I just got done installing my line lock. I bought a used PSP Line Lock Kit from another member a while ago and when I went to install it a couple weeks ago the hard line leaked. It leaked at the fitting on the solenoid and no matter what I did I couldn't get it to stop. I suspect there was a problem with the flared end of the line mating with the inside of the fitting. So I decided to just scrap all the stuff that came with the kit and just use the solenoid to build my own kit. I ended up buying the Summit Line Lock Installation Kit (Part# SUM-G3904). It comes with 4 hard lines that are already flared and have fittings on them. It also comes with an assortment of fittings. Some for the solenoid and some to adapt the hard lines to the brake system. I also bought a rocker switch with an LED on it from my local Advanced Auto and while and while I was there I also picked-up an Add-a-Fuse to tap into the fuse panel for the power supply. All of the other stuff I used I already had. I used two different tubing benders, some 14 gauge wire and a few connectors. All of which will be pictured later in this thread. Here's a few pics of some of the stuff I used...

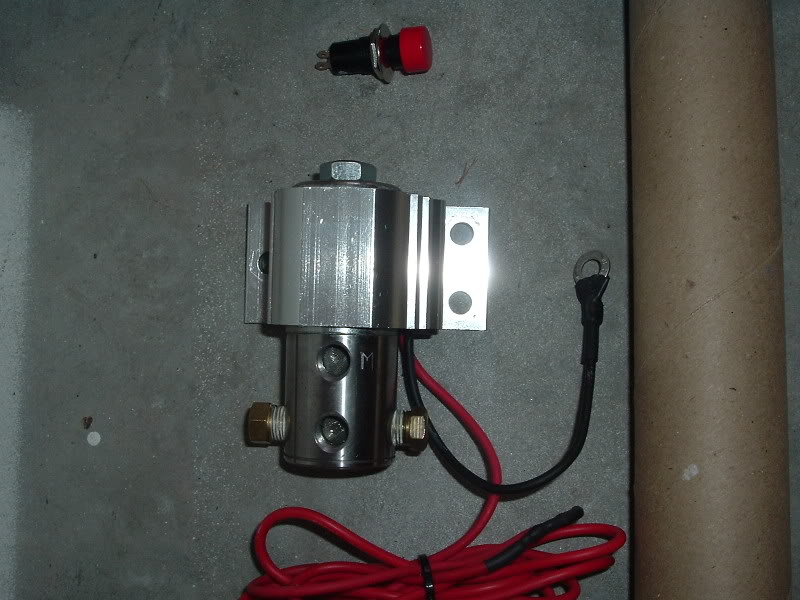

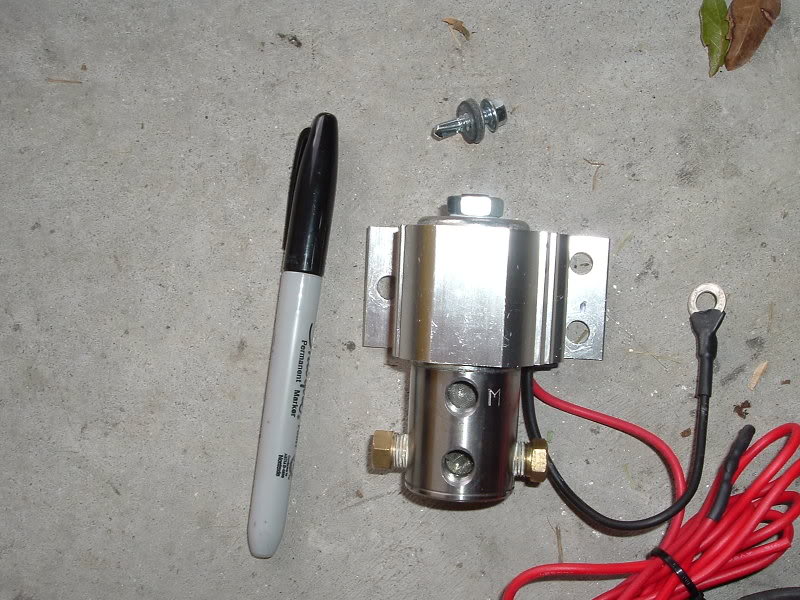

This is the Line Lock that came with the PSP Kit. I removed the sticker but it's a Hurst Solenoid (Part# HUU-1745000) and can be purchased from Summit along with the Install Kit...

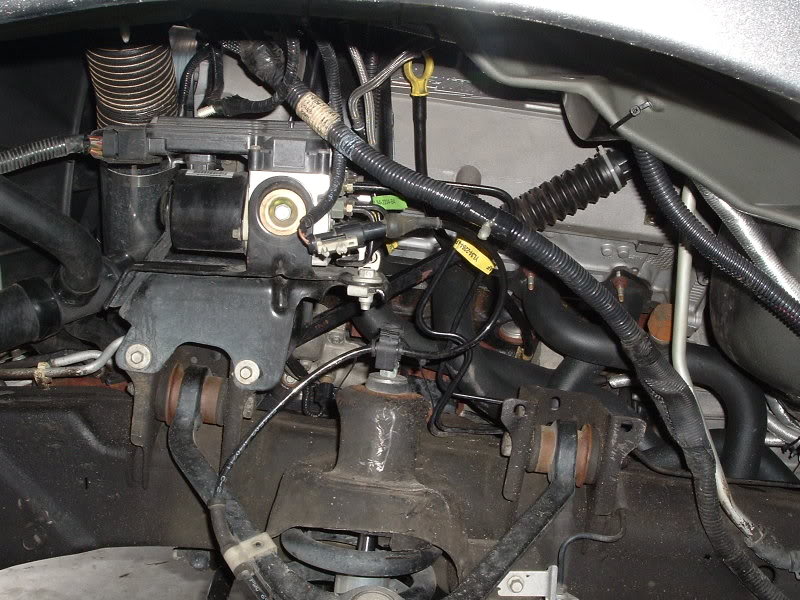

I decided to mount my solenoid in a different spot than most mount theirs. I mounted mine on the firewall underneath the brake booster. It makes for a clean install and keeps the clutter in the engine bay down. First I had to remove the drivers side front tire and the wheel well splash shield. I jacked up that corner and used a jackstand to ensure safety. Removing the tire is obvious and removing the splash shield is as simple as removing 4 screws and a few push pins...

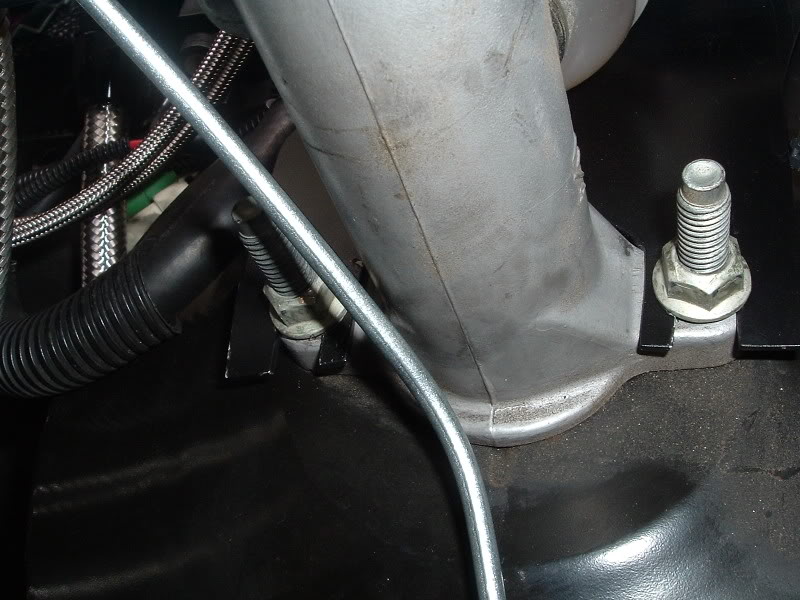

This gave me access to the components of the brake system I needed to modify and the location I chose to mount my line lock solenoid. Next I needed to mark where to drill the holes for the solenoid. I had previously removed the plate bracket that came on the solenoid from PSP. This leaves 3 holes to drill and here is how I marked and drilled them...

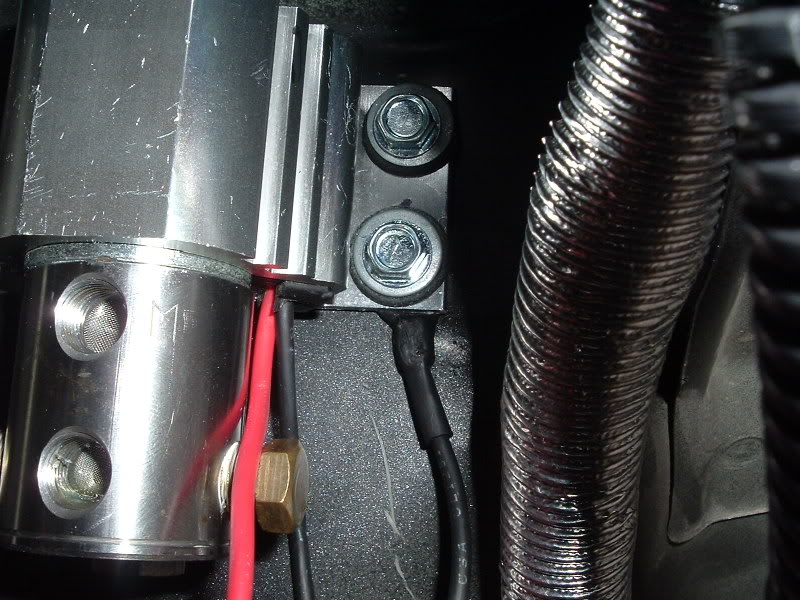

Then I mounted the solenoid using 3 self-tapping screws...

I took this opportunity to go ahead and ground the solenoid. I just grounded the wire between the solenoid and the firewall and secured it with one of the screws I used to mount the solenoid...

I had already extended the positive wire from the solenoid previously. I'll cover how to make a good connection later...

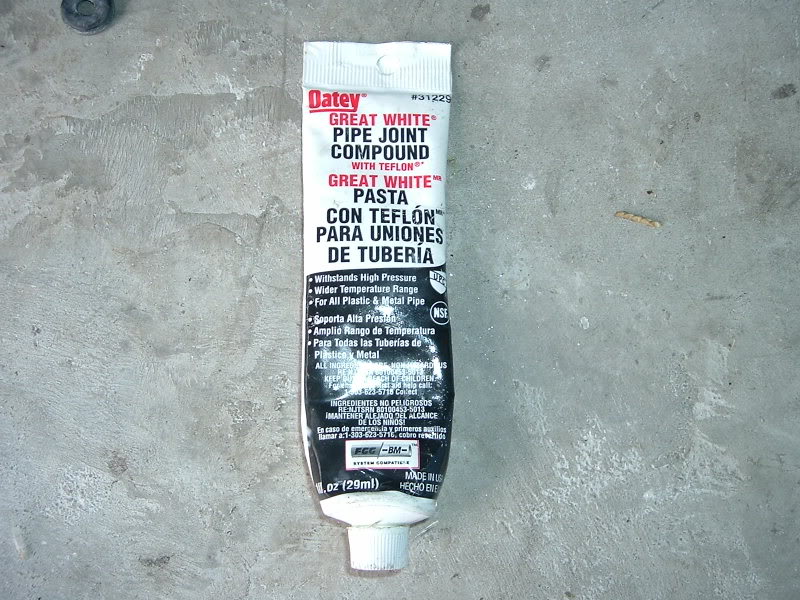

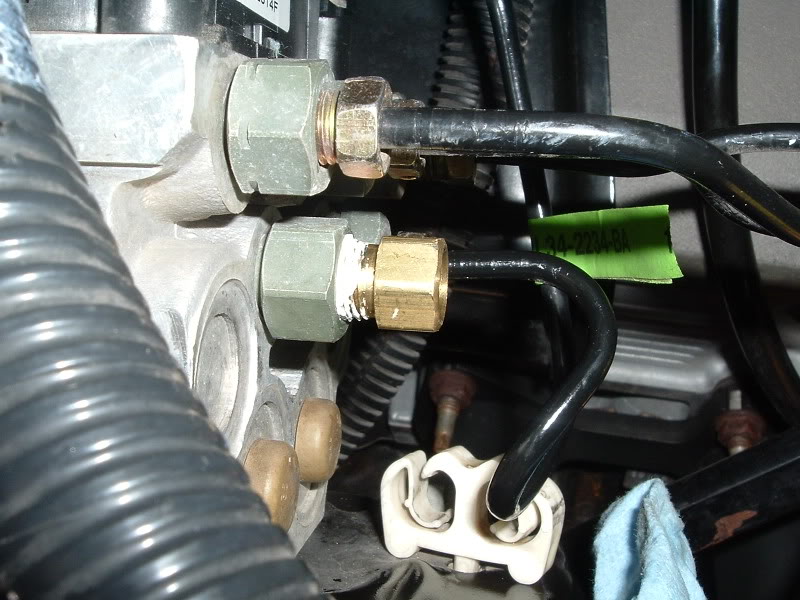

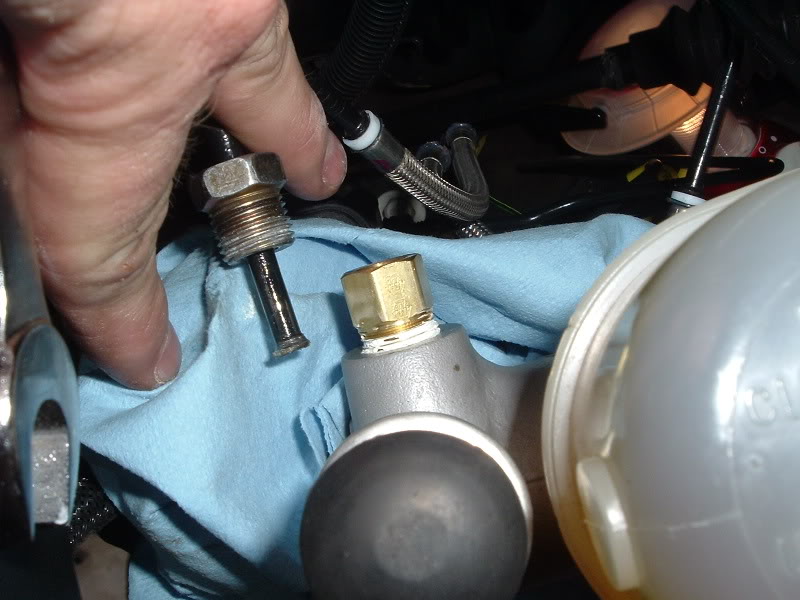

Next I installed the solenoid fittings. I used a little pipe joint compound I already had to ensure a good seal. This particular compound can be purchased at Lowes. A 7/16 wrench is required...

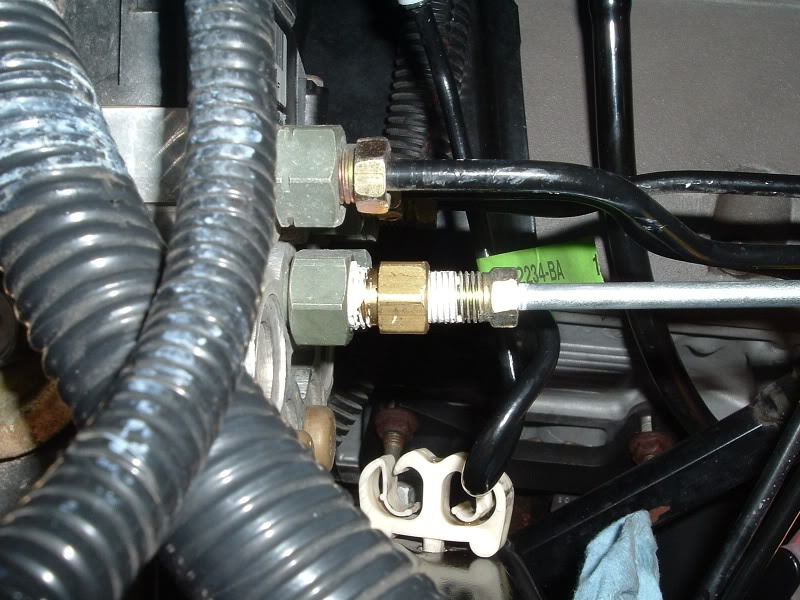

Then I installed the shortest of the 4 hard lines to see what kind of bends I needed to make. I used this hard line to connect the the lower fitting on the solenoid to the ABS fitting...

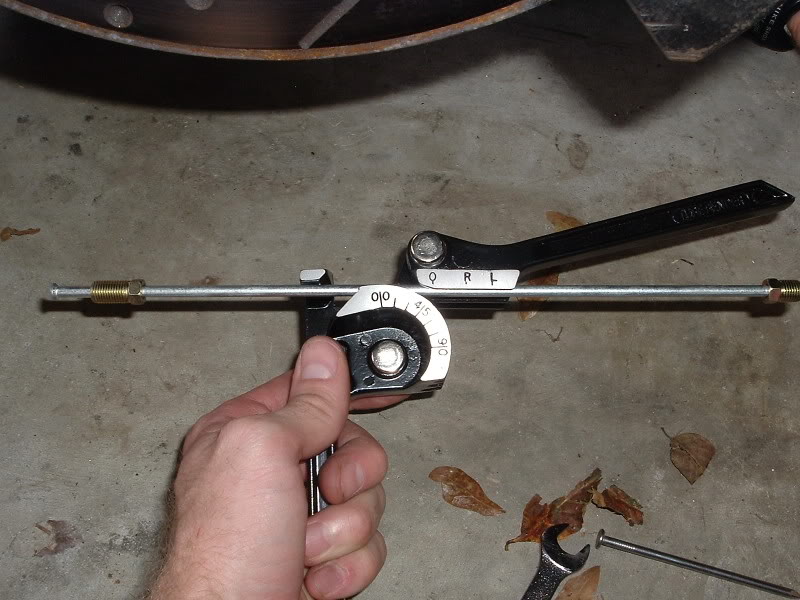

It was sitting dead even with the ABS fitting (lower left hand corner of the ABS block) but I needed to make some bends to get it to fit. The tubing bender I used I purchased from Lowes and it was pretty cheap. I can;t remember the cost as I've had it for about a year. All I had to do to make the tube line up perfect was make 2 45 degree bends....

Next I had to disconnect the stock line from the ABS block. I used a 7/16 wrench to do so. Make sure to place some rags underneath the fitting as you will lose a little fluid once it's removed...

Then I applied some pipe thread compound to one of the fittings that came with the kit and installed it. A 13mm wrench is required to install the new fitting...

Then I installed the line I just got done bending. A 10mm wrench is required to install the hard line fittings at the ABS block and the lower fitting of the solenoid. I went ahead and applied some pipe thread compound to these fittings even though I didn't really have to...

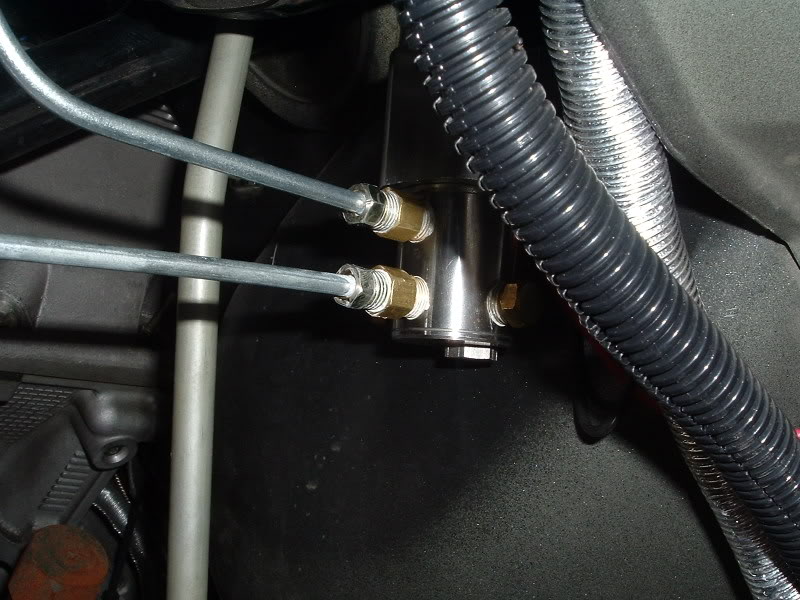

Then I had to remove the fitting from the master cylinder. The correct fitting is the one located in the front portion of the master cylinder as shown in the picture below. This fitting requires a 5/8 wrench to remove...

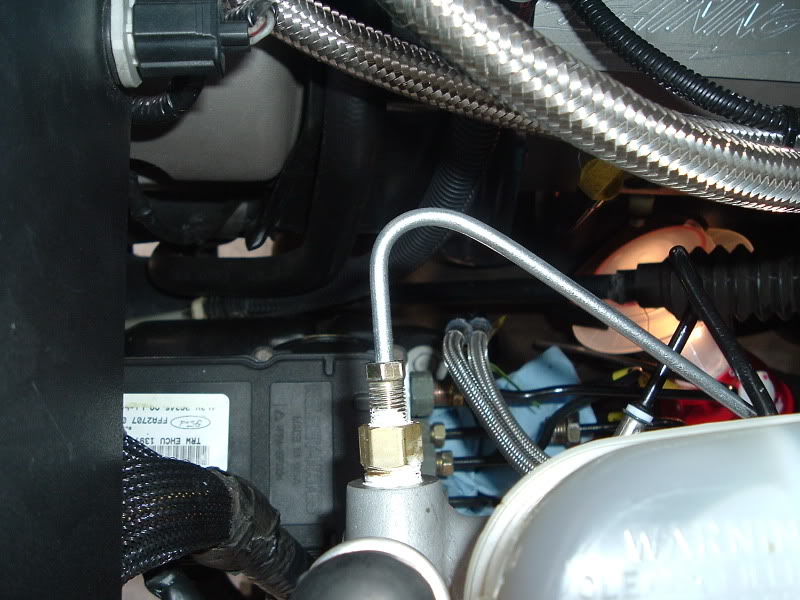

The I applied some pipe thread compound to one of the fittings that came in the kit and installed it into to master cylinder. A 9/16 wrench is required to install this fitting...

At this time I went ahead and removed the factory line as it was no longer needed...

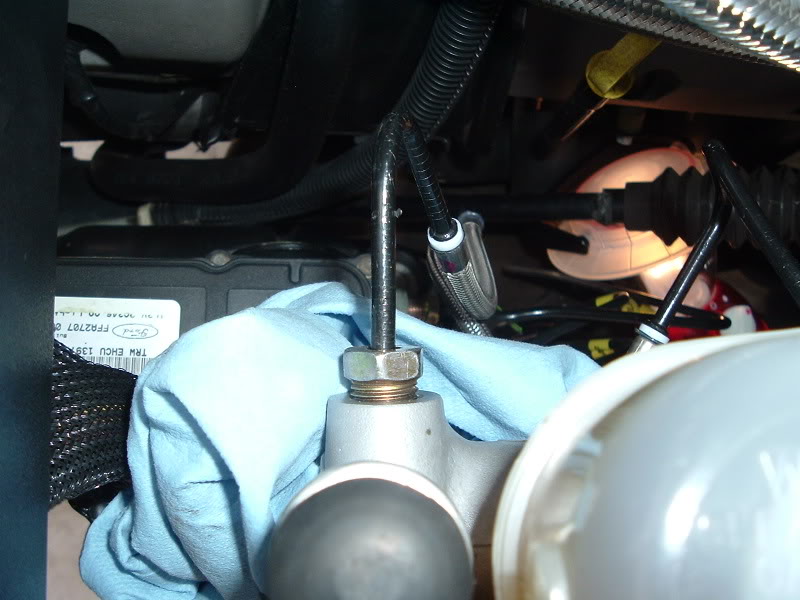

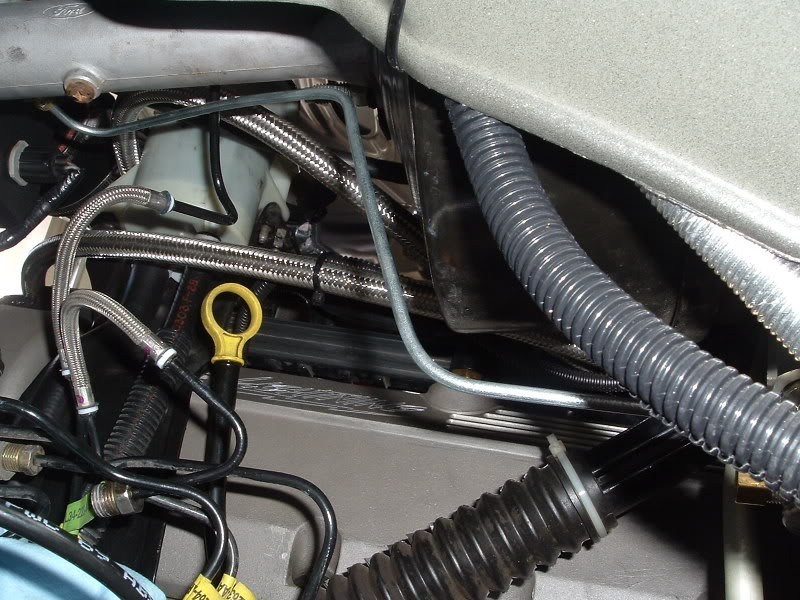

Then I had to bend a hard line to connect the master cylinder to the top fitting on the solenoid. I used the tubing bender shown earlier and also had to use my NOS tubing bender for one of the bends. I purchased the NOS tubing bender from www.nitrousoutlet.com and it is part# NOS-15991. This tubing bender is great for tighter radius bends...

It took a little trial and error to get the tube just right but in the end it fit great. I bent the tube to follow the contour of the brake booster and then underneath the master cylinder. It then comes out and makes a tight bend into the master cylinder. I went ahead and applied some pipe thread compound and installed the line. A 10mm wrench is required for the fittings on the line...

At this point it was time to bleed the brakes and check for leaks. I did and there were none. A 3/8 wrench is required for the bleeder screws to bleed the brakes. It has been said that you only need to bleed the front brakes. That may be but I would feel a lot better bleeding all 4 corners. Remember to bleed them in this order: Passenger side rear, drivers side rear, passenger side front and drivers side front...

Below is an illustration of how I extended the positive wire from the solenoid. This is also how I soldered all of the connections for this install. First I slid some heat-shrink onto the wire...

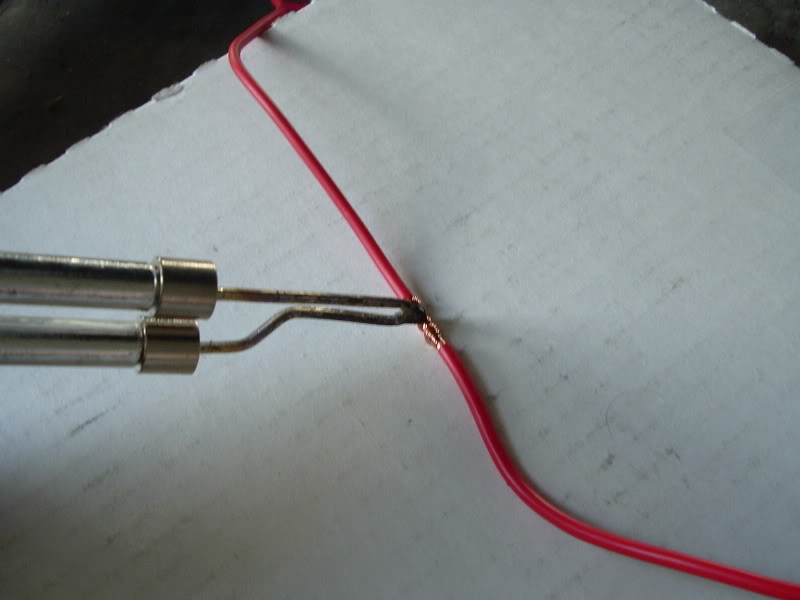

Then I stripped the insulation off both ends that were to be connected and wrapped them around each other...

Then I placed the tip of my soldering iron on the twist and squeezed the trigger to allow the wire to get nice and hot before applying solder...

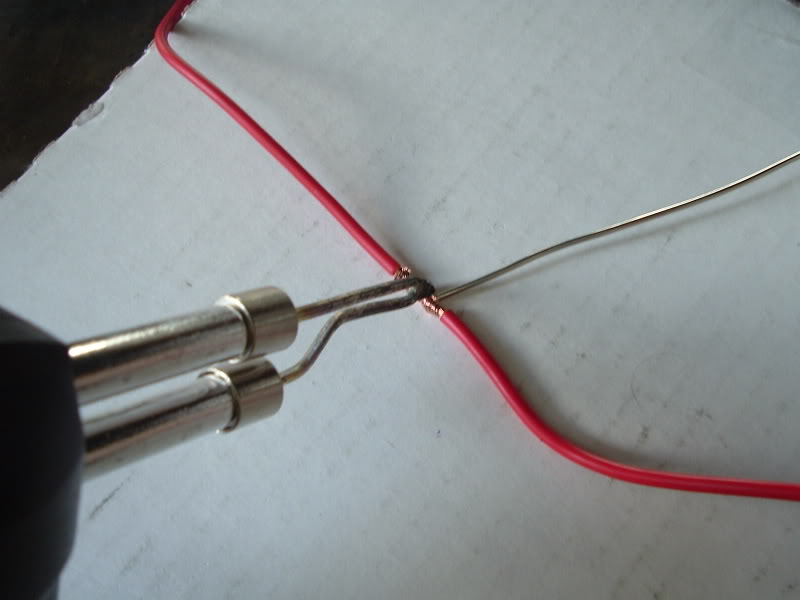

Then I applied some rosin core solder. You know a good soldering connection is made when the solder wicks itself into the wires...

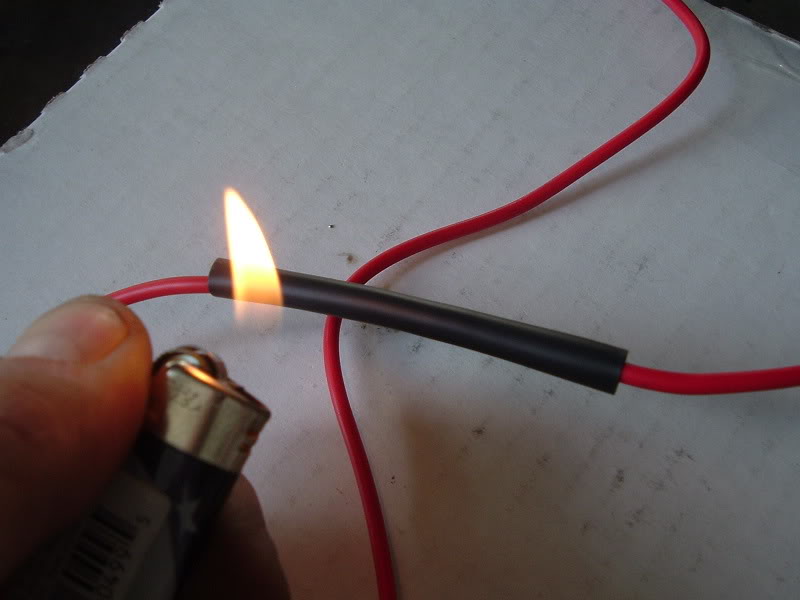

Then I slid the heat-shrink over the connection and applied heat with a lighter...

And here is the end result...

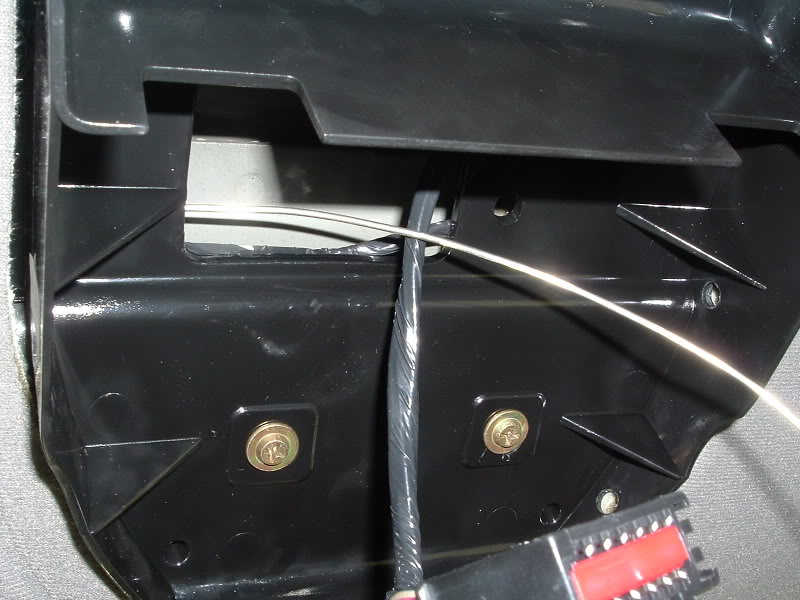

Next I put some black split loom on the positive wire and wrapped some electrical tape around one end. I purchased the split loom and the tape from NAPA...

Then I pushed it up all the way to the solenoid...

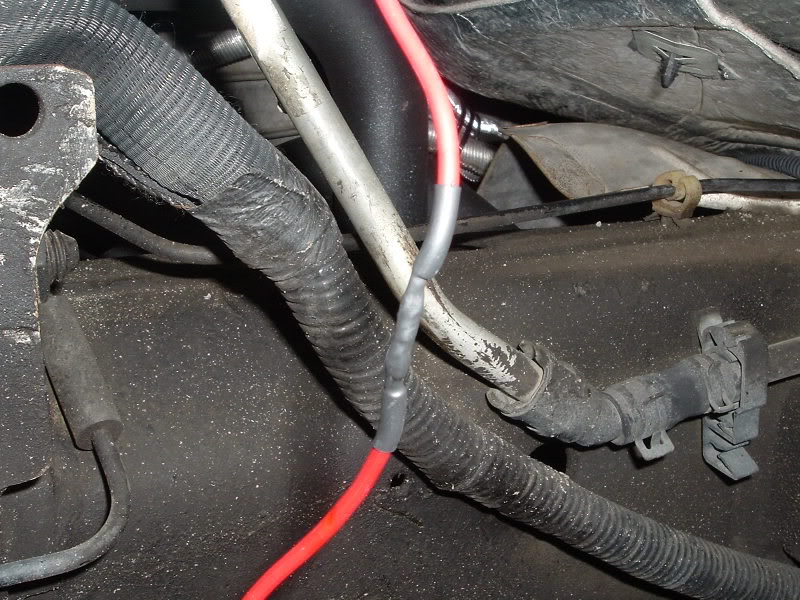

Then I ran the wire along some existing wires and tie wrapped it to them. I could have run this wire through the grommet in the firewall where the boost line comes through. But that grommet was already full with all my nitrous system wires. So I decided to enter the cab through one of the grommets in the floor pan right enderneath where your feet go...

I opened the drivers side door and removed the panel pictured. Just pull on it and it will snap loose. Then I lifted the carpet which allowed me access to the top of the grommet I was using...

Then I ran the wire through the grommet. Don't mind the wire that's already going through it. That goes to something else. Just make a hole in the grommet with a screwdriver and run the wire through...

I intersected the wire with the split loom that was already going through and used electrical tape to seal them together. This grommet is pretty soft and the split loom can be pulled through very easily...

Next I had to find a suitable location to mount the switch. I looked all aver and it took me a good hour to decide on a location. I decided to mount it in the sunglasses holder in the overhead console. This may be a little much for some people so if you decided to mount your switch in a different location the wiring will still be the same. I had to remove the console which was very easy. There is a phillips head screw in the very front that needs to be removed and then just pull on the console and it will snap loose. There is a connector that needs to be disconnected that supplies power to the console display. After that, I just set the console aside. I had to get the solenoid wire, power wire, and switch ground wire over to the console from the pillar but didn't want to remove the headliner or the visor. So I just fed some of my soldering wire from the opening in the console over to the pillar...

Then I wrapped the soldering wire around the 3 wires and pulled them through...

At this time I went ahead and installed the connectors that would allow me to connect the wires to the switch. I removed the insulation on the connectors because I was going to solder them and add heat-shrink tubing...

Next I used a Unibit to drill the hole for the switch. I purchased my Unibit from Grayco Hardware and it drills holes from 1/8" to 1/2"...

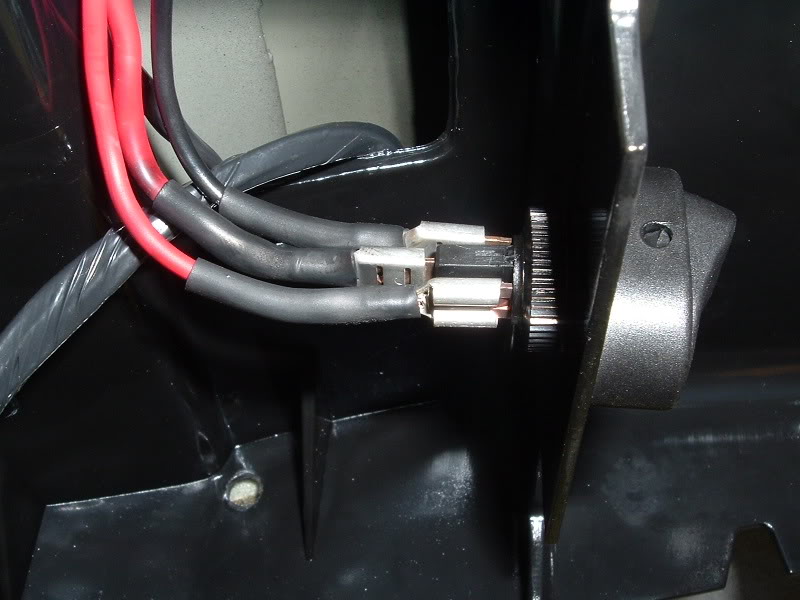

Then I attached the wires. The top wire is the ground for the switch itself. The center wire goes to the line lock solenoid and the bottom wire goes to the power source...

I ran all three wires from the headliner, down the pillar post, behind the weather stripping in the corner of the dash and down to the bottom of the dash. The pillar pod removal is not pictured but it is very easy to do. If you have a gauge pod where your stock pillar pod use to be then you know how to remove it. If not, just remove the caps on the handle and remove the two nuts. Then the handle and the pillar pod can be removed.Here are some pics...

Next I ran the ground wire to it's new home. I used a ground bolt behind the kick-panel for this location. The kick-panel is easily removed by just pulling on it. Once again I removed the insulation from a circular connector and soldered the ground wire to it. I also applied heat-shrink tubing...

Next I had to find a power supply. Most of my keyed-on power sources were being used for other accessories so I decided to use fuse #1 which is the power supply for the audio system. It has constant power but no power will go to the line lock unless the switch is flipped. And that's the main reason I mounted it where I did. So noone could see it and get the "I wonder what that does" idea and so I wouldn't accidentally flip it. I used the Add-a-Fuse I purchased from Advanced Auto to tap into this power source. The Add-a-Fuse comes with instructions but installing it is very easy. Just remove the fuse you want to tap into. put that fuse in the lower slot on the A-A-F and put a new fuse in the top slot. I used a 5 AMP fuse for the line lock. As with all my connections I soldered the power wire coming from the switch to the wire on the A-A-F...

That's pretty much it. Re-install everything in reverse order. I did run into a little snag when re-installing the overhead console. The connector that connects the display was right where the backside of my new switch was. The female connector is mounted to the console and can be moved by pushing down on the little tap on the left side and sliding the connector to the left. After that I reconnected the male and female connectors and just moved it out of the way. It may rattle a little but I'll correct that if it happens...

Then I out the console back on and here's how it looked...

I went out and tested it after I cleaned everything up. It worked great and the cloud of smoke I left in front of my apartment agreed with me. I'm not sure exactly how much it would cost to install this kit the way I did because of the tools involved. But the Hurst Line Lock Solenoid is $111.95 and the Summit Line Lock Installation Kit is $26.95. That should give you some idea. Hurst also sells an installation kit for $27.88 but it doesn't come with all the stuff the Summit kit has.

If there is something important that I missed, please add it to this thread. If anyone has any questions about this install or anything else, please PM me and I'll be glad to help in any way I can.

This is the Line Lock that came with the PSP Kit. I removed the sticker but it's a Hurst Solenoid (Part# HUU-1745000) and can be purchased from Summit along with the Install Kit...

I decided to mount my solenoid in a different spot than most mount theirs. I mounted mine on the firewall underneath the brake booster. It makes for a clean install and keeps the clutter in the engine bay down. First I had to remove the drivers side front tire and the wheel well splash shield. I jacked up that corner and used a jackstand to ensure safety. Removing the tire is obvious and removing the splash shield is as simple as removing 4 screws and a few push pins...

This gave me access to the components of the brake system I needed to modify and the location I chose to mount my line lock solenoid. Next I needed to mark where to drill the holes for the solenoid. I had previously removed the plate bracket that came on the solenoid from PSP. This leaves 3 holes to drill and here is how I marked and drilled them...

Then I mounted the solenoid using 3 self-tapping screws...

I took this opportunity to go ahead and ground the solenoid. I just grounded the wire between the solenoid and the firewall and secured it with one of the screws I used to mount the solenoid...

I had already extended the positive wire from the solenoid previously. I'll cover how to make a good connection later...

Next I installed the solenoid fittings. I used a little pipe joint compound I already had to ensure a good seal. This particular compound can be purchased at Lowes. A 7/16 wrench is required...

Then I installed the shortest of the 4 hard lines to see what kind of bends I needed to make. I used this hard line to connect the the lower fitting on the solenoid to the ABS fitting...

It was sitting dead even with the ABS fitting (lower left hand corner of the ABS block) but I needed to make some bends to get it to fit. The tubing bender I used I purchased from Lowes and it was pretty cheap. I can;t remember the cost as I've had it for about a year. All I had to do to make the tube line up perfect was make 2 45 degree bends....

Next I had to disconnect the stock line from the ABS block. I used a 7/16 wrench to do so. Make sure to place some rags underneath the fitting as you will lose a little fluid once it's removed...

Then I applied some pipe thread compound to one of the fittings that came with the kit and installed it. A 13mm wrench is required to install the new fitting...

Then I installed the line I just got done bending. A 10mm wrench is required to install the hard line fittings at the ABS block and the lower fitting of the solenoid. I went ahead and applied some pipe thread compound to these fittings even though I didn't really have to...

Then I had to remove the fitting from the master cylinder. The correct fitting is the one located in the front portion of the master cylinder as shown in the picture below. This fitting requires a 5/8 wrench to remove...

The I applied some pipe thread compound to one of the fittings that came in the kit and installed it into to master cylinder. A 9/16 wrench is required to install this fitting...

At this time I went ahead and removed the factory line as it was no longer needed...

Then I had to bend a hard line to connect the master cylinder to the top fitting on the solenoid. I used the tubing bender shown earlier and also had to use my NOS tubing bender for one of the bends. I purchased the NOS tubing bender from www.nitrousoutlet.com and it is part# NOS-15991. This tubing bender is great for tighter radius bends...

It took a little trial and error to get the tube just right but in the end it fit great. I bent the tube to follow the contour of the brake booster and then underneath the master cylinder. It then comes out and makes a tight bend into the master cylinder. I went ahead and applied some pipe thread compound and installed the line. A 10mm wrench is required for the fittings on the line...

At this point it was time to bleed the brakes and check for leaks. I did and there were none. A 3/8 wrench is required for the bleeder screws to bleed the brakes. It has been said that you only need to bleed the front brakes. That may be but I would feel a lot better bleeding all 4 corners. Remember to bleed them in this order: Passenger side rear, drivers side rear, passenger side front and drivers side front...

Below is an illustration of how I extended the positive wire from the solenoid. This is also how I soldered all of the connections for this install. First I slid some heat-shrink onto the wire...

Then I stripped the insulation off both ends that were to be connected and wrapped them around each other...

Then I placed the tip of my soldering iron on the twist and squeezed the trigger to allow the wire to get nice and hot before applying solder...

Then I applied some rosin core solder. You know a good soldering connection is made when the solder wicks itself into the wires...

Then I slid the heat-shrink over the connection and applied heat with a lighter...

And here is the end result...

Next I put some black split loom on the positive wire and wrapped some electrical tape around one end. I purchased the split loom and the tape from NAPA...

Then I pushed it up all the way to the solenoid...

Then I ran the wire along some existing wires and tie wrapped it to them. I could have run this wire through the grommet in the firewall where the boost line comes through. But that grommet was already full with all my nitrous system wires. So I decided to enter the cab through one of the grommets in the floor pan right enderneath where your feet go...

I opened the drivers side door and removed the panel pictured. Just pull on it and it will snap loose. Then I lifted the carpet which allowed me access to the top of the grommet I was using...

Then I ran the wire through the grommet. Don't mind the wire that's already going through it. That goes to something else. Just make a hole in the grommet with a screwdriver and run the wire through...

I intersected the wire with the split loom that was already going through and used electrical tape to seal them together. This grommet is pretty soft and the split loom can be pulled through very easily...

Next I had to find a suitable location to mount the switch. I looked all aver and it took me a good hour to decide on a location. I decided to mount it in the sunglasses holder in the overhead console. This may be a little much for some people so if you decided to mount your switch in a different location the wiring will still be the same. I had to remove the console which was very easy. There is a phillips head screw in the very front that needs to be removed and then just pull on the console and it will snap loose. There is a connector that needs to be disconnected that supplies power to the console display. After that, I just set the console aside. I had to get the solenoid wire, power wire, and switch ground wire over to the console from the pillar but didn't want to remove the headliner or the visor. So I just fed some of my soldering wire from the opening in the console over to the pillar...

Then I wrapped the soldering wire around the 3 wires and pulled them through...

At this time I went ahead and installed the connectors that would allow me to connect the wires to the switch. I removed the insulation on the connectors because I was going to solder them and add heat-shrink tubing...

Next I used a Unibit to drill the hole for the switch. I purchased my Unibit from Grayco Hardware and it drills holes from 1/8" to 1/2"...

Then I attached the wires. The top wire is the ground for the switch itself. The center wire goes to the line lock solenoid and the bottom wire goes to the power source...

I ran all three wires from the headliner, down the pillar post, behind the weather stripping in the corner of the dash and down to the bottom of the dash. The pillar pod removal is not pictured but it is very easy to do. If you have a gauge pod where your stock pillar pod use to be then you know how to remove it. If not, just remove the caps on the handle and remove the two nuts. Then the handle and the pillar pod can be removed.Here are some pics...

Next I ran the ground wire to it's new home. I used a ground bolt behind the kick-panel for this location. The kick-panel is easily removed by just pulling on it. Once again I removed the insulation from a circular connector and soldered the ground wire to it. I also applied heat-shrink tubing...

Next I had to find a power supply. Most of my keyed-on power sources were being used for other accessories so I decided to use fuse #1 which is the power supply for the audio system. It has constant power but no power will go to the line lock unless the switch is flipped. And that's the main reason I mounted it where I did. So noone could see it and get the "I wonder what that does" idea and so I wouldn't accidentally flip it. I used the Add-a-Fuse I purchased from Advanced Auto to tap into this power source. The Add-a-Fuse comes with instructions but installing it is very easy. Just remove the fuse you want to tap into. put that fuse in the lower slot on the A-A-F and put a new fuse in the top slot. I used a 5 AMP fuse for the line lock. As with all my connections I soldered the power wire coming from the switch to the wire on the A-A-F...

That's pretty much it. Re-install everything in reverse order. I did run into a little snag when re-installing the overhead console. The connector that connects the display was right where the backside of my new switch was. The female connector is mounted to the console and can be moved by pushing down on the little tap on the left side and sliding the connector to the left. After that I reconnected the male and female connectors and just moved it out of the way. It may rattle a little but I'll correct that if it happens...

Then I out the console back on and here's how it looked...

I went out and tested it after I cleaned everything up. It worked great and the cloud of smoke I left in front of my apartment agreed with me. I'm not sure exactly how much it would cost to install this kit the way I did because of the tools involved. But the Hurst Line Lock Solenoid is $111.95 and the Summit Line Lock Installation Kit is $26.95. That should give you some idea. Hurst also sells an installation kit for $27.88 but it doesn't come with all the stuff the Summit kit has.

If there is something important that I missed, please add it to this thread. If anyone has any questions about this install or anything else, please PM me and I'll be glad to help in any way I can.