You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Factory Torque Specs needed for '13 clutch

- Thread starter DrTriton

- Start date

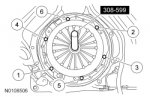

Clutch Pressure Plate Installation.

Inspect the flywheel. Refer to Section 303-00 .

NOTICE: Clutch Aligner 308-599, must be used or clutch damage may occur.

Using the Clutch Aligner, align the entrapped clutch disc in the pressure plate assembly.

NOTICE: If installing the original clutch disc and plate assembly, align it using the index-marks made during removal or a clutch system vibration can occur.

NOTE: Always install new clutch disc and plate assembly bolts.

Using the Clutch Aligner, position the clutch disc and plate assembly on the flywheel using the index-marks made during removal, install the 6 new clutch disc and plate assembly bolts turning them until they contact the clutch housing surface.

Turn the bolts 1 turn at a time until the clutch disc and plate assembly is fully secured. Tighten the bolts in 2 stages, in the sequence shown.

NOTICE: Apply a small amount of PTFE lubricant to the splines of the clutch hub. This will make sure that the clutch will not bind on the transmission input shaft, making sure of correct clutch operation. Using lubricant other than Motorcraft PTFE lubricant may cause clutch chatter.

NOTE: Before securing the transmission to the engine, connect the clutch hydraulic line to the slave cylinder.

Install the transmission. Refer to Section 308-03B .

Bleed the clutch hydraulic system. Refer to Section 308-02 .

After completing the repairs, use the scan tool to perform the Misfire Monitor Neutral Profile Correction procedure, following the on-screen instructions.

Flywheel Installation.

Position the flywheel on the crankshaft pilot and start the 8 flywheel bolts.

Tighten the flywheel bolts evenly in the sequence shown to fully seat the flywheel on the crankshaft pilot.

Install the clutch. For additional information, refer to Section 308-01 .

After completing the repairs, use the scan tool to perform the Misfire Monitor Neutral Profile Correction procedure following the on-screen instructions.

Inspect the flywheel. Refer to Section 303-00 .

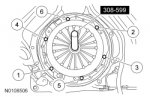

NOTICE: Clutch Aligner 308-599, must be used or clutch damage may occur.

Using the Clutch Aligner, align the entrapped clutch disc in the pressure plate assembly.

NOTICE: If installing the original clutch disc and plate assembly, align it using the index-marks made during removal or a clutch system vibration can occur.

NOTE: Always install new clutch disc and plate assembly bolts.

Using the Clutch Aligner, position the clutch disc and plate assembly on the flywheel using the index-marks made during removal, install the 6 new clutch disc and plate assembly bolts turning them until they contact the clutch housing surface.

Turn the bolts 1 turn at a time until the clutch disc and plate assembly is fully secured. Tighten the bolts in 2 stages, in the sequence shown.

- Stage 1: Tighten to 62 Nm (46 lb-ft).

- Stage 2: Tighten an additional 60 degrees.

NOTICE: Apply a small amount of PTFE lubricant to the splines of the clutch hub. This will make sure that the clutch will not bind on the transmission input shaft, making sure of correct clutch operation. Using lubricant other than Motorcraft PTFE lubricant may cause clutch chatter.

NOTE: Before securing the transmission to the engine, connect the clutch hydraulic line to the slave cylinder.

Install the transmission. Refer to Section 308-03B .

Bleed the clutch hydraulic system. Refer to Section 308-02 .

After completing the repairs, use the scan tool to perform the Misfire Monitor Neutral Profile Correction procedure, following the on-screen instructions.

Flywheel Installation.

Position the flywheel on the crankshaft pilot and start the 8 flywheel bolts.

Tighten the flywheel bolts evenly in the sequence shown to fully seat the flywheel on the crankshaft pilot.

- Tighten to 80 Nm (59 lb-ft).

Install the clutch. For additional information, refer to Section 308-01 .

After completing the repairs, use the scan tool to perform the Misfire Monitor Neutral Profile Correction procedure following the on-screen instructions.

Users who are viewing this thread

Total: 5 (members: 0, guests: 5)