This thread provides some detail on how to do a high quality BAP wiring job. The idea is to have the minimal amount of connections and no less than 10 gauge wire anywhere except the last few inches entering the FPDM. My car already had a 1/0 gauge power cable run to a 1.5F capacitor in the trunk for the audio system, BAP and N20 heater.

To properly solder large gauge wire a decent iron with a large tip is needed to transfer the heat. This one is only $17 (+ $5 for set of tips) from parts express and works great. If extra flux is used (because your iron or tip sucks) be sure to wipe off any excess before covering with heat shrink or it may corrode depending on the type of flux used. The best heat shrink to use is 3:1 (shrink) ratio, high temperature, adhesive type.

Step 1: Prep the BAP. I chose to run the BAP pre-FPDM without the Hobbs switch or control knob. To do this just short the end of each wire pair and it will permanently enable the unit at max voltage output. I had a concern about the FPDM’s output back to the ECM being a higher voltage than the ECM’s protection diodes, but according to Black306 the feedback signal is a square wave and not the actual applied pump voltage. The ‘actual pump voltage’ signal that can be data logged is calculated not measured. Thanks to Black306 for the schematic and answering a few of my questions.

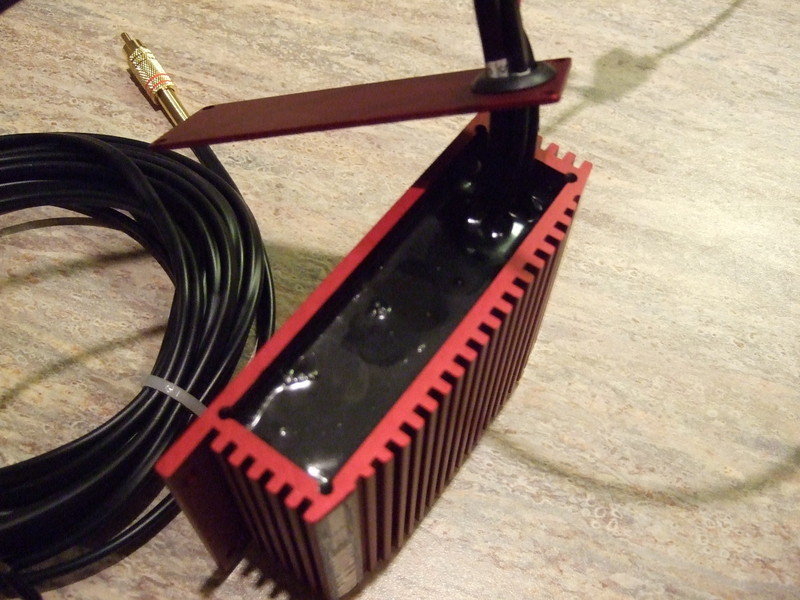

Here is the BAP with the extra wiring:

Upon opening the end plate I found the unit completely potted

My plan of re-soldering the wires on the PCB wasn’t going to work. I shortened, solder shorted and insulated with heat shrink.

3 terminal regulator

Step 2: Relay wiring.

I wanted high reliability relays so I went with these Tyco units. They are rated up to 70A at normal temperatures. The trunk gets hot and they will either make or break 30A of current at 140 F.

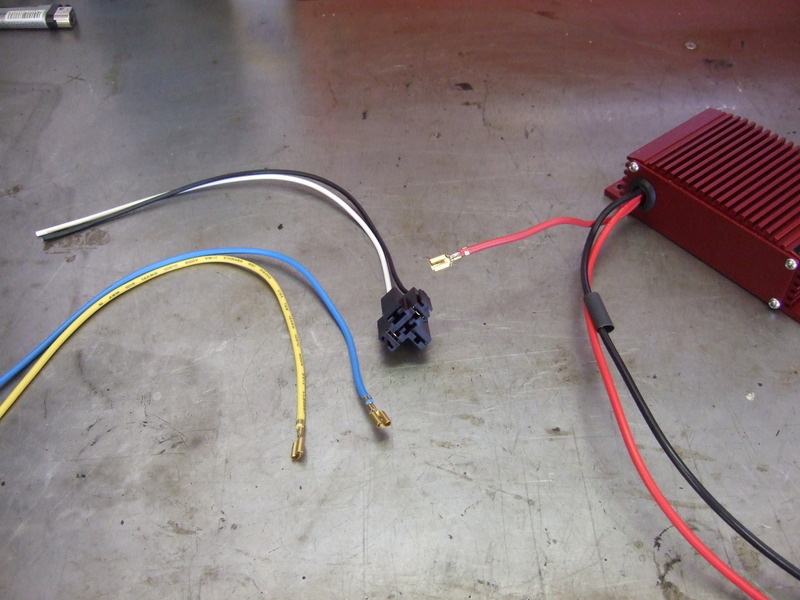

Most relay pigtails have small gauge wiring and should not be used. Best I found was ones have larger gauge wire on 30/87/87A but it is still only 14ga. The wires are removed from the shell and the gold plated terminals themselves are removed from the 14ga wire to be transferred to the 10ga wires on 30 and 87.

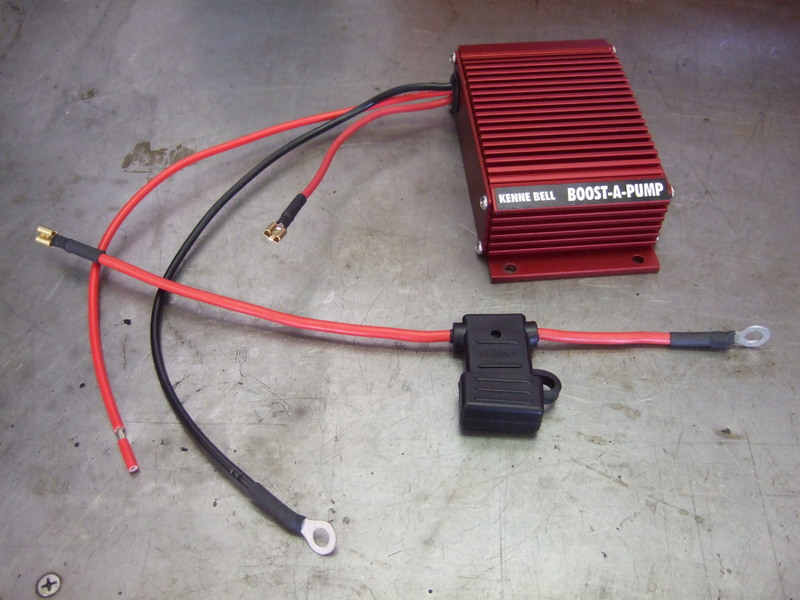

Cut the fuse off the BAP input and solder on a 0.250” disconnect that will connect to terminal 87. Solder a ring to the ground.

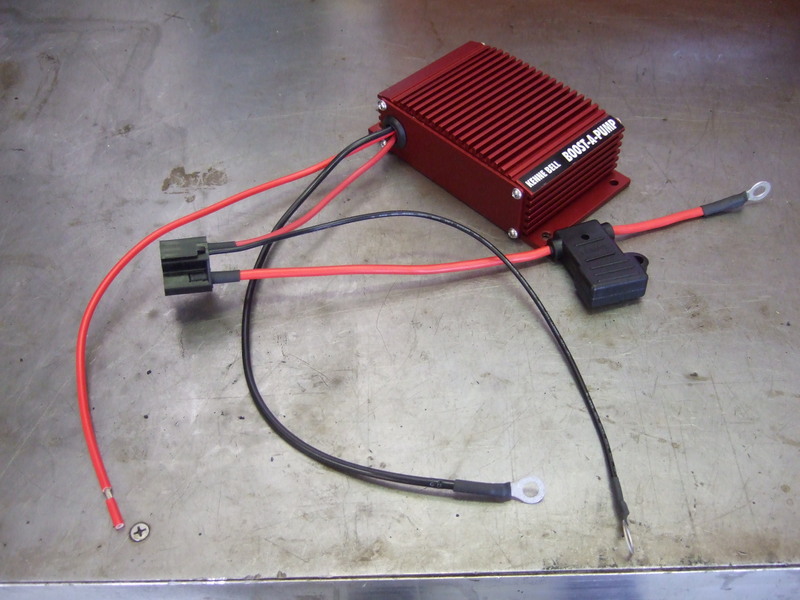

A 10ga ATO fuse holder will go from the power source to terminal 30. Solder on the 0.250” disconnect to one end and connect the other to the power source. In my case it is a large capacitor with a 6mm stud so a ring terminal is used.

The relay housing needed some trimming to get the larger 10ga wire to fit

Step 3: install HW

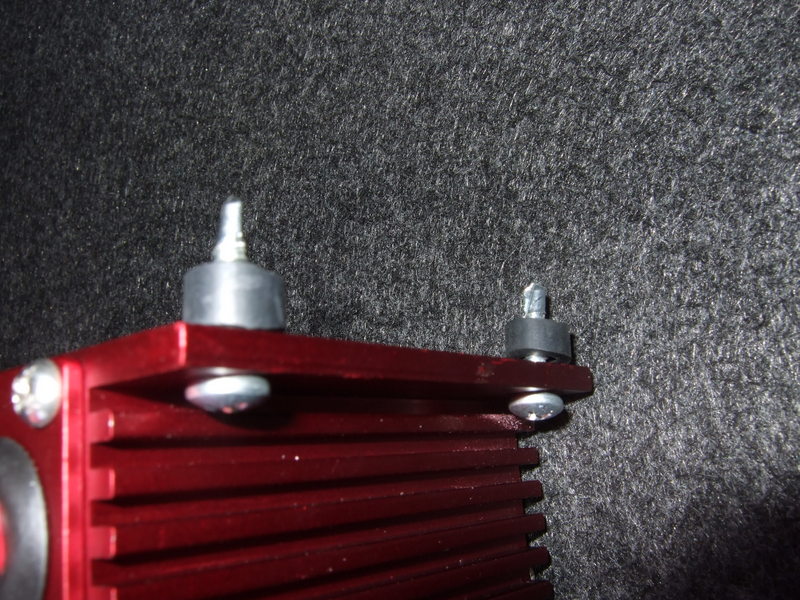

Bap is mounted with rubber isolators

The Green/yellow wire is cut half way between the FPDM and the harness it came out of. The BAP output is soldered to the green/yellow wire that enters the FPDM, the other end is soldered to an extension wire on terminal 85. This comes from the CCM (aka ECM/injector/coil relays) and instead of delivering current to run the pumps it just energizes the relay coil. No need to install the 30A fuse per instructions, in fact a 1A would probably be enough.

BAP and relay mounted.

Before completely wrapping everything, check the operation of the relay and BAP, verify the output is as expected. Mine was 17.3V KOEO and 0V with the key off.

All done. The extra inline ATO fuse holder will be for the N20 bottle heater circuit.

Check for tire spin and enjoy

:beer:

To properly solder large gauge wire a decent iron with a large tip is needed to transfer the heat. This one is only $17 (+ $5 for set of tips) from parts express and works great. If extra flux is used (because your iron or tip sucks) be sure to wipe off any excess before covering with heat shrink or it may corrode depending on the type of flux used. The best heat shrink to use is 3:1 (shrink) ratio, high temperature, adhesive type.

Step 1: Prep the BAP. I chose to run the BAP pre-FPDM without the Hobbs switch or control knob. To do this just short the end of each wire pair and it will permanently enable the unit at max voltage output. I had a concern about the FPDM’s output back to the ECM being a higher voltage than the ECM’s protection diodes, but according to Black306 the feedback signal is a square wave and not the actual applied pump voltage. The ‘actual pump voltage’ signal that can be data logged is calculated not measured. Thanks to Black306 for the schematic and answering a few of my questions.

Here is the BAP with the extra wiring:

Upon opening the end plate I found the unit completely potted

My plan of re-soldering the wires on the PCB wasn’t going to work. I shortened, solder shorted and insulated with heat shrink.

3 terminal regulator

Step 2: Relay wiring.

I wanted high reliability relays so I went with these Tyco units. They are rated up to 70A at normal temperatures. The trunk gets hot and they will either make or break 30A of current at 140 F.

Most relay pigtails have small gauge wiring and should not be used. Best I found was ones have larger gauge wire on 30/87/87A but it is still only 14ga. The wires are removed from the shell and the gold plated terminals themselves are removed from the 14ga wire to be transferred to the 10ga wires on 30 and 87.

Cut the fuse off the BAP input and solder on a 0.250” disconnect that will connect to terminal 87. Solder a ring to the ground.

A 10ga ATO fuse holder will go from the power source to terminal 30. Solder on the 0.250” disconnect to one end and connect the other to the power source. In my case it is a large capacitor with a 6mm stud so a ring terminal is used.

The relay housing needed some trimming to get the larger 10ga wire to fit

Step 3: install HW

Bap is mounted with rubber isolators

The Green/yellow wire is cut half way between the FPDM and the harness it came out of. The BAP output is soldered to the green/yellow wire that enters the FPDM, the other end is soldered to an extension wire on terminal 85. This comes from the CCM (aka ECM/injector/coil relays) and instead of delivering current to run the pumps it just energizes the relay coil. No need to install the 30A fuse per instructions, in fact a 1A would probably be enough.

BAP and relay mounted.

Before completely wrapping everything, check the operation of the relay and BAP, verify the output is as expected. Mine was 17.3V KOEO and 0V with the key off.

All done. The extra inline ATO fuse holder will be for the N20 bottle heater circuit.

Check for tire spin and enjoy

:beer:

Last edited: