20140208_110458 by spaded707, on Flickr

STEP 10:

FROM UNDER VEHICLE REMOVE THE 2 FRONT STUDS 13MM AND 2 FRONT BOLTS 10MM ON OIL PAN THAT GOES THROUGH TO FRONT ENGINE COVER. REMOVE THE 13 BOLTS AND 2 STUDDED BOLTS ON FRONT COVER MOST 10MM AND SOME 13MM. (UPPER RH SIDE HAS A 10MM NUT HOLDING A GROUND STRAP TO A 13MM STUD) REMOVE FRONT ENGINE COVER.

20140208_113047 by spaded707, on Flickr

20140208_113104 by spaded707, on Flickr

STEP 11: **SETTING UP TIMING TO REMOVE CHAINS**

20140208_114314 by spaded707, on Flickr

1: TURN OVER CRANKSHAFT UNTIL SLOTTED KEYWAY IS AT 12'O CLOCK POSITION.

20140208_121221 by spaded707, on Flickr

2:VERIFY THAT ON TOP OF ALL 4 CAM SHAFTS THE DATA MATRIX'S ARE FACING UP. (IF NOT THEN ROTATE CRANKSHAFT 1 FULL ROTATION MORE)

20140208_121252 by spaded707, on Flickr

20140208_121300 by spaded707, on Flickr

WHAT I DO IS MARK 1 LINK WITH WHITE OUT THAT IS RIGHT WHERE THE R IS ON THE RH SIDE CAM PHASER AND THEN MARK 1 LINK ON THE PART OF THE CHAIN THAT IS ON THE CRANKSHAFT SPROCKET.

20140208_121237 by spaded707, on Flickr

20140208_121244 by spaded707, on Flickr

20140208_122235 by spaded707, on Flickr

3: REMOVE THE 2 10MM BOLTS HOLDING THE RH SIDE CHAIN TENSIONER, REMOVE THE CHAIN TENSIONER AND CHAIN. REMOVE RH TIMING CHAIN TENSIONER ARM AND 1 10MM BOLT FOR TIMING CHAIN GUIDE ON RH SIDE.

20140208_122243 by spaded707, on Flickr

4: NOW ROTATE CRANKSHAFT OVER COUNTERCLOCKWISE SO KEYWAY IS AT 9'O CLOCK POSITION. MARK WITH WHITEOUT ON THE LINK ABOVE THE L ON THE LH CAM PHASER. THEN MARK A LINK ON THE CRANKSHAFT SPROCKET.

5: REMOVE THE 2 10MM BOLTS HOLDING THE LH SIDE CHAIN TENSIONER, REMOVE THE CHAIN TENSIONER AND CHAIN. REMOVE THE LH SIDE TIMING CHAIN TENSIONER ARM AND THE 1 10MM BOLT FOR THE TIMING CHAIN GUIDE ON THE LH SIDE. REMOVE THE CRANKSHAFT SPROCKET.

STEP 12:

NOW REMOVE THE 2 8MM, 1 9MM STUD AND 1 13MM STUD ON THE OIL PUMP ASSEMBLY. REMOVE 2 10MM BOLTS FOR THE OIL PICKUP TUBE ON THE BOTTOM (I USED A COMBO 10MM WRENCH AND A RATCHETING 10MM WRENCH) THE BOTTOM ONE IS THE HARDEST PART OF THIS JOB. I POSITIONED A MAGNET UNDER JUST INCASE THE BOLT DROPPED. NOW REMOVE OIL PUMP ASSEMBLY. (VERIFY THAT ORING FOR OIL PICKUP TUBE IS THERE AND ON THE OIL PICKUP TUBE)

20140208_123058 by spaded707, on Flickr

20140208_124043 by spaded707, on Flickr

20140208_132129 by spaded707, on Flickr

20140208_132135 by spaded707, on Flickr

STEP 13:

NOW REMOVE ALL THE T30 TORX BOLTS ON BACK OF PUMP AND REMOVE OLD OIL PUMP GEARS. COAT NEW GEARS IN OIL. INSTALL INTO HOUSEING WITH MMR LOGO FACING TOWARDS YOU THE INSTALLER. REINSTALL ALL T30 TORX BOLTS BACK ONTO PUMP HOUSEING WITH NEW GEARS INSIDE AND TURN PUMP INSIDE WITH FINGERS TO VERIFY NO BINDING INSIDE OF HOUSEING.

20140208_132146 by spaded707, on Flickr

20140208_132657 by spaded707, on Flickr

20140208_133032 by spaded707, on Flickr

20140208_140731 by spaded707, on Flickr

STEP 14: REINSTALL PUMP BACK ONTO CRANKSHAFT, INSTALL BOTH 10MM BOLTS ON OIL PICKUP, THEN INSTALL BOTH 8MM'S, 1 9MM AND 1 13MM STUD BACK ONTO PUMP. TORQUE SPEC FOR PUMP IS...

Stage 1: Hand tighten.

Stage 2: Tighten the bolt (1) to 10 Nm (89 lb-in), the stud bolt (2) to 25 Nm (18 lb-ft), the bolt (3) to 10 Nm (89 lb-in) and the stud bolt (4) to 20 Nm (177 lb-in).

Stage 3: Tighten the bolt (1) an additional 45 degrees, the stud bolt (2) an additional 75 degrees, the bolt (3) an additional 45 degrees and the stud bolt (4) an additional 60 degrees.

20140208_141952 by spaded707, on Flickr

20140208_142444 by spaded707, on Flickr

20140208_142449 by spaded707, on Flickr

20140208_142457 by spaded707, on Flickr

20140208_145241 by spaded707, on Flickr

20140208_145246 by spaded707, on Flickr

20140208_145257 by spaded707, on Flickr

STEP 15:

THEN REVERSE ORDER OF INSTALLING TIMING COMPONENTS BACK ON.

INSTALL LH SIDE CHAIN BACK ON WITH MATCHING BACK UP MARKED COMPONENTS ON TOP AND BOTTOM.

THEN ROTATE CRANKSHAFT BACK CLOCKWISE SO KEYWAY IS BACK AT 12'O CLOCK POSITION.

THEN REINSTALL RH SIDE TIMING CHAIN AND COMPONENTS, MATCH UP MARKED SPOTS.

**NOTE**

**Compress the primary timing chain tensioner plunger, using an edge of a vise. Using a small screwdriver or pick, push back and hold the ratchet mechanism, then push the ratchet arm back into the tensioner housing. Install a suitable pin into the hole of the tensioner housing to hold the ratchet assembly and plunger in place during installation. **

TORQUE BOTH RH AND LH TIMING CHAIN TENSIONER BOLTS TO 89 INCH POUNDS, TORQUE BOTH 10MM TIMING GUIDE BOLTS TO 89 INCH POUNDS.

STEP 16:

BEFORE INSTALLING FRONT ENGINE COVER MAKE SURE TO TURN ENGINE OVER BY HAND SO IT DOES AT LEAST 4 COMPLETE REVOLUTIONS TO VERIFY NOTHING IS HITTING AND ENGINE TURNS OVER FREELY. (WILL MAKE IT EASY IF SPARK PLUGS ARE ALL REMOVED).

20140208_151636 by spaded707, on Flickr

STEP 17:

INSTALL NEW GASKETS ON FRONT ENGINE COVER AND CLEAN OFF OLD SILICONE. PUT NEW SILICONE ON SPOTS MARKED IN PICTURE BELOW.

20140208_123051 by spaded707, on Flickr

STEP 18:

TORQUE FRONT COVER WITHIN 5 MINS OF APPLYING SILICONE, JUST USE A SORT OF STAR PATTERN ON TORQUING DOWN FRONT COVER.

ALL FRONT ENGINE COVER BOLTS GET TORQUED TO 18 FOOT POUNDS AND THEN AN ADDITIONAL 60DEGREES.

THEN TORQUE THE 2 STUDS AND 2 BOLTS ON THE FRONT OF THE OIL PAN TO 89 INCH POUNDS THEN AN ADDITIONAL 45 DEGREES.

20140208_153402 by spaded707, on Flickr

20140208_162845 by spaded707, on Flickr

STEP 19:

REINSTALL ALTERNATOR ASSEMBLY, CRANKSHAFT PULLEY, IDLER'S, BELT TENSIONER, WATER PUMP ASSEMBLY, THERMOSTAT ASSEMBLY, COOLING FAN ASSEMBLY, SERP BELTS, BOTH RH AND LH VALVE COVERS (DONT FORGET TO PUT SILICONE ON WHERE THE FRONT COVER AND CYLINDER HEAD MEETS BEFORE PUTTING ON THE VALVE COVERS), BATTERY TRAY AND BATTERY, AIR CLEANER ASSEMBLY AND DEGAS BOTTLE AND HOSES.

20140208_162913 by spaded707, on Flickr

20140208_163257 by spaded707, on Flickr

20140208_165508 by spaded707, on Flickr

20140208_170331 by spaded707, on Flickr

20140208_174327 by spaded707, on Flickr

20140208_181026 by spaded707, on Flickr

20140208_184029 by spaded707, on Flickr

OTHER TORQUE SPECS:

ALTERNATOR BOLTS- 35 FOOT POUNDS

IDLERS- 35 FOOT POUNDS

BELT TENSIONER- 35 FOOT POUNDS

WATER PUMP BOLTS- 177 INCH POUNDS THEN ADDITIONAL 60 DEGREES

THERMOSTAT HOUSING BOLTS- 89 INCH POUNDS

VALVE COVER BOLTS- 89 INCH POUNDS

WATER PUMP PULLEY BOLTS- 18 FOOT POUNDS

CRANKSHAFT PULLEY BOLT-

Stage 1: Tighten to 140 Nm (103 lb-ft).

Stage 2: Loosen 360 degrees.

Stage 3: Tighten to 100 Nm (74 lb-ft).

Stage 4: Tighten an additional 90 degrees.

STEP 20:

PERFORM ENGINE OIL AND FILTER CHANGE THEN REFILL AND BLEED COOLANT. I ALSO CRANKED ENGINE OVER A COUPLE TIMES BEFORE STARTING TO MAKE SURE OIL GOT EVERYWHERE FIRST.

20140208_184035 by spaded707, on Flickr

-Thomas

<TABLE id=Table4 cellSpacing=2 cellPadding=1 width=600 align=center> <TBODY> <TR> <TD class=cg_text></TD> <TD class=cg_text></TD></TR></TBODY></TABLE>

Last edited: