Under wor no vac should be present any rpm

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Modifying inlet kenne bell project!

- Thread starter venom1997

- Start date

My opening is now 3.25x3.25 square over 1000 cfm and the back is extended 1.5 inches and bosses removed I won't have a restriction until 2.4or bigger blower the stock inlet flows 550 and becomes a restriction at 4500 Rpms with a 1.5l this mathematically will be more flow than needed along with bypass temps will be far lower

How can I check the efficiency of my inlet tract?

To determine overall inlet efficiencies, tap the center of the inlet manifold at the supercharger entrance and connect to a good 0-30” Hg vacuum gauge. Note the peak vacuum reading at WOT. The reading will increase with engine rpm/HP. We use a more sophisticated series of calibrated pressure sensors, one behind each component, and data log the entire dyno run. If your reading is 0” Hg, don’t upgrade any inlet component IF you’re satisfied with the HP number. However, if it’s 1-9”Hg, there’s HP to be gained. 1.0” Hg is often 35-40HP. .1” Hg is 3.5-4HP. This isn’t opinions or theory, but fact. A NASCAR Cup engine makes 850HP. With a restrictor plate, the same engine is 450HP but has approx. 12” Hg vacuum. That’s 8.7 psi or about 6 psi short of God’s 14.7 psi. It’s all about inlet restriction whether it’s supercharged or naturally aspirated. In the ‘60’s, I used a vacuum gauge under the carburetor. Didn’t have throttle bodies then. If the gauge read 0” Hg, the carburetor was large enough. But if it read 2” Hg (13.7 psi) instead of 0” Hg (14.7 psi), I knew that I was “short” 1 psi of God’s Boost or about 7% in HP. 1 ÷ 14.7 = 7%. Same holds true 44 years later with supercharging. The more things change, the more they stay the same.

To determine overall inlet efficiencies, tap the center of the inlet manifold at the supercharger entrance and connect to a good 0-30” Hg vacuum gauge. Note the peak vacuum reading at WOT. The reading will increase with engine rpm/HP. We use a more sophisticated series of calibrated pressure sensors, one behind each component, and data log the entire dyno run. If your reading is 0” Hg, don’t upgrade any inlet component IF you’re satisfied with the HP number. However, if it’s 1-9”Hg, there’s HP to be gained. 1.0” Hg is often 35-40HP. .1” Hg is 3.5-4HP. This isn’t opinions or theory, but fact. A NASCAR Cup engine makes 850HP. With a restrictor plate, the same engine is 450HP but has approx. 12” Hg vacuum. That’s 8.7 psi or about 6 psi short of God’s 14.7 psi. It’s all about inlet restriction whether it’s supercharged or naturally aspirated. In the ‘60’s, I used a vacuum gauge under the carburetor. Didn’t have throttle bodies then. If the gauge read 0” Hg, the carburetor was large enough. But if it read 2” Hg (13.7 psi) instead of 0” Hg (14.7 psi), I knew that I was “short” 1 psi of God’s Boost or about 7% in HP. 1 ÷ 14.7 = 7%. Same holds true 44 years later with supercharging. The more things change, the more they stay the same.

I don't have much input, but it is interesting to read.

Very aggravating KB didn't do a better job with this blower setup or even offer intercooling.

Very aggravating KB didn't do a better job with this blower setup or even offer intercooling.

That's kennebells take on it from their site hence why the mammoth inlet was made the stock 2.2 inlet for the 03/04 was only good to 1000 cfm which was enough for 2.2-2.4 but as the 2.6 2.8 3.2 etc the blower flows more than 1000cfm so the inlet became a restriction as for the 96-98 it was way worse we had a poor design with the crazy dent up front for the throttle bracket and the two rear bolt bosses in rear. That's why 2.1 l new big bores don't make any power over the 1.5 it's inlet restriction

Kennebell had no interest to improve on our years this is all from trial and self improvement this will work great on 1.5l applications and even more on the 2.1 along with a bypass

All 96-98 know kits use same inlet 1.5 1.7 2.1 btw number is stamped 550-A underside where throttle body mounts

I really like the progress that you have made so far. You are pioneering untapped wilderness here, and believe me I have dug through many forums/days of research for the 96-98 cobras. Keep it up!!

I hope this will pave the way for a SN95 Cobra Kenne Bell blower section.

I hope this will pave the way for a SN95 Cobra Kenne Bell blower section.

Last edited:

Once I log iat with the bypass inlet opened up and meth directly under the discharge I will post and numbers too hoping to run 14 psi with the 1.5

Back in 01 or so they did a magazine test with a Saleen 2v and with the 1.5 spun to 19000 Rpms it made 15 psi they found an inlet restriction like I did with the vac gauge in the inlet and opened it up and made 18 psi the most I ever seen the 1.5 put out on the 96-98 cobra is 12-14 psi spun to the max it's definitely the inlet

Have you thought about pursuing the phenolic intercooler that Mystic1996KB had made? He made 470rwhp at 15 psi with a 1.5, just a thought. I sub'd to this thread!

I made 450 10 psi no bypass and one nozzle pre throttle body after doing all this I should surpass 500 really easy 14-15 psi 2.25 upper stock lower 625 ml nozzle pre rotor and 375ml directly under discharge spraying up toward rotors In the open house i contemplated making a three inch core intercooler and just use a cobra r hood to clear everything but I think this dual nozzle setup will be enough cooling

Using a 1 inch diverted valve bypass with 1 inch port tapped to lower intake up into the back of the inlet with 1 inch hose should cool the air and stop compressor surge cavitation can't wait most of all the inlet is a first no one has done it and I'll be first to probe the potential I strongly believe this will free huge power and make the blower scream

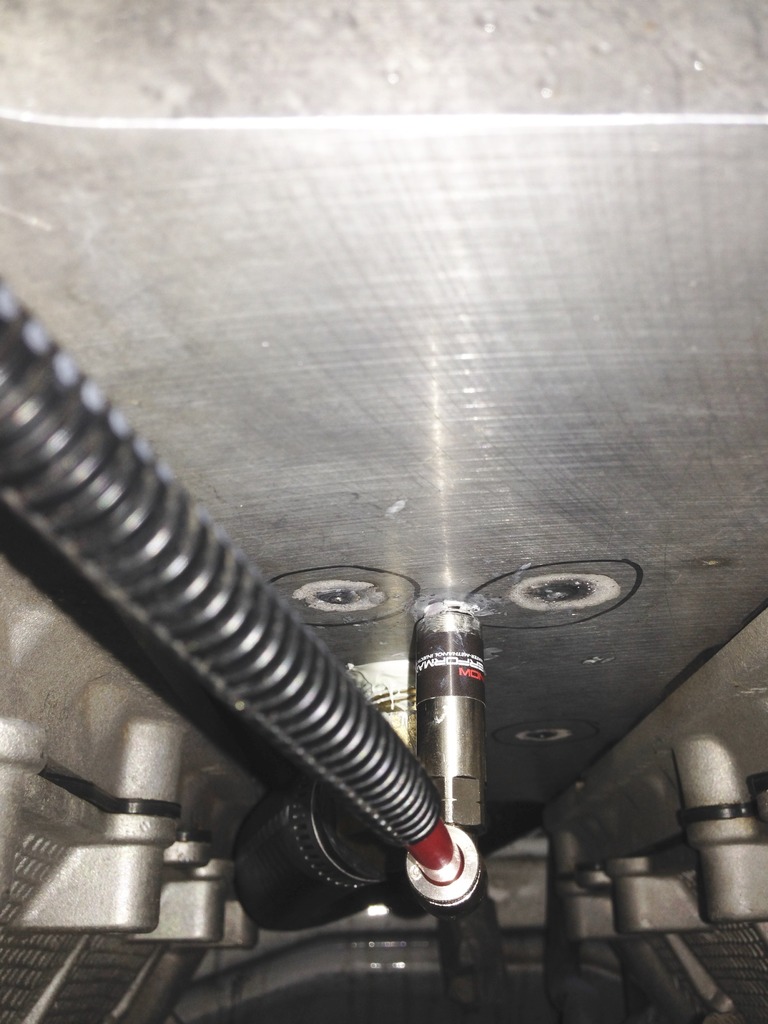

All ready to go on the big brass 90 elbow on the inlet to the back right is the port for the bypass and the middle is the Pre rotor meth nozzle (the other nozzle is under the lower manifold and the other bypass port too)

Bypass valve will go near fire wall with the hose coming from back into the valve then another hose from valve to the inlet

Wiring meth solenoid and outing alternator back on tonight tomorrow the blower goes back on and hopefully fire it up

Pic of under the lower intake meth nozzle and bypass port and hose behind runs up thu back and up firewall method nozzle hose comes to front out next to alternator

where are you mounting a bypass valve at. guess im not following you on this

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)