McLeod RXT install - 03/04 cobra

Parts installed:

Clutch Install:

Input shaft install:

Pivot ball:

Retainer sleeve:

TOB/Clutch Fork:

There's alot of mixed information here on the forum, so i just wanted to try and condense it down into one thread. The setup i posted above is working perfectly.

If any one has any questions about their install, feel free to send me a PM and i can try to help with the knowledge i gained from my install.

Parts installed:

- McLeod RXT

- McLeod Steel Flywheel

- McLeod Retainer Sleeve

- McLeod Adjustable Pivot ball

- Stock TOB (i bought an aftermarket one, F'ed it up via wrong installation)

- Maximum Motorsports Clutch cable, Firewall adjuster, Quadrant

- Tremec 26 spline input shaft

Clutch Install:

- I installed the RXT exactly to the directions given by McLeod. Torqued the pressure plate bolts to 35 FT/LBs.

Input shaft install:

- I originally installed a .42 shim since i saw some one on the forum here got away with using it. I checked the end play with this thickness of shim, and was getting absolutely no movement. I then took it out, and put the stock shim back in. Again, zero movement. Lastly, i installed a .34 shim and this gave me .002 - .003 end play. From what i have read on the forum, the tolerance is .000 - .005, so lands me perfect. Even with this tiny bit of play, the shaft does not move very much at all. I guess it is after all, only about .002 - .003 of movement ;-)

Pivot ball:

- I adjusted the pivot ball using what users recommended here on the forum. 4.5 MM shorter then stock. It works perfect. I did try using the stock pivot ball, but it instantly put preload on the pressure plate fingers. Per McLeod's directions, your TOB should not be in constant contact with the pressure plate fingers.

Retainer sleeve:

- Very simple, open the case and pound the old one out. I used the old retainer sleeve to hammer in the new one, as it fits perfectly on the surface of the new one lol

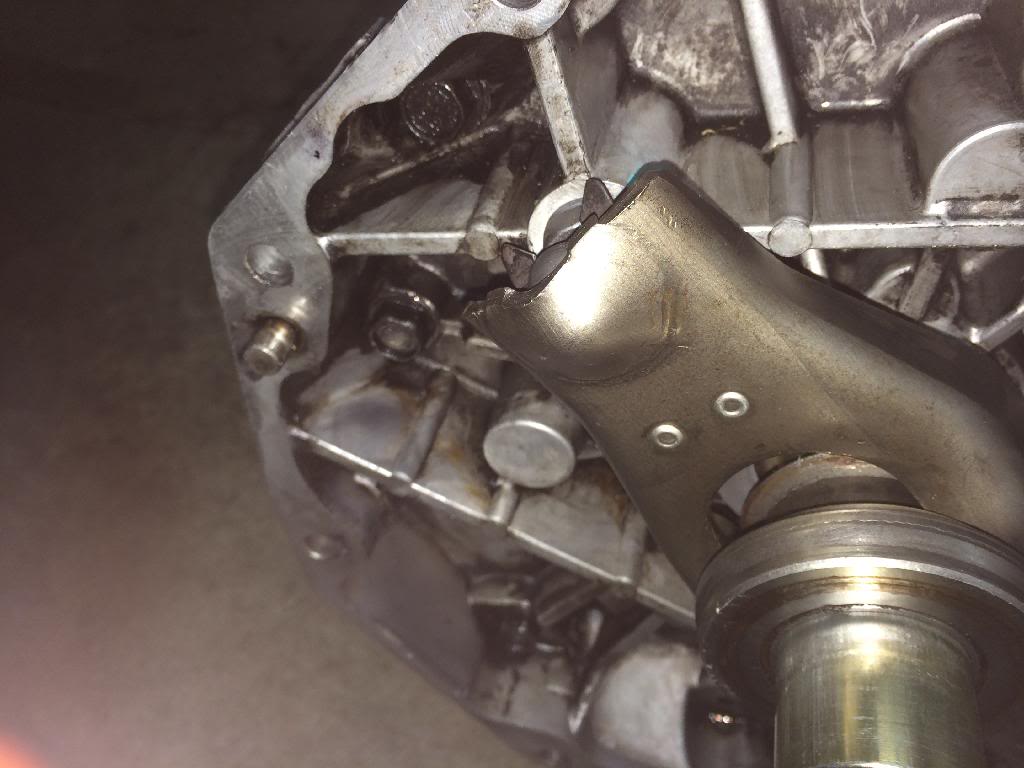

TOB/Clutch Fork:

- My only advice for the TOB is to make sure you install it correctly. It should be installed on top of the springs just like this:

- As far as installing the clutch fork, make sure it seats properly on the pivot ball. This was the biggest mistake i made. See second picture

There's alot of mixed information here on the forum, so i just wanted to try and condense it down into one thread. The setup i posted above is working perfectly.

Last edited: