After months and months of research and talking with some very reliable engine builders, I am coming closer to beginning my turbo motor build. Through out the course of this thread you will find detailed pics, questions, and also witness what it takes precisely step by step to building a stout mod motor. Keep in mind I am still learning valuable things everyday however after seeing and hearing about one too many bad experiences with from a shop I am taking the "trust nobody" approach. I aim for precision and perfection throughout the course of this project...NOT SPEED and how fast I can have a motor in my car.

So far my motor consists of the following (All of which is brand new):

I still need to get my custom pistons from JE. I was fortunate enough to source BlownBlu97's Spec Sheet from him. I also need to get ARP Mainstuds, sidebolts, and headstuds.

Next on my agenda is measuring my bores (although it is brand new) so I can call JE and order my pistons. Keep in mind I am aiming for as close to stock bore as I can get. The block will need minimal machining more or less a touch hone of ~.002 to clean up the cylinder walls from sitting for so long. I will post pics of what it looks like. Pistons will be ordered .002 larger than my largest bore measurement.

Also to clarify so there is no confusion I got a once in a lifetime deal on a Ford Racing Aluminator shortblock, so if you see pics of me disassembling a brand new short block don't be alarmed lol. Lots of upgrading to be done in order to have a solid foundation for the turbo and the power I want to make (1000 on c16 through an auto)

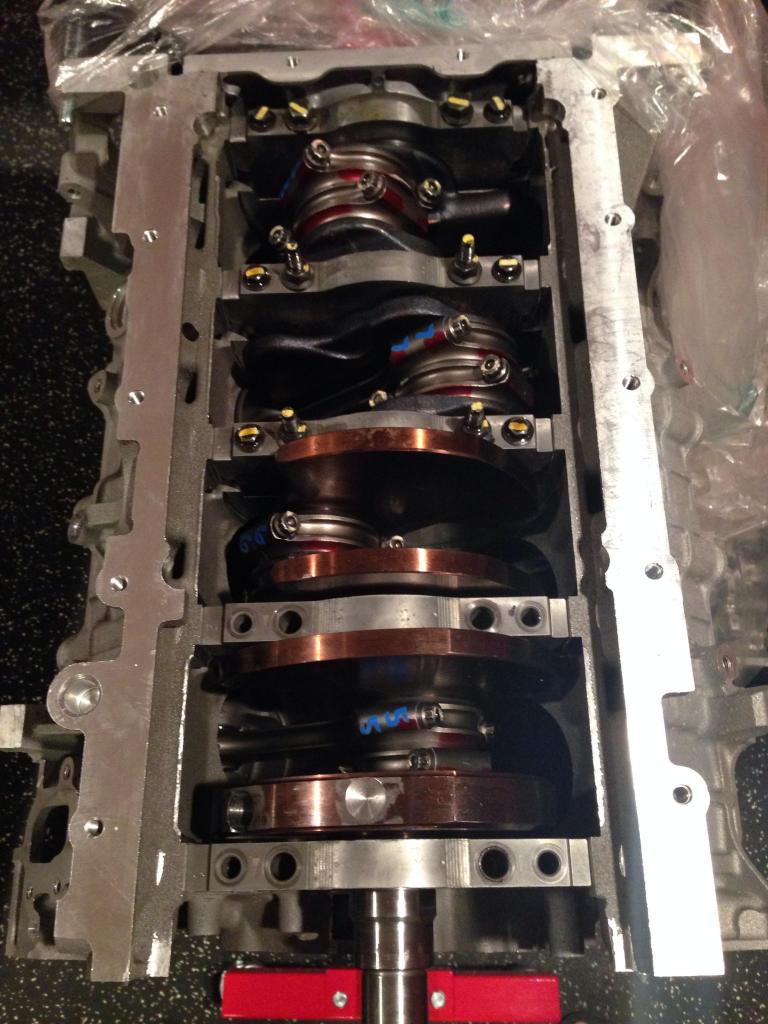

Pics:

Here are some pics of the main areas I noticed need to be deburred. If anyone else wants to chime in and suggest other areas that I should duburr feel free! Basically anywhere I can draw blood will be gone. The last thing I need is some sort of casting slag/imperfection flaking off into my motor.

Stock Pistons and Rods are Removed leaving me a bare block and crank.

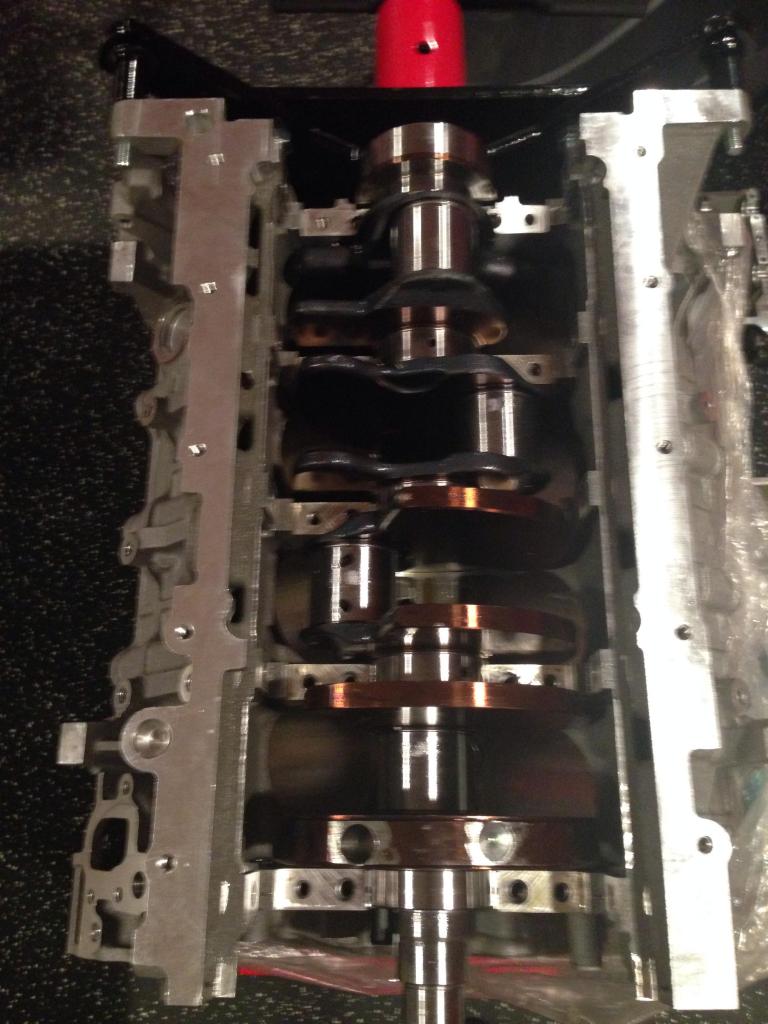

Main Caps Removed:

Crank Removed:

If I remember correctly, rod journals 1-8 all measured at 2.087"

Stay Tuned guys!

So far my motor consists of the following (All of which is brand new):

- 05-10 3v/Aluminator Block

- 03-04 Cobra Kellogg Crank (Stock Stroke)

- Oliver Billet I-Beam Rods w/ ARP 2000 Rod Bolts (5.933')

- Melling Billet Geared Oil Pump

- Canton Street/Strip T Pan (CAN15-780)

- Canton Windage Tray (CAN-20939)

- Roush Revised 9 Thread 05 DC Castings (Heads were Fully Loaded with OEM valves, springs, followers, and cams)

- Ferrea Comp Plus Intake Valves

- Brian Tooley .525 Modular Valve Springs

- Cloyes Hex-A-Just Primary Gears (9-3169A)

- Cloyes Billet Steel Secondary Gears (9-3676X9)

- ARP 12mm Cam Bolts

I still need to get my custom pistons from JE. I was fortunate enough to source BlownBlu97's Spec Sheet from him. I also need to get ARP Mainstuds, sidebolts, and headstuds.

Next on my agenda is measuring my bores (although it is brand new) so I can call JE and order my pistons. Keep in mind I am aiming for as close to stock bore as I can get. The block will need minimal machining more or less a touch hone of ~.002 to clean up the cylinder walls from sitting for so long. I will post pics of what it looks like. Pistons will be ordered .002 larger than my largest bore measurement.

Also to clarify so there is no confusion I got a once in a lifetime deal on a Ford Racing Aluminator shortblock, so if you see pics of me disassembling a brand new short block don't be alarmed lol. Lots of upgrading to be done in order to have a solid foundation for the turbo and the power I want to make (1000 on c16 through an auto)

Pics:

Here are some pics of the main areas I noticed need to be deburred. If anyone else wants to chime in and suggest other areas that I should duburr feel free! Basically anywhere I can draw blood will be gone. The last thing I need is some sort of casting slag/imperfection flaking off into my motor.

Stock Pistons and Rods are Removed leaving me a bare block and crank.

Main Caps Removed:

Crank Removed:

If I remember correctly, rod journals 1-8 all measured at 2.087"

Stay Tuned guys!