Theres ALWAYS alot of discussion when it comes to oil separators; from deleting the PCV altogether, to breathers and catch cans, to rerouted PCV systems and an actual oil separator.

This discussion is about rerouting the PCV and installing a separator. It's what I did with my truck, and it's worked pretty well--I honestly think its been far Better than anything else so far, except the L&S unit, and I'd STILL install that on my rerouting scheme.

So, without further ado, the reasoning behind rerouting and diagrams:

Go with the L&S separator kit, it's the best one out there and the only one that truly returns the oil to the crankcase. *Also, it's probably a good idea to reroute the PCV system to something like this:

This is my setup as it stands, the separator isn't all that great, but it's better than the stock setup:

The L&S will be even better because it'll pull all the oil from the airstream and dump it back into the valve cover thru the oil cap. You don't have to have the check valve, but it does stop any flow reversal under boost, which is why you see oil in the intake boot.

Nice article on the L&S: L&S Automotive Performance - Oil Separator Article

Better writeup by me at NLOC (What PCV do you use-Dime Mod-intake oiling - The National Lightning Owners Club Inc)

L&S has the best setup so far, and the cost isn't near what it costs us in time and materials pulling the blowers to clean out the intercooler and other bits. And I wouldn't think twice about running the L&S with my routing scheme (which has been working on my rig since early 2007, nonstop).*

And what's y'alls time worth?? hell, what's a blown motor worth?

hell, what's a blown motor worth?

This discussion is about rerouting the PCV and installing a separator. It's what I did with my truck, and it's worked pretty well--I honestly think its been far Better than anything else so far, except the L&S unit, and I'd STILL install that on my rerouting scheme.

So, without further ado, the reasoning behind rerouting and diagrams:

Go with the L&S separator kit, it's the best one out there and the only one that truly returns the oil to the crankcase. *Also, it's probably a good idea to reroute the PCV system to something like this:

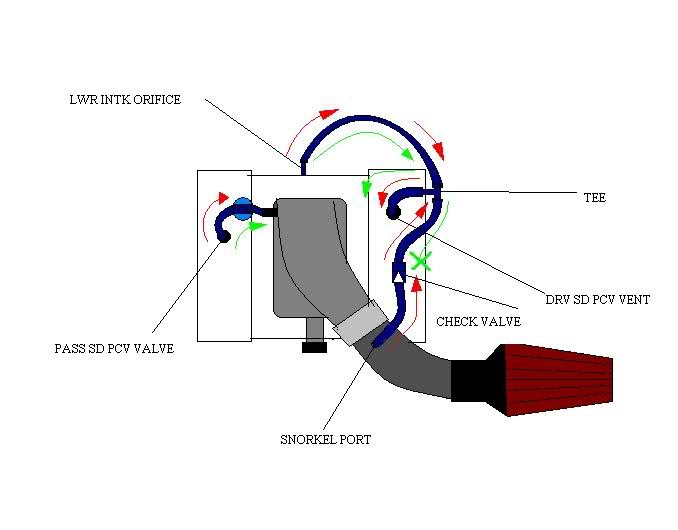

This is my setup as it stands, the separator isn't all that great, but it's better than the stock setup:

The L&S will be even better because it'll pull all the oil from the airstream and dump it back into the valve cover thru the oil cap. You don't have to have the check valve, but it does stop any flow reversal under boost, which is why you see oil in the intake boot.

Nice article on the L&S: L&S Automotive Performance - Oil Separator Article

Better writeup by me at NLOC (What PCV do you use-Dime Mod-intake oiling - The National Lightning Owners Club Inc)

Dangit, Jason, why didn't you mention our little rerouting scheme?? *Can't believe I came in THIS late on the discussion!

First off, we all need to remember the reasons for a positive crankcase ventilation system: *1) *to evacuate unburnt hydrocarbons, exhaust blowby gases (both of which contaminate oil and damage it), and to place the crankcase under slight vacuum to help the rings seal better. *Yes, the EPA requires PCV; *but the benefits truly do outweigh the negatives. *

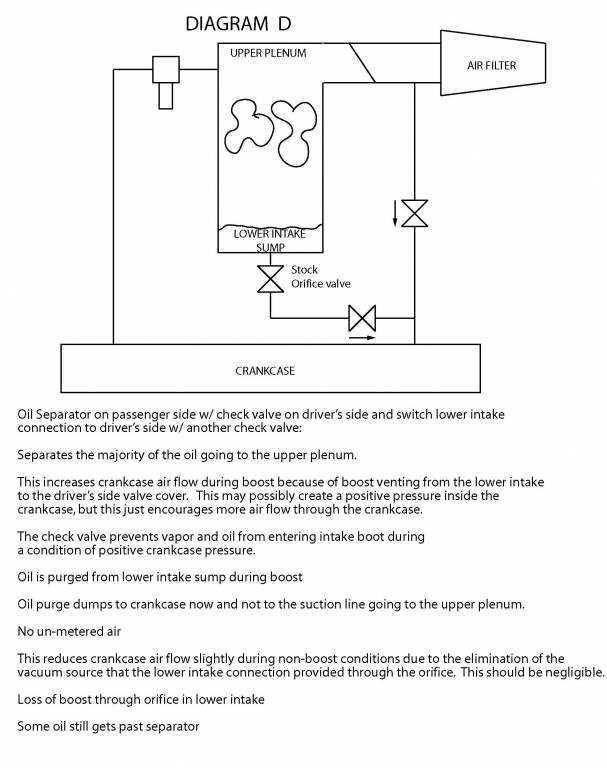

The stock system works like this: *the intake snorkel is the fresh air intake for the system, which goes into the driver's side valvecover; *air goes thru the crankcase and picks up the oil/fuel/combustion vapors, and they get sucked up into the passenger side PCV vent, thru that fake valve, thru the tee, and up into the vacuum port in the upper intake. *At the tee, that's where the slug of oil (as Jason puts it) comes from the lower intake; *once that oil is gone, you get a little air, but it ends up in the upper intake.

Jason's right: *the orifice in the lower intake is meant to evacuate the oil that pools in the lower intake; *if you plug it, you will get a buildup of oil down there that will eventually end up being sucked into the combustion chambers and burnt; *and we all know that having a nice oil coating on the intake side isn't good, and a burnt oil coating on the valves, pistons, plugs, and exhaust tracts aren't good either. * And that's the problem: *by running the outlet for the lower intake orifice into the tee on the driver's side, you're still cycling oil into the blower/IC/lower intake.

So we need to control the oil, and keep it out of the intake, right?

There's been alot of argument here about how it should be done. *Separators help, but aren't 100%, and that line from the lower intake to the tee in the vacuum side of the system is the weak link in our applications.

Jason and I discussed it, and we came up with a couple of ideas; *my first idea involved a pair of separators on both sides, but only the passenger side one ever got any oil, and I still got some oil in the boot; *so one day, the lightbulb went off in my head, and I did what is detailed in this thread, which is this:

By moving the tube from the lower intake to the driver's side, you force it to dump the oil into the air stream that's already there from the boot. *To be safe, in case the crankcase pressurizes, a check valve is put between the tee at the PCV vent and the boot, to keep air from going back into the boot. *By doing it this way, you eliminate that "looping slug of oil" you get with the stock system; *and your separator doesn't have to filter as much.

The weak link, tho, is the separator: *that C-H unit I use isn't really meant for oil, it's meant for water, and some oil still gets past the "filter" in the middle, and into the intake tract. *So we either need a separator that's more efficient at filtering oil, or something like the L&S unit, or the MotoBlue Oil Separator kit, both of which return the separated oil back to the engine, which to me is the better way to do things. *

The only drawback to Jason's/my system is it seems to pull alot of vacuum, and on older engines you might get a howling noise from low on the engine, I'd guess the front main seal--tho I'm not *100% on that, that's what I heard when I put it on rickgig's truck (with 120k miles, btw), so I could be wrong, we never left it implemented.

It's good to keep discussing this. *I plan on testing a larger "industrial" unit I got cheap, and test a couple ideas to see how much oil I can trap; *or, I can get the L&S and be done with it.

L&S has the best setup so far, and the cost isn't near what it costs us in time and materials pulling the blowers to clean out the intercooler and other bits. And I wouldn't think twice about running the L&S with my routing scheme (which has been working on my rig since early 2007, nonstop).*

And what's y'alls time worth??