Continuation thread of this

http://www.svtperformance.com/forums/terminator-talk-229/909177-thought-id-share-pics-my-k-member-upr.html

I just finished this setup, with the following

96-04 upr k member

12-250lb coil over springs, amp performance 03 04 cobra coilovers

energy suspension motor mounts

I used factory bilstein struts bc they have internal bumpstops this way you will have no noise on a coil over setup.

4 bolt ebay cc plates, 115.00 these are awesome with great bearings, no noise at all driving it.

new bushings for stabilizers

stage 8 locking header bolts

pacesetter longtube headers with matching x pipe

upr bumpsteer kit

First thing you need to do, is take an allen wrench and put it into the strut ontop of the strut tower, then take a wrench while holding the allen wrench in the strut and brake that nut loose,

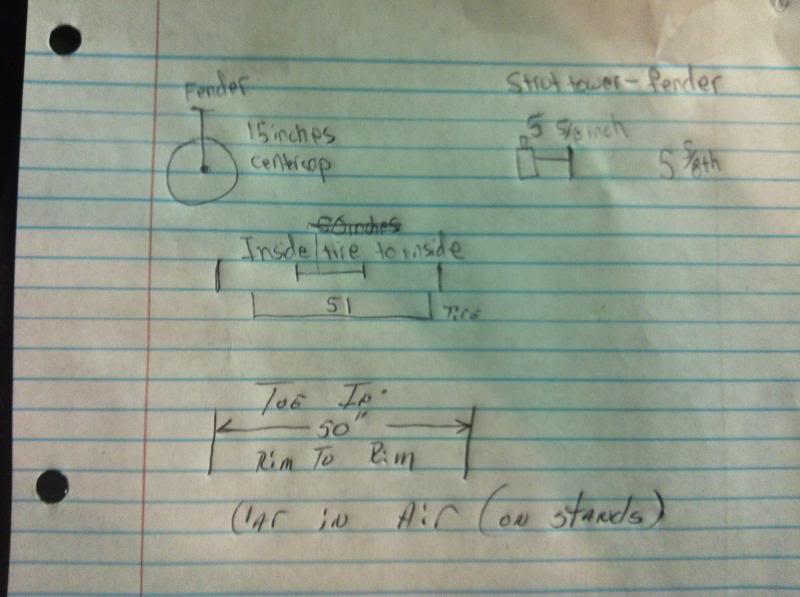

then take quite a few measurements. I took measurements from inside of the tire to other side on inside

also strut tower to fender, and center of hubcap to fender.

I wanted to get it as close as possible as the way it was for when i go to get an alignment done.

now you want to get the car as far up in the air as you can, i placed wooden blocks under the rear tires and jack stands on the frame rails and removed the front tires,

now its time to remove the rotors, brake calipers struts and cc plates, and the spindles

note : the abs sensor takes a special socket, its called an E BIT, e8 torx bit socket female end to remove, i had to go purchase this.

I took a jack and placed it under the control arm and jacked it a few times to compress the spring to loosen everything and slowly let the jack down, as the spring is under pressure, this was very easy to do. also remove the stabilizer bars on swaybar.

now i purchased the harbor frieght engine support bar, and put the chains on the timing cover bolts, as u see below, this was safe as i held the engine up for several days with no problems as i tackled this install.

Also to be safe i placed a jack under the transmission for backup.

This engine bar is a must, because when you goto to put the longtubes on u can raise and lower the engine per side your working on.

http://www.svtperformance.com/forums/terminator-talk-229/909177-thought-id-share-pics-my-k-member-upr.html

I just finished this setup, with the following

96-04 upr k member

12-250lb coil over springs, amp performance 03 04 cobra coilovers

energy suspension motor mounts

I used factory bilstein struts bc they have internal bumpstops this way you will have no noise on a coil over setup.

4 bolt ebay cc plates, 115.00 these are awesome with great bearings, no noise at all driving it.

new bushings for stabilizers

stage 8 locking header bolts

pacesetter longtube headers with matching x pipe

upr bumpsteer kit

First thing you need to do, is take an allen wrench and put it into the strut ontop of the strut tower, then take a wrench while holding the allen wrench in the strut and brake that nut loose,

then take quite a few measurements. I took measurements from inside of the tire to other side on inside

also strut tower to fender, and center of hubcap to fender.

I wanted to get it as close as possible as the way it was for when i go to get an alignment done.

now you want to get the car as far up in the air as you can, i placed wooden blocks under the rear tires and jack stands on the frame rails and removed the front tires,

now its time to remove the rotors, brake calipers struts and cc plates, and the spindles

note : the abs sensor takes a special socket, its called an E BIT, e8 torx bit socket female end to remove, i had to go purchase this.

I took a jack and placed it under the control arm and jacked it a few times to compress the spring to loosen everything and slowly let the jack down, as the spring is under pressure, this was very easy to do. also remove the stabilizer bars on swaybar.

now i purchased the harbor frieght engine support bar, and put the chains on the timing cover bolts, as u see below, this was safe as i held the engine up for several days with no problems as i tackled this install.

Also to be safe i placed a jack under the transmission for backup.

This engine bar is a must, because when you goto to put the longtubes on u can raise and lower the engine per side your working on.