Just completed another step in my build which was rather unexpected but it's something most people never considered (including me) and actually makes a lot of sense from some perspectives and not much from others (mainly the effort required but as you probably already know I'm pretty tenacious).

What started me down this path was ruining my dash pad in a welding accident so I bought one from a fellow SVTP member and got burned :nonono:

http://www.svtperformance.com/forum...fellow-STVP-member-que4dog&highlight=dash+pad

After seeing the dash assembly had been damaged (I think he smushed it parking a car in the garage the frame was bent and the dash pad mounting bosses were broken off) I removed the pad from the frame and noted how flimsy the frame was (it wiggled like Jello).

One thing that drives me crazy is having a beautiful car that has been carefully built and is a joy to drive only to have a dash that rattles worse than a gypsy bandwagon at every bump! When new they are pretty quiet but will loosen-up overtime carrying all that weight so I decided to add gussets to reinforce the frame and am extremely pleased with the outcome. Here is the finished results:

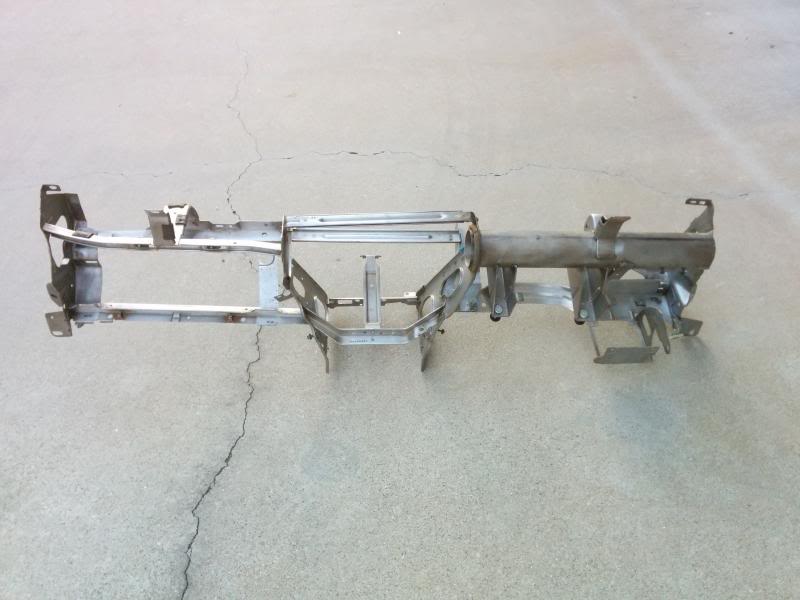

Before & After (that quedog's frame in the foreground which is now destine for the dumpster)

The difference in stiffness is astounding! Wiggle the factory frame at one end and it quickly oscillates from side to side at the other end. The whole frame readily twists in your hands. No such movement in the welded frame the only thing you feel is a low frequency vib when you set it down on concrete and it doesn't budge trying to twist it. It's welded mainly with .040 thk. chromyl sheet which is fairly thin and light I estimate I added about 3 lbs to the frame which are pretty light to begin with (I'll weigh both frames and post the results).

Lots of pre-fit for clearance checks before welding up the frame. Cardboard patterns were used to create the gussets, helps having a bend brake as well.

.

.

This is something I would not recommend doing unless you have patients and time there is 8 hours of straight welding work alone here. A lot of thought went into the design and placement of the gussets. Long term I expect the dash on this car to be even quieter then when new :rockon:

What started me down this path was ruining my dash pad in a welding accident so I bought one from a fellow SVTP member and got burned :nonono:

http://www.svtperformance.com/forum...fellow-STVP-member-que4dog&highlight=dash+pad

After seeing the dash assembly had been damaged (I think he smushed it parking a car in the garage the frame was bent and the dash pad mounting bosses were broken off) I removed the pad from the frame and noted how flimsy the frame was (it wiggled like Jello).

One thing that drives me crazy is having a beautiful car that has been carefully built and is a joy to drive only to have a dash that rattles worse than a gypsy bandwagon at every bump! When new they are pretty quiet but will loosen-up overtime carrying all that weight so I decided to add gussets to reinforce the frame and am extremely pleased with the outcome. Here is the finished results:

Before & After (that quedog's frame in the foreground which is now destine for the dumpster)

The difference in stiffness is astounding! Wiggle the factory frame at one end and it quickly oscillates from side to side at the other end. The whole frame readily twists in your hands. No such movement in the welded frame the only thing you feel is a low frequency vib when you set it down on concrete and it doesn't budge trying to twist it. It's welded mainly with .040 thk. chromyl sheet which is fairly thin and light I estimate I added about 3 lbs to the frame which are pretty light to begin with (I'll weigh both frames and post the results).

Lots of pre-fit for clearance checks before welding up the frame. Cardboard patterns were used to create the gussets, helps having a bend brake as well.

This is something I would not recommend doing unless you have patients and time there is 8 hours of straight welding work alone here. A lot of thought went into the design and placement of the gussets. Long term I expect the dash on this car to be even quieter then when new :rockon: