________________________________________

From: Osuntokun, Olaniyi O

Sent: Tuesday, September 02, 2014 8:07 PM

Some of you may know I broke the crank of my 9.5:1 compression alluminator with ported heads/Ford racing exhaust cams running the Cobra jet 10 rib set up with a 2.9 Whipple.

I had MMR build me a new BOSS long block and was afraid of using the Whipple again.I was fortunate? to have been able to buy back my TVS that I had sold to forum member when I made the switch.

I sent the blower to Steigmeir for the snake bite drive(1.3),venom cooler case blueprint(not sure what that means) and he ported matched the inlet to the L&M elbow I had before.

I ran the Whipple with the new engine for the break-in period since the snake biye TVS was not ready and then switched

I initially had the 82 mm 8 rib pulley thinking I would see 17-18 psi based on my rpm calculations.I only saw 14-15 per my gauge.

I then started having problems with engine cover side of the belt shredding(may have been getting cut on the cover) so decided to go down a pulley-75 mm size since I was going to be doing a new belt after my Ford guy machined the cover some more

After that install he noticed belt was walking forward on the damper with high revs.I contacted VMP and he was great,quickly offering to send me the new design damper that has a lip.

Lund has been tuning the car since I had the Whipple and had reviewed my street logs on race gas.

I decided to go ahead and dyno the car on E85 while waiting on the damper.The Guys at Fathous who have been great noted it was dropping fuel pressure after 5500 rpm and that the boost dipped/belt slipped.

I have Lethal's return system with 2 Walbro pumps and it was previously enough to support 800 rwhp on the Whipple

Lund wanted the fuel system rerouted to a "true return system" and add a third pump.

I had them do a pull on race gas to see if it would be less lean but it still was,belt also started shredding.

I had fat house redo the fuel system and install the new damper and while they were at it they machined the cover some more and tried to get the alignment right.Also found the a return fuel line with 4 kinks which could have been the cause of the fuel problems but I agree with lund who said something like "overbuilt super safe".lol

Unfortunately after hours of labor and consultation with Justin(many thanks) that belt is still walking forward on the new damper.

I had them do one dyno pull at least to make sure the fuel issues were fixed.It is now running rich so

it looks like that is fixed.I will send logs to Lund and may be he will adjust the tune.

Unfortunately we may have run out ideas on how to fix the belt alignment(Justin already suggested and have moved the blower and manifold as far back as it can go)

We will try the 82 mm pulley since the problems started with the 75 mm but they are not optimistic that will fix it.

If that fails I will try a 6 rib belt and may end up with the 6 rib pulleys if that fails.

Not here to criticize anything/anyone as Justin and the guys at Fathouse have been great and spent many hours trying to fix this.

I still have my 2.9 whipple/10 rib set up and may just reuse it if I want more after maxing out the TVS-I may run a 69 mm pulley with the 1.3 drive if I go back to the 6 rib pulleys.

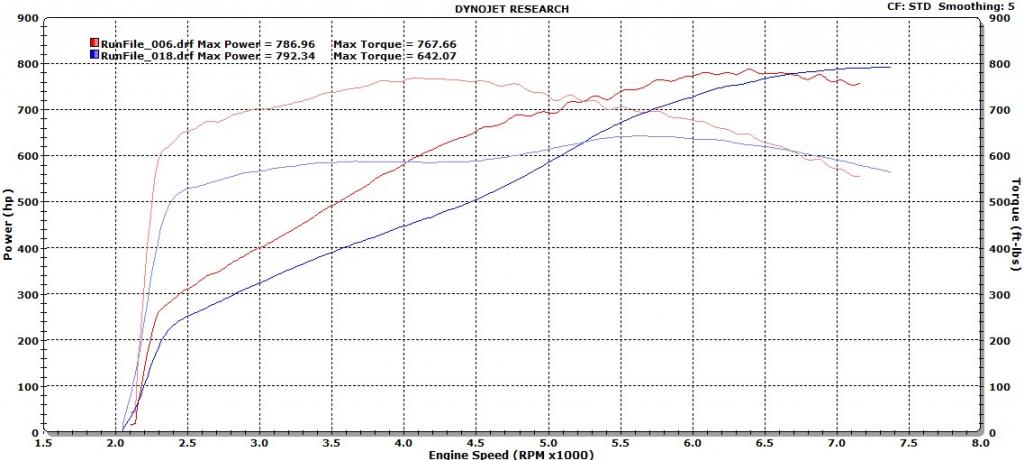

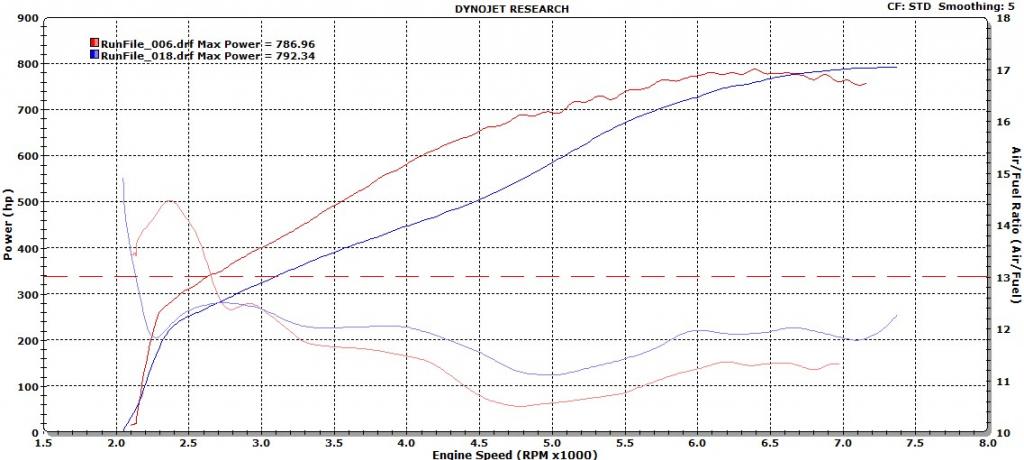

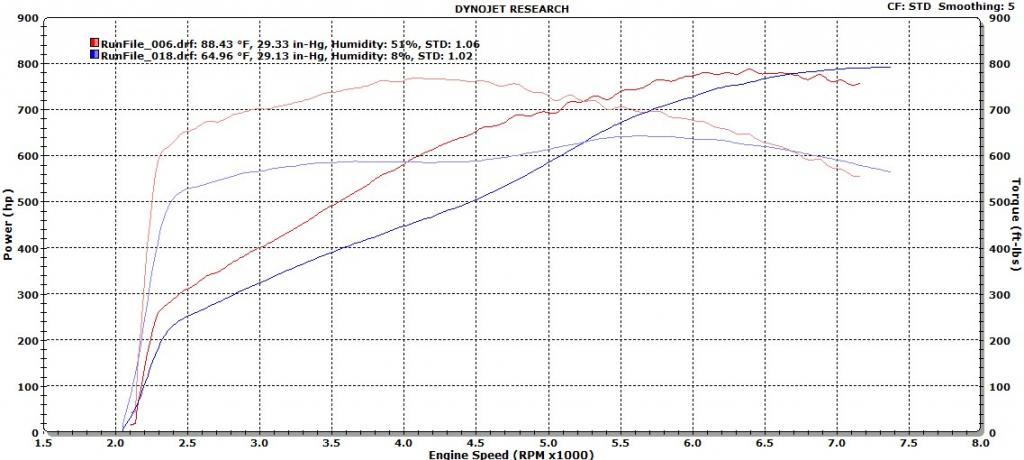

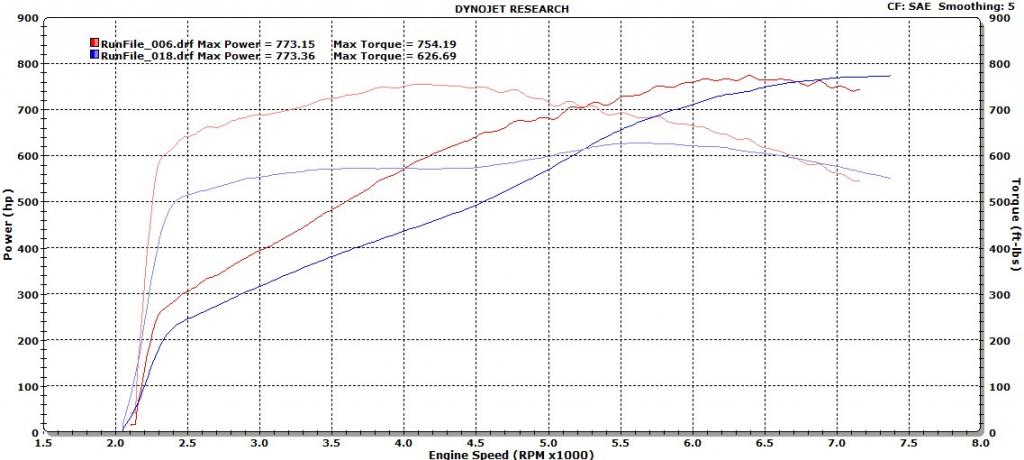

I know dyno graphs are for comparison and tuning purposes only but have only been able to run the car once to feel it out since the new engine with the TVS-It ran 10.93@136 so making enough power even with the 82 mm pulley.

The numbers for the the whipple were on a different dyno in February .The whipple is blue and the TVS red

Boost PSI was 17-18 with both of them.Only the last graph is SAE and I thought it was intersting they made identical power!

From: Osuntokun, Olaniyi O

Sent: Tuesday, September 02, 2014 8:07 PM

Some of you may know I broke the crank of my 9.5:1 compression alluminator with ported heads/Ford racing exhaust cams running the Cobra jet 10 rib set up with a 2.9 Whipple.

I had MMR build me a new BOSS long block and was afraid of using the Whipple again.I was fortunate? to have been able to buy back my TVS that I had sold to forum member when I made the switch.

I sent the blower to Steigmeir for the snake bite drive(1.3),venom cooler case blueprint(not sure what that means) and he ported matched the inlet to the L&M elbow I had before.

I ran the Whipple with the new engine for the break-in period since the snake biye TVS was not ready and then switched

I initially had the 82 mm 8 rib pulley thinking I would see 17-18 psi based on my rpm calculations.I only saw 14-15 per my gauge.

I then started having problems with engine cover side of the belt shredding(may have been getting cut on the cover) so decided to go down a pulley-75 mm size since I was going to be doing a new belt after my Ford guy machined the cover some more

After that install he noticed belt was walking forward on the damper with high revs.I contacted VMP and he was great,quickly offering to send me the new design damper that has a lip.

Lund has been tuning the car since I had the Whipple and had reviewed my street logs on race gas.

I decided to go ahead and dyno the car on E85 while waiting on the damper.The Guys at Fathous who have been great noted it was dropping fuel pressure after 5500 rpm and that the boost dipped/belt slipped.

I have Lethal's return system with 2 Walbro pumps and it was previously enough to support 800 rwhp on the Whipple

Lund wanted the fuel system rerouted to a "true return system" and add a third pump.

I had them do a pull on race gas to see if it would be less lean but it still was,belt also started shredding.

I had fat house redo the fuel system and install the new damper and while they were at it they machined the cover some more and tried to get the alignment right.Also found the a return fuel line with 4 kinks which could have been the cause of the fuel problems but I agree with lund who said something like "overbuilt super safe".lol

Unfortunately after hours of labor and consultation with Justin(many thanks) that belt is still walking forward on the new damper.

I had them do one dyno pull at least to make sure the fuel issues were fixed.It is now running rich so

it looks like that is fixed.I will send logs to Lund and may be he will adjust the tune.

Unfortunately we may have run out ideas on how to fix the belt alignment(Justin already suggested and have moved the blower and manifold as far back as it can go)

We will try the 82 mm pulley since the problems started with the 75 mm but they are not optimistic that will fix it.

If that fails I will try a 6 rib belt and may end up with the 6 rib pulleys if that fails.

Not here to criticize anything/anyone as Justin and the guys at Fathouse have been great and spent many hours trying to fix this.

I still have my 2.9 whipple/10 rib set up and may just reuse it if I want more after maxing out the TVS-I may run a 69 mm pulley with the 1.3 drive if I go back to the 6 rib pulleys.

I know dyno graphs are for comparison and tuning purposes only but have only been able to run the car once to feel it out since the new engine with the TVS-It ran 10.93@136 so making enough power even with the 82 mm pulley.

The numbers for the the whipple were on a different dyno in February .The whipple is blue and the TVS red

Boost PSI was 17-18 with both of them.Only the last graph is SAE and I thought it was intersting they made identical power!