A: It start knockin' on Heavens door!

So just a quick short story. I did an oil change a few months back and fill up with some Amsoil 5w20. Put 6 quarts in and called it a day. Fast forward a couple months later, I got on her hard and quickly noticed a ticking noise shortly after. I could not hear it all the time but enough to where it was noticeable when driving next to a wall or concrete barrier. I parked the car that night as I was a bit worried and didn't want to do any more damage if there was any.

Next day, I go out to the car to investigate the noise. I check the oil and find that the car is low 4 quarts. WTF? Where did it go? The car has always burned oil and give a typical puff of smoke on startup. Typically, she may go through a half quart or so every few months. I check it periodically but since riding the motorcycle for most of the summer, the car has sat and wasn't too worried since I recently changed the oil.

Anyways, I start doing my investigation and my father suggests that I check the PCV valve since I do run her pretty hard. His guess seems to have been a very accurate one as the inside of the hose from the PCV to the intake was drenched in oil. Further analysis of the PCV shows that it was not working at all. Now there is some irony in this as well. I purchased a new PCV valve from Ford shortly after the oil change with anticipation of replace the Purolator I had installed.

So I replace the PCV with the new one, verify that the car has the proper amount of oil and start her up. At first, I don't hear a ticking noise until I start playing with the RPMs. At around 2000 RPMs, I was able to hear a little bit of chatter but would then go away when reaching 4000 RPMs. Worst thought ever came to my head and decided to let her sit until I can get her on a lift and see how bad the carnage may be.

Moving forward to Thursday, I took the car over to the hobby shop and got it on a lift so I can inspect the bottom end. We get the K member out of the way and get the oil pan off. First analysis of the inside of the oil pan does not look promising. In the residual oil, you can see pretty large pieces of metal floating around. I mean to tell you that some of the metal chunks were about 1/8" or so long!

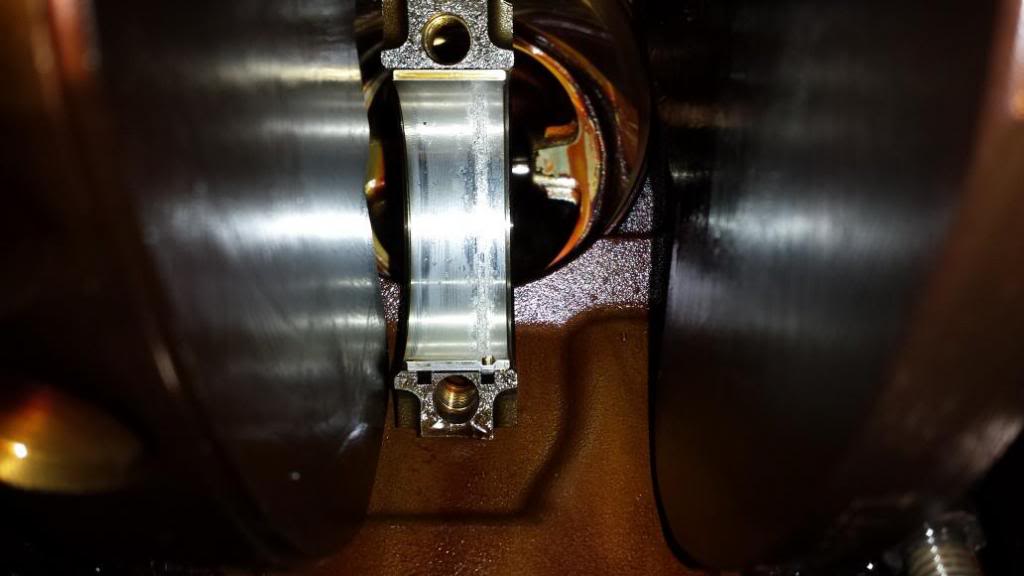

As we moved to removing the connecting rod caps, I start to get this sick feeling about how the rods and crank are going to look.

I pop the #8 connecting rod cap to take a look. The site was a bit bothersome. You could see bearing material sitting on the crank looking as if it was just a raised part of the journal. It did not look good but as I picked at it with my fingernail, a slight bit of hope could be seen. just the mere rubbing of my fingernail was lifting the transferred bearing material.

Working my way through the removal of connecting rod caps, hope increased as the journals for 4, 7, and 3 looked great! I get to connecting rod #6 and my heart sinks pretty deep. It is now obvious as to which rod was making the most noise. The bearing did not spin but there was quite a bit of material transferred from the bearing to the crank. It does not look like it was gouged but the amount of transferred material made me worry that the engine will need a full rebuild. I finish pulling off the caps and only see a little bit of wear on the journals but nothing as bad a #6.

By now, it is at the end of the evening and the hobby shop is ready to close. I do a further inspections of the crank with a set of micrometers. Amazingly enough, all journals look to be in spec!

Now, I know many people say that with this type of damage, it is best to just replace the motor and move on. Well to me, I took it as a chance to move forward on building an engine. For the time being, I decided that I would try to polish the journals and see what I get. Aluminum is so much softer than our forged cranks that I thought maybe, just maybe, that I might have a chance on recovering this crank though polishing without damaging the shape of the journals.

Today, I started my journey with cleaning of the journals. Of course, I could not get a buffing wheel in there so bought some 6000 sanding belt, a leather welding apron to make strips of leather from and some typical polishing compound. This setup turned out to be a tedious yet very successful outcome! It took about 5 hours to hand polish the journals but all of the debris came off and was completely within the tolerances of the specs in regards to the connecting rod journals.

I installed some new bearings, and connecting rod bolts and started to reassemble the bottom end. I ran out of time so still need to install the oil pan. pickup and k member. Once that is all installed, I'm going to prime the car and fill it up with some cheap 5w30. Let it run for a little bit and then drain the oil and but some better stuff in. If she does well for about a 500 miles or so, I'll then change the fluid out again and get Amsoil 5w20 in her and hope she lasts long enough for me to finish building the new engine.

Lesson learned... Replace PCV often with OEM PCV and keep a close eye on fluid levels! A little bit of maintenance and replacement of a $5.00 part could end up saving you from spending thousands of dollars on a new engine or replacement car.

So my short story was a little bit longer. Here are just a few piture to make up for it.

So just a quick short story. I did an oil change a few months back and fill up with some Amsoil 5w20. Put 6 quarts in and called it a day. Fast forward a couple months later, I got on her hard and quickly noticed a ticking noise shortly after. I could not hear it all the time but enough to where it was noticeable when driving next to a wall or concrete barrier. I parked the car that night as I was a bit worried and didn't want to do any more damage if there was any.

Next day, I go out to the car to investigate the noise. I check the oil and find that the car is low 4 quarts. WTF? Where did it go? The car has always burned oil and give a typical puff of smoke on startup. Typically, she may go through a half quart or so every few months. I check it periodically but since riding the motorcycle for most of the summer, the car has sat and wasn't too worried since I recently changed the oil.

Anyways, I start doing my investigation and my father suggests that I check the PCV valve since I do run her pretty hard. His guess seems to have been a very accurate one as the inside of the hose from the PCV to the intake was drenched in oil. Further analysis of the PCV shows that it was not working at all. Now there is some irony in this as well. I purchased a new PCV valve from Ford shortly after the oil change with anticipation of replace the Purolator I had installed.

So I replace the PCV with the new one, verify that the car has the proper amount of oil and start her up. At first, I don't hear a ticking noise until I start playing with the RPMs. At around 2000 RPMs, I was able to hear a little bit of chatter but would then go away when reaching 4000 RPMs. Worst thought ever came to my head and decided to let her sit until I can get her on a lift and see how bad the carnage may be.

Moving forward to Thursday, I took the car over to the hobby shop and got it on a lift so I can inspect the bottom end. We get the K member out of the way and get the oil pan off. First analysis of the inside of the oil pan does not look promising. In the residual oil, you can see pretty large pieces of metal floating around. I mean to tell you that some of the metal chunks were about 1/8" or so long!

As we moved to removing the connecting rod caps, I start to get this sick feeling about how the rods and crank are going to look.

I pop the #8 connecting rod cap to take a look. The site was a bit bothersome. You could see bearing material sitting on the crank looking as if it was just a raised part of the journal. It did not look good but as I picked at it with my fingernail, a slight bit of hope could be seen. just the mere rubbing of my fingernail was lifting the transferred bearing material.

Working my way through the removal of connecting rod caps, hope increased as the journals for 4, 7, and 3 looked great! I get to connecting rod #6 and my heart sinks pretty deep. It is now obvious as to which rod was making the most noise. The bearing did not spin but there was quite a bit of material transferred from the bearing to the crank. It does not look like it was gouged but the amount of transferred material made me worry that the engine will need a full rebuild. I finish pulling off the caps and only see a little bit of wear on the journals but nothing as bad a #6.

By now, it is at the end of the evening and the hobby shop is ready to close. I do a further inspections of the crank with a set of micrometers. Amazingly enough, all journals look to be in spec!

Now, I know many people say that with this type of damage, it is best to just replace the motor and move on. Well to me, I took it as a chance to move forward on building an engine. For the time being, I decided that I would try to polish the journals and see what I get. Aluminum is so much softer than our forged cranks that I thought maybe, just maybe, that I might have a chance on recovering this crank though polishing without damaging the shape of the journals.

Today, I started my journey with cleaning of the journals. Of course, I could not get a buffing wheel in there so bought some 6000 sanding belt, a leather welding apron to make strips of leather from and some typical polishing compound. This setup turned out to be a tedious yet very successful outcome! It took about 5 hours to hand polish the journals but all of the debris came off and was completely within the tolerances of the specs in regards to the connecting rod journals.

I installed some new bearings, and connecting rod bolts and started to reassemble the bottom end. I ran out of time so still need to install the oil pan. pickup and k member. Once that is all installed, I'm going to prime the car and fill it up with some cheap 5w30. Let it run for a little bit and then drain the oil and but some better stuff in. If she does well for about a 500 miles or so, I'll then change the fluid out again and get Amsoil 5w20 in her and hope she lasts long enough for me to finish building the new engine.

Lesson learned... Replace PCV often with OEM PCV and keep a close eye on fluid levels! A little bit of maintenance and replacement of a $5.00 part could end up saving you from spending thousands of dollars on a new engine or replacement car.

So my short story was a little bit longer. Here are just a few piture to make up for it.

Attachments

-

1150517_10201217565574997_1346085220_o_zps7454f7ab.gif6.4 KB · Views: 156

1150517_10201217565574997_1346085220_o_zps7454f7ab.gif6.4 KB · Views: 156 -

1074098_10201217563894955_517492601_o_zpse3172840.gif6.4 KB · Views: 166

1074098_10201217563894955_517492601_o_zpse3172840.gif6.4 KB · Views: 166 -

1167284_10201217564094960_184184772_o_zps29191cc1.gif6.4 KB · Views: 157

1167284_10201217564094960_184184772_o_zps29191cc1.gif6.4 KB · Views: 157 -

77960_10201217565134986_2054470659_o_zps2895e2ee.gif6.4 KB · Views: 158

77960_10201217565134986_2054470659_o_zps2895e2ee.gif6.4 KB · Views: 158 -

1167458_10201217564734976_750699261_o_zpsb68e6696.gif6.4 KB · Views: 156

1167458_10201217564734976_750699261_o_zpsb68e6696.gif6.4 KB · Views: 156

Last edited: