I never post much on here but I thought this might be worthy of a post.

I have always been interested in making my car as light as possible to take advantage of all the many benefits. I was always fascinated with the high end supercars using carbon fiber and I watch all Christian Von Koenigsegg videos I can get my hands on. About a year ago I got motivated to start experimenting with the stuff and this summer I slowly put together my own resin infusion setup.

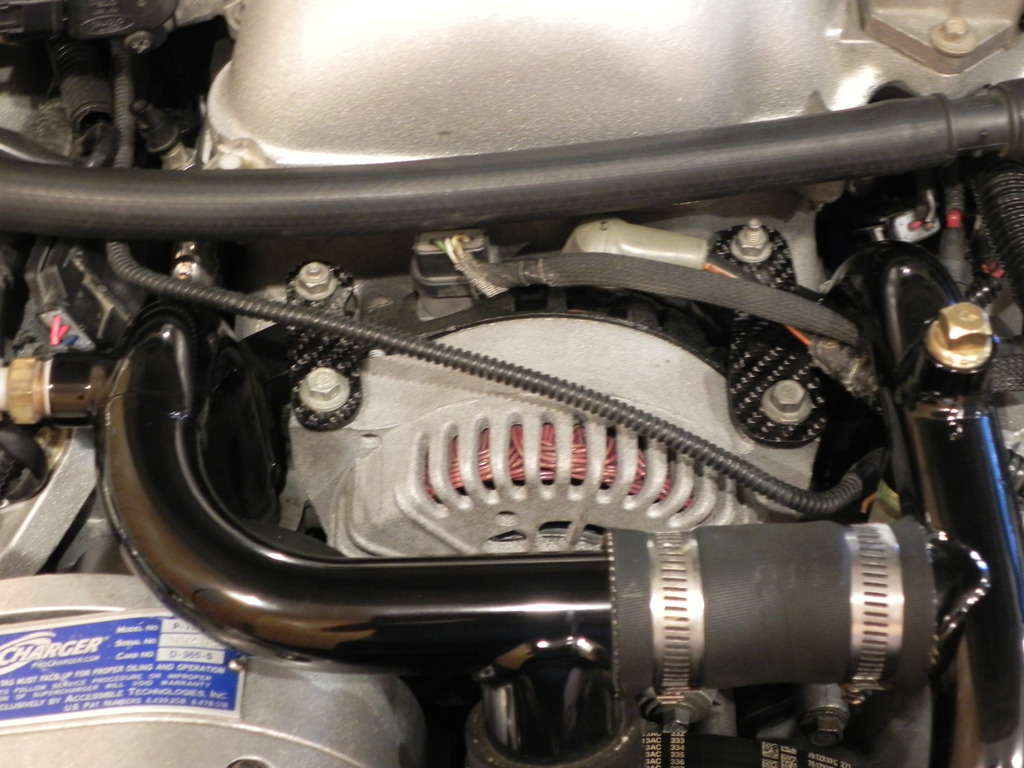

Well, this week I finally finished my first small part, alternator brackets. I used high-temp resin that is good to 300 degrees to allow for use on engine parts. You can see the weight difference in the pictuers. The stock bracket is 7.5oz., the aluminum brackets that I've used for the past few years are 1oz. and the carbon brackets come in at less than half an ounce.

I have always been interested in making my car as light as possible to take advantage of all the many benefits. I was always fascinated with the high end supercars using carbon fiber and I watch all Christian Von Koenigsegg videos I can get my hands on. About a year ago I got motivated to start experimenting with the stuff and this summer I slowly put together my own resin infusion setup.

Well, this week I finally finished my first small part, alternator brackets. I used high-temp resin that is good to 300 degrees to allow for use on engine parts. You can see the weight difference in the pictuers. The stock bracket is 7.5oz., the aluminum brackets that I've used for the past few years are 1oz. and the carbon brackets come in at less than half an ounce.

Last edited: