Sounds like my most recent dyno session. It was on a Dynomite Dyno I think. Nothing like hearing your newly whippled cobra made 524rwhp. You know it's bad when the dyno has software built in to show what it would make on a dynojet.Yes, it was 90 plus outside and he said iats were 150 plus the whole session.

Mustang dyno are heart breakers for sure. With my old combo I had 601 & 602 at the wheels on 2 different dyno jets. Put it on a mustang dyno and made 480 at the wheels. I was shocked at the difference.

Sent from my Pixel 2 XL using Tapatalk

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Self Tuning With SCT Pro Racer

- Thread starter 03cobra#2

- Start date

OK found an area of my tune that needs work!

While cruising on the highway today in 6th gear and give it part throttle (enough to get into low boost) the car drifts lean and starts to shake a bit. Give it a bit more throttle (like half throttle) and it smooths right out and goes to commanded af.

Easiest way to recreate it is being in 5th or 6th gear lower rpm's cruising then give it like 1/3 throttle. I wonder if it's getting into boost and still being in closed loop is causing an issue. Or maybe the maf curve needs work.

Edit: looking at my logs it seems that I hit a 2.0 load (and boost) at around 200 throttle position. I'm not exactly sure how much boost that is because I don't have boost logged but it's probable a decent amount (10spi?). I have open loop transition set at 300 TP. So I think the issue is that I'm getting into boost while the ecu is still in closed loop trying to maintain 1.0 lambda.

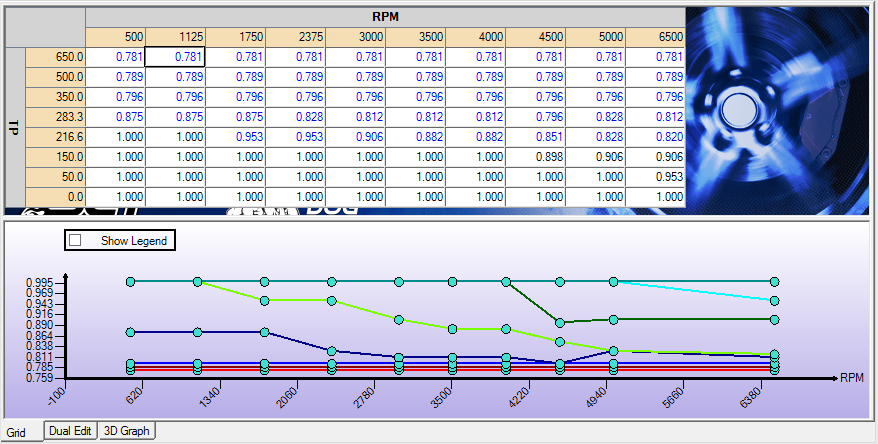

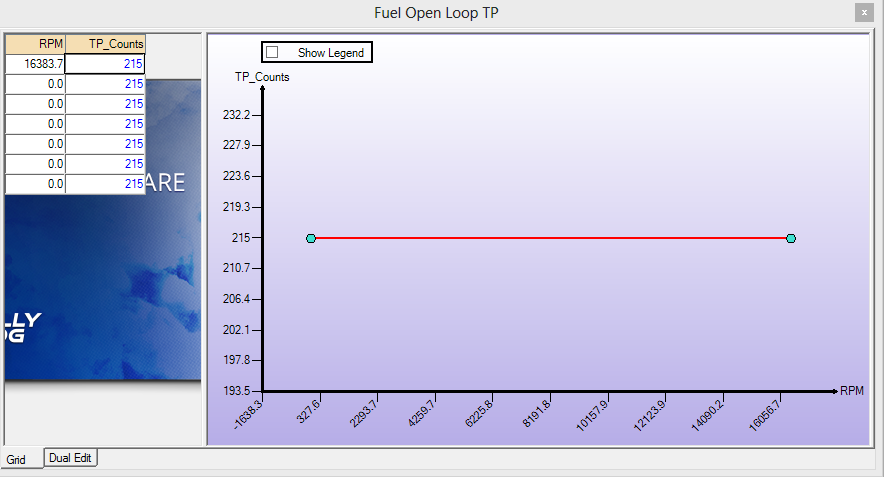

I lowered my open loop TP threshold table down to 200 TP counts from 300...so I get into open loop sooner. I would think ideally you want to transition to open loop as boost comes on. I also did a bit of tweaking in my base fuel table so to get more fuel at the lower Throttle position counts. Here is a couple screen shots. I hope this works.

If I need to get more aggressive with the fuel down low in my table I will... But I think this will improve things.

While cruising on the highway today in 6th gear and give it part throttle (enough to get into low boost) the car drifts lean and starts to shake a bit. Give it a bit more throttle (like half throttle) and it smooths right out and goes to commanded af.

Easiest way to recreate it is being in 5th or 6th gear lower rpm's cruising then give it like 1/3 throttle. I wonder if it's getting into boost and still being in closed loop is causing an issue. Or maybe the maf curve needs work.

Edit: looking at my logs it seems that I hit a 2.0 load (and boost) at around 200 throttle position. I'm not exactly sure how much boost that is because I don't have boost logged but it's probable a decent amount (10spi?). I have open loop transition set at 300 TP. So I think the issue is that I'm getting into boost while the ecu is still in closed loop trying to maintain 1.0 lambda.

I lowered my open loop TP threshold table down to 200 TP counts from 300...so I get into open loop sooner. I would think ideally you want to transition to open loop as boost comes on. I also did a bit of tweaking in my base fuel table so to get more fuel at the lower Throttle position counts. Here is a couple screen shots. I hope this works.

If I need to get more aggressive with the fuel down low in my table I will... But I think this will improve things.

Last edited:

Figured I would update this.

First issue I had was when the ecu pulls timing. In the stock tune it starts to pull timing at 100* intake temps and by the time you hit 150* it's pulling a total of around 4*.

Solution was to start pulling at 130* and ramp to 160*. My wot logs are showing I'm getting the full 21* now at still safe iat2 temps (edit: I think I'm going to back timing down to 20). I felt that running E85 its a safe bet to raise that a bit.

My part throttle issue I was having is good now as well. Just to recap I was getting a shake / Loss of power during certain part throttle driving. My logs showed that at 200-300 throttle position counts I am in boost (6-10psi) and still in closed loop with the ecu trying to maintain 1.0 lambda. My short term fuel trims was even showing the ecu was pulling 5-10% fuel to maintain 1.0 af.....not good.

Solution was to enable open loop starting at 200 to counts instead of 300 so that I go open loop pretty much right as I start seeing boost. That's solved the issue. Getting back on the road and data logging the same situation showed that when I was commanding .8-.9 lambda my wideband was showing about 5-10% rich. It seems that my maf curve needs a bit of adjustment in the 400-500 count range. All is good. It seems that 400-500 maf counts is the forgotten area sometimes. It sits between normal part throttle and wot.

It just goes to show you that most shops are not going to give you a great tune, but a good / acceptable tune. Can't wait to hit the dyno in the fall.

First issue I had was when the ecu pulls timing. In the stock tune it starts to pull timing at 100* intake temps and by the time you hit 150* it's pulling a total of around 4*.

Solution was to start pulling at 130* and ramp to 160*. My wot logs are showing I'm getting the full 21* now at still safe iat2 temps (edit: I think I'm going to back timing down to 20). I felt that running E85 its a safe bet to raise that a bit.

My part throttle issue I was having is good now as well. Just to recap I was getting a shake / Loss of power during certain part throttle driving. My logs showed that at 200-300 throttle position counts I am in boost (6-10psi) and still in closed loop with the ecu trying to maintain 1.0 lambda. My short term fuel trims was even showing the ecu was pulling 5-10% fuel to maintain 1.0 af.....not good.

Solution was to enable open loop starting at 200 to counts instead of 300 so that I go open loop pretty much right as I start seeing boost. That's solved the issue. Getting back on the road and data logging the same situation showed that when I was commanding .8-.9 lambda my wideband was showing about 5-10% rich. It seems that my maf curve needs a bit of adjustment in the 400-500 count range. All is good. It seems that 400-500 maf counts is the forgotten area sometimes. It sits between normal part throttle and wot.

It just goes to show you that most shops are not going to give you a great tune, but a good / acceptable tune. Can't wait to hit the dyno in the fall.

Last edited:

I wanted to add a bit more. As I make my way through the various parameters I turned my attention to injector timing and did a few hours of research on the subject.

Injector timing: When you have stock cams, and are degreed stock (no overlap) you can keep everything is SCT set to 0. The parameter is injector timing vs ECT. This parameter dictates when the injector fires in relation to TDC (stock is set to fire exactly at TDC). When you have aftermarket cams with overlap this is when you may want to adjust this parameter. There are a couple schools of thought as far as having the injector fire before TDC or after TDC. One thought is you want to fire the injector before TDC (or slightly before the intake valve opens) so you are firing the injector on a closed intake valve. The thought is that if you fire the fuel on the hot closed valve is aids in fuel atomazation (this could hurt cold engine drive-ability). The potential problem comes in when you have a more aggressive cam with valve overlap (with overlap the intake and exhaust valve will be open at the same time for a certain period of time). If you are firing the injector before the exhaust valve fully closes you are flushing fuel out of the exhaust (hence why you may get a strong fuel smell from the exhaust when the car is sitting at idle). So the other school of thought is to delay the injector firing so that it fires after the exhaust valve is closed. So, while the injector won't be firing and fuel hitting the intake valve at just the right time at least there won't be fuel going out the exhaust.

This is one of those parameters that you need to play with. I don't think there is really a right or wrong answer...but adjusting this could help smooth out drive-ability. What you need to do is plug your cam specs into a calculator (duration, center-line, lsa, ect) and see exactly where your intake valve is opening and where your exhaust valve closes in relation to TDC. In my case I degreed my cams to Comps specs and don't have a lot of overlap. Then change the parameter in PRP. If you enter a negative value that makes the injector fire earlier (before TDC). If you enter a positive value it delays the injector firing (after TDC). According to my calculations and how I degreed my cams my exhaust valve is fully closed around 5* after TDC so I put 8* in PRP for my injector to fire a couple degrees after the exhaust valve is closed and go from there.

I just wanted to touch on this as there are a few threads here and there. I'm not an expert on this but I believe this is the basics.

Injector timing: When you have stock cams, and are degreed stock (no overlap) you can keep everything is SCT set to 0. The parameter is injector timing vs ECT. This parameter dictates when the injector fires in relation to TDC (stock is set to fire exactly at TDC). When you have aftermarket cams with overlap this is when you may want to adjust this parameter. There are a couple schools of thought as far as having the injector fire before TDC or after TDC. One thought is you want to fire the injector before TDC (or slightly before the intake valve opens) so you are firing the injector on a closed intake valve. The thought is that if you fire the fuel on the hot closed valve is aids in fuel atomazation (this could hurt cold engine drive-ability). The potential problem comes in when you have a more aggressive cam with valve overlap (with overlap the intake and exhaust valve will be open at the same time for a certain period of time). If you are firing the injector before the exhaust valve fully closes you are flushing fuel out of the exhaust (hence why you may get a strong fuel smell from the exhaust when the car is sitting at idle). So the other school of thought is to delay the injector firing so that it fires after the exhaust valve is closed. So, while the injector won't be firing and fuel hitting the intake valve at just the right time at least there won't be fuel going out the exhaust.

This is one of those parameters that you need to play with. I don't think there is really a right or wrong answer...but adjusting this could help smooth out drive-ability. What you need to do is plug your cam specs into a calculator (duration, center-line, lsa, ect) and see exactly where your intake valve is opening and where your exhaust valve closes in relation to TDC. In my case I degreed my cams to Comps specs and don't have a lot of overlap. Then change the parameter in PRP. If you enter a negative value that makes the injector fire earlier (before TDC). If you enter a positive value it delays the injector firing (after TDC). According to my calculations and how I degreed my cams my exhaust valve is fully closed around 5* after TDC so I put 8* in PRP for my injector to fire a couple degrees after the exhaust valve is closed and go from there.

I just wanted to touch on this as there are a few threads here and there. I'm not an expert on this but I believe this is the basics.

Very cool man, thanks for sharing I love the updates and I'm kinda learning a ballpark of the tuning world through these posts.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)