I'm aware there are a couple threads on this already but I just wanted to share what I did as others have done little, no, or improper measurements regarding their RXT install. My install involves an adjustable pivot ball as any twin disc install should include. First I started with just a standard flywheel insert replacement, balance check (should be done IMO) and clutch install. I also fixed an issue I had with my cobra engineering head cooling mod while I was in there.

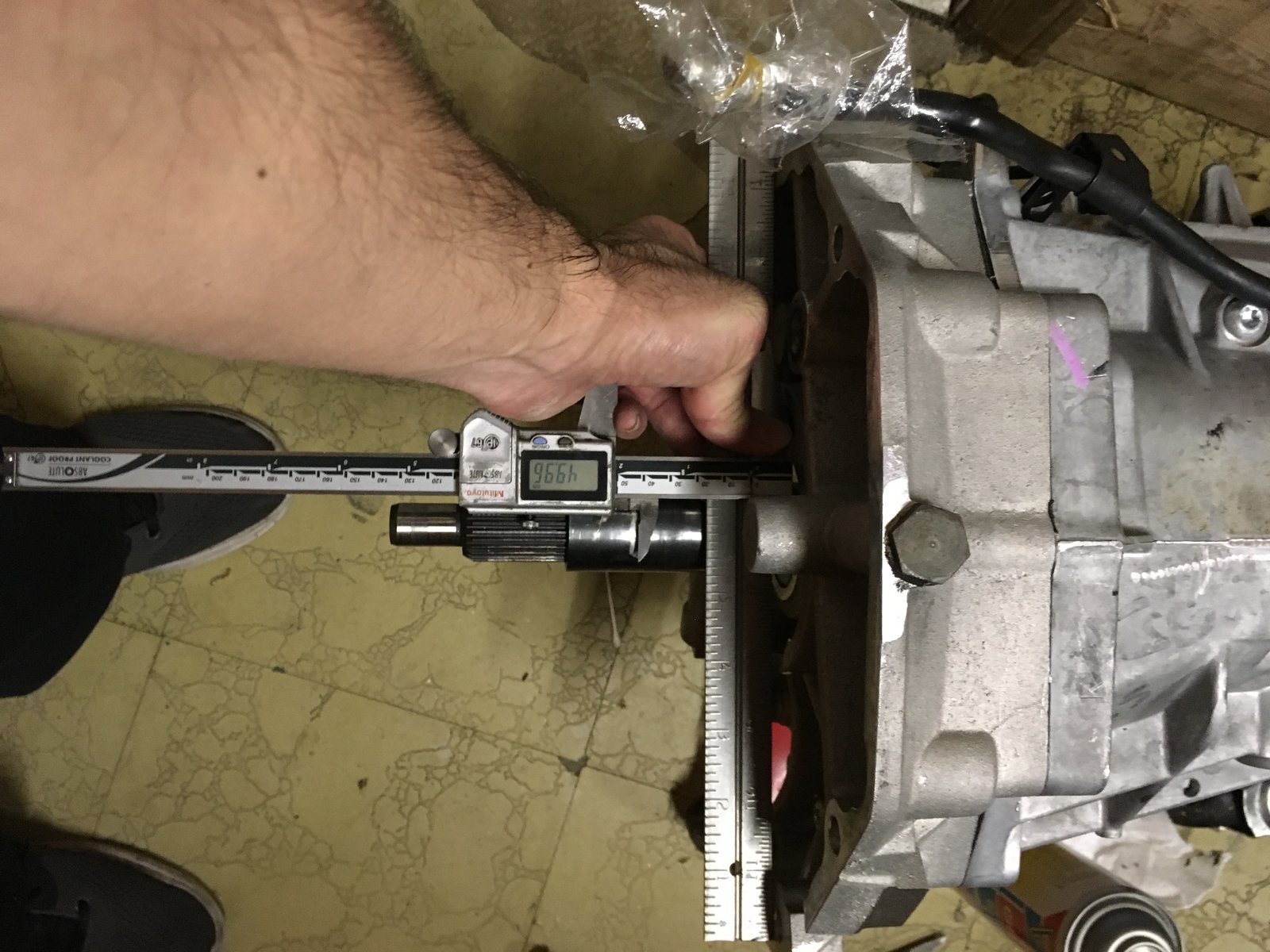

I then installed my bellhousing, and used a straight edge across the face and used a set of calipers to drop down perpendicularly to find the distance to the pressure plate fingers. I took 3 measurements around the fingers as they're not perfect, and averaged the value. When you do this don't forget you have to subtract the thickness of the ruler.

I then used the same straight edge to measure and mark from the trans mounting face to the throw out bearing sleeve, this will be the location of contact between the TOB and the fingers.

As for the pivot ball I measured the stock one from the mounting face of the nut (the side that contacts the trans front case) and measured to the back of the ball radius as a datum. Stock I get as 28mm. I set mine 6.5mm shorter (21.5mm) and put the TOB and fork on dry to check everything out. Well not surprising, with the fork all the way back against the trans case the TOB was well above the mark, by probably 1-2mm. This means if I had installed the trans the pressure plate fingers would constantly be partially depressed, and the fork bottomed out against the trans case... no good.

This was to be expected as T-56 magnum owners will know the case is different, several different features are in the way of the fork travel and it will not pull back as far as a factory T-56. But before I dealt with that I figured I would go for the low hanging fruit, and see how far I could screw in the pivot ball. Well the mcleod adjustable pivot ball is quite long, and it would bottom out in the case at I think 18mm or so (10mm shorter than stock). So first thing I did was cut and grind it down about 4-5 threads. I screwed it in further, but there's only so far you can go before you start having the retaining spring fingers on the fork contact the jam nut when you actuate the clutch. I wanted to avoid this as even with red loctite I was worried it could work the nut loose eventually. I found 16mm was about the shortest I wanted to go (12mm shorter than stock). That helped with the TOB location but I still couldn't pull it back enough to see my mark.

So then I took my brand new ford fork and started cutting on it. I marked all the locations it was contacting before hand and started cutting. I was trying to avoid cutting on my pristine T-56 magnum case but I could see if I kept going on the fork it was going to get too weak. So I then cut on the case carefully, marking and checking, cutting, marking and checking. Slowly but surely I was able to get the fork weight to hit the case bolts (I have no pics but I'm sure you guys know which I'm talking about). I clearanced the fork weight and continued clearancing the case/fork until the fork itself contacted the case bolt, at that point I called it good.

I now could hit the pressure plate finger mark with the TOB and had extra room to spare (for clutch wear). After it was all done I marked the new location of the fork bottoming out and measured it all. I also layed out the predicted disengagement point based on Mcleods literature saying the clutch only needs .440" of travel. I found that from the pressure plate finger contact mark to the full back mark the TOB had 6.6mm of extra room, again to hopefully account for clutch disc wear. Hope this is helpful to someone, I installed the trans tonight... once. I hooked up the clutch cable and stuck the driveshaft in and had a friend rotate it while I actuated the clutch, worked flawlessly... in one time and done. Highly recommend doing this rather than guess and check and hope.

I then installed my bellhousing, and used a straight edge across the face and used a set of calipers to drop down perpendicularly to find the distance to the pressure plate fingers. I took 3 measurements around the fingers as they're not perfect, and averaged the value. When you do this don't forget you have to subtract the thickness of the ruler.

I then used the same straight edge to measure and mark from the trans mounting face to the throw out bearing sleeve, this will be the location of contact between the TOB and the fingers.

As for the pivot ball I measured the stock one from the mounting face of the nut (the side that contacts the trans front case) and measured to the back of the ball radius as a datum. Stock I get as 28mm. I set mine 6.5mm shorter (21.5mm) and put the TOB and fork on dry to check everything out. Well not surprising, with the fork all the way back against the trans case the TOB was well above the mark, by probably 1-2mm. This means if I had installed the trans the pressure plate fingers would constantly be partially depressed, and the fork bottomed out against the trans case... no good.

This was to be expected as T-56 magnum owners will know the case is different, several different features are in the way of the fork travel and it will not pull back as far as a factory T-56. But before I dealt with that I figured I would go for the low hanging fruit, and see how far I could screw in the pivot ball. Well the mcleod adjustable pivot ball is quite long, and it would bottom out in the case at I think 18mm or so (10mm shorter than stock). So first thing I did was cut and grind it down about 4-5 threads. I screwed it in further, but there's only so far you can go before you start having the retaining spring fingers on the fork contact the jam nut when you actuate the clutch. I wanted to avoid this as even with red loctite I was worried it could work the nut loose eventually. I found 16mm was about the shortest I wanted to go (12mm shorter than stock). That helped with the TOB location but I still couldn't pull it back enough to see my mark.

So then I took my brand new ford fork and started cutting on it. I marked all the locations it was contacting before hand and started cutting. I was trying to avoid cutting on my pristine T-56 magnum case but I could see if I kept going on the fork it was going to get too weak. So I then cut on the case carefully, marking and checking, cutting, marking and checking. Slowly but surely I was able to get the fork weight to hit the case bolts (I have no pics but I'm sure you guys know which I'm talking about). I clearanced the fork weight and continued clearancing the case/fork until the fork itself contacted the case bolt, at that point I called it good.

I now could hit the pressure plate finger mark with the TOB and had extra room to spare (for clutch wear). After it was all done I marked the new location of the fork bottoming out and measured it all. I also layed out the predicted disengagement point based on Mcleods literature saying the clutch only needs .440" of travel. I found that from the pressure plate finger contact mark to the full back mark the TOB had 6.6mm of extra room, again to hopefully account for clutch disc wear. Hope this is helpful to someone, I installed the trans tonight... once. I hooked up the clutch cable and stuck the driveshaft in and had a friend rotate it while I actuated the clutch, worked flawlessly... in one time and done. Highly recommend doing this rather than guess and check and hope.

Last edited: