Hi

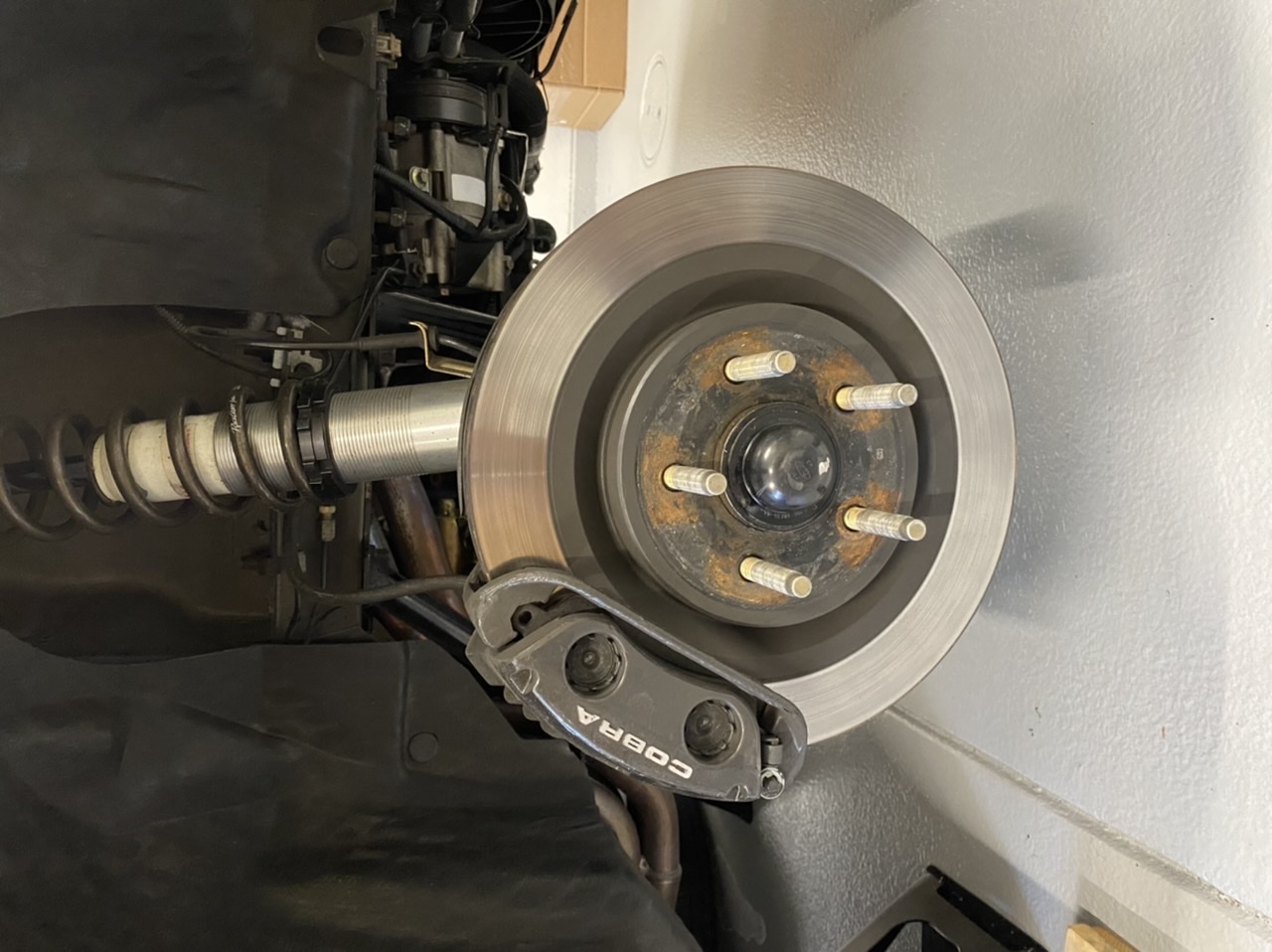

I just got finished installing a Wilwood front brake kit and figured I’d put up some pictures in case it’d be helpful to someone in the future.

I was looking for something that would clear a 15 inch wheel in the front and take some weight off of the front while doing it. I had been able to fit the stock cobra rotors and calipers but these cars are heavy, and any weight off of the front end is a good thing.

This is part number 140-10016 for the brake kit and 220-6458 for the SS hoses. Stock setup is a two-piston floating caliper and 13.0” rotors on the front, and these are fixed calipers with 11.75” vented rotors.

The car is driven around town occasionally and raced down the quarter-mile; I got the thumbs up from Wilwood that this set up would be appropriate for both scenarios despite the smaller rotor size. It’s important to consider a vented rotor for the street, as the thinner solid (and much lighter!) rotors can warp if they are exposed to too much heat.

This was a relatively straight forward swap. Get the car up onto jackstands, pull the front wheels. Remove the two caliper mount bolts from the front spindles and set the caliper assembly on the a-arm. Remove the rotor.

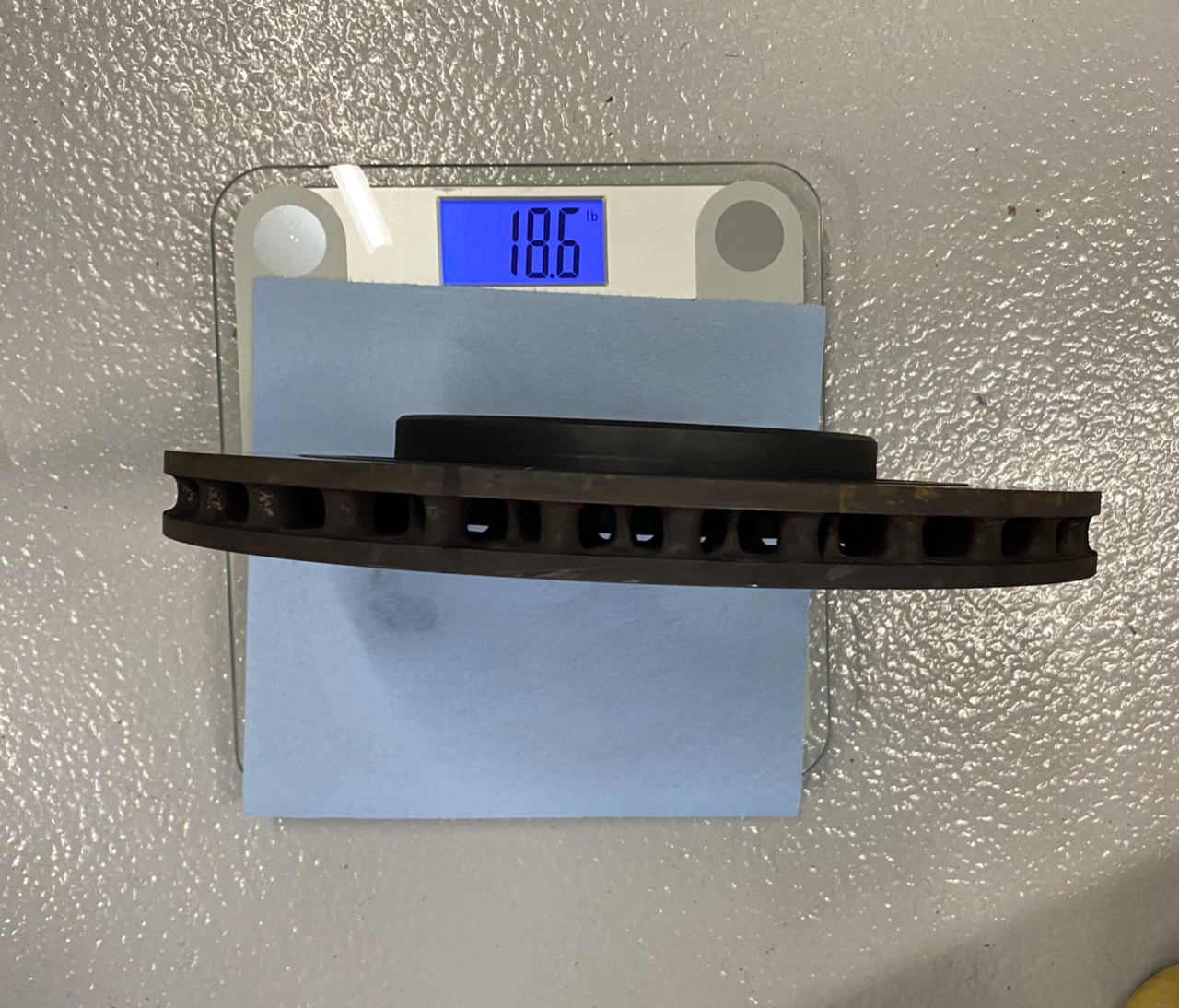

The next thing I did was to assemble the new front rotors/hats. This is where a lot of the weight savings comes in, as they are two-piece, with the hats being made out of aluminum.

I used lacquer thinner to clean the threads in the hat as well as those on the bolts that secure them to the rotor. Red Loctite, 25ftlbs, tightened in a star pattern. I used safety wire to keep the bolts from backing out… First time using it so the aesthetics aren’t quite perfect

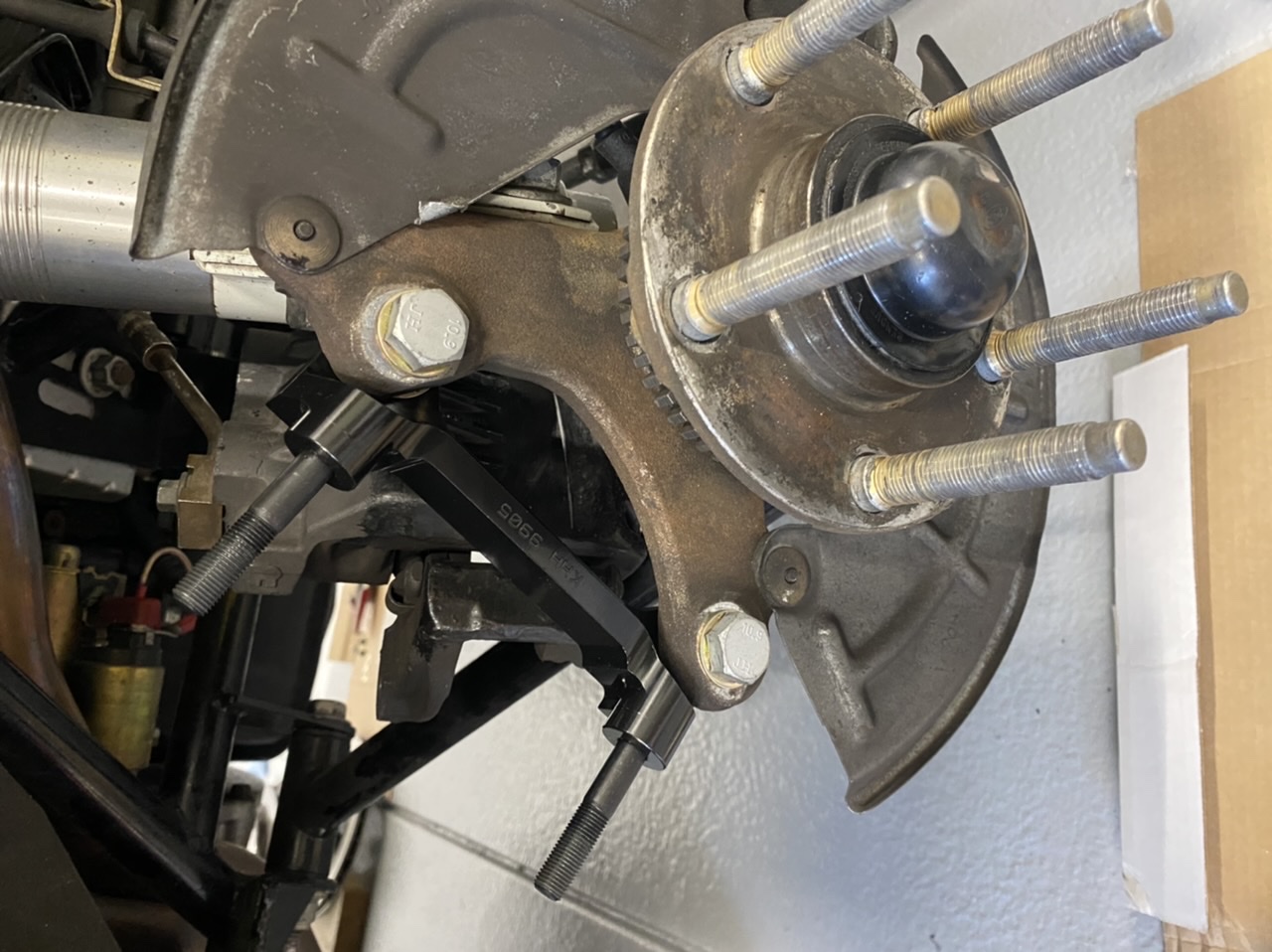

I set the new rotors aside and then added the fixed caliper mounts to the spindles.

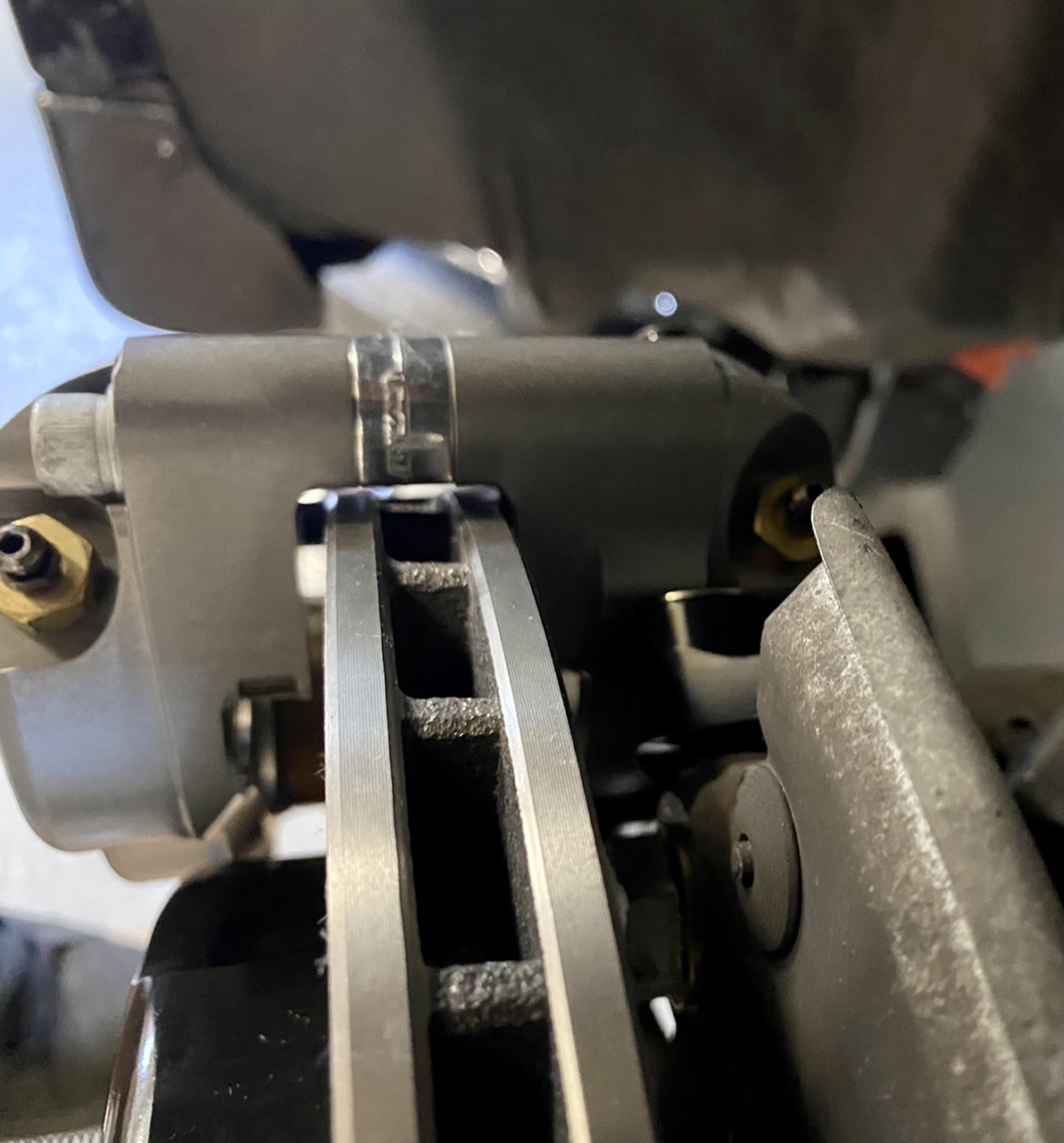

Wilwood supplies shims with the kit in order to center the caliper about the outer diameter of the rotor; it’s hard to get pictures of this, but the more shims you add, the farther inboard the caliper moves. Use three lug nuts in cross-pattern to snug the rotor up to the hub, slide the caliper down the mount studs, snug down the caliper, and measure.

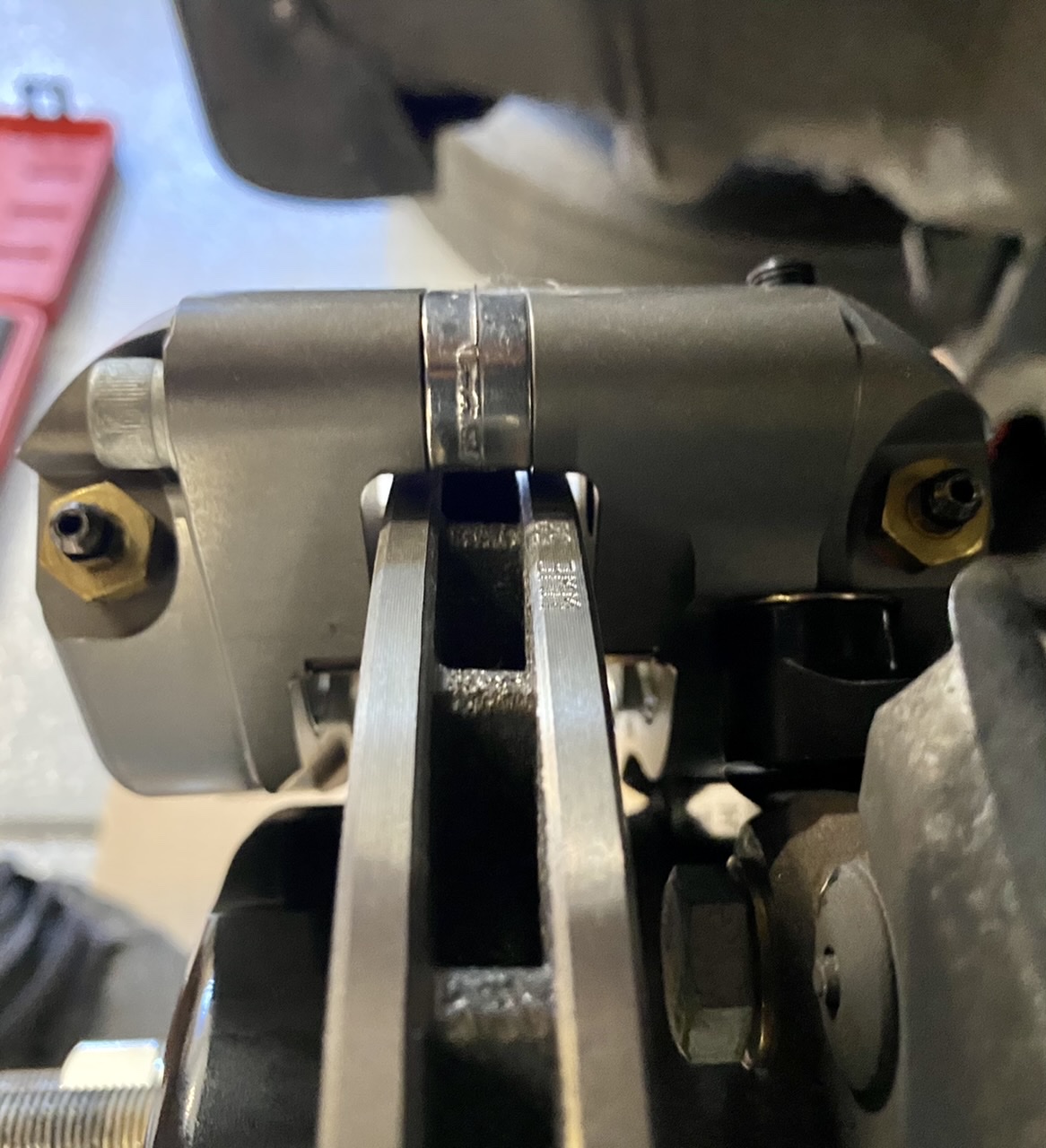

This was with one shim:

Next with two shims:

This measured out well. This is especially important with fixed versus floating calipers, as opposing pistons need to travel the same distance for both inboard and outboard pads to contact the rotor at the same time.

Once you are caliper is set on that axis, the next thing to do is to slide the pads into the caliper and shim radially in regard to the rotor. You want the pads to fully contact the rotor, and as far out to the edge as possible for the most effective braking leverage. These calipers allow you to drop the pads in from the top; pads are retained with a single bolt, which makes access to them pretty easy for the future. I used lithium grease on the backside of the pads to keep noise/chatter to a minimum.

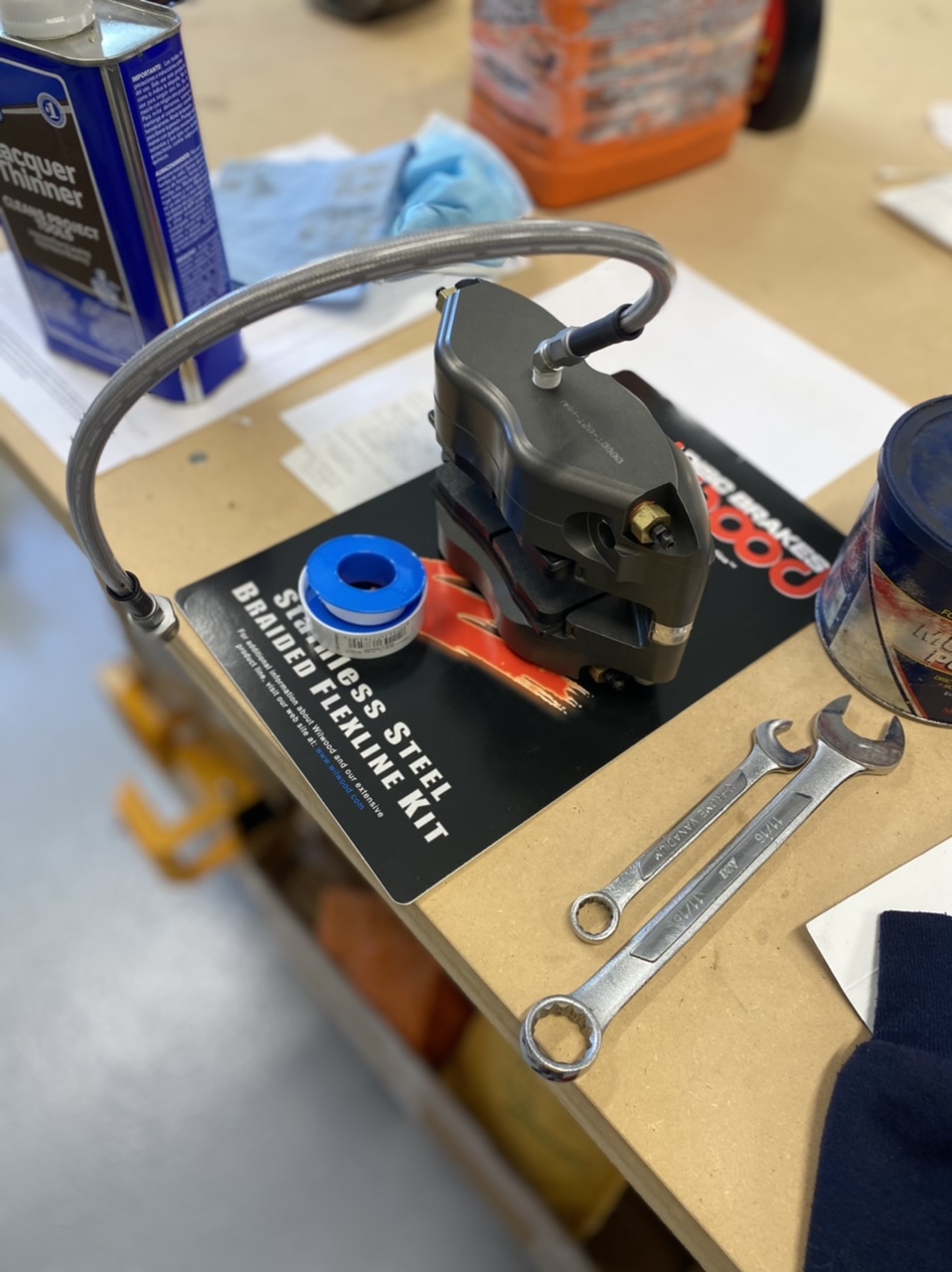

Next, I used the new hose kit and fittings. A 45° NPT to AN fitting goes into the caliper with Teflon tape, then attaching to the brake hose.

I routed the new hoses along the same path as the factory hoses by keeping the 45° bend angled toward the front of the car.

I just got finished installing a Wilwood front brake kit and figured I’d put up some pictures in case it’d be helpful to someone in the future.

I was looking for something that would clear a 15 inch wheel in the front and take some weight off of the front while doing it. I had been able to fit the stock cobra rotors and calipers but these cars are heavy, and any weight off of the front end is a good thing.

This is part number 140-10016 for the brake kit and 220-6458 for the SS hoses. Stock setup is a two-piston floating caliper and 13.0” rotors on the front, and these are fixed calipers with 11.75” vented rotors.

The car is driven around town occasionally and raced down the quarter-mile; I got the thumbs up from Wilwood that this set up would be appropriate for both scenarios despite the smaller rotor size. It’s important to consider a vented rotor for the street, as the thinner solid (and much lighter!) rotors can warp if they are exposed to too much heat.

This was a relatively straight forward swap. Get the car up onto jackstands, pull the front wheels. Remove the two caliper mount bolts from the front spindles and set the caliper assembly on the a-arm. Remove the rotor.

The next thing I did was to assemble the new front rotors/hats. This is where a lot of the weight savings comes in, as they are two-piece, with the hats being made out of aluminum.

I used lacquer thinner to clean the threads in the hat as well as those on the bolts that secure them to the rotor. Red Loctite, 25ftlbs, tightened in a star pattern. I used safety wire to keep the bolts from backing out… First time using it so the aesthetics aren’t quite perfect

I set the new rotors aside and then added the fixed caliper mounts to the spindles.

Wilwood supplies shims with the kit in order to center the caliper about the outer diameter of the rotor; it’s hard to get pictures of this, but the more shims you add, the farther inboard the caliper moves. Use three lug nuts in cross-pattern to snug the rotor up to the hub, slide the caliper down the mount studs, snug down the caliper, and measure.

This was with one shim:

Next with two shims:

This measured out well. This is especially important with fixed versus floating calipers, as opposing pistons need to travel the same distance for both inboard and outboard pads to contact the rotor at the same time.

Once you are caliper is set on that axis, the next thing to do is to slide the pads into the caliper and shim radially in regard to the rotor. You want the pads to fully contact the rotor, and as far out to the edge as possible for the most effective braking leverage. These calipers allow you to drop the pads in from the top; pads are retained with a single bolt, which makes access to them pretty easy for the future. I used lithium grease on the backside of the pads to keep noise/chatter to a minimum.

Next, I used the new hose kit and fittings. A 45° NPT to AN fitting goes into the caliper with Teflon tape, then attaching to the brake hose.

I routed the new hoses along the same path as the factory hoses by keeping the 45° bend angled toward the front of the car.

Last edited: