Just like many of you, the alternator on my 2008 GT500 went out. My car is mostly stock, save for Borla Stinger catbacks. Anyway, she barely has 25k miles on her, so I'm sure you can see my frustration. To top it off, she's my daily driver for now! I've been either walking to work or getting rides. Luckily, I work less than 2 miles away from home.

Anyway, after doing some research, I decided to buy my alternator from Adam at Nations Starter & Electric. However, instead of buying the model that most everybody purchsed for $700, which is the XP-270A, he said he had an XP-200A in the back for $500. He said they were the same thing, just different amperages. I asked him for help installing it, and he said it's literally a straight plug-and-play, the only thing I have to do is drill a larger hole (5/18) into the alternator's connection eyelet socket. Also, a little off topic, but the pulley size is different. I'm at work, so I don't remember if it's larger or smaller. But, how will that affect me when putting the belt back on? I've never worked with belts, so will my tensioner automatically adjust without me needing to do anything?

I removed the old alternator with the help of a friend, and installed the new one. This is where I'm stuck. Under the car, the connection that's supposed to hook up to the alternator is too short! Adam said there should be enough slack, but clearly I'm having troubles. I'm hoping that you guys can help me out. I really hope I don't have to replace the cable, because I have no idea what I'm doing when it comes to wiring.

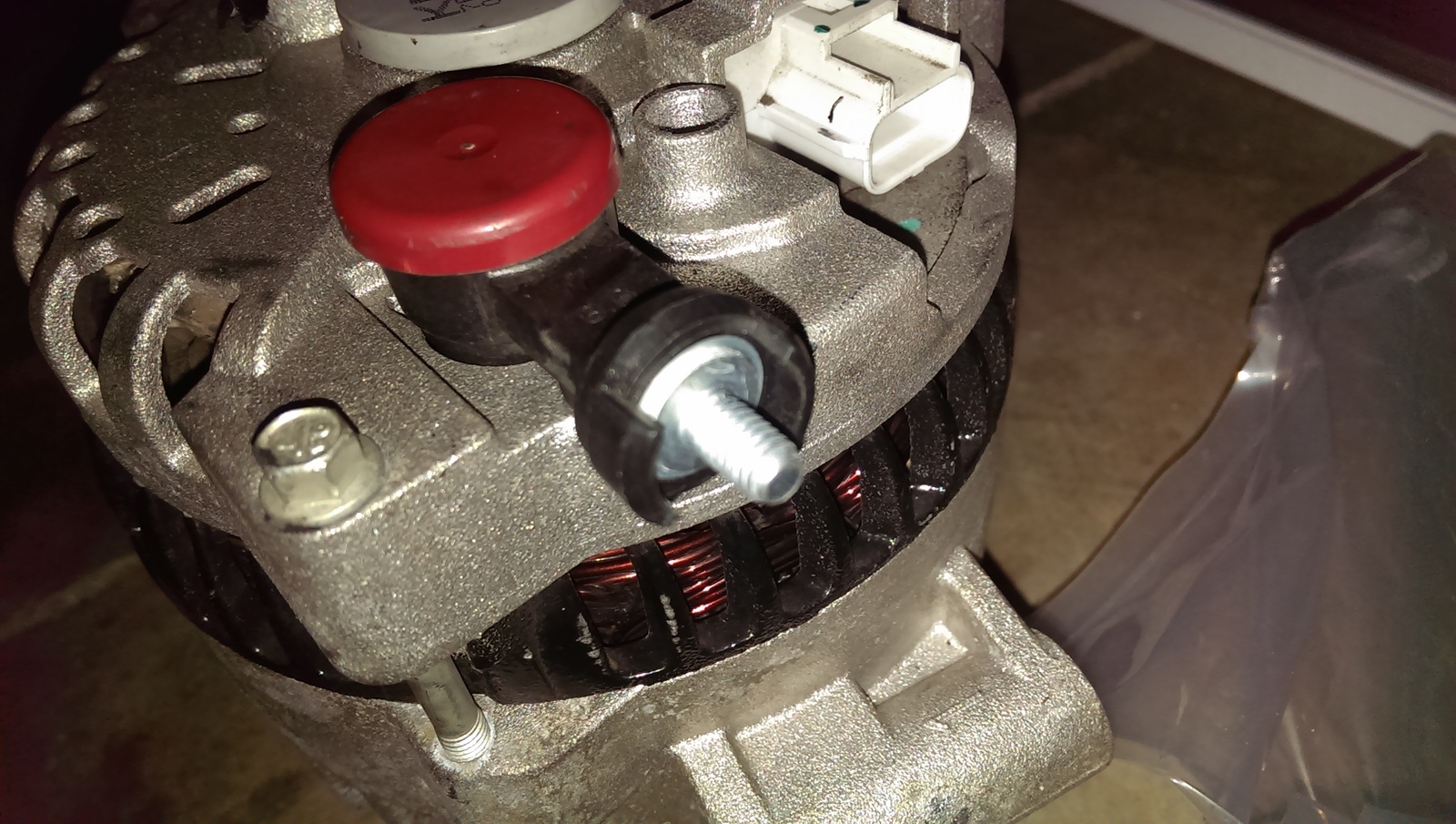

Here's the old alternator, as you can see, the connection has a little elbow that extends it out, letting the cable connect to it with ease:

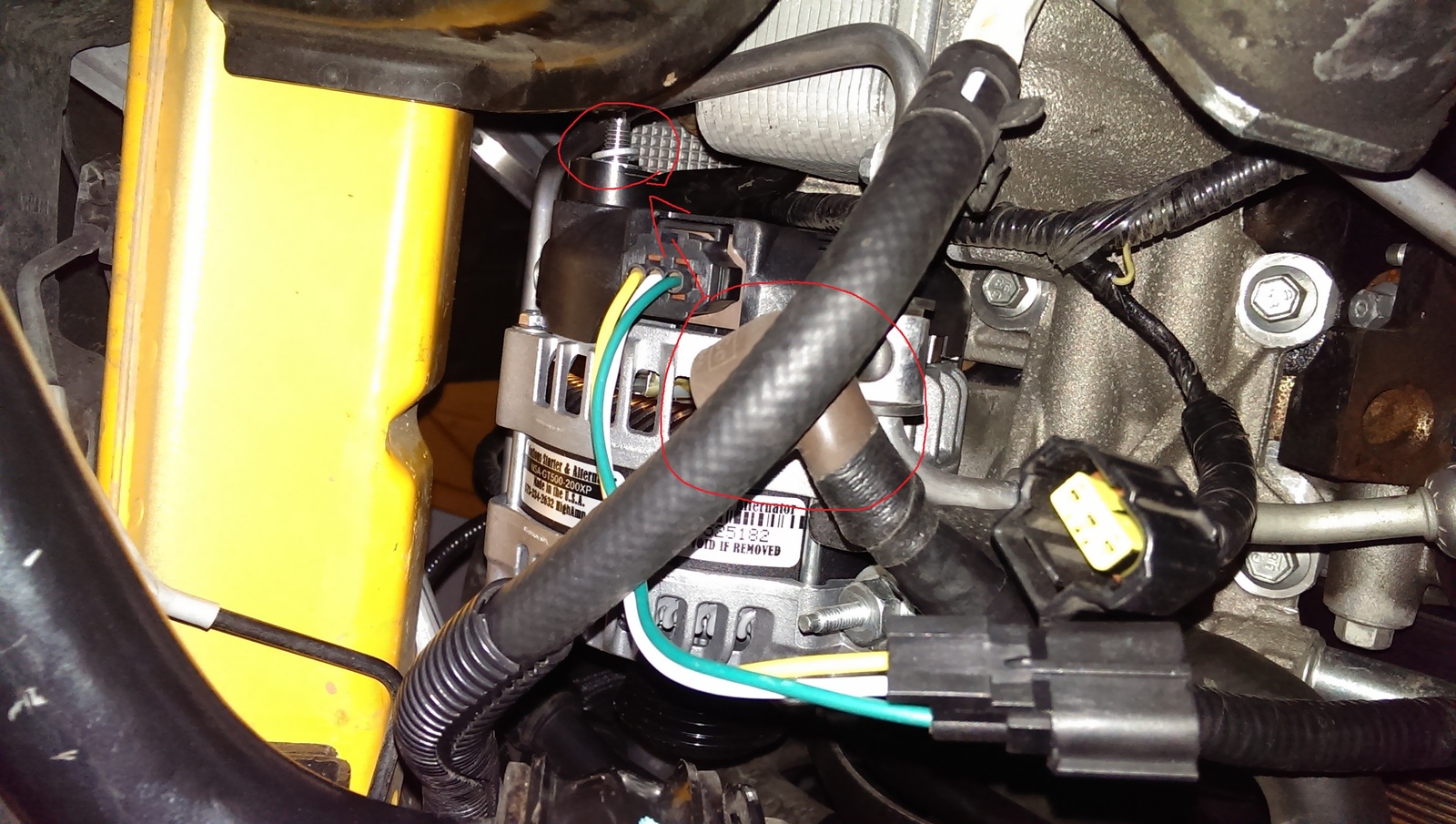

Here's the new alternator already installed, and the connection is further back. I circled my two connection problems:

I also tried unscrewing the wire from where it was being held in place, but that didn't give me any more slack. The only solution I can see is a new wire, but I'm really hoping it doesn't boil down to that. If that's the case, can anybody please point me in the right direction!

Thanks a lot!

Anyway, after doing some research, I decided to buy my alternator from Adam at Nations Starter & Electric. However, instead of buying the model that most everybody purchsed for $700, which is the XP-270A, he said he had an XP-200A in the back for $500. He said they were the same thing, just different amperages. I asked him for help installing it, and he said it's literally a straight plug-and-play, the only thing I have to do is drill a larger hole (5/18) into the alternator's connection eyelet socket. Also, a little off topic, but the pulley size is different. I'm at work, so I don't remember if it's larger or smaller. But, how will that affect me when putting the belt back on? I've never worked with belts, so will my tensioner automatically adjust without me needing to do anything?

I removed the old alternator with the help of a friend, and installed the new one. This is where I'm stuck. Under the car, the connection that's supposed to hook up to the alternator is too short! Adam said there should be enough slack, but clearly I'm having troubles. I'm hoping that you guys can help me out. I really hope I don't have to replace the cable, because I have no idea what I'm doing when it comes to wiring.

Here's the old alternator, as you can see, the connection has a little elbow that extends it out, letting the cable connect to it with ease:

Here's the new alternator already installed, and the connection is further back. I circled my two connection problems:

I also tried unscrewing the wire from where it was being held in place, but that didn't give me any more slack. The only solution I can see is a new wire, but I'm really hoping it doesn't boil down to that. If that's the case, can anybody please point me in the right direction!

Thanks a lot!

Last edited: