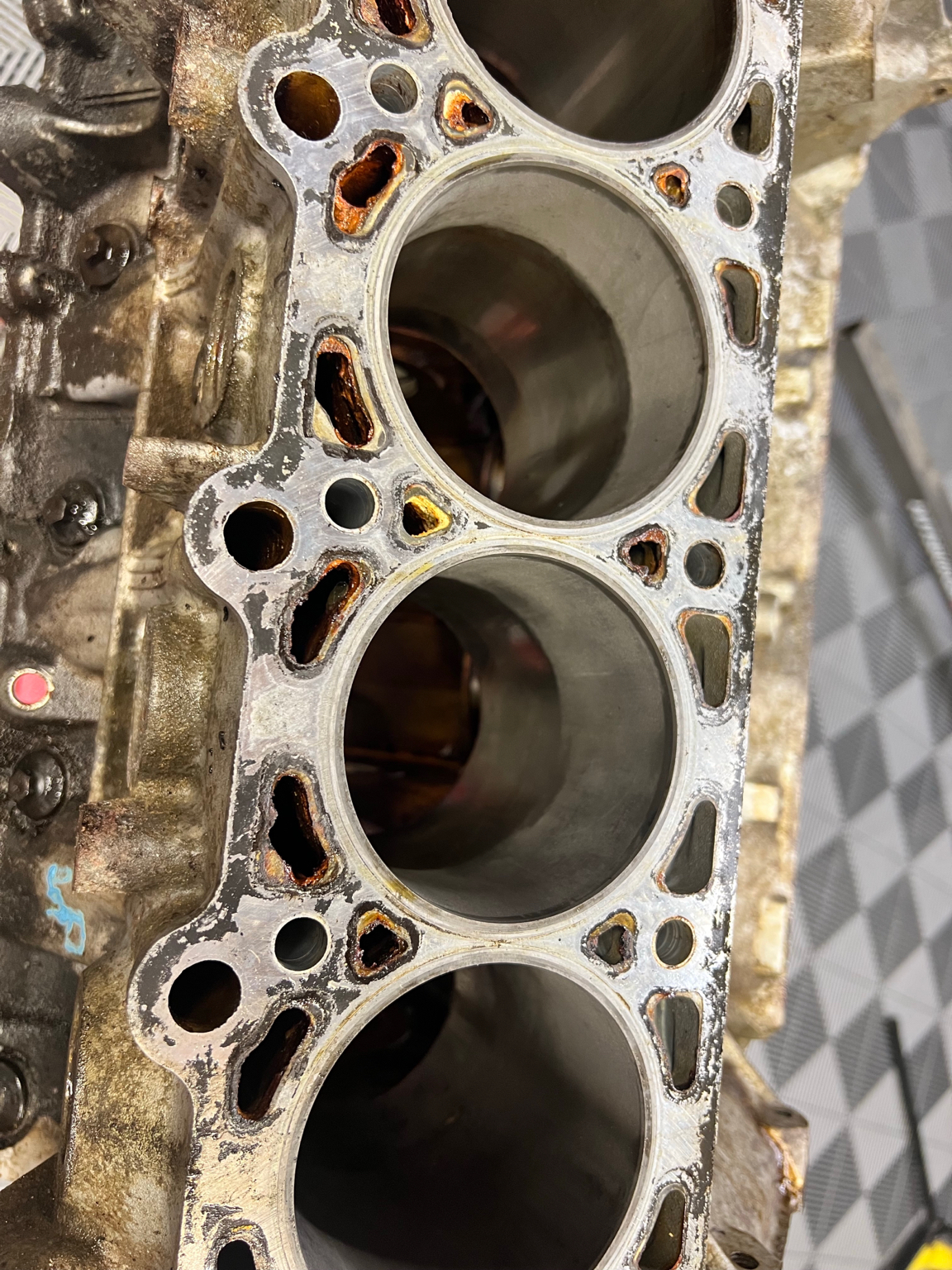

So I recently got burned pretty bad on Facebook Market on a Gen 1 Teksid. It was so corroded that it’s going to need a resleeve. I soaked the damaged cylinders in White Vingar for 24 hrs then did same in Evaporust. Still couldn’t turn the motor over. I eventually had to hammer the pistons back and forth and finally got it. I tried to hone them and clean them up. Nada. So I cleaned, oiled and wrapped to store it.

As you can see the cylinders are way too pitted to do anything with other than sleeve

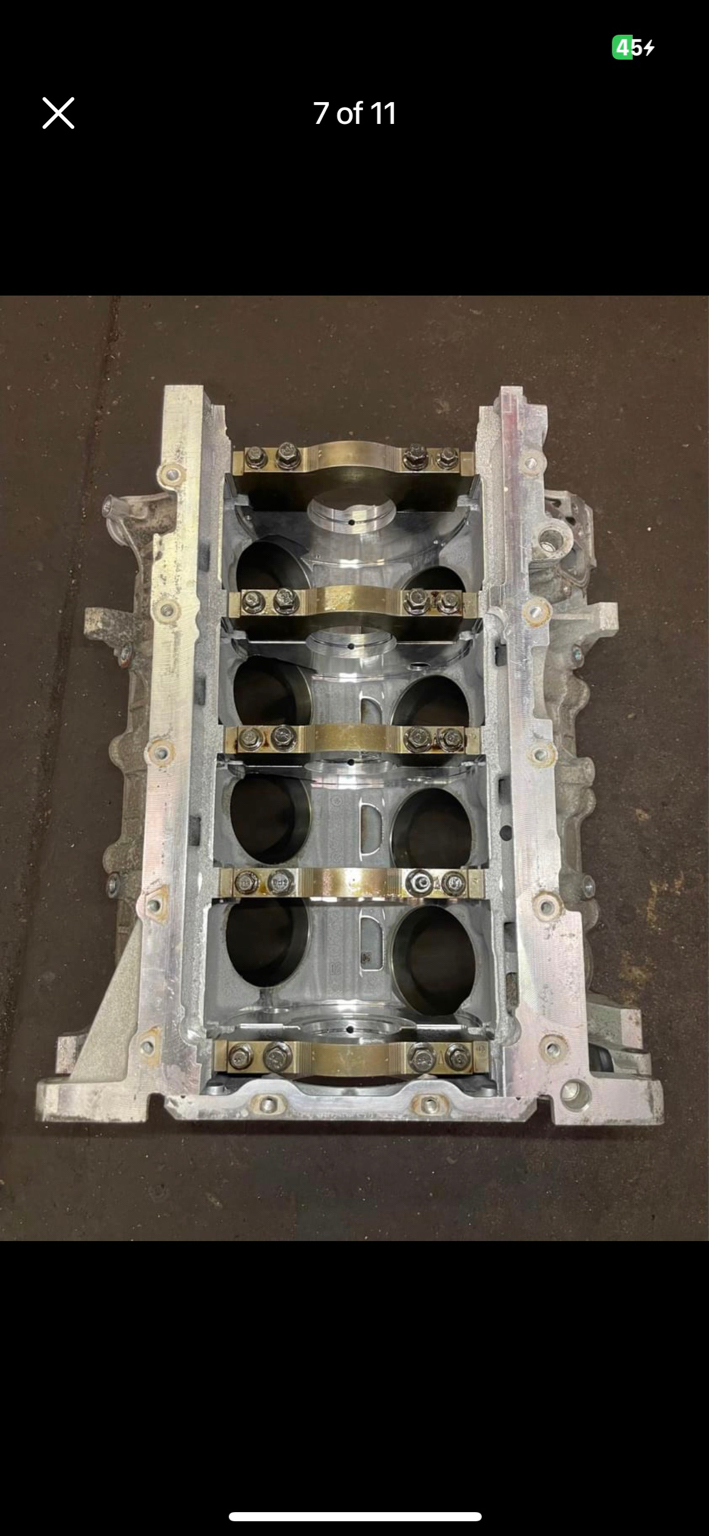

Then I came across a mint Nemak out of an 05 Aviator for 700 shipped to my door

RF-3L2E-6015-CC

I have heard the whole Teksid is KING, the WAP Wagon etc. I have heard Nemak is not strong etc.

I want to hear from y’all.

I plan on Manley Crank, Molnar PA rods, Diamond Pistons, E85, 25-30#boost, camsand possibly ported heads. Maybe 1100 hp max.

What do y’all think? Bad choice in block?

Sent from my iPhone using the svtperformance.com mobile app

As you can see the cylinders are way too pitted to do anything with other than sleeve

Then I came across a mint Nemak out of an 05 Aviator for 700 shipped to my door

RF-3L2E-6015-CC

I have heard the whole Teksid is KING, the WAP Wagon etc. I have heard Nemak is not strong etc.

I want to hear from y’all.

I plan on Manley Crank, Molnar PA rods, Diamond Pistons, E85, 25-30#boost, camsand possibly ported heads. Maybe 1100 hp max.

What do y’all think? Bad choice in block?

Sent from my iPhone using the svtperformance.com mobile app