Is there anyone in here that has mill their head much?

What issues did you have?

-I just sent my Cyl. heads to the porter and I'm contemplating how much to have them mill the cylinder heads.

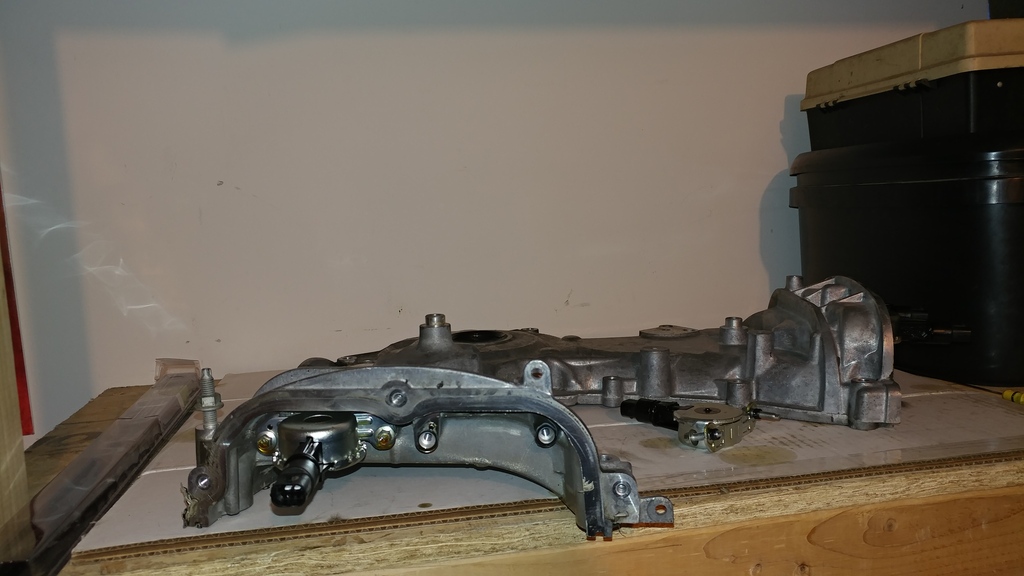

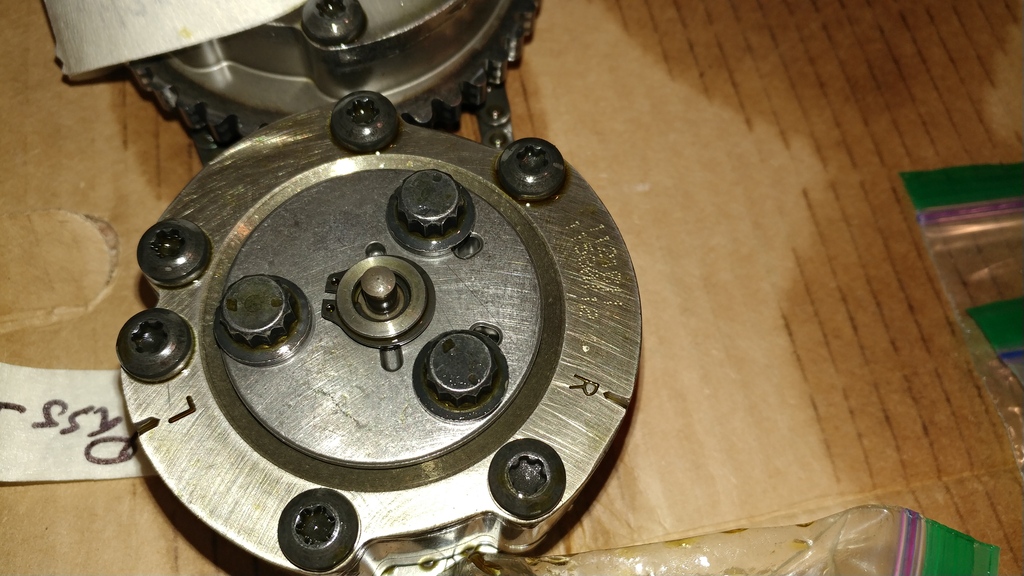

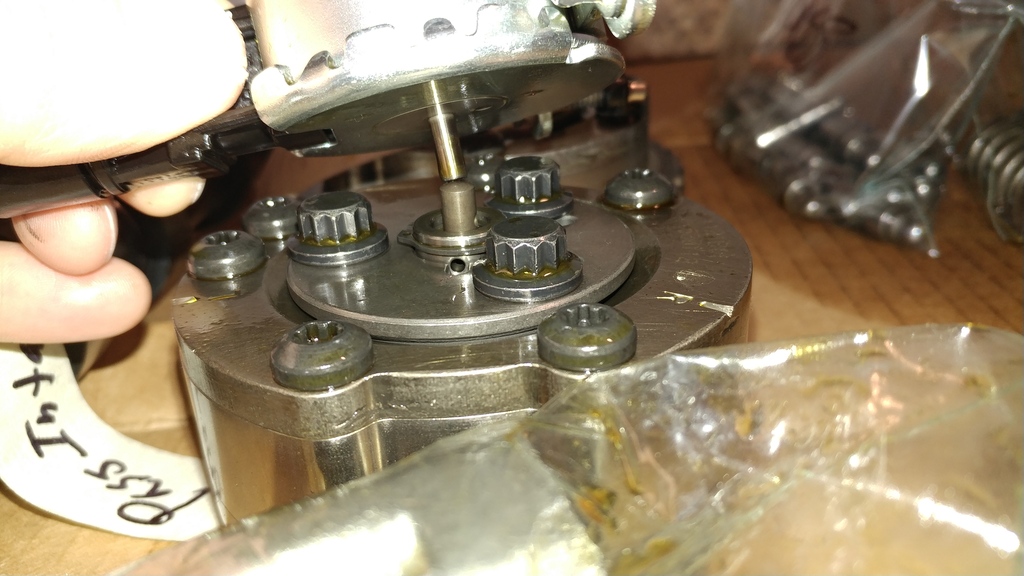

-It looks like there is going to be an issue with the VCT solenoid alignment and some with the intake manifold, but not much. As milling only moves the ports closer to the vertical center line of the engine.

-I wish I still had a mill because the VCT timing cover would be short work, but as it stands I will have to pay someone to modify the timing cover.

What issues did you have?

-I just sent my Cyl. heads to the porter and I'm contemplating how much to have them mill the cylinder heads.

-It looks like there is going to be an issue with the VCT solenoid alignment and some with the intake manifold, but not much. As milling only moves the ports closer to the vertical center line of the engine.

-I wish I still had a mill because the VCT timing cover would be short work, but as it stands I will have to pay someone to modify the timing cover.

Last edited: