Car has erratic idle and surges while cruising, air fuel ratios are all over the place and so are my fuel trims at idle any ideas would be great guys thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

04 svt po171 and po174 code

- Thread starter cobra21987

- Start date

Car has erratic idle and surges while cruising, air fuel ratios are all over the place and so are my fuel trims at idle any ideas would be great guys thanks

see your a new member this year..welcome

vaccum leak is most common...you might want to list your mods ...

most manuals are written for stock form....some times the changes made to car are the cause,...

was there any other codes ?

i ask because sometimes guys go in to read codes see 5 than clear them before writting them down,,than 1 or 2 come back and they only list those ..

Borla catback exhaust, walbro fuel system from lethal, sra, viper spec tranny, 2.80 upper pulley with 2 pound lower, jlt cai, 2400 big mass sct sensor, 60 pound siemans injectors, spec stage 3 plus clutch, pcv deleted and egr also. Thanks for anyone i really appreciate it

I'd start with the small stuff first. These codes both indicate lean coniditons on bank 1 and 2. So start by cleaning the MAF. It's a good maintenance thing to do anyway, but it may also help resolve your problem.

Also, double check to make sure you don't have any vacuum leaks. You stated you've deleted the PCV and EGR so while messing with all those hoses, one could've been overlooked and left disconnected. Just a thought. Also, were these changes made in the tune also? If not, your Cobra will not like that they were deleted with no changes made in the computer which could bring up the issues you're having.

If those don't fix the issue, try datalogging to see what your fuel pumps and injectors are doing. The problem may be there and datalogging will make it apparent and easier to track down.

Also, double check to make sure you don't have any vacuum leaks. You stated you've deleted the PCV and EGR so while messing with all those hoses, one could've been overlooked and left disconnected. Just a thought. Also, were these changes made in the tune also? If not, your Cobra will not like that they were deleted with no changes made in the computer which could bring up the issues you're having.

If those don't fix the issue, try datalogging to see what your fuel pumps and injectors are doing. The problem may be there and datalogging will make it apparent and easier to track down.

Clean mass air, changed o2s, new iac, new tps, and my fuel trims are all over the place at idle and mass air meter reads 3 volts. The pcv And egr were deleted in the tune. It is driving me crazy not knowing what it is

It has to be something major to run the way you are describing. A small Vac leak wont effect it that much.

Sounds like you may have dropped a fuel pump. That or you have a huge vaccum leak somewhere. Thats easy to check for. Get some ether and start spraying all the main vaccum hoses. It doesnt take alot. If the engine revs up you found it. Id do this before moving any further.

Sounds like you may have dropped a fuel pump. That or you have a huge vaccum leak somewhere. Thats easy to check for. Get some ether and start spraying all the main vaccum hoses. It doesnt take alot. If the engine revs up you found it. Id do this before moving any further.

It has to be something major to run the way you are describing. A small Vac leak wont effect it that much.

Sounds like you may have dropped a fuel pump. That or you have a huge vaccum leak somewhere. Thats easy to check for. Get some ether and start spraying all the main vaccum hoses. It doesnt take alot. If the engine revs up you found it. Id do this before moving any further.

Good advice. I'd also like to add that a MAF reading of 3 volts at idle is a clue. I believe you have unmetered air entering the induction system causing a lean condition.

Check the MAF with key on engine off. If it still reads 3 volts that could be your problem.

did you have the car tuned for the new pumps? my buddy had a simular problem and the fuel pump tables in the tune were wrong when he changed to the gt pumps.

Yea i had it tuned with all the mods i have on it and when i got the car back it ran awesome. Then half way through the summer it just gradually got worse. I am getting them lean codes but im definately not running lean lol my gas mileage sucks ass. I tryed the carb spray but nothing found. Could i have a leaky injector maybe our a exhaust leak. My boost guage is all over for vacuum anywhere from 22 to 28 at idle certain days are different i dont understand someone please help lol its driving me insane. Thanks

My buddy has a snap on scanner and we looked at the fuel trims at idle and there all over the place

i would do a compression check,,,,its free and will tell alot

how do i find out if it is a exhaust leak for sure

how do i find out if it is a exhaust leak for sure

for an exhaust leak to be bank 1 and bank 2 it would be noticeable..

have you done anything to fix the 3v at maf first?

how would i fix it to make it have more volts

start with just reading first..are you sure po171/174 were the only codes?

does this snap-on scanner do a engine running test?

what does it say for fuel trims at idle...stuck on +25? or -25?...

maf? have you rechecked connection? did you do a wiggle test while watching volts to see a change?

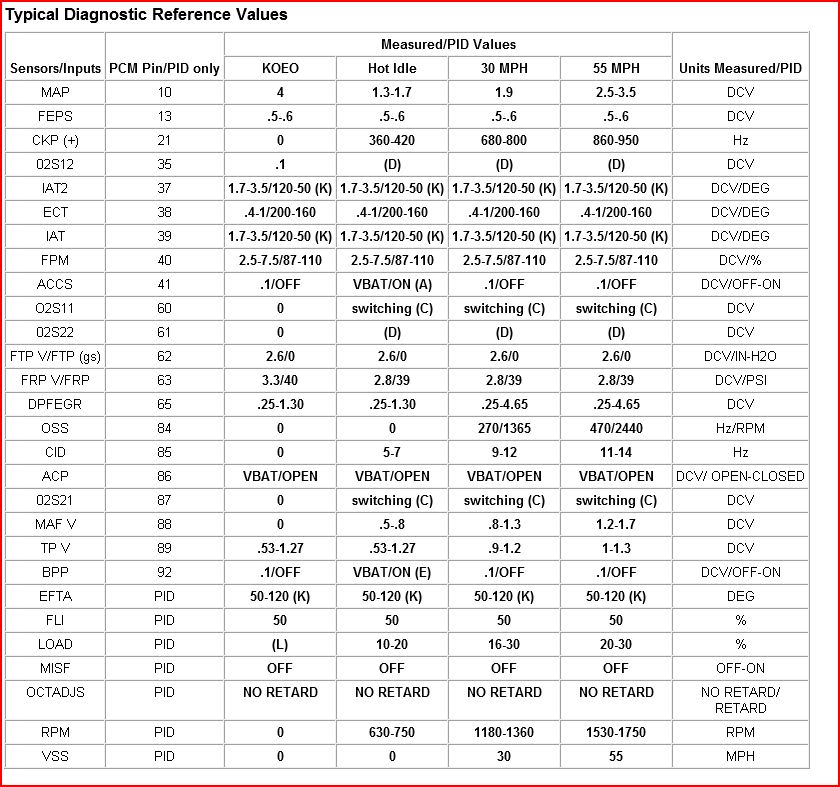

heres from manual

2003 PCED OBD SECTION 2: Diagnostic Methods

Procedure revision date: 12/19/2002

--------------------------------------------------------------------------------

Adaptive Fuel DTCs Diagnostic Techniques

Adaptive Fuel DTCs Diagnostic Techniques help isolate the root cause of the adaptive fuel concern. Before proceeding, attempt to verify if any driveability concerns are present. These diagnostic aids are meant as a supplement to the pinpoint test steps in Section 5. For a description of fuel trim, refer to Section 1 , Powertrain Control Software, Fuel Trim.

Obtain Freeze Frame Data

Freeze Frame Data can be helpful in duplicating and diagnosing adaptive fuel concerns. This data (a snapshot of certain PID values, recorded at the time the DTC was stored in Continuous Memory) is helpful to determine how the vehicle was being driven when the fault occurred, and can be especially useful on intermittent concerns. Freeze Frame Data, in many cases, can help to isolate possible areas of concern as well as rule out others. Refer to Freeze Frame Data in this section for a more detailed description of this data.

Using the LONGFT1 and LONGFT2 (dual bank engines) PIDs

The LONGFT1/2 PIDs can be useful for diagnosing fuel trim concerns. A negative PID value indicates that fuel is being reduced to compensate for a rich condition, while a positive PID value indicates that fuel is being increased to compensate for a lean condition. It is important to know that there is a separate LONGFT value that is used for each rpm/load point of engine operation. When viewing the LONGFT1/2 PIDs, the values may change a great deal as the engine is operated at different rpm and load points. This is because the fuel system may have learned corrections for fuel delivery concerns that can change as a function of engine rpm and load. The LONGFT1/2 PIDs will display the fuel trim currently being used at that rpm and load point. Observing these changes in LONGFT1/2 can help when diagnosing fuel system concerns. For example:

A contaminated MAF sensor would result in matching LONGFT1/2 correction values that are negative at idle (reducing fuel), but positive (adding fuel) at higher rpm and loads.

LONGFT1 values that differ greatly from LONGFT2 values would rule out concerns that are common for both banks (for example, fuel pressure concerns, MAF sensor, etc. could be ruled out).

Vacuum leaks would result in large rich corrections (positive LONGFT1/2 value) at idle, but little or no correction at higher rpm and loads.

A plugged fuel filter will result in no correction at idle, but large rich corrections (positive LONGFT1/2 value) at high rpm and load.

Resetting Long Term Fuel Trims

Long term fuel trim corrections can be reset by resetting the PCM Keep Alive Memory (KAM). Refer to Resetting Keep Alive Memory in this section to reset KAM. After making a fuel system repair, KAM must be reset. For example, if dirty/plugged injectors cause the engine to run lean and generate rich long term corrections, replacing the injectors and not resetting KAM will now make the engine run very rich. The rich correction will eventually be "learned out" during closed loop operation, but the vehicle may have poor driveability and have high CO emissions while it is learning.

P0171/P0174 System Too Lean Diagnostic Aids

Note: If the system is lean at certain conditions, then the LONGFT PID would be a positive value at those conditions, indicating that increased fuel is needed.

The ability to identify the type of lean condition causing the concern can be crucial to a correct diagnosis.

Air Measurement System:

With this condition, the engine may actually run rich or lean of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. One possibility is that the mass of air entering the engine is actually greater than what the MAF sensor is indicating to the PCM. For example, with a contaminated MAF sensor, the engine would run lean at higher rpm because the PCM would deliver fuel for less air than is actually entering the engine.

Examples: MAF sensor measurement inaccurate (corroded connector, contamination/dirty (a contaminated MAF sensor will typically result in a rich system at low airflows (PCM will reduce fuel) and a lean system at high airflows (PCM will increase fuel), etc).

Vacuum Leaks/Unmetered Air:

With this condition, the engine may actually run lean of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. This condition can be caused by unmetered air entering the engine, or due to a MAF malfunction. In this situation, the volume of air entering the engine is actually greater than what the MAF sensor is indicating to the PCM. Vacuum leaks will normally be most apparent when high manifold vacuum is present (for example, during idle or light throttle). If freeze frame data indicates that the fault occurred at idle, a check for vacuum leaks/unmetered air might be the best starting point.

Examples: Loose, leaking or disconnected vacuum lines, intake manifold gaskets or o-rings, throttle body gaskets, brake booster, air inlet tube, stuck/frozen/aftermarket PCV valve, unseated engine oil dipstick, etc.

Insufficient Fueling:

With this condition, the engine may actually run lean of stoichiometry (14.7:1 air/fuel ratio) if the PCM is not able to compensate enough to correct for the condition. This condition can be caused by a fuel delivery system concern that restricts or limits the amount of fuel being delivered to the engine. This condition will normally be most apparent when the engine is under a heavy load and at high rpm, when a higher volume of fuel is required. If freeze frame data indicates that the fault occurred under a heavy load and at higher rpm, a check of the fuel delivery system (checking fuel pressure with engine under a load) might be the best starting point.

Examples: low fuel pressure (fuel pump, fuel filter, fuel leaks, restricted fuel supply lines), fuel injector concerns, etc.

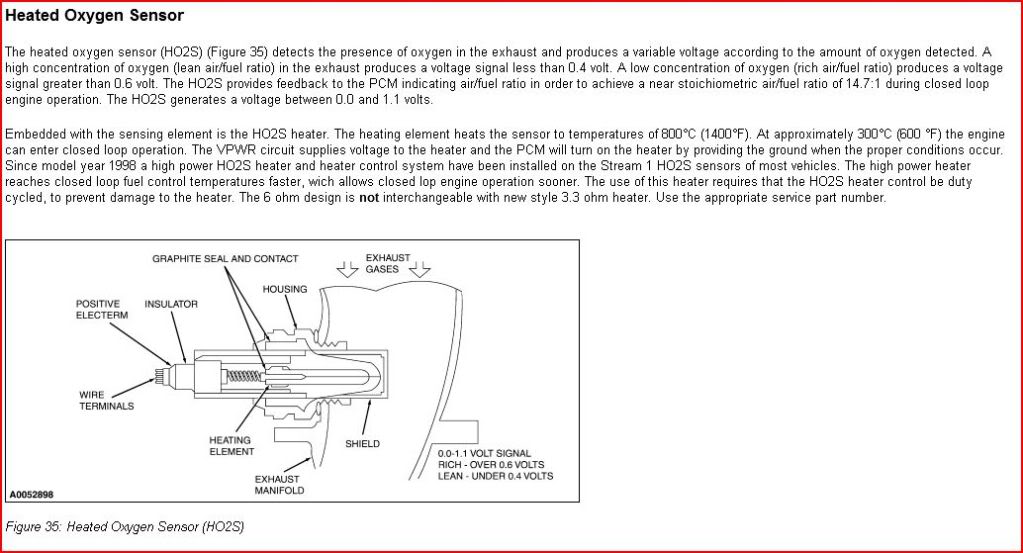

Exhaust System Leaks:

In this type of condition, the engine may actually be running rich of stoichiometry (14.7:1 air / fuel ratio) because the fuel control system is adding fuel to compensate for a perceived (not actual) lean condition. This condition is caused by oxygen (air) entering the exhaust system from an external source. The HO2S will react to this exhaust leak by increasing fuel delivery. This condition will cause the exhaust gas mixture from the cylinder to be rich.

Examples: Exhaust system leaks upstream or near HO2S, poorly welded/leaking HO2S boss, malfunctioning Secondary Air Injection system, etc.

P0172/P0175 System Too Rich Diagnostic Aids

Note: If the system is rich at certain conditions, then the LONGFT PID would be a negative value at that airflow, indicating that decreased fuel is needed.

System rich concerns are usually caused by fuel system concerns, although the MAF sensor, and base engine (for example, engine oil contaminated with fuel) should also be checked.

Air Measurement System:

With this condition, the engine may actually run rich or lean of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. One possibility is that the mass of air entering the engine is actually less than what the MAF sensor is indicating to the PCM. For example, with a contaminated MAF sensor, the engine would run rich at idle because the PCM would deliver fuel for more air than is actually entering the engine.

Examples: MAF sensor measurement inaccurate (corroded connector, contamination/dirty (a contaminated MAF sensor will typically result in a rich system at low airflows (PCM will reduce fuel) and a lean system at high airflows (PCM will increase fuel), etc.).

Fuel System:

With this condition, the engine may actually run rich of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. This situation can be caused by a fuel delivery system that is delivering excessive fuel to the engine.

Examples:

Fuel pressure regulator causes excessive fuel pressure (system rich at all airflows)(fuel pressure can be intermittent, going to pump deadhead pressure, then returning to normal after engine is turned off then restarted).

Fuel pressure regulator vacuum hose off (causes excessive fuel pressure at idle, system rich at idle airflows).

Fuel pressure regulator diaphragm ruptured (fuel leaking into intake manifold, system rich at lower airflows).

Fuel return line crimped/damaged (fuel pressure high, system rich at lower airflows).

Fuel injector leaks (injector delivers extra fuel).

EVAP canister purge valve leak (if canister is full of vapors, introduces extra fuel).

Fuel rail pressure sensor (electronic returnless fuel systems) concern causes sensor to indicate lower pressure than actual. PCM commands higher pressure to the fuel pump driver module (FPDM), causing high fuel pressure (system rich at all airflows).

Base Engine

Engine oil contaminated with fuel can contribute to a rich running engine.

--------------------------------------------------------------------------------

2003 PCED OBD SECTION 5: Pinpoint Tests

Procedure revision date: 08/19/2002

--------------------------------------------------------------------------------

DC: Mass Air Flow (MAF) Sensor DC: Introduction

--------------------------------------------------------------------------------

DC1 DTC P1101: CHECK FOR MAF SENSOR CONTINUOUS MEMORY DTCs

Drive vehicle for 6 to 10 minutes.

Rerun KOER, KOEO Self-Test and retrieve Continuous Memory DTCs.

Is a Continuous Memory DTC present with the KOER DTC P1101?

Yes No

For Continuous Memory DTC P0102:

GO to DC2 .

For Continuous Memory DTC P0103:

GO to DC20 .

All other Continuous Memory DTCs:

GO to Section 4, Powertrain Diagnostic Trouble Code (DTC) Charts . KEY OFF. GO to DC3 .

DC2 DTC P0102: CHECK MAF SENSOR SIGNAL LOW INPUT TO PCM

Check for broken/loose air outlet tube clamps (throttle body and air cleaner assembly ends), cracks/holes in air outlet tube, worn gaskets between MAF sensor and air cleaner assembly. Verify MAF sensor is connected. Repair as necessary.

Start engine and bring to idle.

If a KOER DTC P0505 is present, go to Section 4, Powertrain Diagnostic Trouble Code (DTC) Charts . For A/T vehicles, if the engine stalls and cannot maintain an idle, GO to DC7 .

Run engine up 1500 rpm for 5 seconds, then bring it back to idle.

Access MAF V PID.

Is MAF V PID less than 0.23 volt?

Yes No

KEY OFF. GO to DC4 . KEY OFF. GO to DC3 .

DC3 DTC P1101: CHECK FOR MAF SENSOR SIGNAL OUT OF SELF-TEST RANGE

Note: DTC P1101 can be generated by a low charged vehicle battery or the garage exhaust ventilation system. Repair battery as necessary. Then remove ventilation system and properly vent to outside atmosphere. Rerun KOEO Self-Test.

Verify MAF sensor is connected. If not, repair as necessary.

Key on, engine running.

Access MAF V PID.

Is MAF V PID between 0.46-2.44 volts?

Yes No

Unable to identify fault at this time. GO to Z1 . KEY OFF. GO to DC4 .

DC4 CHECK VPWR VOLTAGE TO MAF SENSOR

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Disconnect MAF sensor.

Key on, engine off.

Measure voltage between VPWR circuit at the MAF sensor harness connector and battery negative post.

Is voltage greater than 10.5 volts?

Yes No

GO to DC5 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC5 CHECK PWR GND CIRCUIT TO MAF SENSOR

Measure voltage between PWR GND circuit at the MAF sensor harness connector and battery positive post.

Is voltage greater than 10.0 volts?

Yes No

KEY OFF. GO to DC6 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC6 CHECK MAF CIRCUIT SHORT TO PWR GND OR MAF RTN IN THE HARNESS

PCM disconnected.

Disconnect scan tool from DLC.

Measure resistance between MAF and PWR GND circuits at the MAF sensor harness connector.

Measure resistance between MAF and MAF RTN circuits at the MAF sensor harness connector.

Is each resistance greater than 10,000 ohms?

Yes No

GO to DC7 . REPAIR short circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC7 CHECK MAF RTN CIRCUIT SHORT TO PWR GND IN THE HARNESS

Measure resistance between MAF RTN and PWR GND circuits at the MAF sensor harness connector.

Is the resistance greater than 10,000 ohms?

Yes No

GO to DC8 . REPAIR short circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC8 CHECK MAF CIRCUIT FOR SHORT TO PWR GND IN THE PCM

Reconnect PCM.

Measure resistance between MAF and PWR GND circuits at the MAF sensor harness connector.

Is the resistance greater than 10,000 ohms?

Yes No

RECONNECT scan tool to DLC. GO to DC9 REPLACE PCM (refer to Section 2, Flash Electrically Erasable Programmable Read Only Memory (EEPROM) ).

DC9 CHECK MAF CIRCUIT VOLTAGE CYCLING INTEGRITY

Key on, engine off.

Access MAF V PID.

Record the MAF V PID reading.

Jumper MAF RTN and PWR GND circuits at the MAF sensor harness connector.

Jumper MAF and VPWR circuits at the MAF sensor harness connector.

Does the MAF V PID change from less than 0.23 volt (closer to zero volts) to greater than 4.50 volts?

Yes No

REPLACE MAF sensor. RESET Keep Alive Random Access Memory (RAM)(REFER to Section 2, Powertrain Control Module (PCM) Reset ). For DTC P1101 without P0102 present:

KEY OFF. GO to DC11 .

For DTC P0102:

KEY OFF. GO to DC10 .

DC10 CHECK MAF CIRCUIT FOR OPEN IN HARNESS

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Disconnect PCM.

Measure resistance of MAF circuit between PCM harness connector pin and MAF sensor harness connector.

Is resistance less than 5.0 ohms?

Yes No

GO to DC11 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC11 CHECK PWR GND CIRCUIT FOR OPEN IN HARNESS

PCM disconnected.

Disconnect scan tool from DLC.

Measure resistance of PWR GND circuit between MAF sensor harness connector and battery negative post.

Is resistance less than 10 ohms?

Yes No

RECONNECT scan tool. GO to DC12 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC12 CHECK MAF RTN FOR OPEN IN HARNESS

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Measure resistance of MAF RTN circuit between PCM harness connector pin and MAF sensor harness connector.

Is resistance less than 5.0 ohms?

Yes No

REPLACE PCM (refer to Section 2, Flash Electrically Erasable Programmable Read Only Memory (EEPROM) ). REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC16 DTC P1100: CHECK MAF CIRCUIT FOR INTERMITTENT VOLTAGE TO PCM

Start engine and bring it to idle.

If idle is not stable, GO to Section 3 , Symptom Charts.

Run throttle up to 1500 rpm for 5 seconds, and bring back to idle.

Access MAF V PID.

Lightly tap on MAF sensor and wiggle harness connector to simulate road shock.

Is MAF V PID changing below the minimum 0.23 volt or above a maximum 4.60 volts?

Yes No

INSPECT MAF sensor connector. If OK, REPLACE the MAF sensor. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ). GO to DC17 .

DC17 CHECK FOR MAF SENSOR CIRCUIT FOR INTERMITTENT OPENS OR SHORTS

Key on, engine running.

Again access the MAF V PID.

Complete the following:

Grasp the MAF sensor harness and MAF sensor harness connector.

Wiggle, shake and bend the harness from the MAF sensor to the PCM.

Is the MAF V PID reading changing below the minimum 0.23 volt or above the maximum 4.60 volts?

Yes No

REPAIR as necessary. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ). Unable to duplicate or identify fault at this time. GO to Z1 .

DC20 DTC P0103: CHECK MAF SENSOR SIGNAL HIGH INPUT TO PCM

Note: DTC P0103 can be generated by foreign material blocking the MAF sensor screen causing an air flow restriction. If contaminants are found on the screen, check air cleaner element installation in air cleaner housing and proper sealing of air cleaner and air tubes before proceeding. Rerun Quick Test after service.

Start engine and bring to idle.

If a KOER DTC P0505 is present, GO to Section 4, Powertrain Diagnostic Trouble Code (DTC) Charts .

Run throttle up to 1500 rpm for 5 seconds, and bring it back to idle.

Note: MAF V PID is greater than 4.60 volts.

Access MAF V PID.

Key off.

Disconnect MAF sensor.

Jumper PWR GND and MAF RTN circuits at the MAF sensor harness connector.

Key on, engine running.

Again access MAF V PID.

Did MAF V PID drop from the original reading to below 0.23 volt?

Yes No

REMOVE jumper. REPLACE MAF sensor. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ). KEY OFF. REMOVE jumper. GO to DC21 .

DC21 CHECK MAF CIRCUIT FOR SHORT TO VPWR IN HARNESS

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Disconnect PCM.

Key on, engine off.

Measure voltage between MAF and PWR GND circuits at the PCM harness connector.

Is voltage less than 1.0 volt?

Yes No

If an idle concern is not present:

REPLACE PCM (refer to Section 2, Flash Electrically Erasable Programmable Read Only Memory (EEPROM) ).

If a fault was not detected and an idle concern is still present:

Disregard DTC P0102 at this time. RETURN to Section 3 , Symptom Charts. REPAIR short circuit.

DC25 DTC P0171, P0172, P0174, P0175, P1131, P1132, P1151, P1152, P1130, P1150, P2195, P2196, P2197, P2198 OR LEAN DRIVEABILITY CONCERNS: CHECK CONDITIONS RELATED TO MAF SENSOR

Note: Most weather service reports are a local barometric pressure that has been corrected to sea level. However, the BARO PID reports the actual barometric pressure for the altitude the vehicle is being diagnosed in. Local weather conditions (high or low pressure areas) will change the local barometric pressure by several inches of mercury [+/- 3 Hz. (+/- 1 in.Hg.)].

Verify the MAF sensor is connected. If not, repair as necessary.

Key on, engine running.

Access the BARO, LONGFT1, LONGFT2 and MAF V PIDs on fully warmed-up engine.

Check that the BARO PID is approximately the same as the barometric pressure reading for the location, day and altitude the vehicle is being diagnosed at.

BARO PID values in Keep Alive Memory require updating at high throttle openings. If vehicle is driven down from higher altitudes for diagnosing, complete three or four heavy accelerations at greater than half-throttle to allow BARO PID to update.

BARO PID must be within +/- 6 Hz. (+/- 2 in.Hg.) of the altitude value in Barometric Pressure Reference Chart (at the beginning of this pinpoint test).

Make BARO PID comparisons to Barometric Pressure Reference Chart or daily airport barometric pressure reports, if available.

Check that the LONGFT1 and LONGFT2 PIDS for all injector banks at idle is not more negative than -12%.

Check that the MAF V PID at idle and neutral is not greater than 30% of the normal MAF V listed in Section 6 , Reference Values (or not greater than 1.1 volts).

Are two of the above three checks OK?

Yes No

For DTC P0171, P0172, P0174, P0175, P1131, P1132, P1151, P1152, P1130, P1150, P2195, P2196, P2197 or P2198 : GO to H42 (or GO to HA42 for natural gas vehicles only). For driveability symptoms without DTCs : RETURN to Section 3 , Symptom Charts for further diagnosis. KEY OFF. GO to DC26 .

DC26 CHECK TO ISOLATE MAF SENSOR FROM LEAN DRIVEABILITY OCCURENCE

Note: Due to increasingly stringent emission/OBD II requirements, a fuel system DTC on some vehicles will be generated without a noticeable driveability concern with or without the MAF sensor disconnected. Under these conditions, if the BARO, LONGFT1, LONGFT2 and MAF V PID indicates a MAF sensor concern, replace the MAF sensor.

Disconnect the MAF sensor.

Key on, engine running.

Drive the vehicle.

Is the lean driveability symptom (lack of power, spark knock/detonation, buck/jerk or hesitation/surge on acceleration) gone?

Yes No

REPLACE MAF sensor.

RESET Keep Alive random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

VERIFY a symptom no longer exists. For DTC P0171, P0172, P0174, P0175, P1131, P1132, P1151, P1152, P1130, P1150, P2195, P2196, P2197 or P2198 : GO to H42 (or GO to HA42 for natural gas vehicles only).

For lean driveability symptoms listed without DTCs : RETURN to Section 3 , Symptom Charts for further diagnosis.

--------------------------------------------------------------------------------

does this snap-on scanner do a engine running test?

what does it say for fuel trims at idle...stuck on +25? or -25?...

maf? have you rechecked connection? did you do a wiggle test while watching volts to see a change?

heres from manual

2003 PCED OBD SECTION 2: Diagnostic Methods

Procedure revision date: 12/19/2002

--------------------------------------------------------------------------------

Adaptive Fuel DTCs Diagnostic Techniques

Adaptive Fuel DTCs Diagnostic Techniques help isolate the root cause of the adaptive fuel concern. Before proceeding, attempt to verify if any driveability concerns are present. These diagnostic aids are meant as a supplement to the pinpoint test steps in Section 5. For a description of fuel trim, refer to Section 1 , Powertrain Control Software, Fuel Trim.

Obtain Freeze Frame Data

Freeze Frame Data can be helpful in duplicating and diagnosing adaptive fuel concerns. This data (a snapshot of certain PID values, recorded at the time the DTC was stored in Continuous Memory) is helpful to determine how the vehicle was being driven when the fault occurred, and can be especially useful on intermittent concerns. Freeze Frame Data, in many cases, can help to isolate possible areas of concern as well as rule out others. Refer to Freeze Frame Data in this section for a more detailed description of this data.

Using the LONGFT1 and LONGFT2 (dual bank engines) PIDs

The LONGFT1/2 PIDs can be useful for diagnosing fuel trim concerns. A negative PID value indicates that fuel is being reduced to compensate for a rich condition, while a positive PID value indicates that fuel is being increased to compensate for a lean condition. It is important to know that there is a separate LONGFT value that is used for each rpm/load point of engine operation. When viewing the LONGFT1/2 PIDs, the values may change a great deal as the engine is operated at different rpm and load points. This is because the fuel system may have learned corrections for fuel delivery concerns that can change as a function of engine rpm and load. The LONGFT1/2 PIDs will display the fuel trim currently being used at that rpm and load point. Observing these changes in LONGFT1/2 can help when diagnosing fuel system concerns. For example:

A contaminated MAF sensor would result in matching LONGFT1/2 correction values that are negative at idle (reducing fuel), but positive (adding fuel) at higher rpm and loads.

LONGFT1 values that differ greatly from LONGFT2 values would rule out concerns that are common for both banks (for example, fuel pressure concerns, MAF sensor, etc. could be ruled out).

Vacuum leaks would result in large rich corrections (positive LONGFT1/2 value) at idle, but little or no correction at higher rpm and loads.

A plugged fuel filter will result in no correction at idle, but large rich corrections (positive LONGFT1/2 value) at high rpm and load.

Resetting Long Term Fuel Trims

Long term fuel trim corrections can be reset by resetting the PCM Keep Alive Memory (KAM). Refer to Resetting Keep Alive Memory in this section to reset KAM. After making a fuel system repair, KAM must be reset. For example, if dirty/plugged injectors cause the engine to run lean and generate rich long term corrections, replacing the injectors and not resetting KAM will now make the engine run very rich. The rich correction will eventually be "learned out" during closed loop operation, but the vehicle may have poor driveability and have high CO emissions while it is learning.

P0171/P0174 System Too Lean Diagnostic Aids

Note: If the system is lean at certain conditions, then the LONGFT PID would be a positive value at those conditions, indicating that increased fuel is needed.

The ability to identify the type of lean condition causing the concern can be crucial to a correct diagnosis.

Air Measurement System:

With this condition, the engine may actually run rich or lean of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. One possibility is that the mass of air entering the engine is actually greater than what the MAF sensor is indicating to the PCM. For example, with a contaminated MAF sensor, the engine would run lean at higher rpm because the PCM would deliver fuel for less air than is actually entering the engine.

Examples: MAF sensor measurement inaccurate (corroded connector, contamination/dirty (a contaminated MAF sensor will typically result in a rich system at low airflows (PCM will reduce fuel) and a lean system at high airflows (PCM will increase fuel), etc).

Vacuum Leaks/Unmetered Air:

With this condition, the engine may actually run lean of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. This condition can be caused by unmetered air entering the engine, or due to a MAF malfunction. In this situation, the volume of air entering the engine is actually greater than what the MAF sensor is indicating to the PCM. Vacuum leaks will normally be most apparent when high manifold vacuum is present (for example, during idle or light throttle). If freeze frame data indicates that the fault occurred at idle, a check for vacuum leaks/unmetered air might be the best starting point.

Examples: Loose, leaking or disconnected vacuum lines, intake manifold gaskets or o-rings, throttle body gaskets, brake booster, air inlet tube, stuck/frozen/aftermarket PCV valve, unseated engine oil dipstick, etc.

Insufficient Fueling:

With this condition, the engine may actually run lean of stoichiometry (14.7:1 air/fuel ratio) if the PCM is not able to compensate enough to correct for the condition. This condition can be caused by a fuel delivery system concern that restricts or limits the amount of fuel being delivered to the engine. This condition will normally be most apparent when the engine is under a heavy load and at high rpm, when a higher volume of fuel is required. If freeze frame data indicates that the fault occurred under a heavy load and at higher rpm, a check of the fuel delivery system (checking fuel pressure with engine under a load) might be the best starting point.

Examples: low fuel pressure (fuel pump, fuel filter, fuel leaks, restricted fuel supply lines), fuel injector concerns, etc.

Exhaust System Leaks:

In this type of condition, the engine may actually be running rich of stoichiometry (14.7:1 air / fuel ratio) because the fuel control system is adding fuel to compensate for a perceived (not actual) lean condition. This condition is caused by oxygen (air) entering the exhaust system from an external source. The HO2S will react to this exhaust leak by increasing fuel delivery. This condition will cause the exhaust gas mixture from the cylinder to be rich.

Examples: Exhaust system leaks upstream or near HO2S, poorly welded/leaking HO2S boss, malfunctioning Secondary Air Injection system, etc.

P0172/P0175 System Too Rich Diagnostic Aids

Note: If the system is rich at certain conditions, then the LONGFT PID would be a negative value at that airflow, indicating that decreased fuel is needed.

System rich concerns are usually caused by fuel system concerns, although the MAF sensor, and base engine (for example, engine oil contaminated with fuel) should also be checked.

Air Measurement System:

With this condition, the engine may actually run rich or lean of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. One possibility is that the mass of air entering the engine is actually less than what the MAF sensor is indicating to the PCM. For example, with a contaminated MAF sensor, the engine would run rich at idle because the PCM would deliver fuel for more air than is actually entering the engine.

Examples: MAF sensor measurement inaccurate (corroded connector, contamination/dirty (a contaminated MAF sensor will typically result in a rich system at low airflows (PCM will reduce fuel) and a lean system at high airflows (PCM will increase fuel), etc.).

Fuel System:

With this condition, the engine may actually run rich of stoichiometry (14.7:1 air/fuel ratio) if the Powertrain Control Module (PCM) is not able to compensate enough to correct for the condition. This situation can be caused by a fuel delivery system that is delivering excessive fuel to the engine.

Examples:

Fuel pressure regulator causes excessive fuel pressure (system rich at all airflows)(fuel pressure can be intermittent, going to pump deadhead pressure, then returning to normal after engine is turned off then restarted).

Fuel pressure regulator vacuum hose off (causes excessive fuel pressure at idle, system rich at idle airflows).

Fuel pressure regulator diaphragm ruptured (fuel leaking into intake manifold, system rich at lower airflows).

Fuel return line crimped/damaged (fuel pressure high, system rich at lower airflows).

Fuel injector leaks (injector delivers extra fuel).

EVAP canister purge valve leak (if canister is full of vapors, introduces extra fuel).

Fuel rail pressure sensor (electronic returnless fuel systems) concern causes sensor to indicate lower pressure than actual. PCM commands higher pressure to the fuel pump driver module (FPDM), causing high fuel pressure (system rich at all airflows).

Base Engine

Engine oil contaminated with fuel can contribute to a rich running engine.

--------------------------------------------------------------------------------

2003 PCED OBD SECTION 5: Pinpoint Tests

Procedure revision date: 08/19/2002

--------------------------------------------------------------------------------

DC: Mass Air Flow (MAF) Sensor DC: Introduction

--------------------------------------------------------------------------------

DC1 DTC P1101: CHECK FOR MAF SENSOR CONTINUOUS MEMORY DTCs

Drive vehicle for 6 to 10 minutes.

Rerun KOER, KOEO Self-Test and retrieve Continuous Memory DTCs.

Is a Continuous Memory DTC present with the KOER DTC P1101?

Yes No

For Continuous Memory DTC P0102:

GO to DC2 .

For Continuous Memory DTC P0103:

GO to DC20 .

All other Continuous Memory DTCs:

GO to Section 4, Powertrain Diagnostic Trouble Code (DTC) Charts . KEY OFF. GO to DC3 .

DC2 DTC P0102: CHECK MAF SENSOR SIGNAL LOW INPUT TO PCM

Check for broken/loose air outlet tube clamps (throttle body and air cleaner assembly ends), cracks/holes in air outlet tube, worn gaskets between MAF sensor and air cleaner assembly. Verify MAF sensor is connected. Repair as necessary.

Start engine and bring to idle.

If a KOER DTC P0505 is present, go to Section 4, Powertrain Diagnostic Trouble Code (DTC) Charts . For A/T vehicles, if the engine stalls and cannot maintain an idle, GO to DC7 .

Run engine up 1500 rpm for 5 seconds, then bring it back to idle.

Access MAF V PID.

Is MAF V PID less than 0.23 volt?

Yes No

KEY OFF. GO to DC4 . KEY OFF. GO to DC3 .

DC3 DTC P1101: CHECK FOR MAF SENSOR SIGNAL OUT OF SELF-TEST RANGE

Note: DTC P1101 can be generated by a low charged vehicle battery or the garage exhaust ventilation system. Repair battery as necessary. Then remove ventilation system and properly vent to outside atmosphere. Rerun KOEO Self-Test.

Verify MAF sensor is connected. If not, repair as necessary.

Key on, engine running.

Access MAF V PID.

Is MAF V PID between 0.46-2.44 volts?

Yes No

Unable to identify fault at this time. GO to Z1 . KEY OFF. GO to DC4 .

DC4 CHECK VPWR VOLTAGE TO MAF SENSOR

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Disconnect MAF sensor.

Key on, engine off.

Measure voltage between VPWR circuit at the MAF sensor harness connector and battery negative post.

Is voltage greater than 10.5 volts?

Yes No

GO to DC5 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC5 CHECK PWR GND CIRCUIT TO MAF SENSOR

Measure voltage between PWR GND circuit at the MAF sensor harness connector and battery positive post.

Is voltage greater than 10.0 volts?

Yes No

KEY OFF. GO to DC6 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC6 CHECK MAF CIRCUIT SHORT TO PWR GND OR MAF RTN IN THE HARNESS

PCM disconnected.

Disconnect scan tool from DLC.

Measure resistance between MAF and PWR GND circuits at the MAF sensor harness connector.

Measure resistance between MAF and MAF RTN circuits at the MAF sensor harness connector.

Is each resistance greater than 10,000 ohms?

Yes No

GO to DC7 . REPAIR short circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC7 CHECK MAF RTN CIRCUIT SHORT TO PWR GND IN THE HARNESS

Measure resistance between MAF RTN and PWR GND circuits at the MAF sensor harness connector.

Is the resistance greater than 10,000 ohms?

Yes No

GO to DC8 . REPAIR short circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC8 CHECK MAF CIRCUIT FOR SHORT TO PWR GND IN THE PCM

Reconnect PCM.

Measure resistance between MAF and PWR GND circuits at the MAF sensor harness connector.

Is the resistance greater than 10,000 ohms?

Yes No

RECONNECT scan tool to DLC. GO to DC9 REPLACE PCM (refer to Section 2, Flash Electrically Erasable Programmable Read Only Memory (EEPROM) ).

DC9 CHECK MAF CIRCUIT VOLTAGE CYCLING INTEGRITY

Key on, engine off.

Access MAF V PID.

Record the MAF V PID reading.

Jumper MAF RTN and PWR GND circuits at the MAF sensor harness connector.

Jumper MAF and VPWR circuits at the MAF sensor harness connector.

Does the MAF V PID change from less than 0.23 volt (closer to zero volts) to greater than 4.50 volts?

Yes No

REPLACE MAF sensor. RESET Keep Alive Random Access Memory (RAM)(REFER to Section 2, Powertrain Control Module (PCM) Reset ). For DTC P1101 without P0102 present:

KEY OFF. GO to DC11 .

For DTC P0102:

KEY OFF. GO to DC10 .

DC10 CHECK MAF CIRCUIT FOR OPEN IN HARNESS

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Disconnect PCM.

Measure resistance of MAF circuit between PCM harness connector pin and MAF sensor harness connector.

Is resistance less than 5.0 ohms?

Yes No

GO to DC11 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC11 CHECK PWR GND CIRCUIT FOR OPEN IN HARNESS

PCM disconnected.

Disconnect scan tool from DLC.

Measure resistance of PWR GND circuit between MAF sensor harness connector and battery negative post.

Is resistance less than 10 ohms?

Yes No

RECONNECT scan tool. GO to DC12 . REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC12 CHECK MAF RTN FOR OPEN IN HARNESS

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Measure resistance of MAF RTN circuit between PCM harness connector pin and MAF sensor harness connector.

Is resistance less than 5.0 ohms?

Yes No

REPLACE PCM (refer to Section 2, Flash Electrically Erasable Programmable Read Only Memory (EEPROM) ). REPAIR open circuit. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

DC16 DTC P1100: CHECK MAF CIRCUIT FOR INTERMITTENT VOLTAGE TO PCM

Start engine and bring it to idle.

If idle is not stable, GO to Section 3 , Symptom Charts.

Run throttle up to 1500 rpm for 5 seconds, and bring back to idle.

Access MAF V PID.

Lightly tap on MAF sensor and wiggle harness connector to simulate road shock.

Is MAF V PID changing below the minimum 0.23 volt or above a maximum 4.60 volts?

Yes No

INSPECT MAF sensor connector. If OK, REPLACE the MAF sensor. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ). GO to DC17 .

DC17 CHECK FOR MAF SENSOR CIRCUIT FOR INTERMITTENT OPENS OR SHORTS

Key on, engine running.

Again access the MAF V PID.

Complete the following:

Grasp the MAF sensor harness and MAF sensor harness connector.

Wiggle, shake and bend the harness from the MAF sensor to the PCM.

Is the MAF V PID reading changing below the minimum 0.23 volt or above the maximum 4.60 volts?

Yes No

REPAIR as necessary. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ). Unable to duplicate or identify fault at this time. GO to Z1 .

DC20 DTC P0103: CHECK MAF SENSOR SIGNAL HIGH INPUT TO PCM

Note: DTC P0103 can be generated by foreign material blocking the MAF sensor screen causing an air flow restriction. If contaminants are found on the screen, check air cleaner element installation in air cleaner housing and proper sealing of air cleaner and air tubes before proceeding. Rerun Quick Test after service.

Start engine and bring to idle.

If a KOER DTC P0505 is present, GO to Section 4, Powertrain Diagnostic Trouble Code (DTC) Charts .

Run throttle up to 1500 rpm for 5 seconds, and bring it back to idle.

Note: MAF V PID is greater than 4.60 volts.

Access MAF V PID.

Key off.

Disconnect MAF sensor.

Jumper PWR GND and MAF RTN circuits at the MAF sensor harness connector.

Key on, engine running.

Again access MAF V PID.

Did MAF V PID drop from the original reading to below 0.23 volt?

Yes No

REMOVE jumper. REPLACE MAF sensor. RESET Keep Alive Random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ). KEY OFF. REMOVE jumper. GO to DC21 .

DC21 CHECK MAF CIRCUIT FOR SHORT TO VPWR IN HARNESS

Note: Refer to the PCM connector pin numbers in the beginning of this pinpoint test.

Disconnect PCM.

Key on, engine off.

Measure voltage between MAF and PWR GND circuits at the PCM harness connector.

Is voltage less than 1.0 volt?

Yes No

If an idle concern is not present:

REPLACE PCM (refer to Section 2, Flash Electrically Erasable Programmable Read Only Memory (EEPROM) ).

If a fault was not detected and an idle concern is still present:

Disregard DTC P0102 at this time. RETURN to Section 3 , Symptom Charts. REPAIR short circuit.

DC25 DTC P0171, P0172, P0174, P0175, P1131, P1132, P1151, P1152, P1130, P1150, P2195, P2196, P2197, P2198 OR LEAN DRIVEABILITY CONCERNS: CHECK CONDITIONS RELATED TO MAF SENSOR

Note: Most weather service reports are a local barometric pressure that has been corrected to sea level. However, the BARO PID reports the actual barometric pressure for the altitude the vehicle is being diagnosed in. Local weather conditions (high or low pressure areas) will change the local barometric pressure by several inches of mercury [+/- 3 Hz. (+/- 1 in.Hg.)].

Verify the MAF sensor is connected. If not, repair as necessary.

Key on, engine running.

Access the BARO, LONGFT1, LONGFT2 and MAF V PIDs on fully warmed-up engine.

Check that the BARO PID is approximately the same as the barometric pressure reading for the location, day and altitude the vehicle is being diagnosed at.

BARO PID values in Keep Alive Memory require updating at high throttle openings. If vehicle is driven down from higher altitudes for diagnosing, complete three or four heavy accelerations at greater than half-throttle to allow BARO PID to update.

BARO PID must be within +/- 6 Hz. (+/- 2 in.Hg.) of the altitude value in Barometric Pressure Reference Chart (at the beginning of this pinpoint test).

Make BARO PID comparisons to Barometric Pressure Reference Chart or daily airport barometric pressure reports, if available.

Check that the LONGFT1 and LONGFT2 PIDS for all injector banks at idle is not more negative than -12%.

Check that the MAF V PID at idle and neutral is not greater than 30% of the normal MAF V listed in Section 6 , Reference Values (or not greater than 1.1 volts).

Are two of the above three checks OK?

Yes No

For DTC P0171, P0172, P0174, P0175, P1131, P1132, P1151, P1152, P1130, P1150, P2195, P2196, P2197 or P2198 : GO to H42 (or GO to HA42 for natural gas vehicles only). For driveability symptoms without DTCs : RETURN to Section 3 , Symptom Charts for further diagnosis. KEY OFF. GO to DC26 .

DC26 CHECK TO ISOLATE MAF SENSOR FROM LEAN DRIVEABILITY OCCURENCE

Note: Due to increasingly stringent emission/OBD II requirements, a fuel system DTC on some vehicles will be generated without a noticeable driveability concern with or without the MAF sensor disconnected. Under these conditions, if the BARO, LONGFT1, LONGFT2 and MAF V PID indicates a MAF sensor concern, replace the MAF sensor.

Disconnect the MAF sensor.

Key on, engine running.

Drive the vehicle.

Is the lean driveability symptom (lack of power, spark knock/detonation, buck/jerk or hesitation/surge on acceleration) gone?

Yes No

REPLACE MAF sensor.

RESET Keep Alive random Access Memory (RAM) (REFER to Section 2, Powertrain Control Module (PCM) Reset ).

VERIFY a symptom no longer exists. For DTC P0171, P0172, P0174, P0175, P1131, P1132, P1151, P1152, P1130, P1150, P2195, P2196, P2197 or P2198 : GO to H42 (or GO to HA42 for natural gas vehicles only).

For lean driveability symptoms listed without DTCs : RETURN to Section 3 , Symptom Charts for further diagnosis.

--------------------------------------------------------------------------------

Last edited:

yea today it was running like ass got 28 for vacuum at idle with a high idle went to the gas station shut it off and then when i started it back up i got 24 for a vacuum with low loopy idle i just dont get this its bothering the hell outta me and i dont wanna bring it in cause theres no good tuners around here i wanna go to so idk what i should do guys

yea today it was running like ass got 28 for vacuum at idle with a high idle went to the gas station shut it off and then when i started it back up i got 24 for a vacuum with low loopy idle i just dont get this its bothering the hell outta me and i dont wanna bring it in cause theres no good tuners around here i wanna go to so idk what i should do guys

start with the suggestions,,go over everything that was changed from stock form...

all of the things you listed can be a cause for po171/174...

if you can post some clear pics of your engine and what changes done on deletes,it might show your problem...

follow the codes instruction in manual PC/ED section,codes and pinpoint tests...watch for footnotes/cautions

you will need to borrow your friends scanner for awhile to school yourself on check engine light repair...unplug things to throw code than read to compare...99% the pcm will be right and code falls into problem

here is section of manual to remove the intercooler under the blower,,just look it over and compare the changes on vaccum hoses as to egr delete/pcv delete...notice pcv hose that runs under blower in the back,,,very common leak spot..

https://acrobat.com/#d=ChRT*wSZUQ25nxuHNnwOcA

if you need a manual look at the stickys in terminator section,1 has a download 50/50 if it works...

chiltons library for 2003 information is from ford along with trainning vids and tech...it has everything ive posted

Gale Cengage Product Failure

this was the first site i joined 5yrs ago when warrenty expired at 70k,,,im at 303k now ,,,i knew only your basic maintinance

,,,between manual and site ive fixed all the issues that have came along,

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)