After taking on many projects because of the wonderful write ups found on this site by fellow owners that love their cars, here’s my contribution.

This is a dedicated to all those that have found themselves faced with the seemly impossible task of “Removing the stock Lower Pulley.” I'm a visual learner so I put up plenty of pictures of almost everything I did.

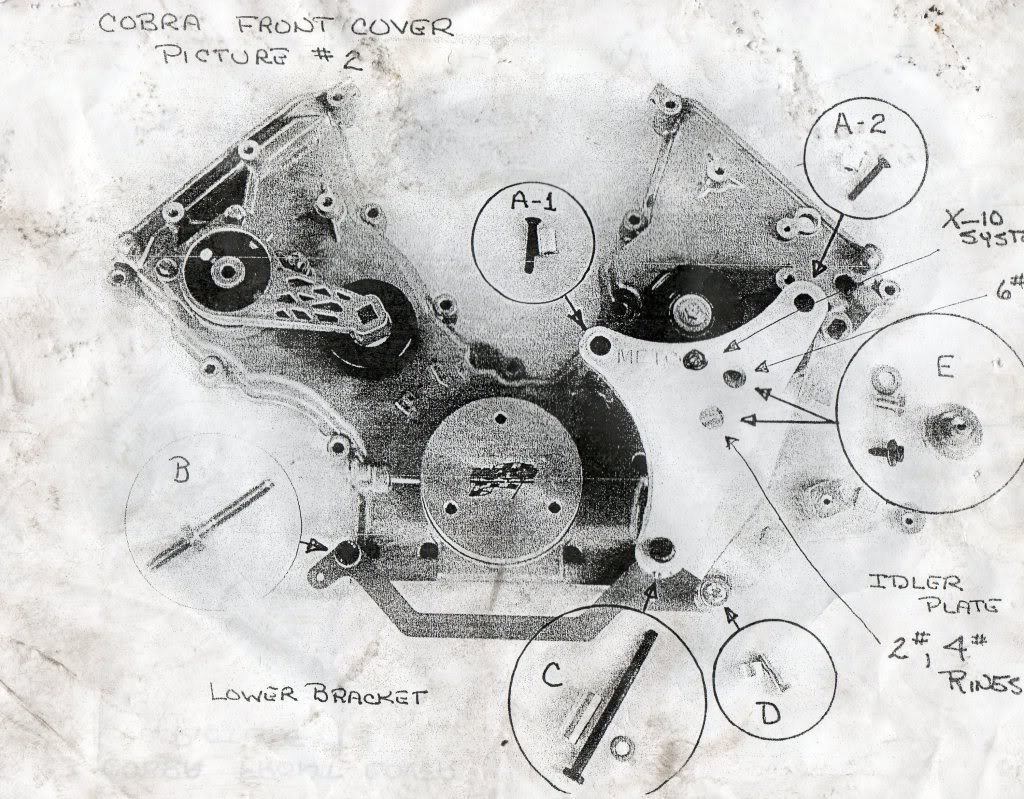

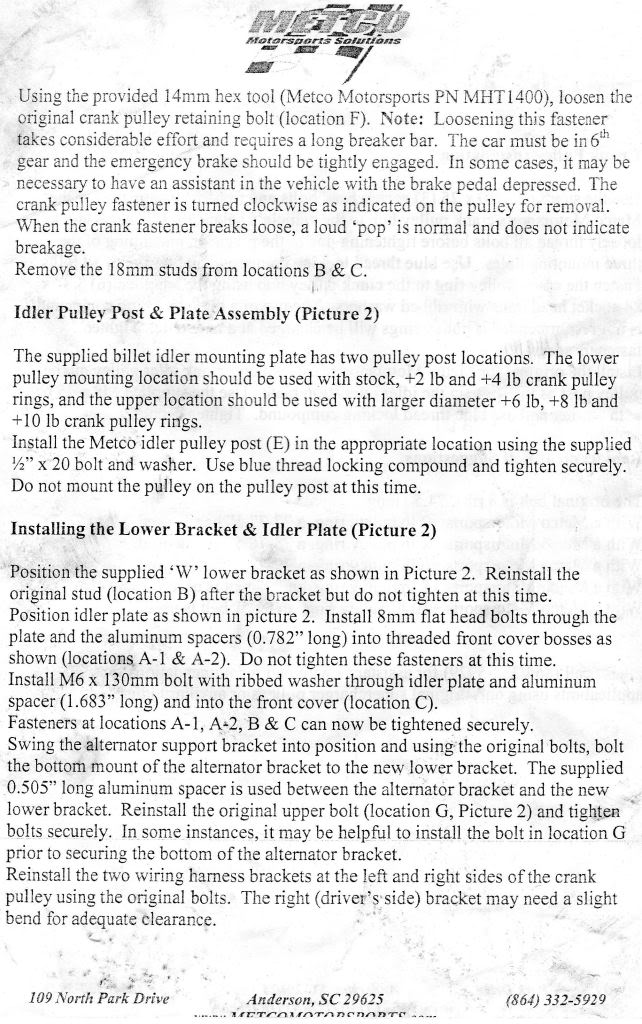

***The FULL Metco instructions are at the end***

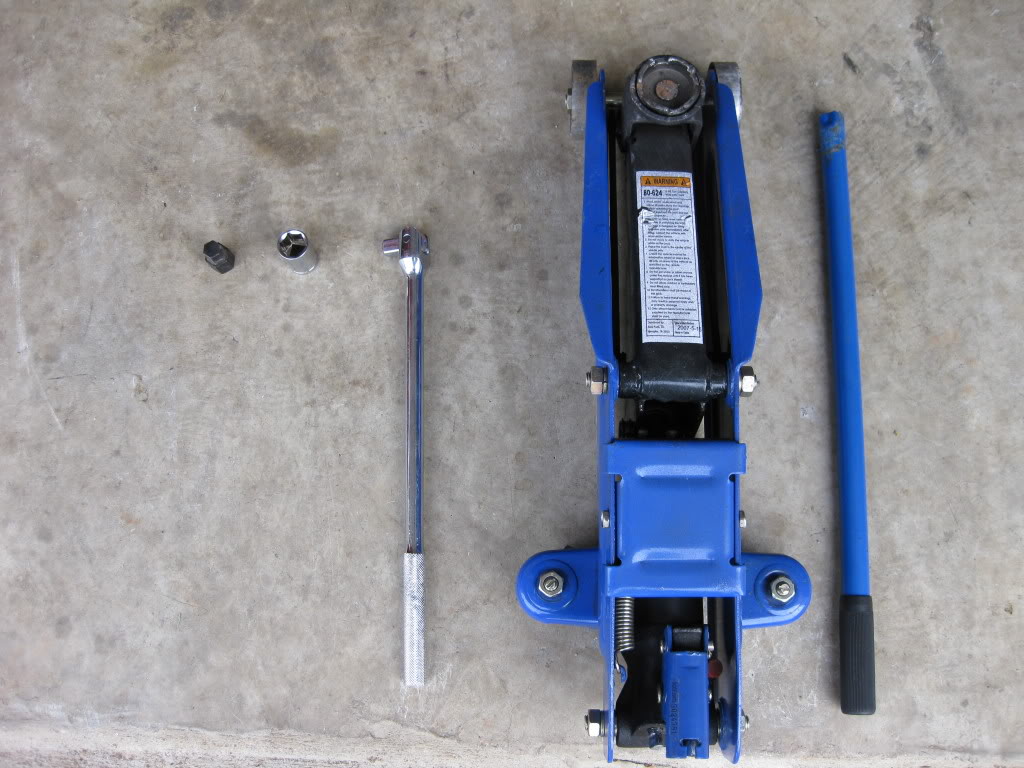

What’s needed:

1 - Hex tool - (Comes with Metco Lower Pulley Kit)

1 - 19mm Socket

1 - 18 inch / 1/2 inch breaker bar

1 - Jack

2 - Jack stands

PREFACE

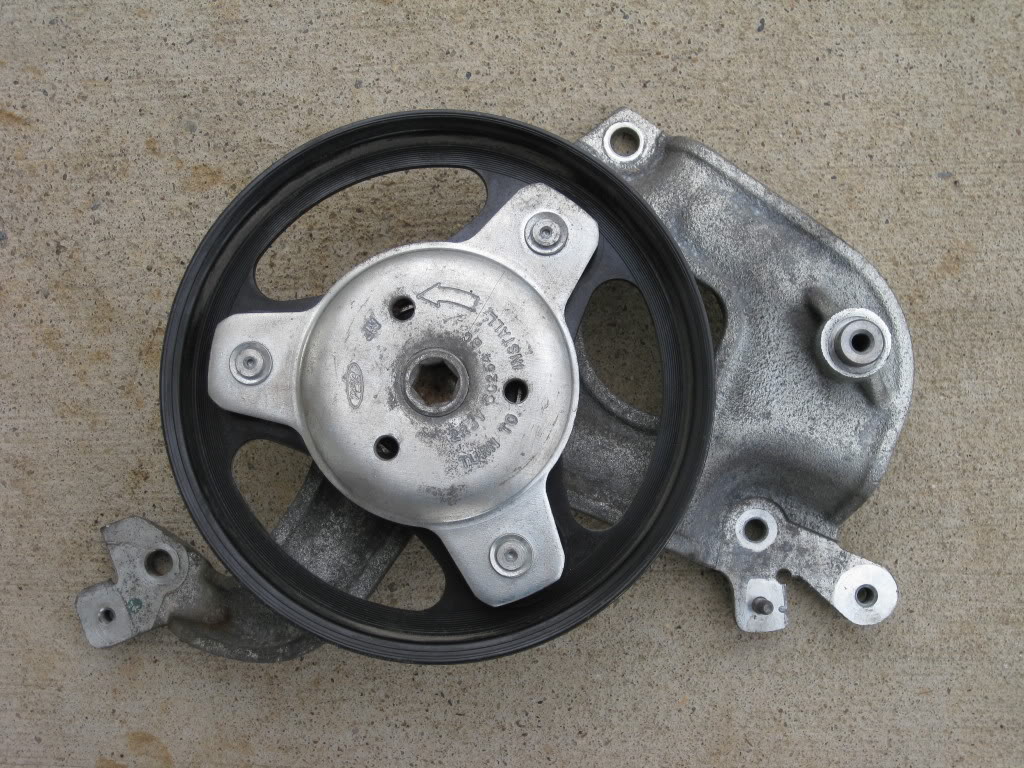

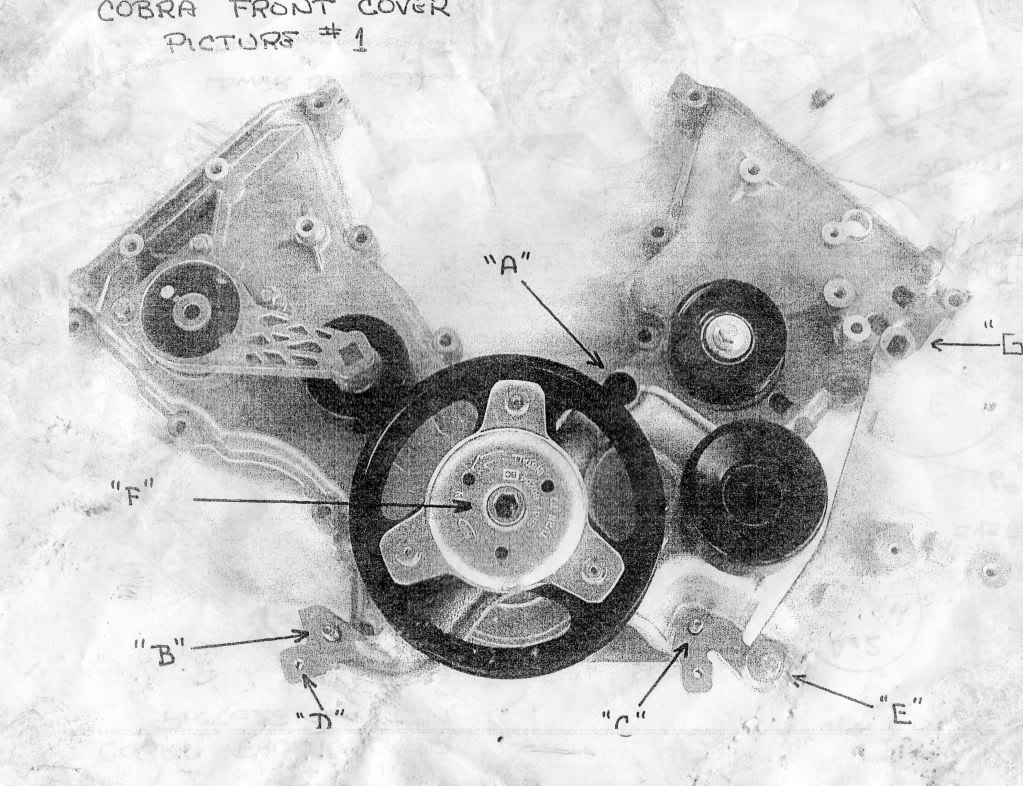

First, before I get into it, I want to give some background information on what the Lower Pulley actually looks like. This will prove helpful for those of us who never saw a stock lower off the car.

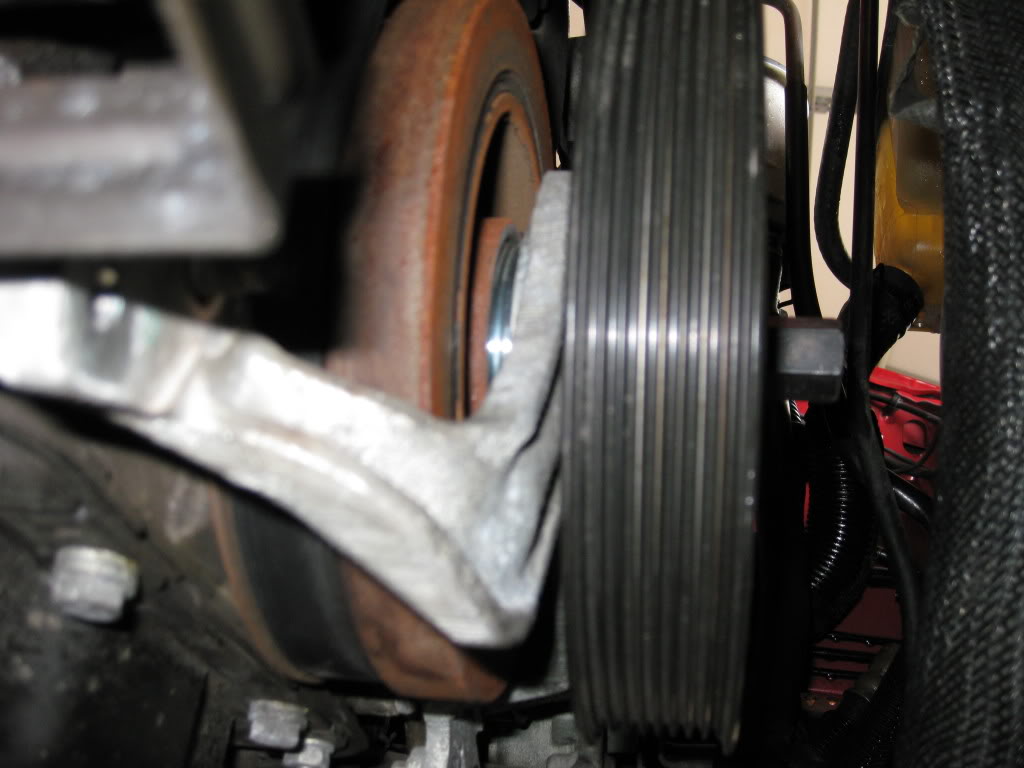

The stock lower isn’t just a ring. It is a full cage with a ring affixed to it. This ENTIRE thing is one piece and comes off as one piece.

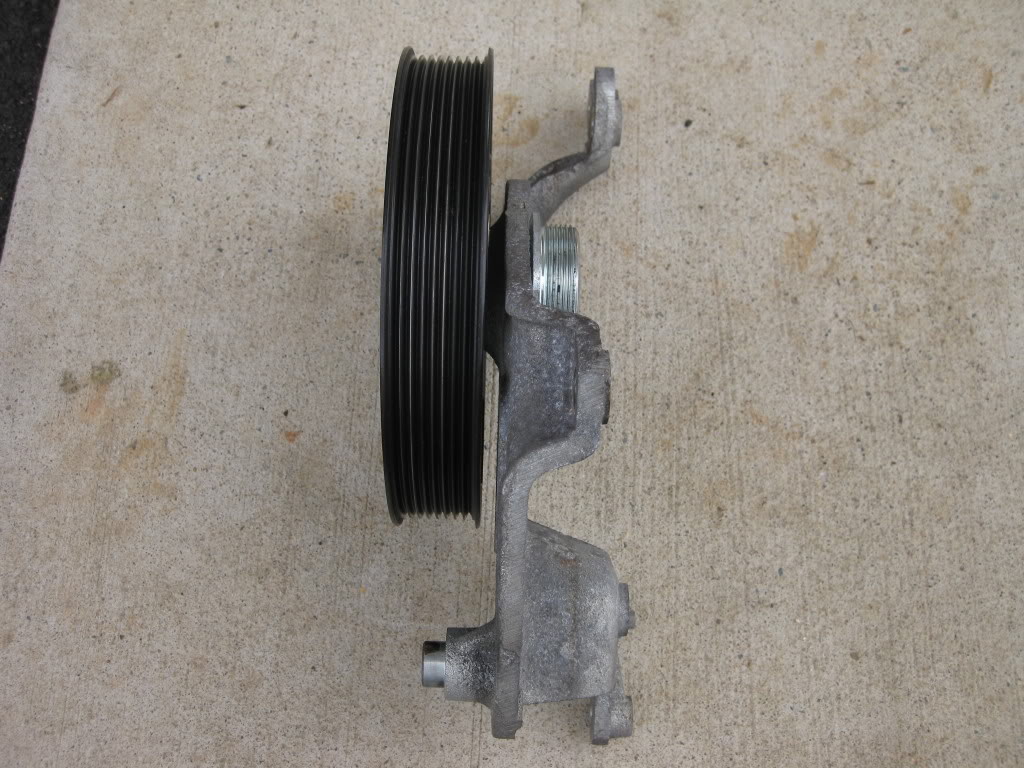

On the back of the pulley is a nice size screw/threaded hub that actually screws into the crank balancer.

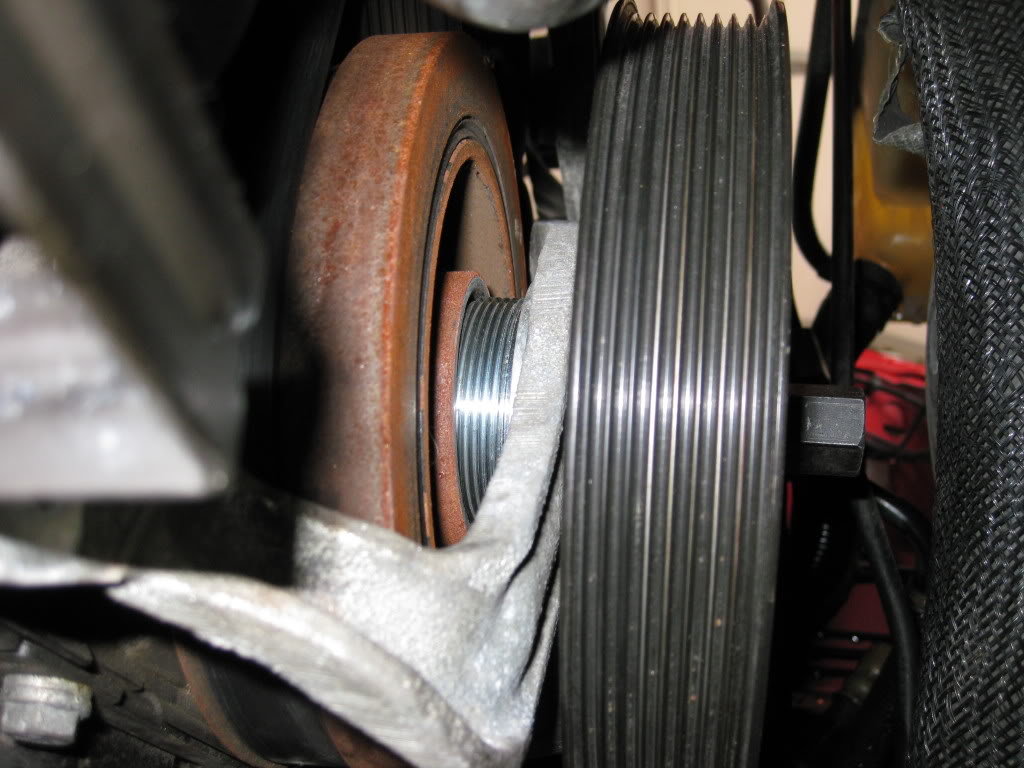

In the center of the front of the lower pulley/cage is a hex hole.

A special tool came with my Metco Lower Pulley kit. The tool, a double sided hex tool, has a big side and a small side. The smaller side fits right inside the front of the lower pulley assembly. ^^^^^^^ Pic right above

Ok, enough talk, let’s gett ‘er done.

1. Put the car in 6th gear and put up the E-Brake. Put the front of the car on jack stands. Do not extent the stands. Leave them on their lowest setting. As you can see, my wheels are still on the ground.

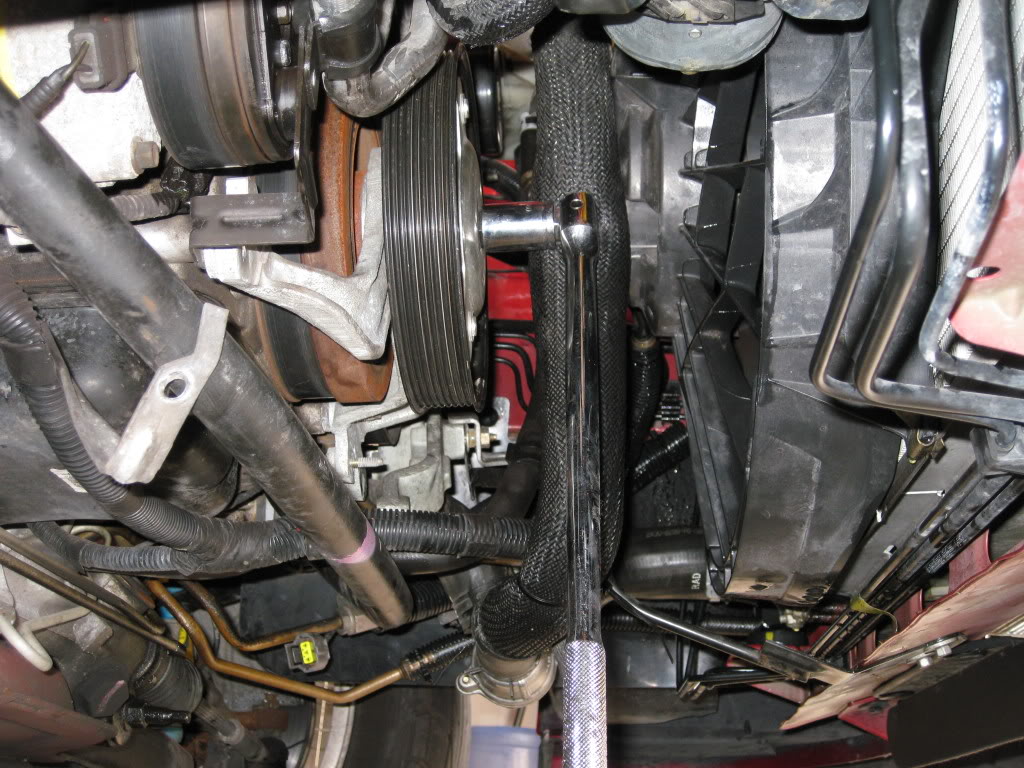

2. Under the car, it should look like this...

I’ve already followed the directions that came with my Metco kit and removed all the necessary bolts to free the cage. That never seems to be the problem, that’s why this write up is focused on getting the stock lower off.

3. Put the supplied tool into the front of the lower pulley assembly

4. Put the 19mm socket on the breaker bar. Now put the socket over the back of the tool.

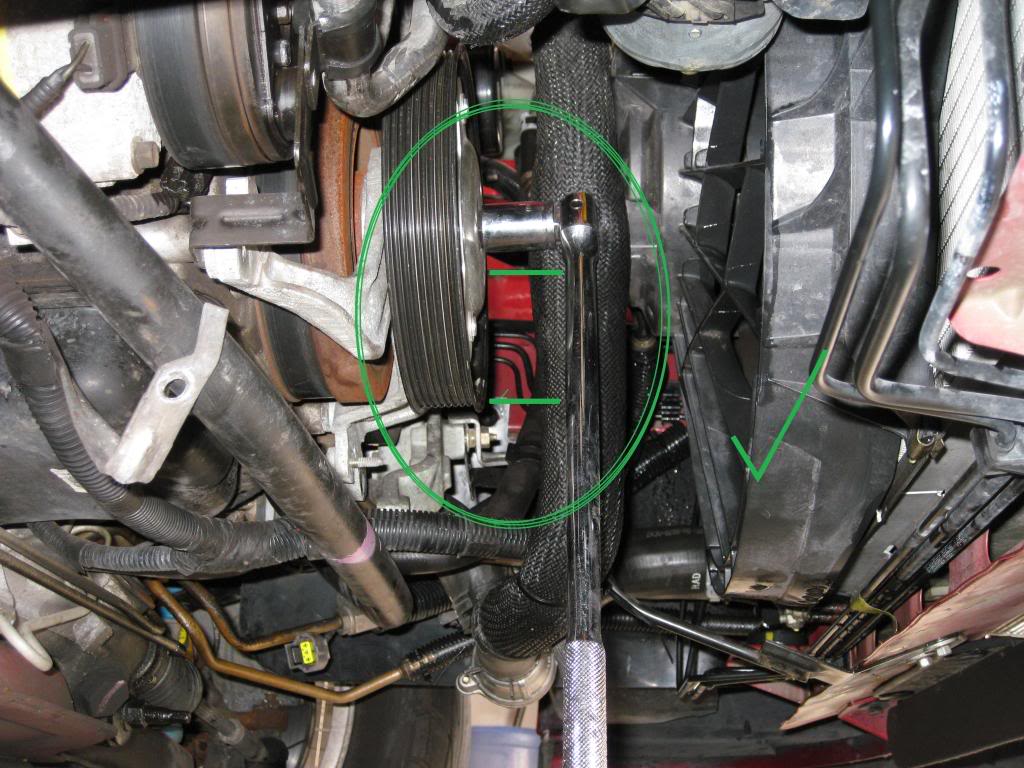

The breaker bar should be around the 6:30 position from the front of the car. You may need to adjust the socket on the tool so the you can position the breaker bar in the correct position.

The lower pulley is threaded backwards so Righty/Loosey, Lefty?Tighty. You are going to be turning the breaker bar clockwise. Reference the preface pictures of the hex hole and you'll see what it says on it!

HERE’S THE CURE FOR GETTING IT OFF!!!

5. Take the jack and position it so the end of the breaker bar is sitting in the cup of the jack. I jacked it up with my left hand while holding the breaker bar in position.

6. Put the jack bar into the jack and jack it up. PAY CLOSE ATTENTION TO THE BREAKER BAR, MAKING SURE ITS STRAIGHT AS ITS BEING JACKED. The space between the top of the breaker bar and the bottom of the balance is the same. Thats how you can assure you are jacking it up straight.

I put this picture here so you can see what "INCORRECT" looks like.

This is the "CORRECT" way. As you can see the green lines are even from the top and bottom.

And here's the same image without the drawing so you can see it clearly...

7. Now jack the end of the breaker bar up. The jack is now acting as your super human strength to break the pulley loose. ***It should be noted that the ring will turn a little before the gears actually catch and prevent the pulley from rotating any further. Your jack should have enough lift to break it loose. If not, adjust the position of the breaker bar and try again.

You will hear a loud POP!!! Its normal. I didn’t read the Metco directions thoroughly to know that it was suppose to happen so it scared me. I thought I broke something. Again, it’s normal.

After you hear that Pop, lower the jack and move it to the side. You no longer need it.

8. Get under the car and begin to turn the pulley with your hand (continue turning clockwise). It should turn easily.

As you turn the lower pulley, you will start to see the silver threads of the screw/hub. Continue turning until it comes out.

If you’ve properly removed all the bolts holding the cage to the car, you should be able to pull the cage assembly off.

DONE.

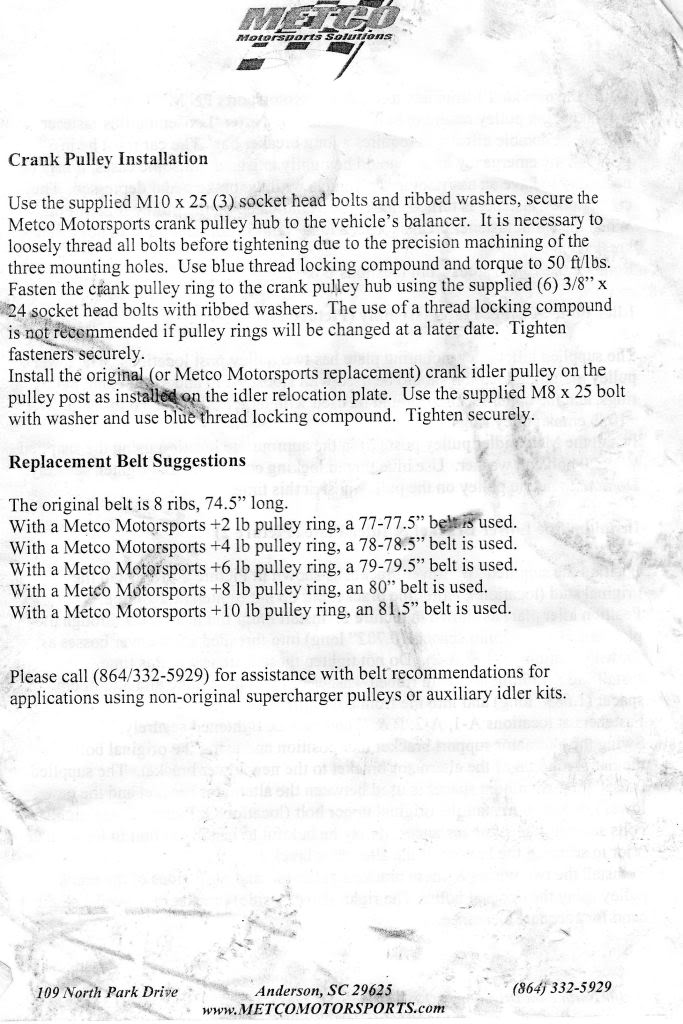

Here are the remaining directions from Metco on how to install your new kit. They are pretty much straight forward.

Good luck.

***METCO DIRECTIONS***

This is a dedicated to all those that have found themselves faced with the seemly impossible task of “Removing the stock Lower Pulley.” I'm a visual learner so I put up plenty of pictures of almost everything I did.

***The FULL Metco instructions are at the end***

What’s needed:

1 - Hex tool - (Comes with Metco Lower Pulley Kit)

1 - 19mm Socket

1 - 18 inch / 1/2 inch breaker bar

1 - Jack

2 - Jack stands

PREFACE

First, before I get into it, I want to give some background information on what the Lower Pulley actually looks like. This will prove helpful for those of us who never saw a stock lower off the car.

The stock lower isn’t just a ring. It is a full cage with a ring affixed to it. This ENTIRE thing is one piece and comes off as one piece.

On the back of the pulley is a nice size screw/threaded hub that actually screws into the crank balancer.

In the center of the front of the lower pulley/cage is a hex hole.

A special tool came with my Metco Lower Pulley kit. The tool, a double sided hex tool, has a big side and a small side. The smaller side fits right inside the front of the lower pulley assembly. ^^^^^^^ Pic right above

Ok, enough talk, let’s gett ‘er done.

1. Put the car in 6th gear and put up the E-Brake. Put the front of the car on jack stands. Do not extent the stands. Leave them on their lowest setting. As you can see, my wheels are still on the ground.

2. Under the car, it should look like this...

I’ve already followed the directions that came with my Metco kit and removed all the necessary bolts to free the cage. That never seems to be the problem, that’s why this write up is focused on getting the stock lower off.

3. Put the supplied tool into the front of the lower pulley assembly

4. Put the 19mm socket on the breaker bar. Now put the socket over the back of the tool.

The breaker bar should be around the 6:30 position from the front of the car. You may need to adjust the socket on the tool so the you can position the breaker bar in the correct position.

The lower pulley is threaded backwards so Righty/Loosey, Lefty?Tighty. You are going to be turning the breaker bar clockwise. Reference the preface pictures of the hex hole and you'll see what it says on it!

HERE’S THE CURE FOR GETTING IT OFF!!!

5. Take the jack and position it so the end of the breaker bar is sitting in the cup of the jack. I jacked it up with my left hand while holding the breaker bar in position.

6. Put the jack bar into the jack and jack it up. PAY CLOSE ATTENTION TO THE BREAKER BAR, MAKING SURE ITS STRAIGHT AS ITS BEING JACKED. The space between the top of the breaker bar and the bottom of the balance is the same. Thats how you can assure you are jacking it up straight.

I put this picture here so you can see what "INCORRECT" looks like.

This is the "CORRECT" way. As you can see the green lines are even from the top and bottom.

And here's the same image without the drawing so you can see it clearly...

7. Now jack the end of the breaker bar up. The jack is now acting as your super human strength to break the pulley loose. ***It should be noted that the ring will turn a little before the gears actually catch and prevent the pulley from rotating any further. Your jack should have enough lift to break it loose. If not, adjust the position of the breaker bar and try again.

You will hear a loud POP!!! Its normal. I didn’t read the Metco directions thoroughly to know that it was suppose to happen so it scared me. I thought I broke something. Again, it’s normal.

After you hear that Pop, lower the jack and move it to the side. You no longer need it.

8. Get under the car and begin to turn the pulley with your hand (continue turning clockwise). It should turn easily.

As you turn the lower pulley, you will start to see the silver threads of the screw/hub. Continue turning until it comes out.

If you’ve properly removed all the bolts holding the cage to the car, you should be able to pull the cage assembly off.

DONE.

Here are the remaining directions from Metco on how to install your new kit. They are pretty much straight forward.

Good luck.

***METCO DIRECTIONS***

Last edited: