When you say writing....you mean copying and pasting.

If you can't figure that out, sorry man.

When you say writing....you mean copying and pasting.

Easy, Easy. I'll stay in my lane. Paste away!

Jordyn Grzelewski

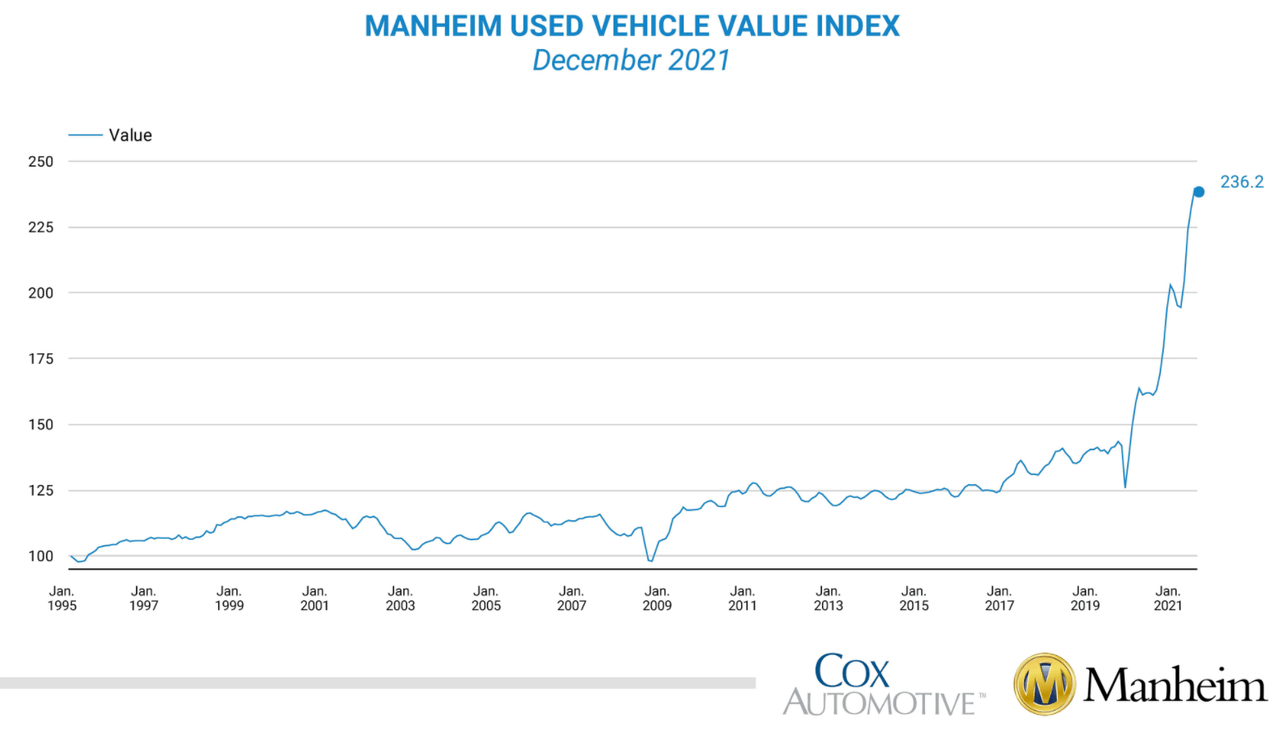

Jordyn Grzelewski2022 is looking to be a continuation of what we saw in 2021, auto production wise due to chip challenges.

It's pretty clear it's going to be well into 2023 AT LEAST before the chip market is back to normal. The demands from 5G, A.I., Automotive, and Machine Learning are just a few of the drivers that are hitting on all cylinders right now.

Anyone have knowledge on wheel hub assy for 2019 and newer f150 4x4?

Cousin has been waiting for months for 2 of them.

Sadly maybeMight have to go salvage hunting.