Losen this bolt so you can slide the canister out of the way to get to the next bolt.

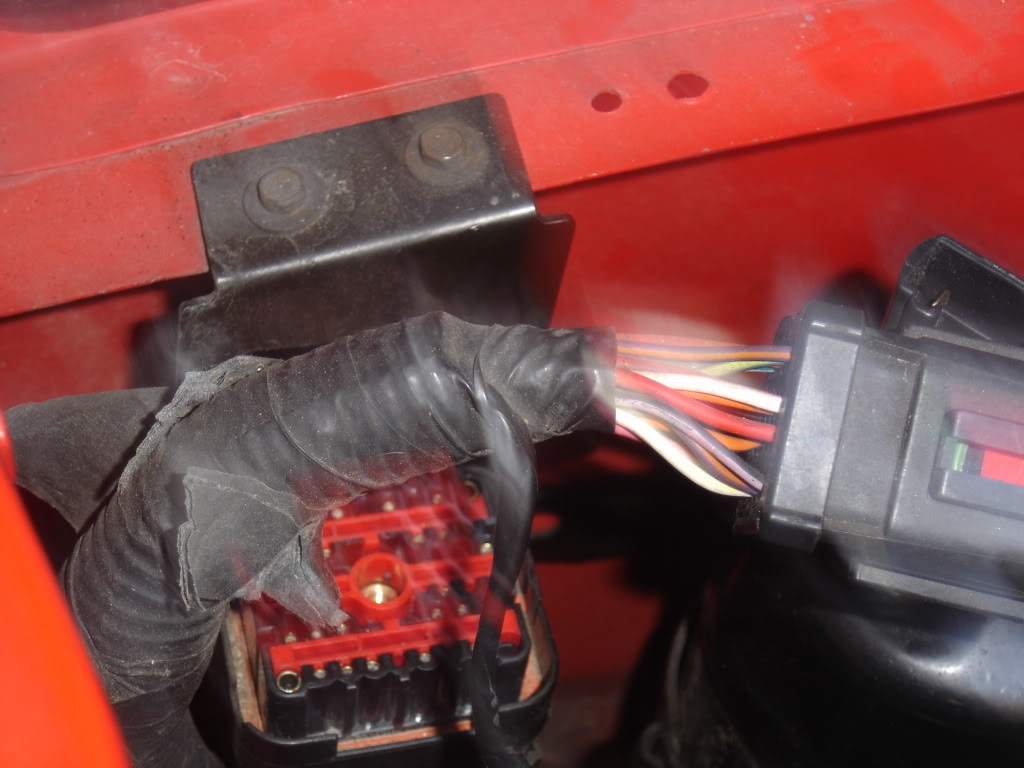

Also moved this out of the way for access...

Now take this Nut off...

Also moved this out of the way for access...

Now take this Nut off...