Im getting some plans ready for a week from Saturday when I plan on porting my M122 Supercharger. Ive got my extended length die grinder and Tungsten Carbide bit. Picking up some supercharger oil sometime this coming week.

Car setup: M122, 2.5 upper only, JLT 123mm, Whipple standard oval port TB, VMP S/C heavy duty tensioner, BPS idler bracket w/ 90mm pulley, NGK plugs, WOT Box, Lethal O/R H pipe, McLeod RXT, MGW Gen 2, Alum Driveshaft, full BMR rod end drag set up, Viking DA shocks and springs, Ford racing 4.10 rear gears. Tuned by Lund Racing. May or may not install my headers before heading to the strip in Phoenix for the first time.

Goals: 600+ RWHP and Torque or breaking into the high 10's. Prefer getting into the 10's Fuel will be approx 93 octane (100 VP race gas and Chevron 91 mixed to 93)

Ive researched a few patterns of opened up supercharger ports that Ill want to cut. Posi Ported M122s seem to have a very nice but simple opening at the rear of the discharge port:

I hear nothing but awesome reviews of Posi port M122s. BJ from VMP went into the 10s with his Posi, 2.6 upper, 10% lower (same as just a 2.5" upper) intake, TB and 4,10s like I just installed in my car. Im sure hes a better driver than me for sure, but that tells me the potential is definitely there.

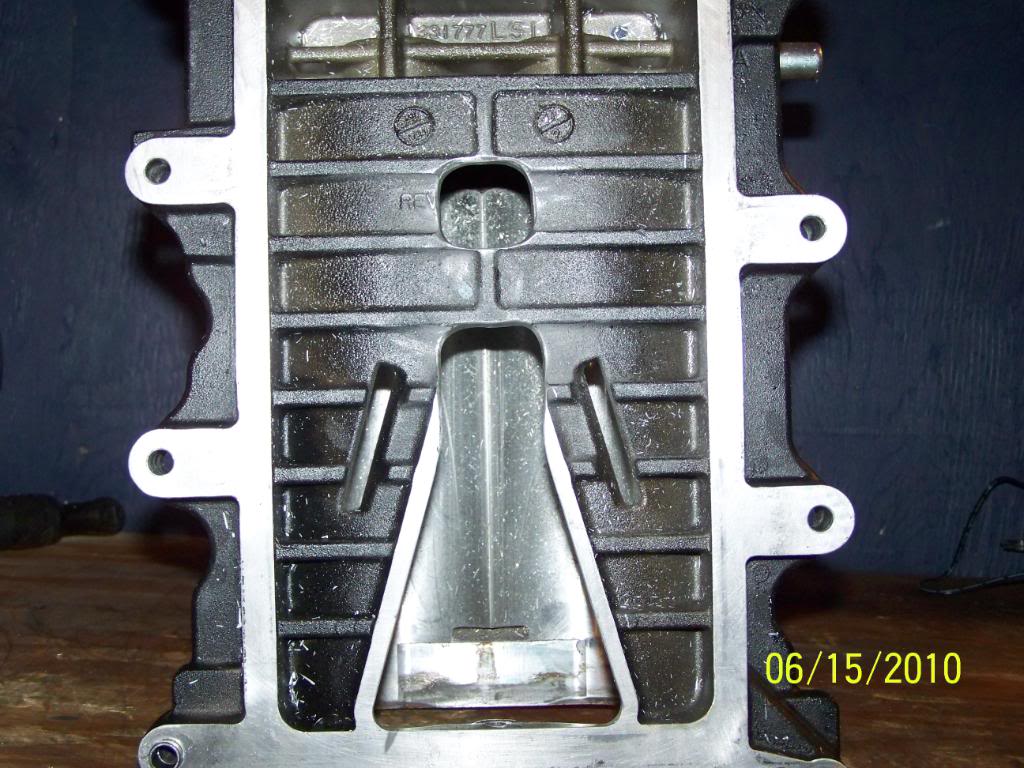

MRL Seems to have taken theirs a step further buy adding a small but separate port further back like so:

One other port job by a company called Joker Performance is a bit more extreme in the lower port but havent joined it with the main port. This isnt an M122, but similar to what they would do:

Stiegmeier does a much more intricate design, but the concept remains the same. Not an M122 but for visual reference:

With so many people who have had Posi ports, Im leaning heavily toward his simple opening style, perhaps a bit more open like the MRL style. I had been toying with the idea of removing the material from the port to the silencer ports. Probably would make the M122 SCREAM, but Im worried it may make the port worse than leaving it alone if I did that.

Any and ALL tips, hints etc would be greatly appreciated!

What kind of locktite do I need for the case seal?

Car setup: M122, 2.5 upper only, JLT 123mm, Whipple standard oval port TB, VMP S/C heavy duty tensioner, BPS idler bracket w/ 90mm pulley, NGK plugs, WOT Box, Lethal O/R H pipe, McLeod RXT, MGW Gen 2, Alum Driveshaft, full BMR rod end drag set up, Viking DA shocks and springs, Ford racing 4.10 rear gears. Tuned by Lund Racing. May or may not install my headers before heading to the strip in Phoenix for the first time.

Goals: 600+ RWHP and Torque or breaking into the high 10's. Prefer getting into the 10's Fuel will be approx 93 octane (100 VP race gas and Chevron 91 mixed to 93)

Ive researched a few patterns of opened up supercharger ports that Ill want to cut. Posi Ported M122s seem to have a very nice but simple opening at the rear of the discharge port:

I hear nothing but awesome reviews of Posi port M122s. BJ from VMP went into the 10s with his Posi, 2.6 upper, 10% lower (same as just a 2.5" upper) intake, TB and 4,10s like I just installed in my car. Im sure hes a better driver than me for sure, but that tells me the potential is definitely there.

MRL Seems to have taken theirs a step further buy adding a small but separate port further back like so:

One other port job by a company called Joker Performance is a bit more extreme in the lower port but havent joined it with the main port. This isnt an M122, but similar to what they would do:

Stiegmeier does a much more intricate design, but the concept remains the same. Not an M122 but for visual reference:

With so many people who have had Posi ports, Im leaning heavily toward his simple opening style, perhaps a bit more open like the MRL style. I had been toying with the idea of removing the material from the port to the silencer ports. Probably would make the M122 SCREAM, but Im worried it may make the port worse than leaving it alone if I did that.

Any and ALL tips, hints etc would be greatly appreciated!

What kind of locktite do I need for the case seal?