Anyone have a link to these Sai fuel setups.

Or a way to contact him

PM 04compgt, that's his username here.

Anyone have a link to these Sai fuel setups.

Or a way to contact him

800rwhp +/-. 16.5-17 lbs of boost (VMP Gen2), e85. In-car video in sig w/slip.

This was only the second pass on the new motor, I only have the two so far.. 9.94 and 9.69. They boot me after I get a run so I don't get to tune at the track, and both times I've identified either issues (9.94) or opportunities (9.69) to go faster. With no hardware changes, I think 9.4-9.5 is definitely possible as she sits.

So when is this write up coming Dustin? You're slacking. Lol

See post 44

You use a 13/14 GT500 Hat... As it comes.

I run this style system in my '15, and just upgraded to ID1300 injectors and a VMP BAP that I "de-tuned" to 16.6V.

Works pretty good for me.

Not feeling that froggy lol

Like I said, this is pretty simple. So the details will be minimal, but will include the basics to get 'er done.

13-14 Gt500 parts list

Fuel hat pigtail

Cu2z14s411TA

This is the pig tail for the Gt500 hat. You can run your old yellow power wire from the old pump to one of the new pumps, or use it to trigger the main relay. If you run the yellow wire to the relay, tell your tuner. You do not want varying voltage to a relay requiring 12v.

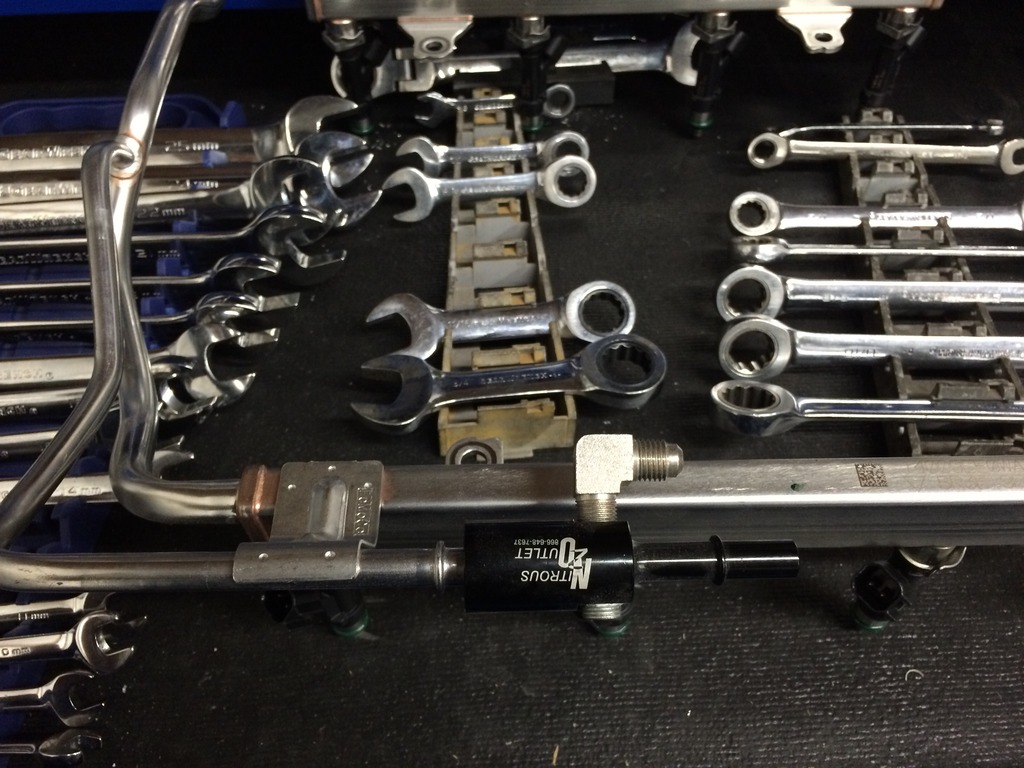

We use a hobb switch for the second pump.

Adapter for return. This is just a nitrous adapter fitting to supply the nitrous kit with fuel. Here we'll use it as a return instead. Let the pump feed the injectors first, and return what is not needed. Feed this return into pretty much any boost referenced regulator. Feed it in the side of the regulator. Then use the return port on the regulator as normal, and run back to tank. There you will have tapped the top of the Gt500 hat for a 90 deg return fitting. I like -6 for the return especially for stock cars so we don't see a fuel pressure spike on shifts:

Fuel line adapter. This is a fitting we use. The factory fuel line is already 3/8 but came w 5/16 on the hat for some reason. The '15's came with 3/8 already so this change isn't needed.

At the end of the fitting you will need to trim a little off the pump side so it till engage the gt500 nipple. The nipple is a bit short compared to the length the fitting needs to grab. You can remove the inner plastic to test fit before putting fitting on.

http://m.ebay.com/itm/Dorman-800-08...el-to-3-8-In-Nylon-T-/161880957126?nav=SEARCH

Fuel line repair tool. This the correct tool to install the fitting. It basically forces the fitting into the nylon hose. If you have a brake line flare tool, you can use the clamp that would normally hold the brake line if you want. Force it on by hand from there. Can't be a crybaby if you want to do it by hand though. Gonna take some force lol

http://m.summitracing.com/parts/rnb-800-301?seid=srese1&gclid=CMCmnuHLmskCFQOUaQodbY8JUA

If you want to get crazy there are things you could do to make this a little better. Could use the original feed as a return, and weld on fittings to the rails and feed them equally.

You can also add a BAP on these for a gt500 if you really want to stretch it. Go forth and use your savings to buy a turbo kit lol. Enjoy ladies. :coolman::thumbsup:

Stock feed with this setup has been proven for nearly 1000rwhp on a TT auto car.

Stock feed with this setup has been proven for nearly 1000rwhp on a TT auto car.

Sooo i'm just trying to wrap my head around this... So one pump will be connected to the one relay like the stock single pump, and run like the stock single pump. And the other will turn on from a direct 12v fused line from the battery off a hobbs switch (once in boost). Am i correct?

Just keep it simple.

Have the pumps come on with key on. Use the key on 12v wire thats going to the factory FPDM as a switch for the relays.