Okay... I have been having the hardest time getting my new Accufab Single Blade Throttle body to work with any plenum I have because of my IAC (idle air control) valve. What is the problem you may ask? The simple fact that the IAC valve is what the ECU uses to measure 2 static pressures... Static pressure #1 is static air from before the Throttle body but after the Mass Air Flow sensor. Static pressure #2 is static air after the throttle body but on the vacuum side of the plenum (non boost). Static pressure #2 after the throttle body ultimately controls the valve but air needs to move freely across the plunger (the bridge in the IAC that connects static #1 to #2) in the IAC. The problem with Single Blade throttle bodies that I have found is that unless you buy the matching plenum to that throttle body your car will never idle or run right because IAC static port #1 is either blocked or is actually getting pitot pressure (direct air) forcing the plunger shut. I picked up an accufab throttle body that doesnt have a static port so it just blocks off the MAF static air thus canceling out the vacuum needed to operate the IAC valve. I could do one of two things... Buy a power plenum = hundreds of dollars or buy the MMR remote IAC adapter (which doesnt come with a IAC block off plate for the original location of the IAC on the plenum) not to mention they are on back order with a wait time of a several months.

So I took matters into my own hands and got a few parts and tools together listed below:

-1/2" Drill

-1/8 drill bit (actually one size smaller)

-1/8 pipe threaded brass vacuum fitting (Vato Zone)

-2' of 5/16 vacuum line or fuel line

-ultra black gasket maker

-1/8 pipe thread tap set

I decided to drill about an 1/8" hole into the MAF to throttle body side of the IAC valve lets calls this "static #1" I then tapped it with 1/8 pipe thread. I cleaned out the IAC thoroughly and let it dry. I then installed my new billet flow plenum and Accufab SBTB. I placed a dab of ultra black rtv on the threads of the brass fitting and threaded it into the IAC until good n tight. I installed the IAC onto the billet flow plenum and bypassed the Throttle Body by attaching my 5/16 vacuum line to my new fabbed brass fitting on the IAC and attached the other end of the 5/16 vacuum line to the vacuum port on my intake tube after the MAF. I started the car up and it ran great. The throttle response greatly improved and my idle was around 900 or less.

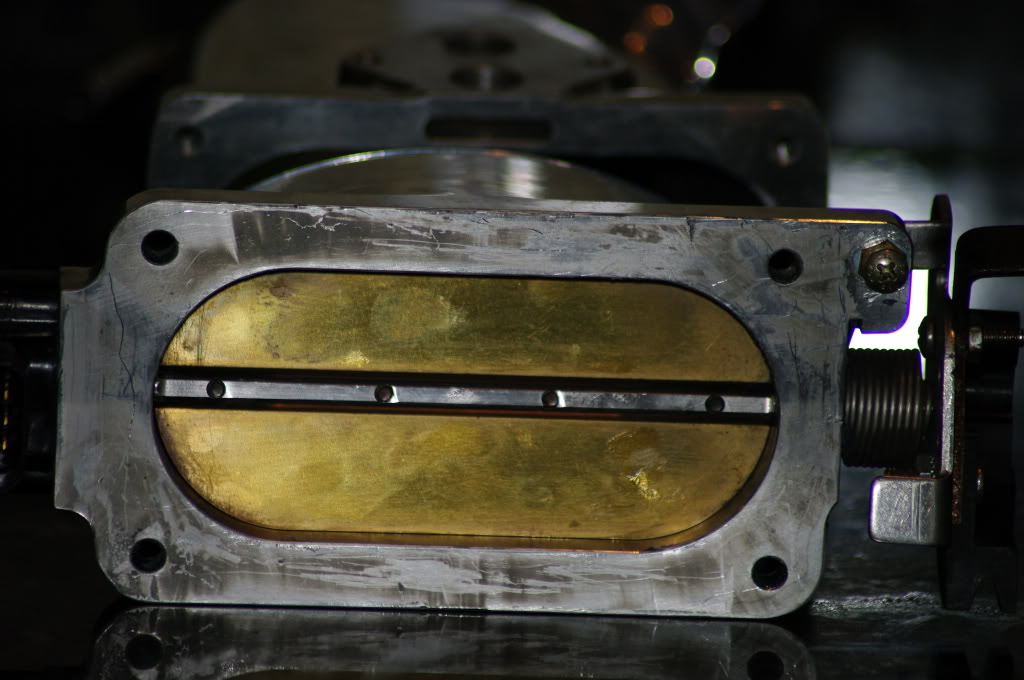

You can see the throttle body side of this Billet flow plenum has the slot cut out for a before throttle body static air input, but you will see that unless you have a billetflow TB which are hard to find and $450 your IAC will not work.

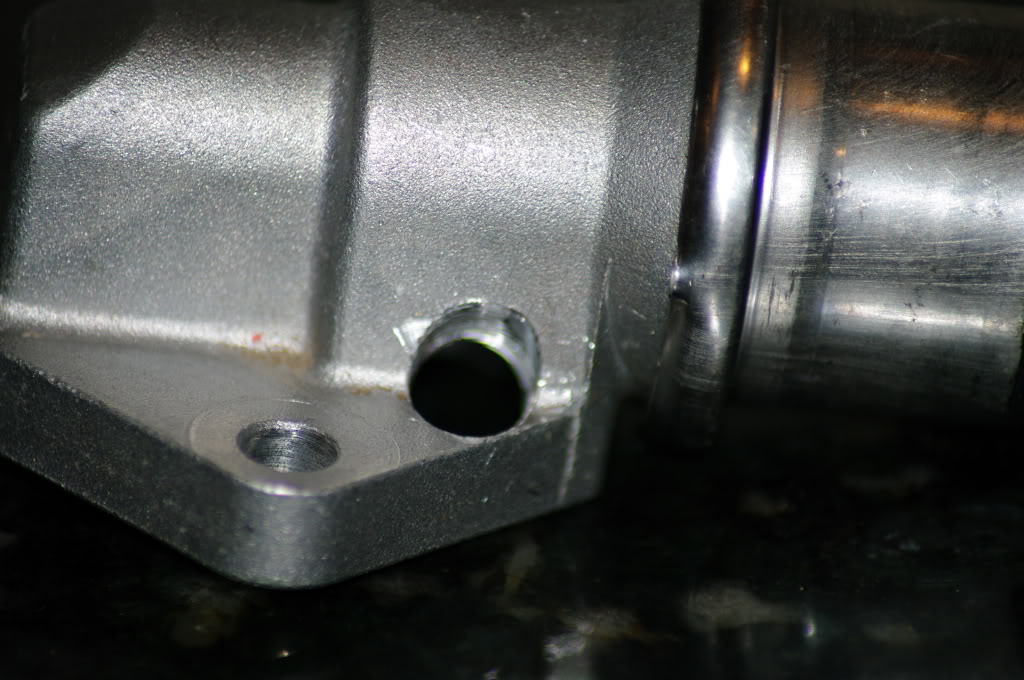

Again you can see that there is no static port on the throttle body where it mounts to the plenum

Here is the side view of my IAC valve after I drilled and tapped it... To the left you see the brass vacuum fitting

The underneath side of the IAC giving you a picture of how it works

IAC valve with new vacuum fitting installed

this is everything completed and working

Its not the prettiest but I am a function over form kind of guy with little patience and I hate wasting money when I dont need to. If you can get past the aesthetics its a great and cheap fix to an otherwise expensive and drawn out problem.

So I took matters into my own hands and got a few parts and tools together listed below:

-1/2" Drill

-1/8 drill bit (actually one size smaller)

-1/8 pipe threaded brass vacuum fitting (Vato Zone)

-2' of 5/16 vacuum line or fuel line

-ultra black gasket maker

-1/8 pipe thread tap set

I decided to drill about an 1/8" hole into the MAF to throttle body side of the IAC valve lets calls this "static #1" I then tapped it with 1/8 pipe thread. I cleaned out the IAC thoroughly and let it dry. I then installed my new billet flow plenum and Accufab SBTB. I placed a dab of ultra black rtv on the threads of the brass fitting and threaded it into the IAC until good n tight. I installed the IAC onto the billet flow plenum and bypassed the Throttle Body by attaching my 5/16 vacuum line to my new fabbed brass fitting on the IAC and attached the other end of the 5/16 vacuum line to the vacuum port on my intake tube after the MAF. I started the car up and it ran great. The throttle response greatly improved and my idle was around 900 or less.

You can see the throttle body side of this Billet flow plenum has the slot cut out for a before throttle body static air input, but you will see that unless you have a billetflow TB which are hard to find and $450 your IAC will not work.

Again you can see that there is no static port on the throttle body where it mounts to the plenum

Here is the side view of my IAC valve after I drilled and tapped it... To the left you see the brass vacuum fitting

The underneath side of the IAC giving you a picture of how it works

IAC valve with new vacuum fitting installed

this is everything completed and working

Its not the prettiest but I am a function over form kind of guy with little patience and I hate wasting money when I dont need to. If you can get past the aesthetics its a great and cheap fix to an otherwise expensive and drawn out problem.