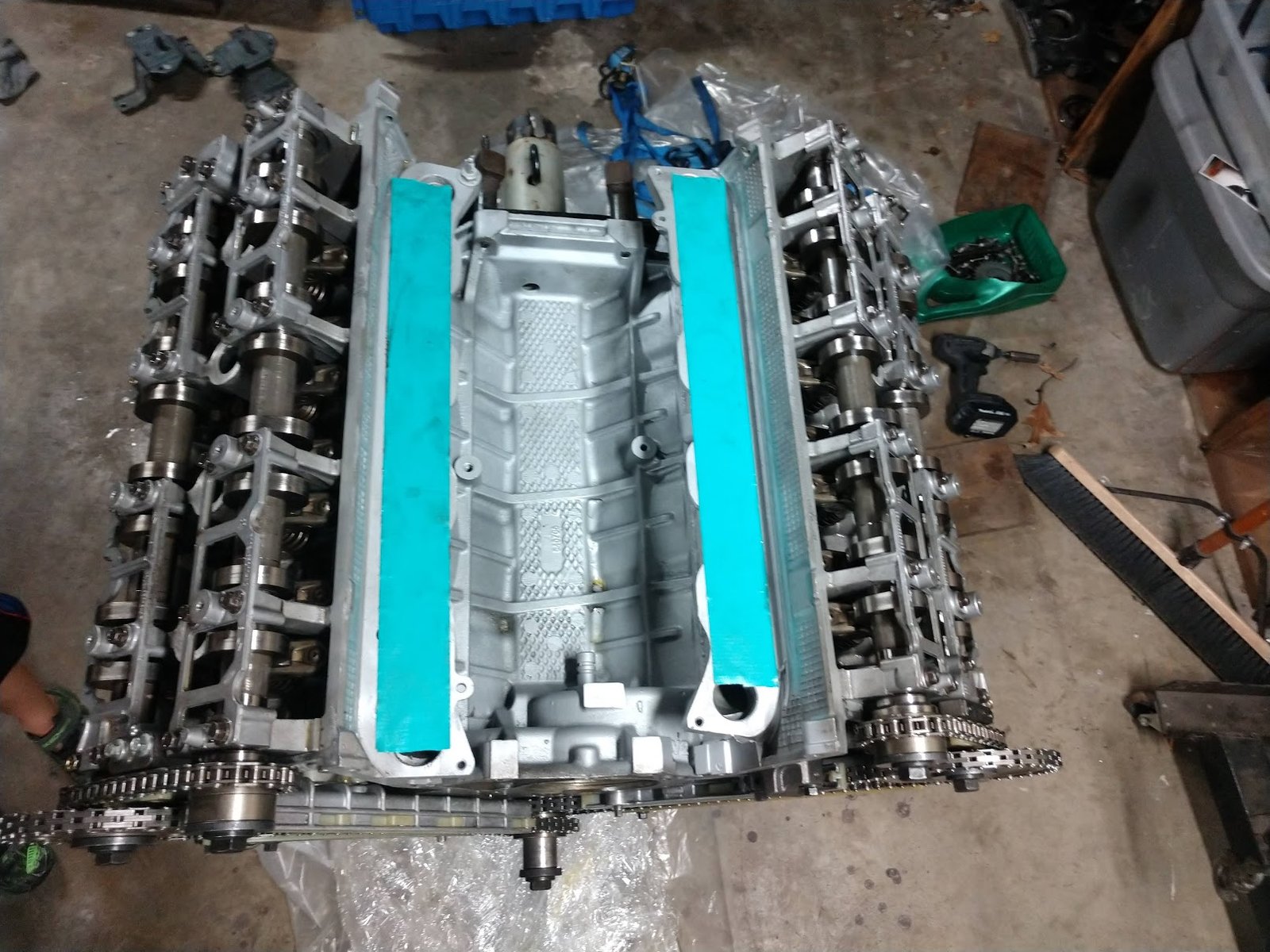

Hey guys, so long story short I got this bit pile of parts and have slowly been reassembling it into something that looks like a car. I got the motor back from the shop and last night after installing the trans, putting it on the k member, all of that, i go to seat the crank pulley.

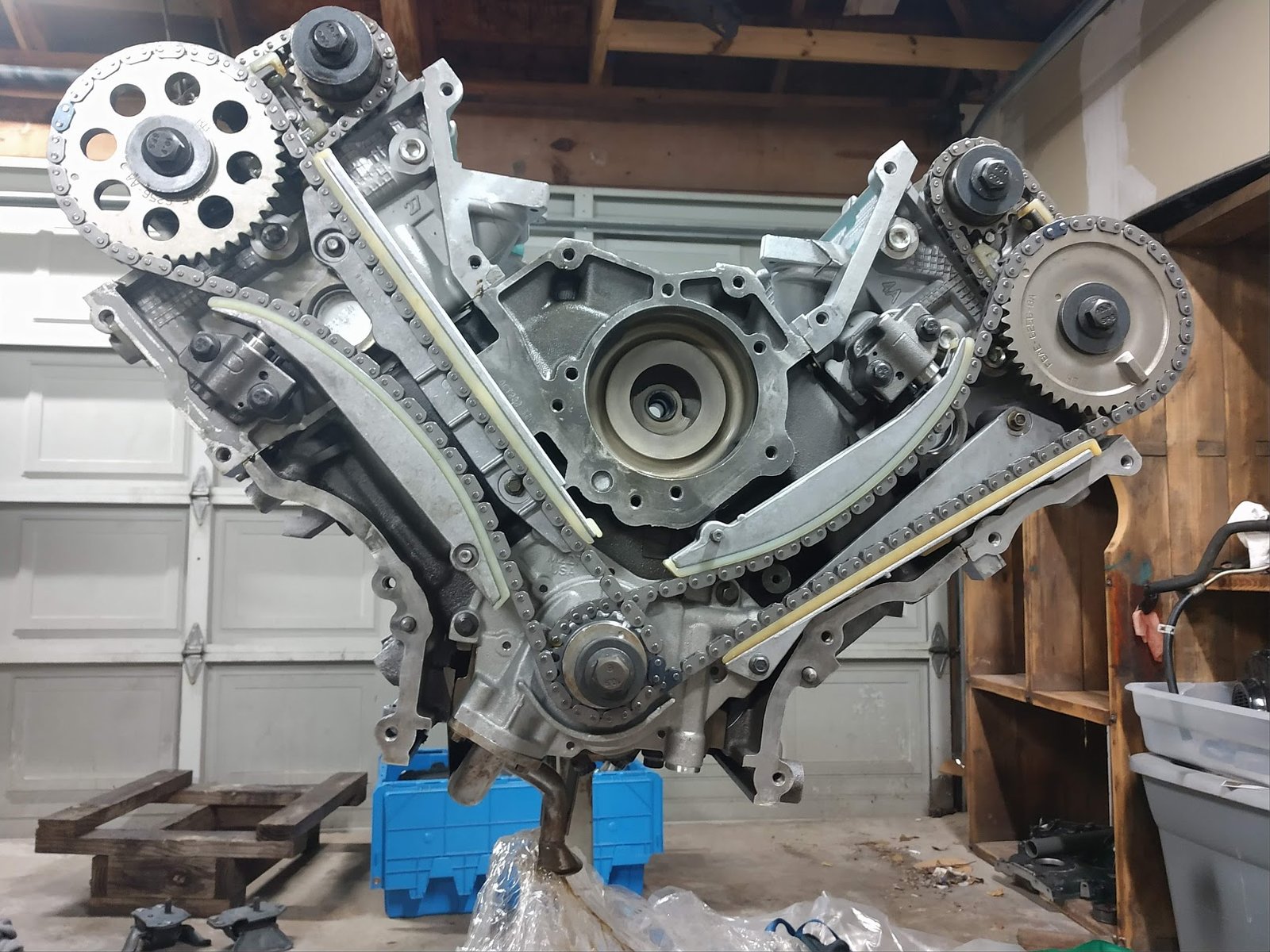

well, i seated it alright but apparently there's some procedure to it where it doesn't just go as far back as it can? (still not clear on the exact procedure).

so here's the problem, the pulley is touching the timing chain cover so it won't spin freely anymore.

I'm used to older engines so in my experience you just get that pulley on as far as it can go and you're golden. i definitely am pretty sure I used more than 60 ft lbs to seat this thing.

I THINK the solution is to pull it out, follow the installation procedure by the book, and maybe it'll be the right distance from the front of the motor BUT I've also read that there are 2 different crank sprockets and maybe my builder used the wrong one?

its a 99 longblock with a 97 front timing chain cover.

I've texted my builder asking what i should do next but I figured you guys might have been through this before.

well, i seated it alright but apparently there's some procedure to it where it doesn't just go as far back as it can? (still not clear on the exact procedure).

so here's the problem, the pulley is touching the timing chain cover so it won't spin freely anymore.

I'm used to older engines so in my experience you just get that pulley on as far as it can go and you're golden. i definitely am pretty sure I used more than 60 ft lbs to seat this thing.

I THINK the solution is to pull it out, follow the installation procedure by the book, and maybe it'll be the right distance from the front of the motor BUT I've also read that there are 2 different crank sprockets and maybe my builder used the wrong one?

its a 99 longblock with a 97 front timing chain cover.

I've texted my builder asking what i should do next but I figured you guys might have been through this before.